A robust infrastructure coated with a sustainable vision

By Staff Report | October 24, 2024 3:37 pm SHARE

Cutting-edge advancements in paint technology are vital in the quest for sustainable infrastructure. With features like enhanced weather resistance and eco-friendly formulations, the latest innovations in coatings are not just about aesthetics but about building a robust future for our environments.

How have advancements in paint coatings technology contributed to creating more resilient and sustainable infrastructure?

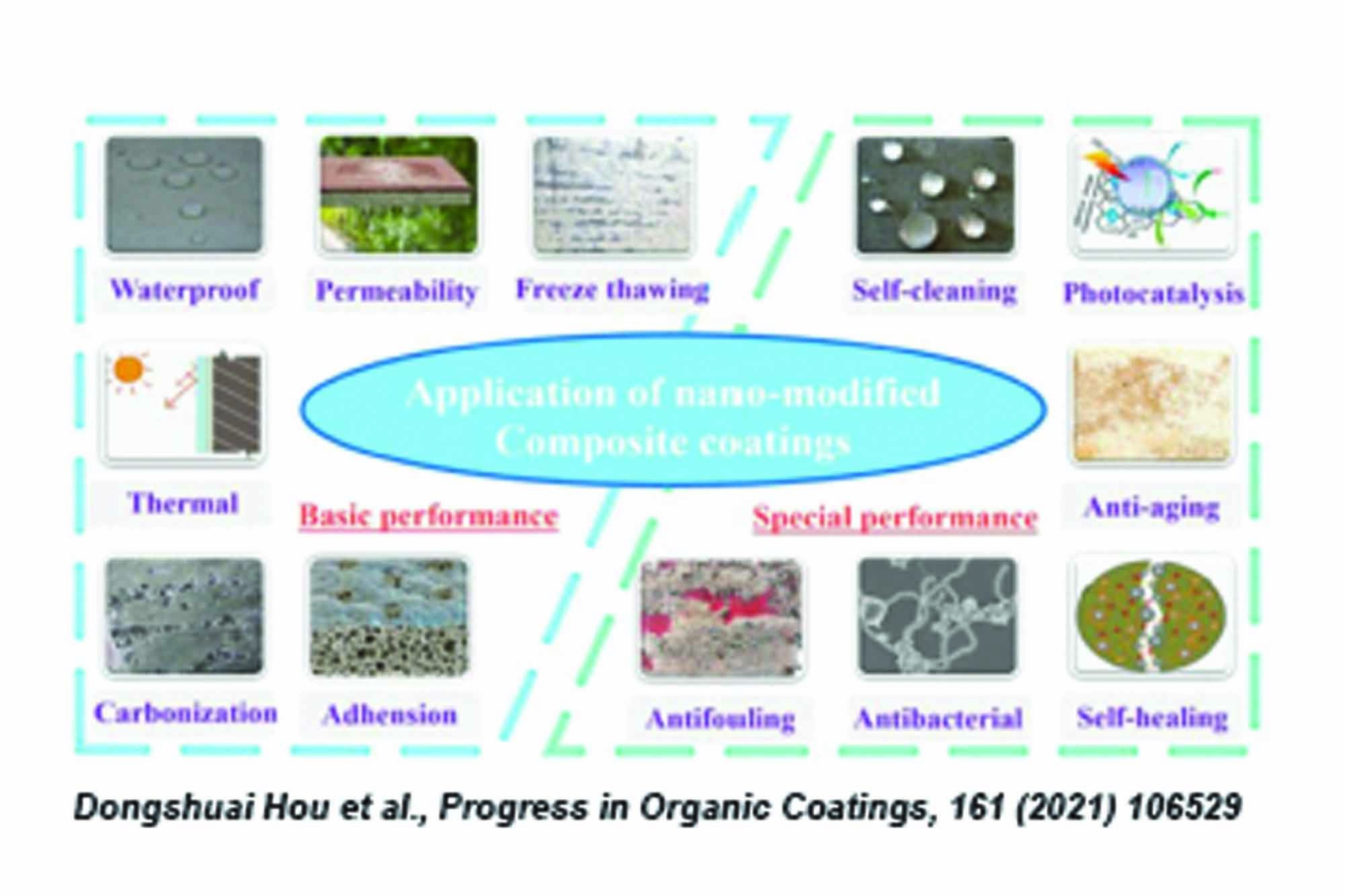

Today’s paint industry has several new features in paints that solve many inherent problems in the infrastructure industry. In addition to several conventional paint systems, we have Functional and smart coatings for weathering resistance – resistance from sunlight, rain, and high winds. Nano-technology has changed the scenario of the coating industry by creating several pluses: saving raw materials, enhancing the strength of the coating and its durability, reducing thickness, and enhancing corrosion resistance. Many new coating systems are made robust using nano-particles; for example, we have created a highly corrosion-resistant coating by adding a very special nano-particle in a conventional epoxy coating that could enhance its resistance to corrosion from pH 1-14. Similarly, using 0.5 percent graphene can make anti-static coatings, while combining graphene and carbon nanotube can create a very effective conducting coating. There are also special functional paints that can reduce roof temperatures, thereby creating a lower temperature in the room, providing comfort to people or reducing electricity expenditure for running air conditioning.

