Nilkamal offers the Aisle-Master trucks with lift-heights of up-to 14m

By Edit Team | February 17, 2020 5:19 am SHARE

Mihir Contractor, Sr. Vice President, Nilkamal Ltd sheds light on his company and other product ranges which set them apart from the competition in Material Handling Equipment industry.

What are the different types of material handling equipments offered by Nilkamal?

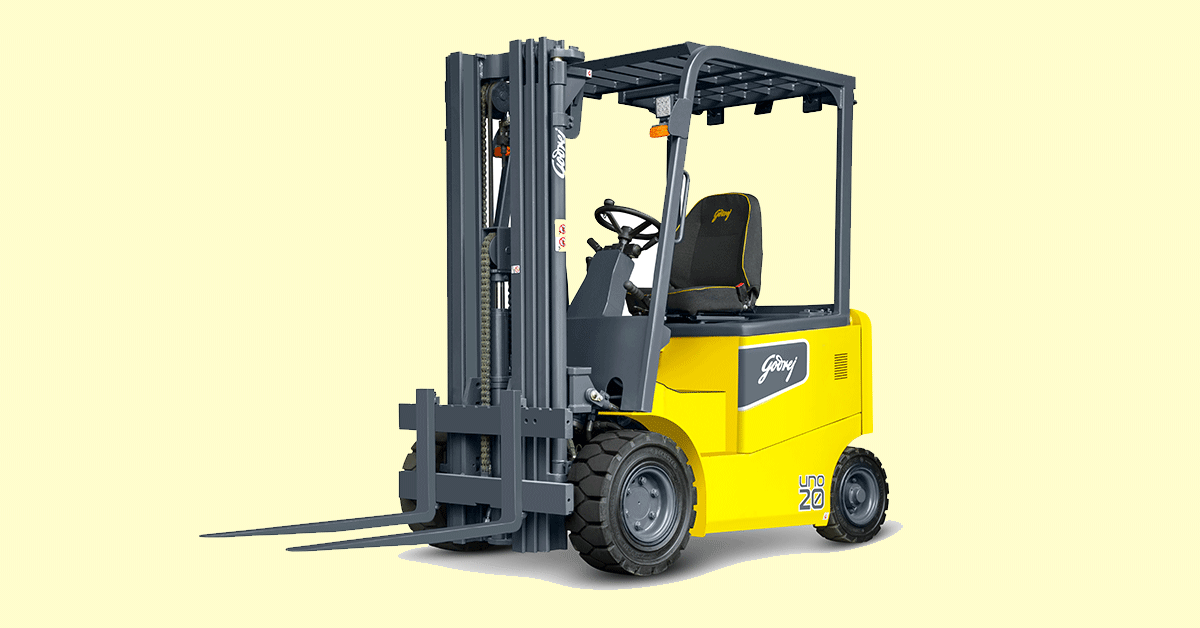

We directly sell and service across India an entire range of industrial material handling and cleaning equipments to improve storage, productivity, safety, and hygiene at our customers’ factories and warehouses. The range includes pallet trucks, stackers, reach-trucks, order pickers, Aisle-Master articulated fork-lift trucks for very narrow aisles, electric and diesel/LPG forklift trucks, Combilift multi-directional fork-lift trucks for long loads, Combilift straddle carriers for shipping containers and awkward loads, dock-levellers, mobile docks, carton/bag conveyers, vacuum-tube lifters, sweepers, scrubbers, vacuum cleaners, pressure-washers, and industrial fans.

What kinds of innovative technology are emerging in MHEs around the globe?

- In developed parts of the world, where labour is expensive and scarce, and the weighted average cost of capital (WACC) is low, automatic guided vehicles (AGV’s) are becoming popular to store and retrieve materials in factories and warehouses. In developing countries like India where labour is affordable and available, the WACC is high, most customers prefer operator driven equipment which gives them a higher return on their investment.

- Lithium ion batteries are emerging as a quicker-charging and longer lasting option to traditional traction batteries. Li-ion should get popular once India develops norms around their end-of-life recycling and disposal.

- 3) We’re seeing a strong trend in India towards high-reach very narrow aisle trucks that are similar in their driving comfort and ease to traditional fork-lift trucks. Nilkamal offers the Aisle-Master trucks with lift-heights of up-to 14 m along with our racking systems across a variety of industries. We couple this with medium and high-level order pickers so both pallets and cases/cartons can be picked in the same narrow-aisle.

- We’re also seeing an increase in inquiries for our Combilift multi-direction trucks to safely handle long and awkward loads in tight spaces.

- And we’re of course seeing a surge in demand of our scrubbers, sweepers, vacuum cleaners, and high-pressure washers to hygienically clean industrial and commercial spaces. This is a logical extension of India’s Swacch Bharat Abhiyaan initiative, and Nilkamal’s sales of waste-bins and waste-management systems.

What is your core strength/USP that differentiates your MHE solutions from the competitors?

- A direct sales and after-sales service team comprising of a 500+ field force operating from 40+ offices and warehouses reaching 30,000 live customers annually.

- The broadest range of material handling solutions from a single Indian company including crates-and-bins, pallets, MHE, and racking-and-shelving, all of which we directly sell, service, install, and selectively lease/rent.

- Our crate, pallet, MHE, and racking-shelving presales team is co-located in the same building. This enables quick and proper solution engineering options for customers who prefer a total solution from Nilkamal.

- Our collaborative and strategic relations with global warehouse and factory automation providers.

- Quick and tight management processes and decision-making

- And of course, the ubiquitous Nilkamal brand with a high recall for quality and service across both our consumer (our furniture and lifestyle solutions) and Industrial (our material handling solutions) customers.

What are the challenges faced while selecting an MHE solution for a project?

On large and complex projects, we want to provide our customers a proper solution. Many of our customers appreciate this, and so our best meetings are where we jointly brain-storm, ideate, and iterate revisions to improve our material movement and storage solutions. While this is fun and rewarding, and the learnings are invaluable, the innumerable iterations in layouts and product selection create a lot of cycles in our presales engineering team. All this upfront engineering also takes time, which becomes challenging to manage within our customers tight timelines. And then after all this upfront fun and engineering investment, these projects get put on hold by customers as has been the case through the current downturn in economy. This by far is the biggest challenge.

Mihir Contractor, Sr. Vice President, Nilkamal Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)