B&R develops new track designs for the product transport system

By Edit Team | July 13, 2023 12:29 pm SHARE

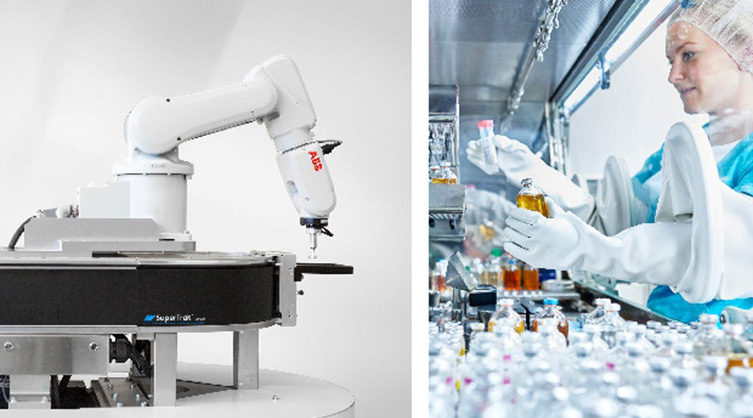

B&R presents new components for its mechatronic product transport systems. New additions to the company’s ACOPOStrak and SuperTrak portfolios create possibilities in new areas of application, opening up new market opportunities for machine builders and manufacturers.

ACOPOStrak – Production technology for cleanrooms:

An IP69K-rated variant of the intelligent track system is now available. With this washdown version, the track can be cleaned with high pressure and temperatures up to 80°C and is also completely dust-protected. In this way, B&R is addressing the requirements of industries such as food and beverage or pharmaceuticals, where the highest standards of hygiene are required.

SuperTrak – The right angle makes the difference:

With a new 90° curved segment, SuperTrak has more layout options with a smaller footprint. Compared to conventional conveyor systems, this adds even more freedom to track design. The new curved element gives machine builders the ability to fit more processing stations inside the track rather than around the outside.

Source: B&R Industrial Automation (A member of the ABB Group)

Website: www.br-automation.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.