Access Equipment: Safe Practices

By Edit Team | July 11, 2024 3:49 pm SHARE

The construction industry’s ascent to towering heights demands advanced access equipment for safety and efficiency. Here is a sneak peek into how innovations in height access are reshaping worksite dynamics, ensuring secure environments and streamlined productivity.

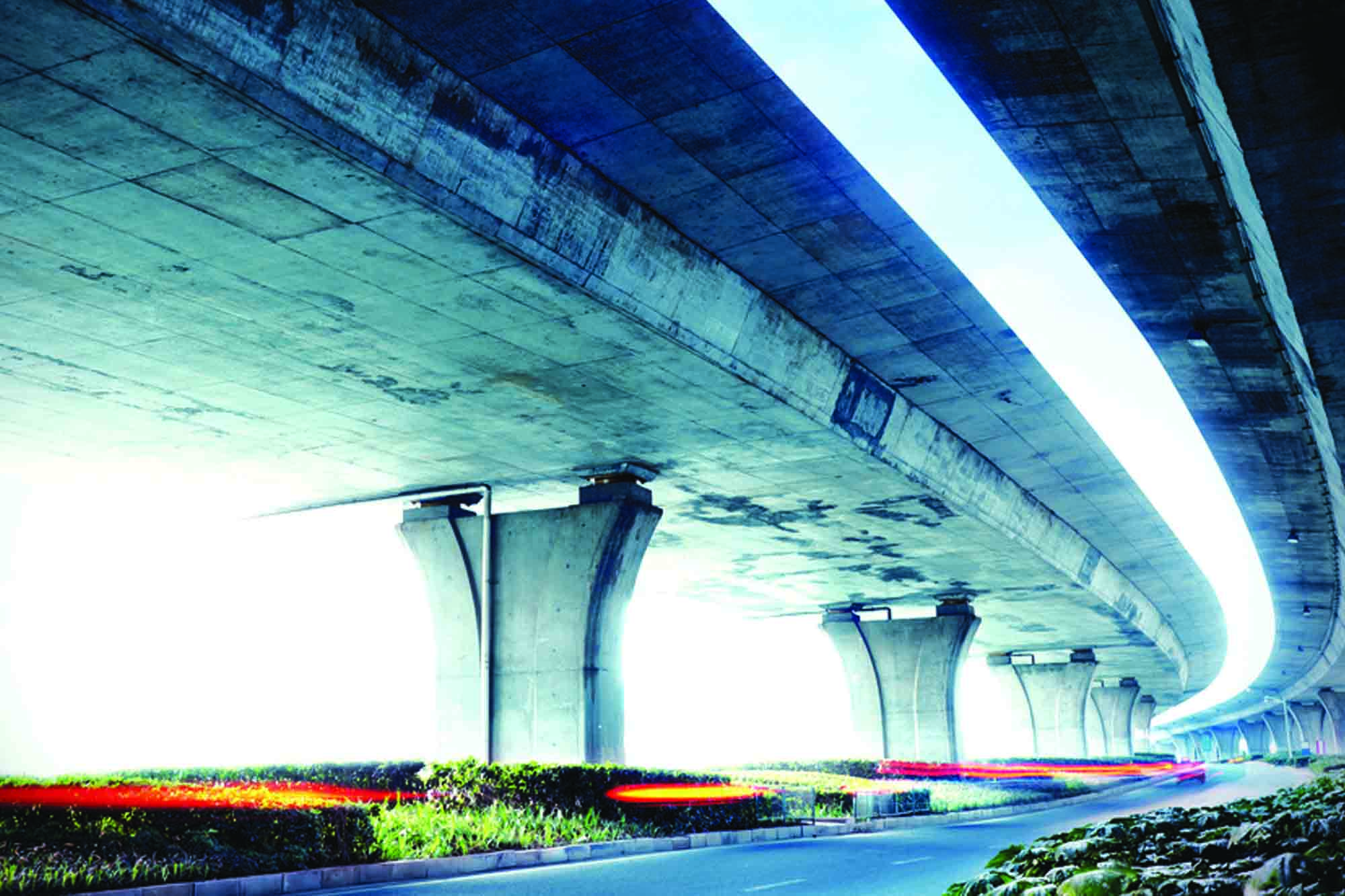

The construction industry is reaching new heights, making access equipment indispensable for working at elevation. High-rise buildings are increasingly common, and more than traditional methods of access and maintenance are required. Modern access equipment has evolved significantly, transitioning from simple ladders to sophisticated Mobile Elevating Work Platforms (MEWPs). By selecting the appropriate access equipment, construction teams can enhance safety protocols and optimise productivity, fostering a secure working environment. Innovations and advanced approaches in height access equipment continue to make working at heights safer and more efficient.