SSPC India offers various training programs and certification courses. How do these programs help professionals stay updated with the latest developments and standards in paint coatings and quality control?

SSPC is a professional body that focuses on paint-related activities. We organised our 20th year last year by hosting the 15th International Conference on Paint Coatings. We regularly conduct training programs for supervisors and Coating Inspectors, known as Level 1 and Level 2 programs, focusing on basic information about paint coatings, issues on surface preparation, paint application techniques, methods of measuring paint properties, and various lab tests available to characterise the paint coatings. The Level 1 course also includes a one-day practical training that familiarises participants with various methods of paint characterisation and demonstrates various testing methods. In Level 2, we focus on specific applications of paint coatings in industries such as Oil and Gas, infrastructure, chemical petrochemical plants, and power plants. So far, we have organised more than 300 such training programs, which ONGC, GAIL, BPCL, and many organisations in the Gulf recognise.

What are the industry’s key challenges regarding surface protection and coatings, and how is SSPC India addressing these issues?

Today’s key challenge is that the industry needs to create a Corrosion Protection monitoring team as projected by the Corrosion Management procedure. Companies don’t hire corrosion experts, who are available from various IITs, UICT, HBTI, and CECRI Karaikudi. No industry, including ONGC, GAIL, HPCL, BPCL, or any Power Plant, has a Dedicated Corrosion Management Team. I recently visited JSPL in Odisha, where they have ten different units at one complex, which need severe and quick replenishment of paint to their infrastructure and critical parts to avoid further corrosion. Instead, work is being organised by retired old employees of the firm who do not possess even basic knowledge of corrosion. I saw the same story at the biggest Ship Harbour at Pipavav in Gujarat and the chemical unit of Deepak fertilisers. Unless all units are monitored and followed by periodic maintenance, nobody can solve their corrosion problems. The second problem is paint application, where little focus is made on surface preparation. Supervision is not up to standard, resulting in premature paint failure.

How is SSPC India contributing to sustainability in the coatings industry, and what future trends do you foresee in protective coatings that align with the goals of building sustainable infrastructure?

We are making significant contributions to sustainability in the coatings industry, reflecting our growing commitment to green technology and environmentally friendly practices. Sustainability has become increasingly prevalent in the paint industry, and several initiatives highlight this commitment. For instance, we have strict lead restrictions in paint formulations, requiring that most paints contain no more than 300 ppm lead levels. The lead content must be even lower for specific products, such as toys designed for children, capped at 90 ppm.

Coatings used for drinking water lines and food-grade applications are subject to various restrictions to ensure safety and compliance. These restrictions include transparency, lack of odour, and limiting heavy and toxic elements such as lead, arsenic, mercury, chromium, sulfates, and cyanides. Such coatings must pass rigorous testing, including food-grade assessments and ROHS compliance, to guarantee their safety for public use.

The movement towards green coatings emphasises the need to restrict volatile organic compounds (VOCs) in paints. VOC levels must either be very low, under 250 mg/l, or completely absent in solventless or waterborne coatings. We also restrict carcinogenic dyes, further supporting the push for safer products.

In terms of sustainable coatings, three key factors are crucial. Reusability, reduced waste generation, and low-temperature technology. These elements are essential for developing coatings that perform well and align with the broader sustainability goals in construction and infrastructure development. As we continue to champion these initiatives, future trends in protective coatings are likely to focus on even more stringent environmental standards, innovative materials that further minimise ecological impact and advanced technologies that enhance the performance and longevity of coatings while prioritising sustainability.

How do the International Symposia and technical meetings organised by SSPC India contribute to setting new standards in the industry? Could you highlight some key outcomes or innovations from recent events?

We have organised more than 15 International conferences since our inception in 2003. We invite participants from paint manufacturers, paint dealers, contractors, R&D organisations, and members from other organisations like IPA, ISSPA, IPCA, and many others. Our conferences cover the latest topics on new paint requirements, new application techniques, and concepts on surface preparation. Inviting lectures from global experts is one of our key features. Technical papers from R&D organisations share their research results with the industry. Each International Conference also includes a Paint Exhibition, which helps participants see new products or discuss their problems with existing products. One of the important advantages of the Exhibition is the opportunity to explore several new equipment/facilities for paint manufacturing and lab equipment. In this expanding and exponentially growing industry, our role is significant. We help train professionals, bring them together to discuss paint issues and provide training in paint application challenges.

For more information, visit: https://www.kptllab.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)