Conveyor Belt cleaning measures with innovative Scraper technology

By Edit Team | October 30, 2023 5:07 pm SHARE

JAWS TECH is setting new benchmarks in conveyor belt maintenance, offering cutting-edge scraper solutions that redefine industry standards.

Over the years, the cleaning of conveyor belts has been a major problem in most plants. Many attempts have been made to develop conveyor belt scrapers and cleaners that would solve the problem of carry-back once and for all. Many belt cleaning products simply don’t satisfy clients’ requirements, while those that do, involve costly specialist service contracts.

In selecting a good belt scraper several factors must be considered. After the material has been discharged, particles adhering to the belt (carry-back) must be removed to prevent spillage along the conveyor and material build-up on the return rollers and around the tail drum. Failure to prevent this carry-back will usually result in tracking issues and damage to the belt edges. Material spillage around the conveyor (typically at transfer points) means extra maintenance and clean-up costs.

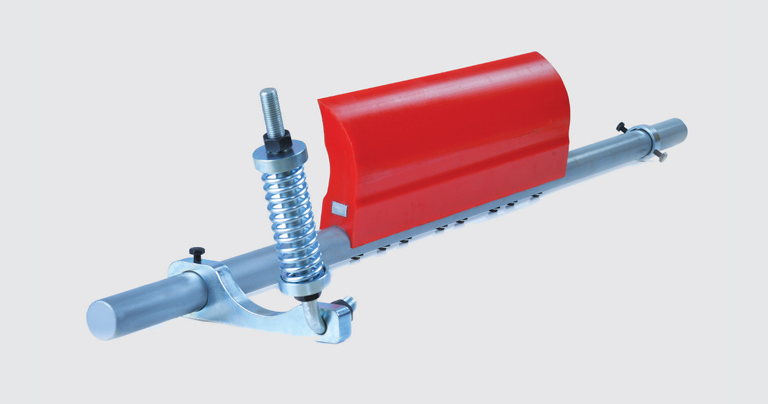

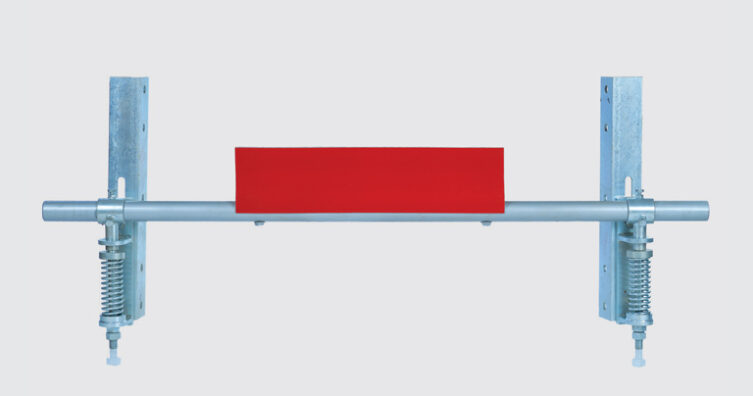

JAWS TECH introduces a wide range of carry-point solutions with a simple installation and easy maintenance structure. Our scraper range has a unique design feature that enables personnel to perform maintenance outside the conveyor chute. The retractable shaft can be easily withdrawn from the chute in one motion, allowing for out-of-chute maintenance. The bearing housings have also been specially designed for quick and easy removal.

The unique design features of our JAWS TECH scrapers allow maintenance to be performed more safely and in a timelier manner, reducing downtime and increasing productivity.

With our innovative design features, belt scrapers are ideal for improving personnel safety, maintenance costs, and productivity.

Crushing and mining operations face unique challenges, so Jaws Tech adopts A personalized approach to design and Production. Whether it’s wearing liners for crushers, polyurethane screens for screening media, or conveyor belt Components for material handling, the Experts at Jaws Tech work closely with Customers to understand their specific Requirements. This results in tailor-made Solutions that perfectly fit their equipment, Enhancing efficiency and effectiveness.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.