Against this backdrop, we sought insights from industry leaders on driving sustainability, enhancing safety standards, and meeting evolving market demands through advanced technologies and strategic initiatives. This article is based on excerpts from their insights. The evolution of access equipment encompasses a wide array of machinery designed to enable safe working at heights and in challenging environments. From aerial work platforms (AWPs) and telehandlers to cranes and material handling equipment (MHE), these tools are indispensable in sectors requiring elevated access for construction, maintenance, and material handling tasks.

Over the years, access equipment has evolved significantly, integrating advanced technologies to enhance safety, operational efficiency, and environmental sustainability. Innovations such as telematics, IoT-enabled systems, and predictive maintenance capabilities are transforming how equipment is managed and operated, ushering in a new era of smart construction and mining practices.

Driving sustainability through technological innovation

In pursuing sustainable development, the construction and mining industries increasingly prioritise eco-friendly practices and technologies. Mark McConway, Managing Director at WEB Systems International, underscores the importance of sustainability in equipment design, stating, “Reducing the carbon footprint of access equipment is crucial for mitigating environmental impact.” Companies are adopting energy-efficient solutions and incorporating recycled materials into their manufacturing processes to minimise waste and conserve natural resources.

Vibrant Engineering exemplifies this commitment with eco-friendly asphalt plants and road construction equipment. By integrating recycled materials like Recycled Asphalt Pavement (RAP) and implementing energy-efficient technologies, Vibrant Engineering enhances operational efficiency and reduces greenhouse gas emissions associated with construction activities.

Enhancing safety standards through innovation

Safety remains paramount in industries where working at height poses inherent risks. Advanced safety features and rigorous compliance with international standards are integral to modern access equipment design. Dr Raghunandan Jagdish, MD & CEO of Nandan GSE Pvt Ltd, emphasises, “Safety innovations such as advanced control systems and ergonomic cabin designs are pivotal in minimising operational hazards and ensuring operator wellbeing.” Companies invest in state-of-the-art technologies that enhance operational safety, including anti-sway systems, automated load monitoring, and comprehensive training programs for equipment operators.

Anubhav Roy, Marketing Manager at Abhay Rana Infra Services Pvt Ltd, highlights the importance of preventive maintenance in maintaining high safety standards, stating, “Regular maintenance and thorough inspections are critical to ensuring equipment reliability and reducing the risk of unexpected failures.” By implementing predictive maintenance strategies facilitated by IoT and data analytics, companies can proactively address potential issues before they escalate, enhancing equipment reliability and prolonging service life.

Empowering operators through training and development

Operator training and skill development are instrumental in optimising equipment performance and ensuring safe operational practices. Srinivasan M, Assistant General Manager at Schwing Stetter India, emphasises the significance of comprehensive training programs: “Empowering operators with advanced training on equipment functionalities and safety protocols enhances operational efficiency and reduces downtime.” Companies like Schwing Stetter India prioritise continuous learning and skill enhancement to equip operators with the knowledge and expertise to operate modern access equipment safely and effectively.

Integrating virtual reality (VR) and augmented reality (AR) technologies in training modules further enhances the learning experience, enabling operators to simulate real-world scenarios and practice complex manoeuvres in a controlled environment. By fostering a culture of continuous learning and skill development, companies enhance operational efficiency and cultivate a safety-first mindset among equipment operators.

Innovative solutions for diverse applications

Access equipment serves diverse applications across construction and mining sectors, each with unique operational requirements and challenges. Amit Bhalla, President & CEO of Bajaj Indef (Hercules Hoists Limited), discusses the versatility of access equipment, stating, “From compact AWPs for indoor maintenance to robust telehandlers for heavy-duty construction projects, our product range caters to diverse industry needs.” Companies like Hercules Hoists Limited leverage their expertise in hoists and cranes to deliver customised solutions that optimise operational workflows and maximise productivity across various applications.

