Concrete around the corner

By Staff Report | December 26, 2024 7:30 pm SHARE

Cement substitutes like blended cement and green concrete are becoming revolutionary in the push for a sustainable built environment. The panel discussion by B2B Purchase examined their affordability, long-term viability, and the necessity of further industry-academia collaboration to advance these technologies.

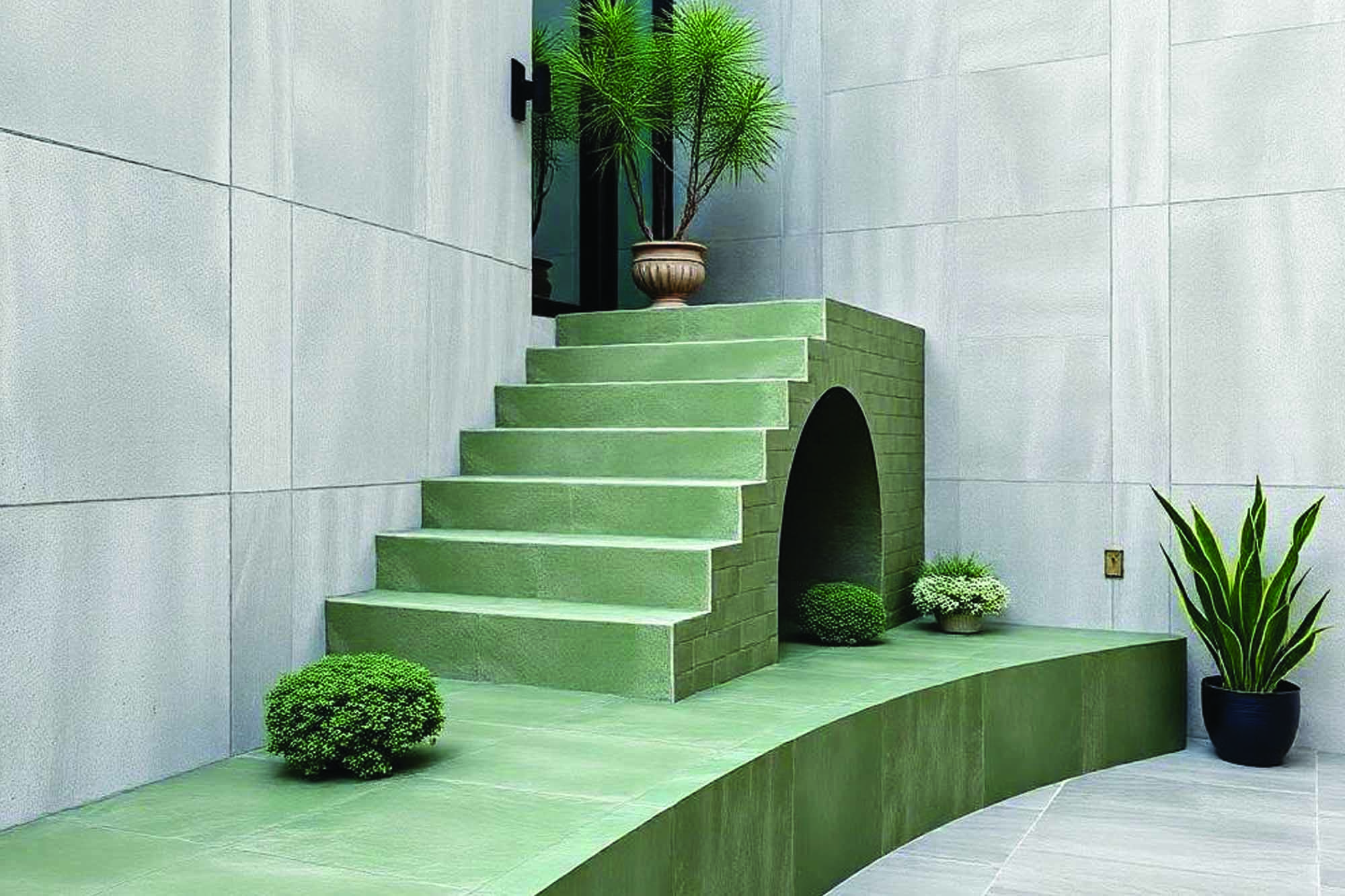

With an increasing emphasis on minimising the environmental impact of products like cement, which has historically been a major contributor to carbon emissions, the construction sector has seen a dramatic change towards sustainability in recent years. Eco-friendly materials are being blended and integrated into cement technologies due to the search for more sustainable options. The recent panel discussion hosted by B2B Purchase on “The future of concrete: Sustainable innovations in cement alternatives” examined the opportunities and challenges in this field, highlighting the possibility of green concrete, blended cement, and industry-academia partnerships.

Comparative cost analysis

The materials used in construction projects largely determine their cost-effectiveness. When asked about the comparative costs of blended cement versus traditional cement, SK Singh, Professor, AcSIR, explained that while there are no significant cost disparities in production, the advantages of blended cement lie in its long-term performance.

“In terms of initial costs, there may not be a noticeable difference between blended cement and traditional cement,” said Prof. Singh. “However, when looking at the long-term lifecycle costs, blended cement provides better durability, which results in a more cost-effective solution over time.”

