PROACTIVE APPROACH IN PROJECT MANAGEMENT

By Staff Report | November 18, 2024 4:08 pm SHARE

Having spent more than three decades navigating the complexities of EPC projects, Subrata Das reflects on the sector’s progression, the persistent gaps in leveraging project management tools, and his strategic approach to cost optimisation and quality management in large-scale projects.

Your extensive experience in the EPC sector spans over three decades. How have you seen the industry evolve in project management and execution?

Over three decades in the EPC sector, we have witnessed a transformative evolution in project execution and management. The shift from manual operations to advanced equipment and machinery has improved execution efficiency, especially as project scales expanded, government initiatives accelerated, and financial institutions offered stronger support.

This advancement in machinery and technology has drastically shortened construction timelines and made construction much safer than before—a stark contrast visible in remote areas today, where concrete is still transported manually by headloads to construct small buildings. Looking back, the construction of large concrete rafts for even large industrial projects used to be done manually, with wheelbarrows and small concrete mixers of capacity 1 Cement Bag along with manual weigh batchers. In project management, the pre-1990s marked an era of manual processes, where teams of engineers used to prepare construction schedules manually on graph paper, using bar charts and shading updates with coloured pencils and pens. By 2004, we witnessed the gradual adoption of software like MS Project for schedule preparation, which simplified preparation, updating, and modification, significantly reducing workload and preparation time for review meetings. Almost every construction company, large and small, uses such software today.

Despite these advancements, many in the construction industry are far behind in utilising all the capabilities of this project management software, particularly for risk identification & prediction and proactive corrective actions. A common challenge remains manual updating of the WBS activities, which is very time-consuming and results in delayed detection of issues; project managers often become aware of delays only after losing precious time, which cannot be regained. While the software has advanced forecasting capabilities, real-time schedule updates remain a bottleneck due to manual updates’ cumbersome and time-intensive nature. Actual progress is often updated in the software only periodically, rather than on a shift or daily basis, and that is also true for the broader activities or milestones of L2 Level rather than (Micro) L4 Level. It is important to note that, without shift-by-shift or daily inputs or updating all micro activities, the software relies on outdated data at broader levels, leading to decision-making based on backdated information, which cannot effectively address real-time issues. Consequently, future critical issues, such as exact time of resource peaks, idling, or design drawing issues, are often overlooked, preventing management from taking timely actions and management is left out with the only option of taking intuitive decisions or ignoring many as same as pre-1990 practices because tens of thousands of activities.

There is a noticeable gap in efficiency: construction equipment is fully utilised, but the project management software’s full potential remains untapped, affecting stakeholders.

Can you discuss your approach to optimising costs without compromising quality? What tools or methodologies do you find most effective?

In my experience, optimising costs without compromising quality is achievable and essential. The notion that cost reduction inherently results in lower quality is a misconception; rather, it’s the opposite because, in large-scale projects, the primary costs extend much beyond just materials, encompassing factors such as idle resources, prolonged project durations, under utilisation — especially of equipment — interest costs, fixed overheads, and repair costs, which can go very high for lack of required quality monitoring.

To address the issue of Cost optimisation, it is crucial to foresee potential bottlenecks and implement mechanisms for timely intervention. Delays in one activity due to any factor often create cascading effects, leading to cumulative backlogs that are challenging to manage on-site without adequate foresight and preparation.

Rather than allowing project milestones to dictate the pace, I advocate a proactive approach to project management rather than reactive. This begins with enhancing the planning capacity through technology integration and upskilling. Decision-makers must be equipped to make informed choices, and while project managers work to mitigate delays, an additional provision for emergency preparedness should be built into the budget. For example, a 0.01 percent increased provision for extra resources for unprecedented times can improve the overall profitability, provided we know exactly when to allocate and scale back in the ever-evolving scenarios in construction.

By leveraging automated monitoring tools integrated with the existing software, we can anticipate risks early and enable the team to make decisions that keep costs and quality aligned.

You developed a mobile application for construction project management. Can you elaborate on its features and how it addresses the complexities of managing documents and workflows in large-scale EPC projects?

