AM/NS India introduces Optigal® colour-coated steel product

By Staff Report | August 22, 2024 7:22 pm SHARE

AM/NS India introduces Optigal®, a novel colour-coated steel with zinc-aluminium-magnesium coating and a 25-year warranty. This environmentally friendly, high-performance product promotes the ‘Make in India’ effort.

ArcelorMittal Nippon Steel India (AM/NS India), a joint venture between ArcelorMittal and Nippon Steel, two of the world’s top steelmakers, has announced the debut of Optigal®, a world-class colour-coated steel brand with a revolutionary Zinc-Aluminum-Magnesium (ZAM) metallic coating.

This high-end value-added steel ‘Optigal®’, patented by ArcelorMittal Europe, is currently available in global markets and AM/NS India is now producing and distributing it in India for the first time. The new offering builds on the company’s pioneering efforts to introduce internationally benchmarked quality products to fulfil the growing demand for indigenous superior quality coated steel.

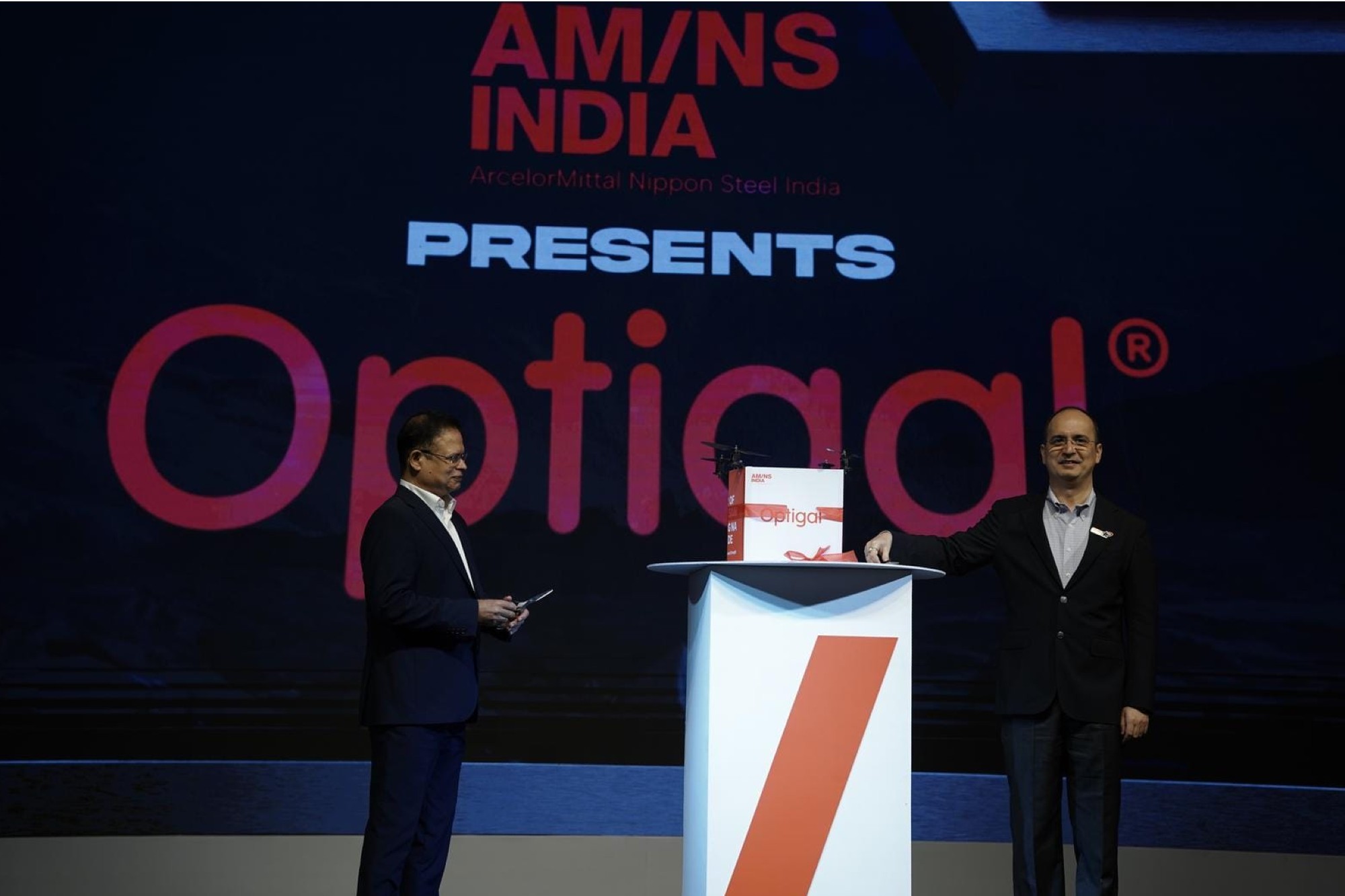

This product, launched by AM/NS India’s Chief Executive Officer (CEO) Dilip Oommen at a spectacular ceremony recently in Kochi, Kerala, also demonstrates the company’s dedication to the ‘Make in India’ effort. Optigal® offers the longest warranty of any colour-coated steel product in India, up to 25 years, making a disruptive entry into India’s speciality steel business.

The annual demand for colour-coated products in India, which presently stands at 3.2 million tonnes, is expected to increase at a compound annual growth rate (CAGR) of 8-10 percent. Optigal’s manufacturing has begun at the company’s plant in Pune, Maharashtra, marking the first phase of a larger production strategy that will soon be expanded to include other facilities.

AM/NS India currently has a colour-coated capacity of around 700,000 tonnes, with ambitions to increase capacity to one million tonnes by 2026. With this capacity development, the company’s market share is expected to increase from 20-22 percent to 25-27 percent.

The new offering’s production process employs a novel ZAM alloy technique, which involves hot dip coating steel strip in a bath of zinc, aluminium, and magnesium alloy. The addition of magnesium improves both performance and durability. The ideal substrate-paint mix ensures good formability and better corrosion resistance for building products. Optigal® is an eco-friendly product that is devoid of hexavalent chromium and heavy metals, reducing environmental impact while promoting safety and sustainability.

Ranjan Dhar, Director and Vice-President of Sales & Marketing at ArcelorMittal Nippon Steel India (AM/NS India), says, “The introduction of Optigal® is an important addition to our growing product portfolio. This launch reaffirms our commitment to delivering world-class, innovative, and sustainable steels to our customers nationwide in line with our brand promise – ‘Smarter Steels, Brighter Futures’. The efforts also reflect our corporate campaign ‘Banaunga Main, Banega Bharat’, apart from highlighting our contribution to the ‘Make in India’ initiative.”

Optigal®’s versatility makes it an appealing choice for a variety of applications, including roofing, fencing, and cladding for residential and commercial projects, dependable materials for pre-engineered buildings, and high-performance steel for architectural facades such as airports, industrial warehouses, and stadiums.

Key benefits of Optigal® include:

- Exceptional cut-edge protection: reduces paint delamination on edges and scratches while outperforming conventional metal coatings by at least three times.

- Outstanding corrosion resistance: Optigal®’s unique alloy composition, which includes the ideal balance of zinc, aluminium, and magnesium, provides outstanding corrosion resistance.

- Optimised flexibility: The highly resistant, adherent metallic layer of the specifically designed Optigal® coating can withstand bending, roll forming, profiling, and other industrial processes without cracking at the bends.

- Globally benchmarked product: The product has undergone worldwide testing and certification.

For more information, visit: https://www.amns.in/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.