Rising energy costs in construction demand smarter management systems

By Staff Report | February 13, 2025 10:48 am SHARE

Following the rapid rise in electricity rates, energy usage has become an increasingly vital component that must be properly managed. Energy management systems have long provided a solution. However, there is an IIoT-supported application for capturing and optimising energy use, which, like many other areas of digitisation, promises significant added value.

For decades, energy costs were a consistent and predictable variable in manufacturing, and at competitive rates of roughly 5 cents per kWh, they were simple to compute. However, several reasons make this computation no longer reliable, the most notable of which are the war in Ukraine and the energy revolution brought about by climate change. In any case, businesses should now budget roughly 25 cents per kWh, implying that energy costs have a far higher impact on production costs, with energy-intensive companies facing significant challenges.

Most importantly, there are no signs of progress. It is quite the reverse; CO2 pricing will raise energy costs, and the urgent need to maintain and expand electrical infrastructure will require that electricity costs be passed on to customers.

Managing energy—a task for today and tomorrow

What is scarce, expensive, and necessary must be ‘ managed’, which is why energy management is the current buzzword. Appropriate IT tools are available and widely used. These use energy meters to record consumption (for electricity, gas, compressed air, and so on), which users may then link to specific areas of production, systems, or even production volumes.

These systems are especially beneficial when they are fully integrated into the organisation’s or production department’s data environment rather than used as standalone devices. This way, the ‘adjustment screws’ for targeted optimisation and explicit allocation of energy costs to certain goods or production steps will be visible (in the best-case scenario).