Integrating advanced technologies such as GPS tracking and remote diagnostics further enhances equipment performance and operational visibility, enabling companies to monitor fleet activities in real-time and streamline maintenance schedules. By offering modular designs and customisable configurations, manufacturers empower customers to adapt access equipment to specific project requirements, enhancing operational flexibility and efficiency.

Partnerships and collaborations driving innovation

Collaboration among industry stakeholders is pivotal in fostering innovation and driving market growth in the access equipment sector. PVS Nageswara Rao, Director and CEO of Mechtrotech Projects Pvt Ltd, emphasises the importance of strategic partnerships, stating, “Collaboration with technology providers and industry peers enables us to leverage cutting-edge solutions and expand our product offerings.” By forging alliances with global manufacturers and technology innovators, companies enhance their technological capabilities and gain access to new markets, strengthening their competitive edge in the industry. Vikram Rana, Director at Abhay Rana Infra Services Pvt Ltd, discusses the strategic importance of partnerships in expanding market reach and enhancing customer satisfaction. “Our collaborations with leading equipment manufacturers such as Magni Telehandlers enable us to deliver high-performance solutions that meet the evolving needs of our customers,” he explains. Companies pool resources and expertise through strategic alliances and joint ventures to develop innovative products and services that address emerging market trends and customer preferences.

Embracing Digital Transformation for operational excellence

Digital transformation is reshaping the access equipment industry, driving operational excellence and enhancing customer experiences through advanced digital solutions. Andrei Geikalo, Founder and CEO of MYCRANE, discusses the role of digital platforms in revolutionising equipment rental services, stating, “MYCRANE leverages digital technologies to optimise crane utilisation and streamline rental processes, offering customers transparency and efficiency.” Digital platforms facilitate seamless equipment booking, real-time tracking, and remote diagnostics, empowering construction and mining companies to optimise fleet management and reduce operational costs. Cloud-based fleet management systems enable companies to centralise data storage and access critical equipment information from anywhere, enhancing decision-making and operational efficiency. These systems provide real-time analytics and predictive maintenance capabilities that allow companies to preemptively address equipment issues and minimise downtime, thereby improving overall productivity and project timelines.

Market dynamics and future outlook

The access equipment market is poised for significant growth, driven by increasing infrastructure investments, urbanisation trends, and technological advancements. According to industry forecasts, the global market for access equipment is projected to expand steadily, with robust demand from sectors such as construction, mining, and industrial manufacturing. Amit Bhalla of Hercules Hoists Limited shares insights on market dynamics, stating, “Rapid urbanisation and infrastructure development initiatives worldwide are driving the demand for versatile access solutions that enhance productivity and safety.”

Emerging markets in Asia-Pacific and Latin America present lucrative opportunities for market players fueled by rapid industrialisation and urban development. Companies are capitalising on these growth opportunities by expanding their regional footprint, establishing manufacturing facilities, and forging strategic alliances with local partners to meet rising demand for access equipment.

Addressing regulatory challenges and sustainability goals

Regulatory compliance and sustainability initiatives are shaping the future of the access equipment industry, influencing product innovation and market strategies. Government regulations to enhance workplace safety and reduce environmental impact are prompting manufacturers to develop energy-efficient equipment and adopt sustainable manufacturing practices.

Vikram Rana of Abhay Rana Infra Services Pvt Ltd highlights the company’s commitment to sustainability, stating, “ARISPL integrates eco-friendly technologies and materials into our equipment offerings, aligning with global sustainability goals.” Companies are investing in research and development to design equipment with lower carbon footprints, optimise energy consumption, and utilise recyclable materials, contributing to environmental conservation and meeting regulatory requirements.

The access equipment sector is at the forefront of innovation, driving sustainable development and safety advancements in the construction and mining industries. Through technological innovation, strategic partnerships, and a commitment to operational excellence, industry leaders are reshaping the landscape of access equipment, enhancing productivity, safety, and environmental stewardship.

As the industry evolves, stakeholders must remain agile and proactive in adopting emerging technologies and sustainable practices to stay competitive and meet growing customer demands. By prioritising safety, sustainability, and operational efficiency, companies can position themselves as leaders in the global access equipment market, driving growth and delivering value across diverse applications and markets.

The future of access equipment lies in its ability to adapt to technological advancements, regulatory requirements, and market dynamics, ensuring safe and efficient operations in the construction and mining sectors. With a focus on innovation and collaboration, the industry is well-positioned to capitalise on emerging opportunities and address challenges, paving the way for a sustainable and prosperous future.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)