Big Mover

By Edit Team | May 28, 2014 7:53 am SHARE

“With focus expected to shift back to infrastructure development after the General Elections, we can expect a robust growth in roofing and cladding segment as well,” says P Srikrishna, Managing Director, National Steel and Agro Industries Ltd.

Though the past one year was challenging for the entire industry due to slowing down of economy, NSAIL could manage positive growth. According to P Srikrishna, “We could manageto achieve growth in our top-line by increasing operational efficiency, focusing on niche products, adding new product lines to our portfolio and spreading our reach to other globalmarkets.” Excerpt from his interview with B2B Purchase:

How do you view the current trends shaping the roofing and cladding industry segment in the country?

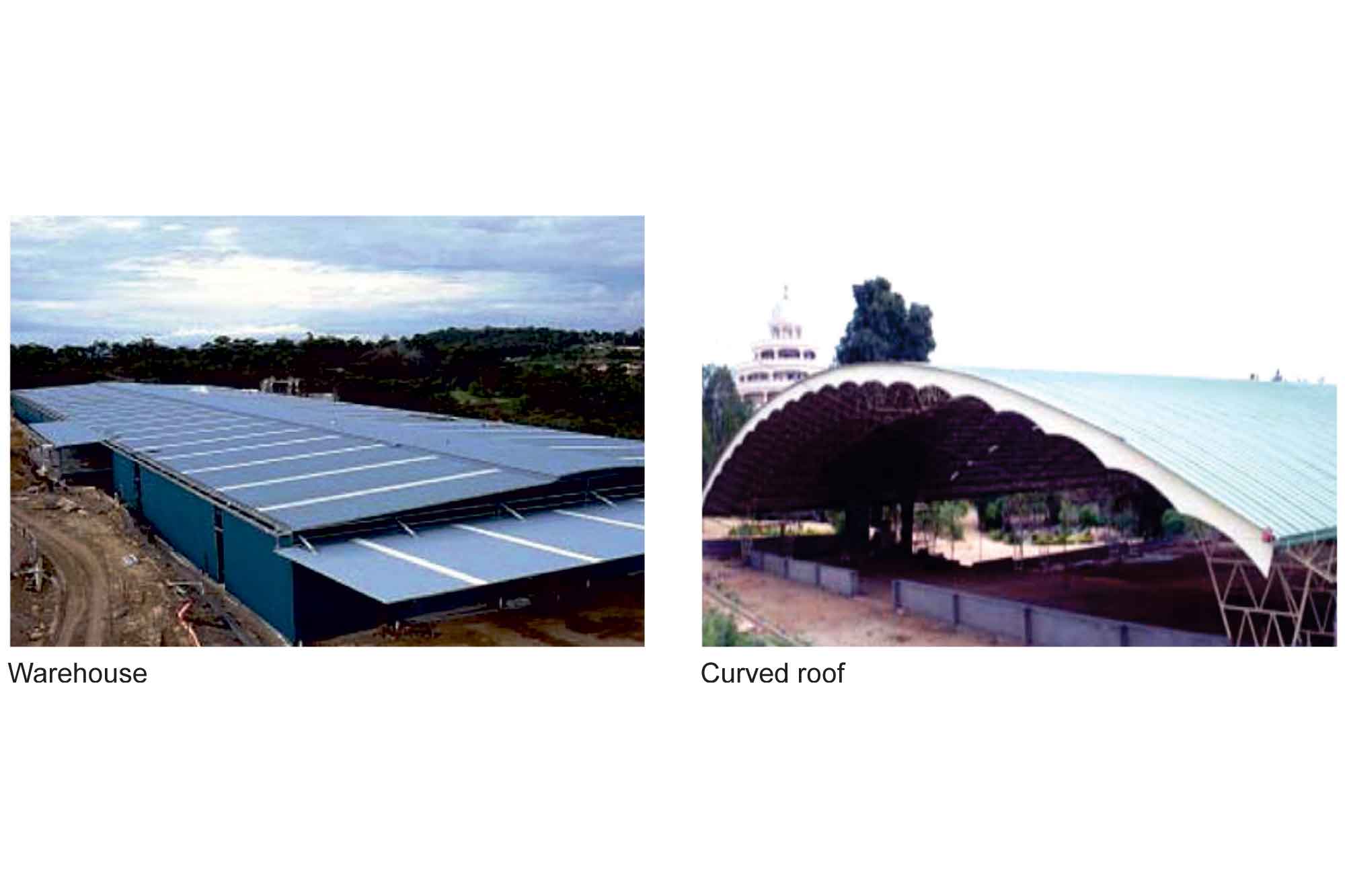

Roofing demand has shifted from plain galvanised corrugated to colour-coated sheets for their

aesthetic looks and durability in semi-urban and urban markets. In rural markets, due to increase in disposable income, demand for galvanised corrugated sheet is showing signs ofimprovement. With focus expected to shift back to infrastructure development after the General Elections, we can expect a robust growth in roofing and cladding segment as well.

If you were to take a look at the past year, what were the growth drivers for leading players like you?

Past one year was challenging due to slowing down of economy. We could manage to achieve growth in our top-line by increasing operational efficiency, focusing on niche products, adding new product lines to our portfolio and spreading our reach to other global markets.

What would you say are the primary challenges that you as a leading player in the industry are dealing with?

Prices of hot rolled steel and zinc which are our basic raw materials have seen lot of volatility in recent times. Further, frequent change in exchange rates adds to the pressure.

Our premium also does come under pressure due to availability of cheaper alternatives of sub-standard material from other regional players. We have been able to ward off this pressure by maintaining our premium in the market through supply of superior quality products and excellent services to our clients.

Lack of infrastructure for exports is another big challenge faced by us. There are regular bottlenecks of port strikes and congestions resulting in disruption of exports cargo movement.Road network up to port though improved over the year, it is still not upto the desired level. Better infrastructure in transporting the goods to the ports by way of better roads would beextremely helpful to secondary steel manufacturers like us.

What has been the growth of NSAIL over the previous years?

The company has been growing steadily and we have posted healthy growth in the last 4-5 years. We added new product lines and increased our capacities of existing products as per the market demand and trend.

During the financial year 2013-14, all our steel verticals have shown growth. We have added a lot many export customers to our clientele apart from consolidating our business in thedomestic segment.

Can you throw some light on the capacities of your plant? Are there any plans to increase capacities or invest in a new plant?

We currently manufacture roughly about 400,000 MT of plain and coated materials in line with market demand for our products. We are coming up with a new colour-coated line with an additional capacity of 80,000 MT per annum. We also have plans to introduce new product lines in 2015-16 and beyond based on market demand and trends.

Considering that India is a price sensitive market, how do you factor in the fluctuating prices of raw material into your overall pricing?

We try to mitigate fluctuation of raw material prices by getting into contracts with our long-term customers. Similarly we try to ensure MoU for at least 50 per cent of our raw materialrequirement which ensures a continuity of raw material availability even during shortage periods. We also review our purchasing strategy from time to time, so as to have ideal andoptimum raw material stock position at any given time.

Success in a very competitive market rests to a great extent on distribution. Would you discuss your distribution network?

On the domestic front, NSAIL has branches almost all over India with key account managers to handle different verticals. Our strength lies in continuity of supplies always in key markets. We have catered to our main customers and key markets in domestic segment even when

markets were more favourable overseas. This approach has helped us in developing a dedicated distribution channel of dealers. We have been successful in linking requirements up to retail levels with our production due to focused approach.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.