EMS 4.0: Comprehensive database for optimising energy consumption

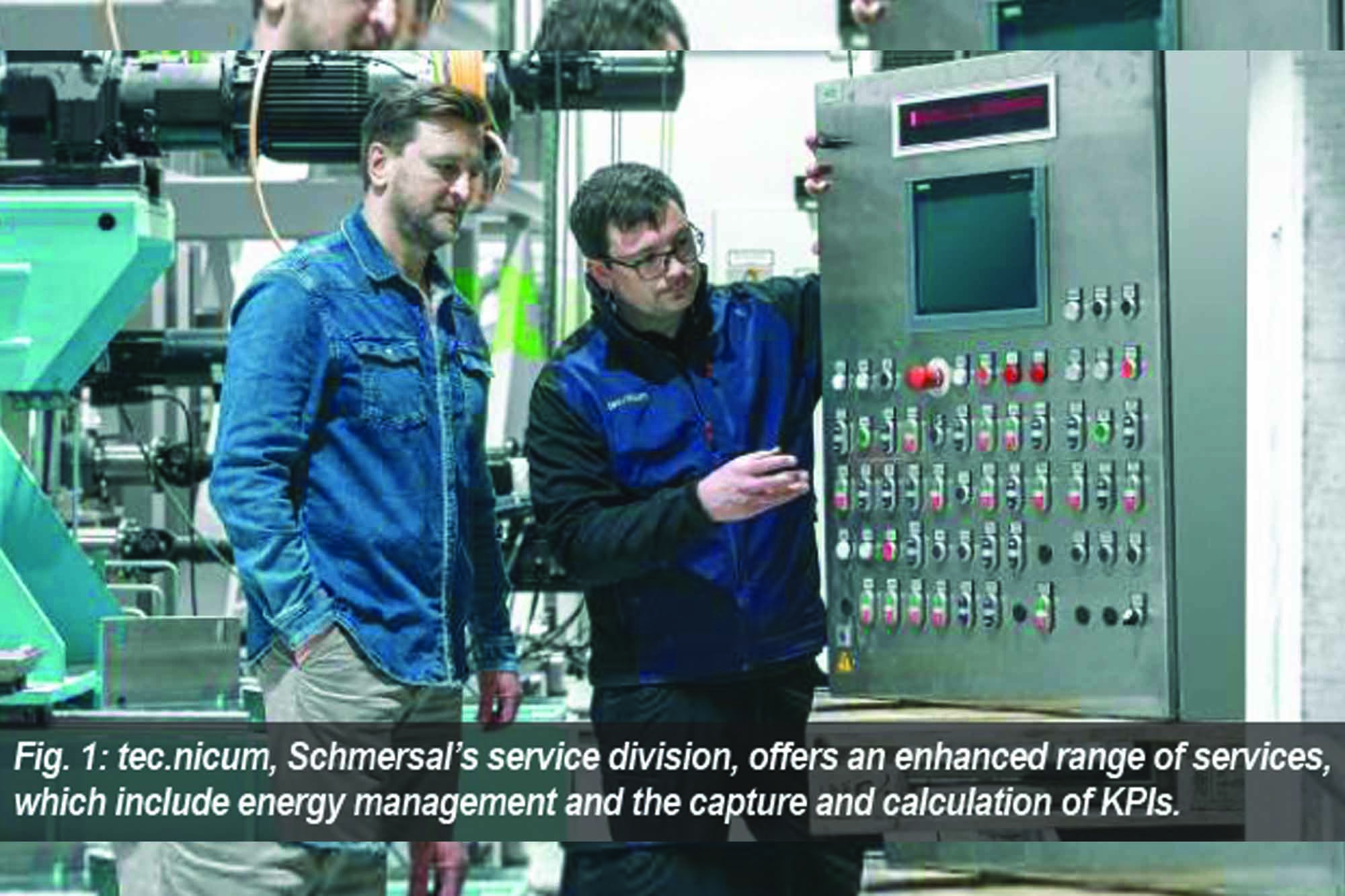

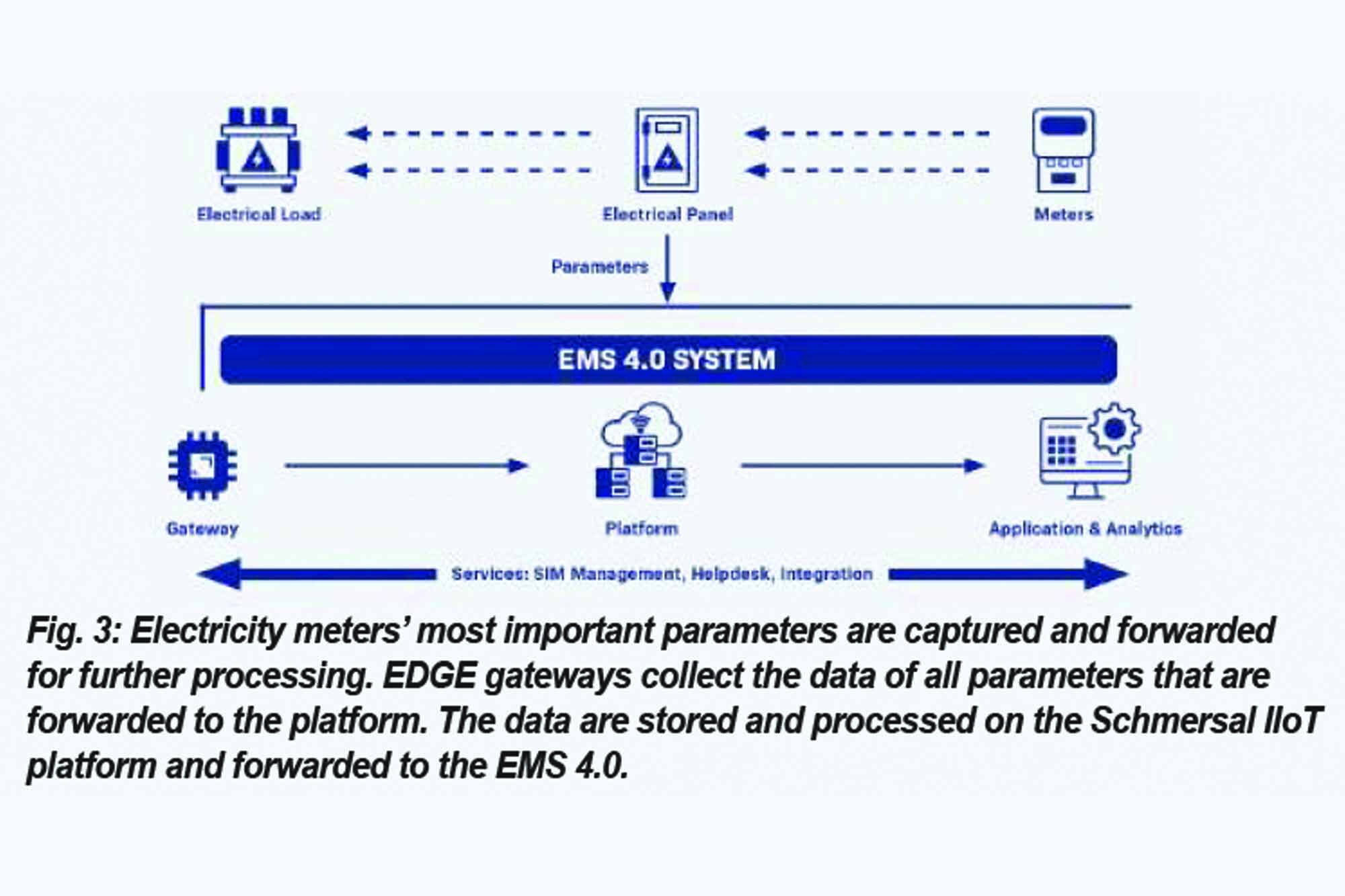

tec.nicum, the Schmersal Group’s newly founded service business, has developed a modular solution known as the ‘Energy Management Solution 4.0’, or EMS. It is part of a larger IIoT platform whose goal is to bring transparency to production and give users a comprehensive database covering far more than simply energy use.