Blended cements, which involve supplementary cementitious materials (SCMs) such as fly ash or slag, offer increased resistance to corrosion and chemical attacks, making them ideal for projects requiring long-term sustainability. While traditional cement may have a lower initial cost, the extended maintenance and repair costs associated with its use often make it less cost-effective in the long run.

Prof. Singh emphasised the importance of considering lifecycle costs rather than just the initial expense. “Blended cements have superior durability, which means fewer repairs and lower maintenance costs over time, making them a more economically viable option in the long term.”

Green concrete

One of the most exciting innovations in the cement sector is the development of green concrete. Nitin Gupta, Lead New Product Transfer Cement, RMX (Ready Mix Concrete), MBM (Morden Building Material), Nuvoco Vistas Corp Ltd, elaborated on the role of green concrete in sustainable construction. A lower carbon footprint characterises green concrete due to partially replacing traditional Portland cement (OPC) with alternative materials that reduce CO2 emissions.

“Green concrete is a crucial advancement in reducing the carbon footprint of construction projects,” Gupta stated. “By replacing a portion of OPC with supplementary cementitious materials (SCMs) such as fly ash and slag, we can reduce CO2 emissions by up to 30-40%.”

He explained that his company has developed green concrete that not only reduces CO2 emissions but also incorporates recycled aggregates from construction and demolition (C&D) waste, further improving its environmental credentials. “We have partnered with various metro cities where C&D waste recycling plants are in place to produce aggregates for concrete. This contributes to a circular economy by reducing waste and improving the sustainability of construction materials,” Gupta added.

In addition to using recycled aggregates, his company has been exploring further innovations to reduce CO2 emissions, aiming for a 70-80% reduction in carbon footprints. “We have developed a carbon footprint calculator that allows us to quantify the CO2 savings from using green concrete and provide certifications to clients,” he shared.

Nitin Gupta also highlighted the development of thermal-insulated concrete, an innovative product that helps reduce energy consumption. “Thermal-insulated concrete can reduce internal temperatures by up to 2°C compared to traditional concrete, leading to lower air conditioning costs and further reducing the building’s carbon footprint.”

The role of industry-academia collaboration

A recurring theme in the discussion was the importance of industry and academic collaboration in driving sustainable innovations in the cement and construction sectors. SK Singh emphasised that the culture of research and development has yet to be fully nurtured in India, particularly in the construction industry.

“Industry-academia collaboration is essential for driving innovation,” Prof. Singh remarked. “However, this culture is still underdeveloped in our country. Indian industries tend to look abroad for technological solutions, but these solutions often aren’t suited to our geo-climatic conditions.”

He advocated for stronger partnerships between industries, research organisations, and academic institutions to create tailored solutions that address local challenges. “Mission-mode projects should be focused on developing sustainable binders and low-carbon materials, specifically designed for the unique needs of the Indian construction sector,” Prof. Singh suggested.

While industry leaders in India have begun recognising the need for collaboration, Prof. Singh pointed out that industry investment remains a barrier. “Industries are often reluctant to invest in research unless they see immediate returns, but we need to take a long-term view,” he added. Countries like China and the US have heavily invested in academia and research, and it’s time for India to follow suit.”

Corrosion resistance and long-term durability of cement alternatives

The long-term durability of cement alternatives, especially corrosion resistance, is one of the main concerns. According to Nitin Gupta, employing SCMs like fly ash improves concrete’s durability and corrosion resistance while lowering CO2 emissions.

“The use of fly ash and other SCMs significantly enhances the corrosion resistance of concrete, especially in aggressive environments,” Gupta explained. “Fly ash-based concrete has better resistance to chemical attacks, which can otherwise cause deterioration over time.”

However, Gupta noted that more research is still needed into the use of bottom ash, a byproduct from thermal power plants that remains largely underutilised. “While fly ash is widely used, bottom ash is abundant and could be an important resource for producing durable concrete,” he said. Research institutions should focus on finding ways to incorporate bottom ash into the production of concrete and other construction materials.”

Innovations and future prospects

The discussion concluded with a forward-looking view on the future of sustainable construction materials. Both panellists agreed that innovation is key to achieving sustainability in the cement industry. While progress has been made in developing green concrete and other alternative materials, much remains to be done to scale these technologies and make them widely available.

“The future of sustainable construction lies in developing materials that reduce our reliance on traditional cement and minimise environmental impact,” Nitin Gupta said. “By continuing to innovate and collaborate, we can create a more sustainable and resilient built environment.”

Prof. Singh echoed this sentiment, highlighting the need for ongoing research and collaboration. “If we want to lead in the global construction sector, we must invest in sustainable technologies and foster stronger links between academia, industry, and research organisations.”

The panel discussion emphasised the importance of innovation in developing sustainable alternatives to cement. Blended cement, green concrete, and the use of recycled resources are revolutionising the construction industry by lowering carbon footprints and enhancing the long-term sustainability of infrastructure and buildings. However, cooperation between industry, academia, and research organisations, along with consistent investment in R&D, is necessary to realise these technologies’ potential fully.

These developments will be crucial in determining the direction of sustainable construction as the cement industry develops further. The panellists’ perspectives indicate that although there are still obstacles to overcome, industry leaders, researchers, and legislators working together will be essential to creating a more economical and sustainable built environment.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)