OEMs are conscious of refurbishing and recycling

By Admin | October 27, 2022 6:17 pm SHARE

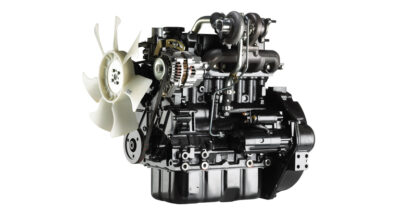

Speaking on delivering superior quality engines for the construction sector, Ryuji Nagase, Managing Director, MITSUBISHI HEAVY INDUSTRIES-VST DIESEL ENGINES PVT. LTD. mentioned their new emission test facility, which allows them to conduct necessary trials inhouse.

Powering the construction and road equipment

With a high power-to-weight ratio and internationally acclaimed quality, our engines are a good fit for the small range of up to 50 hp for versatile applications like Compact/Orchid tractors, Marine Propulsion, Light Towers, Mini Excavators, Compactors, Skid Steers, Power Generation, and Niche Segments like Litter Pickers, Cleaning Machines, Bus Refrigeration, Water Jetting Machines etc.

Our significant presence today is in agricultural machinery. Many leading tractor OEMs prefer to power their orchard tractors with our engines. Not only in India, but a significant portion of such tractors is also exported to international markets. With wide acceptance in the orchard segment, we also started working on conventional tractor projects with these OEMs. Last year, we sold around twenty-four thousand engines to tractors alone for the first time.

Complying with emission norms for energy control in engines

The engines we have now can meet the Indian emission standards like TREM-3A and BS-IV CEV norms. In addition, it can meet global emission standards like EU Stage V and US Tier-IV Final. For the range above 19 kW, we have the C J series in Japan that can meet all the advanced norms that exist in the world. We have initiated the setup of a new emission test facility, conducting necessary trials in-house and ensuring our engines meet stringent emission norms to cater to global requirements.

OEMs based in India do export more than ever. Earlier, exports were preferred to countries with less stringent norms than India. Now manufacturers are considering opportunities to export machines to Europe and the USA. In such cases, they need an engine with the norms of those countries, and we will have them. India also does not want to stay behind and is planning to introduce stricter norms quicker than ever. Therefore, this new series will also be a great proposition for the Indian market.

Challenges in equipment purchase, cost, and uptime

The sudden increase in demand from domestic and export markets was quite obvious and made us take a strategic decision towards capacity enhancement. As everyone knows, the current supply chain crisis is ramping up capacity while facing several in-house and supplier challenges. As an interim action to meet customer demand or expectations, we are closely working on the cycle time/takt time reduction through Kaizens, Jidoka, and Poka Yoke processes, thereby increasing productivity and achieving our targets to some extent. We recently added the new honing machine to our machine shop line, which has been commissioned to be a major bottleneck to increasing our production volumes, and now the issue has been eased out. Our products can meet the next 3–5 years’ business growth with this new machine geared up.

Sustainable equipment and engineered solutions at Mitsubishi

Sustainability comes if quality standards are set and met across the supply chain from the root level. In addition, vendor partners should have continuous education, and the whole supply chain must run with a customer-centric approach. We follow the quality standards set by our parent company in Japan. We also do the same throughout our supply chain and ensure that it happens smoothly through ongoing education of our vendor partners and systematic processes. It works.

Future of reusing and recycling equipment and machine waste

We completed 2 lakh engine production, delivery, and counting on May ‘22. At this moment, we have not made any clear plans regarding the engine refurbishment. Looking at the increase in demand almost two-fold year on year made us think about it. I need to understand OEM customer interest in engine refurbishment and market demand.

Later, we may strive towards leading standard procedures, which should meet the requirements of RRR (Reduce, Reuse, Recycle) in all aspects and be a win-win situation for both manufacturers and OEM customers. This will contribute to and protect the environment alongside resource and energy consumption from most to most minor favourable actions.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.