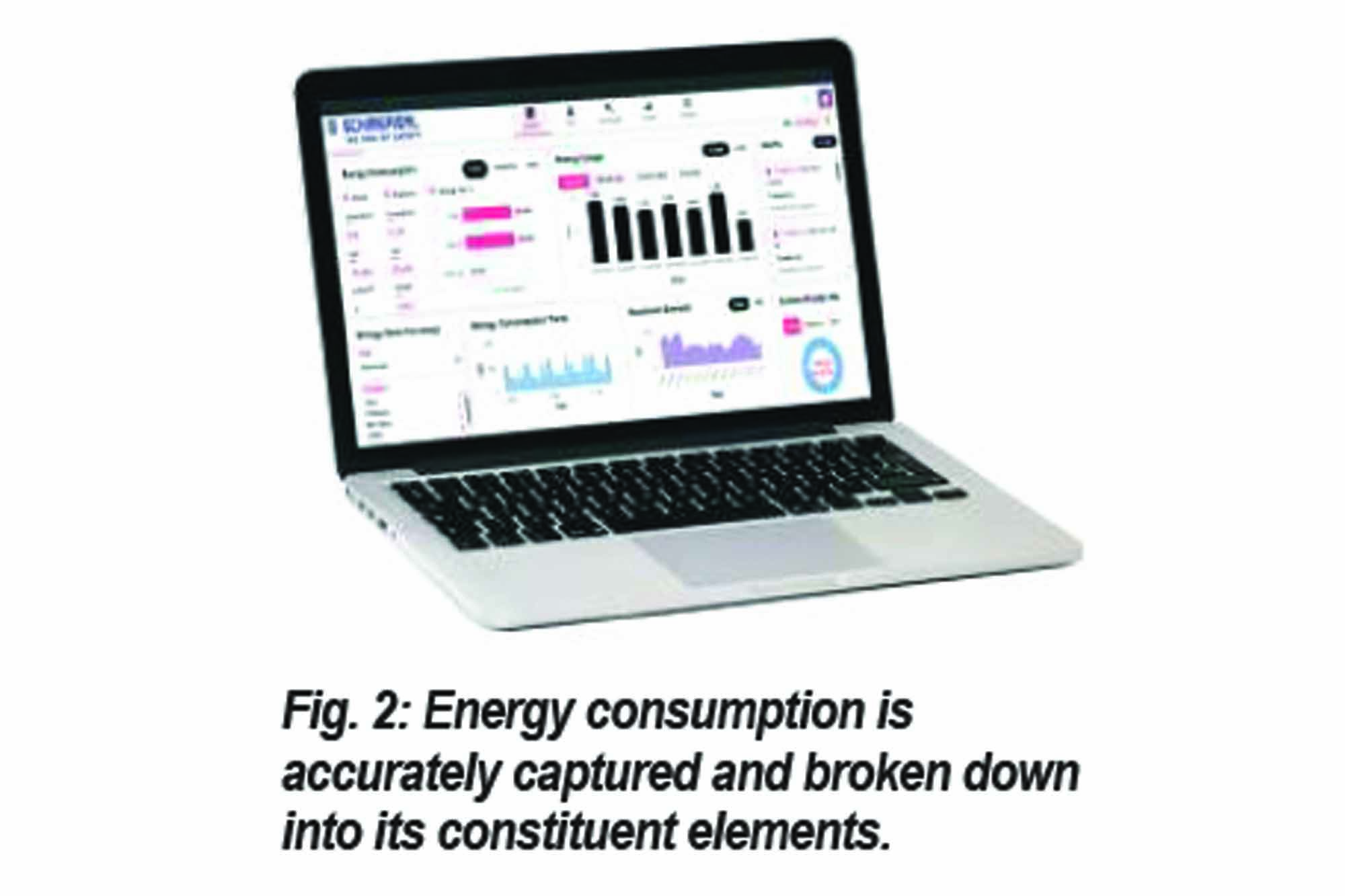

As a plug-and-play module within this system, EMS 4.0 makes setting up and assigning energy meters simple. A dashboard displays the usage and development of all systems. Various evaluation functions enable the creation of thorough reports on energy use, including for specifically set factors. Limit values can be set, and an alarm message is sent if exceeded.