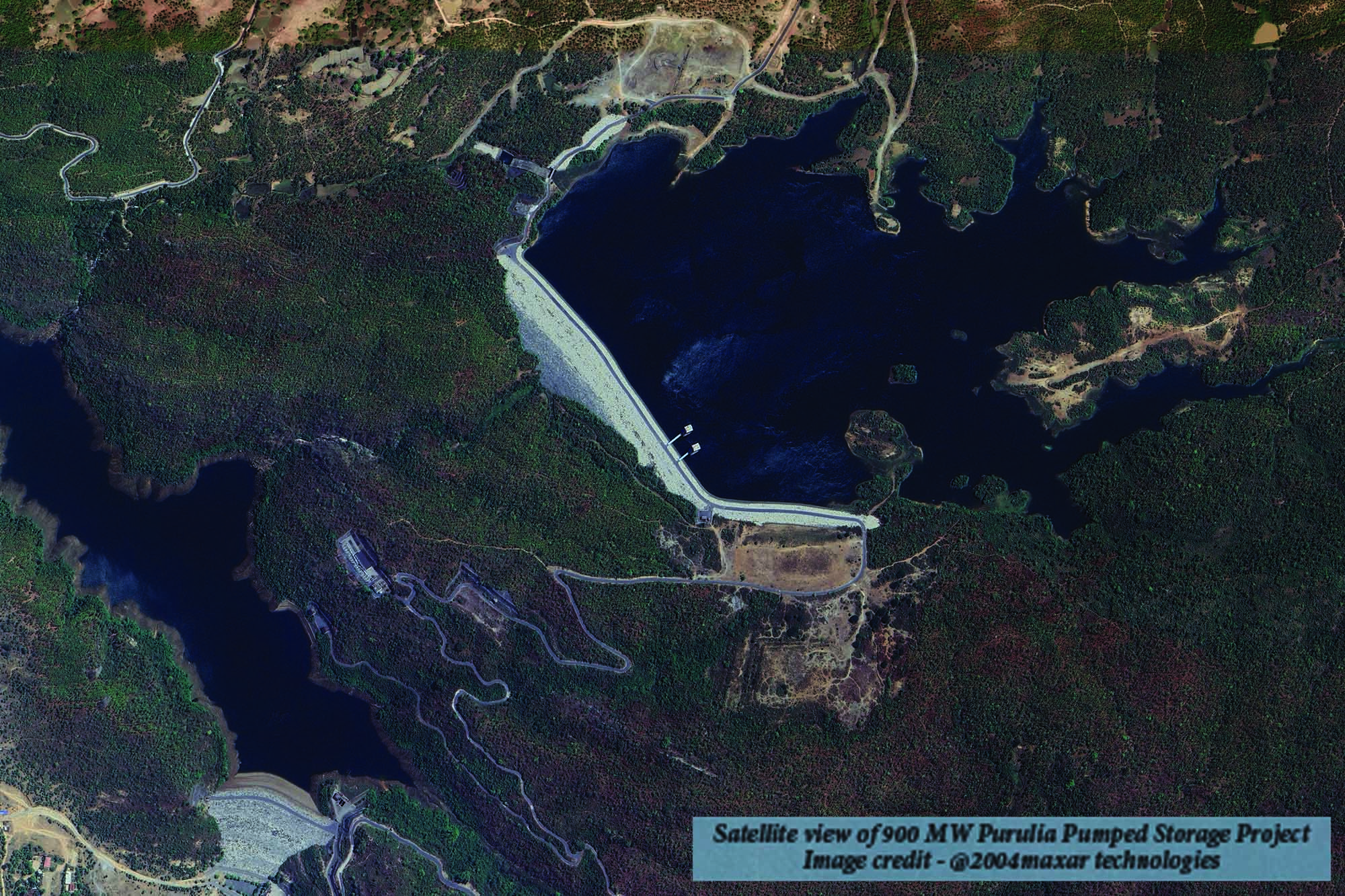

It is not just one mobile application; our digital construction lab has developed multiple custom tools for project management. Before going into their features, let us understand the problem of one scenario. In an EPC Hydro Power project, there are many drawings, engineering calculations, submittals, investigation test reports, and model studies occurring across various geographic locations. Tender conditions specify that each component must undergo review and approval by the developer or engineer at every stage. This process involves numerous transmittals with comments or observations, and the entire cycle repeats until each drawing is approved for construction. Every document for various project components is at a different stage at any given time, making it extremely challenging for stakeholders to track and monitor efficiently. While the document controller or engineering coordinator is fully occupied, achieving a comprehensive snapshot visualisation is nearly impossible at short notice at any given point in time for review.

Adding to this complexity, each drawing links to site activities such as enquiry floating, negotiation, ordering, dispatch, and on-site construction or erection. The lack of integration between engineering and construction processes makes pinpointing critical items a mammoth task for planners. Consequently, decision-makers are often unable to make timely decisions. Work can come to a halt at certain stages due to unapproved drawings, materials, or items. This leaves civil contractor resources unutilised, disrupts the payment cycles and delays projects, often forcing the developer to pay for extended stays. Conversely, hydromechanical and electromechanical contractors also suffer from this impact.

To address this, a custom integrated dashboard was developed, allowing any document controller or design coordinator to update it as soon as they receive a transmittal email on their mobile device whenever a document advances in status. All authorised users of this automated dashboard gain

real-time, interactive visualisation of the entire workflow. With a single click, users can view each drawing or design calculation’s current stage, including details on the submission date, review date, forwarding date, approval date, count of days, automated reminders, and associated observations. The project head no longer needs to call a drawing coordinator for status updates or wait for review meetings to identify potential and impacted delays and their duration. Coordination delays are minimised, and the planning team can dedicate more time to effectively strategising ways to mitigate these delays rather than doing tabulation work in spreadsheets.

As a professor of practice at MIT (WPU), how do you think academia and industry can collaborate more effectively to prepare the next generation of professionals?

As a professor of practice at MIT-WPU, I see an acute need for academia and industry to close the gap between traditional syllabi and the rapidly evolving skill requirements as technology advances in the Engineering, Procurement, and Construction (EPC) sector.

One key approach is co-developing courses in collaboration with industry partners. This helps align the curriculum with emerging trends, ensuring that students are equipped with the necessary engineering practices and industry-ready skillsets. MIT-WPU has made significant progress in this area and greatly benefited the students.

Additionally, industry-sponsored projects, such as research and capstone initiatives, give students valuable hands-on experience by allowing them to work on real-world challenges, providing exposure to cutting-edge technology and industry standards. Another important aspect is the involvement of industry mentors, guest lecturers, and advisory boards, which helps enrich students’ understanding of current sector developments and keeps academic content up-to-date.

Faculty internships offer educators the chance to experience the latest methodologies firsthand. They can then integrate these into their teaching, further enhancing the learning experience for students.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)