50 plus years of history in demolition and material handling

By Edit Team | July 11, 2024 4:14 pm SHARE

Witness VTN’s evolution from pioneers of construction buckets to creators of versatile tools like the CI-Revolution shear, setting new standards in demolition.

VTN was born in 1973. The only product they manufactured at the start of their journey was construction buckets. They went on to launch the first grapple and demolition tools in 1988. Today, VTN specialises in all types of demolition and material handling tools viz Concrete Crusher, Pulverizer, Multiprocessor, Demolition Grapple, Stone grab, and Log grab. However, the absolute protagonist of their demolition line is the CIRevolution shear.

The VTN shear can almost do everything that its name suggests. While it is perfect for cutting and recovering ferrous material, it also finds natural use in aerial and ground demolition. Its versatility also allows it to cut multiple materials, such as tyres, cables, armatures, and even small beams. Mounted in the place of a bucket or arm, the Cl-R hydraulic shear is offered in 13 models for excavators of different sizes.

Is it the right choice to satisfy the needs of more specialised work?

Many technical features explain the success of this model. The shear structure is based on a heavy-duty frame made with the best high-strength steel. This allows significant weight reductions, optimises performance, and maintains unchanged characteristics in all load combinations. The heavy-duty principle is also applied to rotation, which sees the use of large-diameter washers, a choice that allows the use of the shear in the most demanding and extreme situations. The work is also facilitated by protection valves in flow regulators that ensure easy and precise positioning. Also noteworthy is the overturned hydraulic cylinder, which, with its large bore, guarantees excellent performance and protection of the rod from accidental impacts.

The performance is also guaranteed by the adoption of the Speed Valve, which reduces the working time through an oil regeneration circuit mounted on the cylinder. Shrink-fit technology for the fulcrum pin allows the optimal alignment of the movable jaw with the fixed one, guaranteeing the best performance and maintaining the best cutting precision.

The adoption of tampons with a double guide (one on each side) prevents the jaw from flexion, ensuring high precision and cutting efficiency. The interchangeable and reversible cutting blades ensure operational performance four times before the need for replacement. Maintenance is very easy, as the hydraulic system is easily accessible.

Material handling attachments:

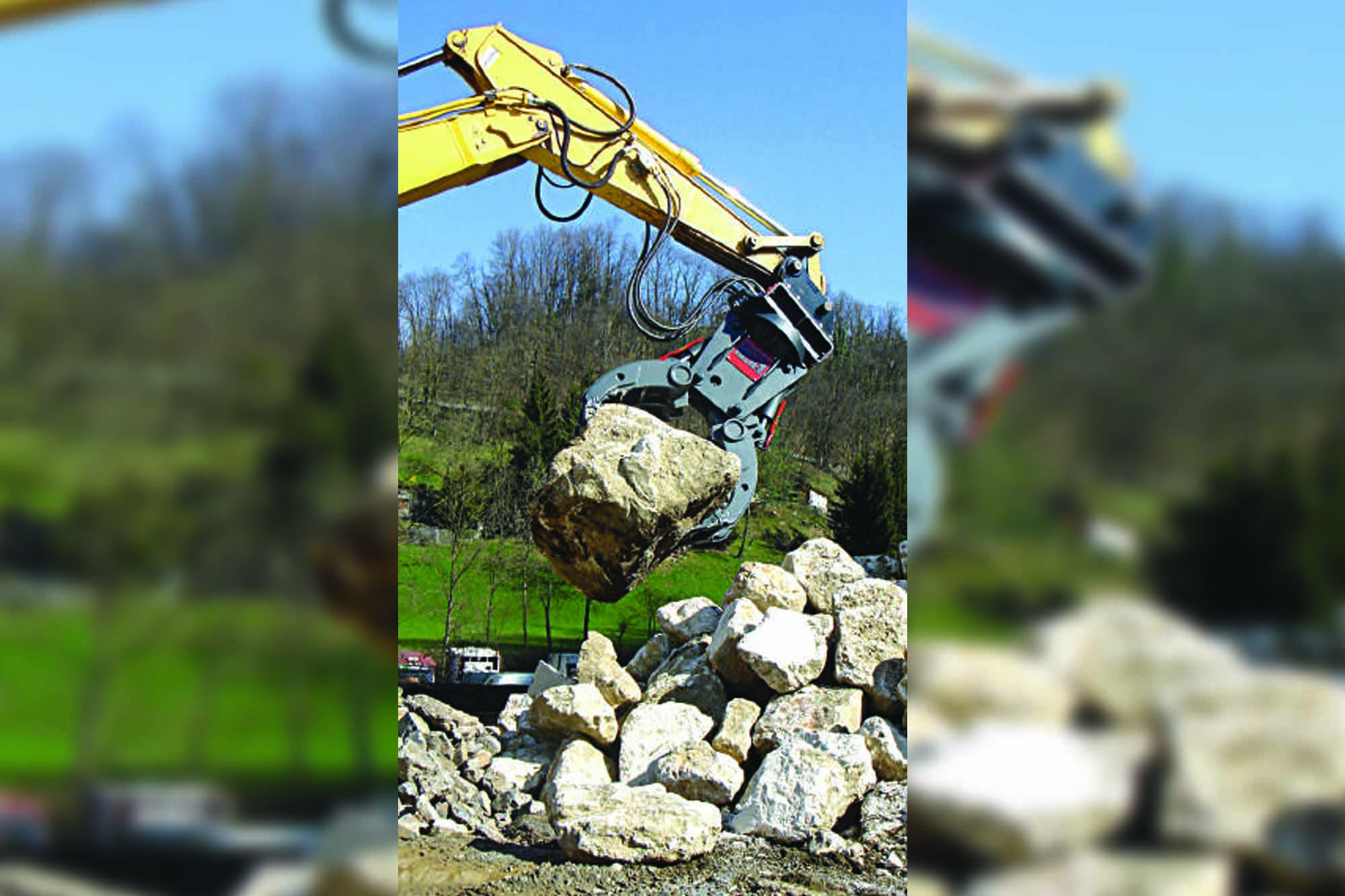

Sometimes, operators need help moving materials around the job site. VTN grapple buckets turn an excavator from a dig-only machine into one capable of lifting and shifting materials around the work area. This can be useful in various situations on construction job sites, including land clearing and demolition tasks.

Four important factors to remember when deciding on a Grapple:

• Is your machine equipped with a coupler system?

• Do you plan on performing continuous lifting and placing tasks?

• What would be the primary application you would like the grapple to handle?

• What kind of grapple you would want to have?

When the project requires lifting and moving items of various sizes and shapes, hydraulic grapples are quite handy. These attachments offer a bigger and tighter grasp on materials, and some even offer the ability to rotate. The most popular grapple for excavators is a fixed grapple that boasts two jaws-one with three tines and one with two tines. Rotating attachments like grapples have become more popular with mini excavators and backhoes. Accessories such as tilt rotators further expand a grapple’s versatility and can improve the excavator operator’s productivity.

Grapple attachments can be used to handle Rocks, Boulders, Scrap, and Logs and for precision work like placing Tertrapods. Grapples can also be used to demolish brick structures.

VTN values after-sales assistance enormously. “Beyond the quality of all our equipment, service is our strength.” When a company buys VTN equipment, it is always followed up with quality product support because the sale can never be an end in itself. Suretech looks after VTN product support in the Indian subcontinent.

Call #DrDigger

#AttachmentSpecialist since 1990 on 1800 120 7873

sales@suretech.co.in

www.suretech.co.in

Transforming the way you use your machines

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.