This gives customers a solid foundation for energy efficiency projects, allowing them to test and analyse the efficacy of specific measures and compile data for CSR reporting, which is already required for bigger enterprises in the EU. This need will be gradually rolled out to smaller businesses.

Energy efficiency as a KPI factor

EMS 4.0 differs from previous energy management systems in that it is integrated into the Schmersal Group’s full IIoT concept, offering its customers a platform. This IIoT platform was primarily designed for ‘Safety as a Service’ and IIoT-supported service ideas (condition monitoring and predictive maintenance). However, because it captures and analyses a wide range of (production) data, it can also serve as a foundation for energy management.

Task: To capture overall equipment effectiveness (OEE)

And, because calculating KPIs is part of the IIoT concept created by tec.nicum (together with condition monitoring and predictive maintenance), energy efficiency can be linked to KPI-related data. More particularly, because the IIoT platform captures major KPIs for production, energy-related data may be incorporated into these KPIs, such as the overall equipment effectiveness (OEE) KPI. It measures the productivity and efficacy of a production system, allowing systems (in the same or separate production facilities of an organisation) to be compared, as well as focused optimisation of this KPI.

First usage example: Production of household appliances

Schmersal’s ‘Energy Management Solution 4.0’ first user is utilising just this feature. Plant management at a global household appliance manufacturer’s Indian production facility had set a goal of increasing energy efficiency in production yearly, with a 2 percent to 5 percent reduction in energy consumption with production volume each year—and a corresponding positive impact on carbon emissions from the site (which are also accurately recorded).

The organisation was searching for a complete, IT-supported solution that would provide transparency to the existing situation while allowing KPIs like OEE to be captured. The final demand was that the database document progress would be used for worldwide ESG reporting.

The site managers approached the Schmersal Group’s IIoT Global Competence Centre located in India with their list of requirements. The Competence Centre was already planning the ‘Energy Management Solution 4.0’ market launch and could use the factory as an early ‘use case’.

Hardware: Failsafe edge solution

When selecting hardware components, special effort was made to guarantee that the components can communicate with the web server for a set time, even if there is a power failure. Data captured from equipment and drive systems, as well as data recorded by energy meters and other sensors, are collected at the edge level or in the immediate neighbourhood of production and then processed in real-time. 4G Modbus IoT gateways are just one type of equipment utilised for this.

This means that customers always have access to practically real-time data, which may be used to manage energy supply and generation directly. In addition, comprehensive reports are provided to record efforts to lower energy use and carbon emissions.

The benefits of digitalisation—fusing energy and production data

The household appliance manufacturer is completely delighted with this solution: the people’s effort necessary to capture and assess energy usage has been much reduced, and the OEE key figure has improved significantly. Operational safety has also been addressed by closely monitoring major energy consumers and generators. The same principle applies to energy distribution systems. Irregularities are recognised in real-time and communicated to the person in charge as soon as possible, for example, via SMS text message.

Transparency even extends to capturing the energy utilised by each made product—that is, for each household item that leaves the factory. To ensure this, the energy data must be linked to the digital plant’s production data. Schmersal’s IIoT platform also supports this.

New responsibilities for tec.nicum: Energy management and ‘safety as a service’

The Schmersal Group recently revamped its service, consulting, and engineering capabilities, combining them into an independent firm called tec.nicum – Solution & Services GmbH. The division operates globally and now employs 162 people, most of whom are technicians and trained functional safety engineers.

More important than the new structure is the significantly expanded range of services, particularly in digitalisation and software, where tec.nicum provides new solutions such as a tool for conducting risk assessments and new digital services such as cloud solutions, IIoT applications, and energy management software.

The ‘backbones’ of these services comprise a solid IIoT platform that provides consistent communication among all parties. This tec.nicum-developed platform has proven useful in the IIoT-supported energy management system described here and in other applications. Experts at tec.nicum are already working on the next step, in which the platform will gather, transmit, and analyse safety data. This establishes the conditions for completely new, comprehensive services and a new business model known as ‘Safety as a Service’.

E-mail: info-in@schmersal.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.