Covid is not causing any corrosion damage to the components

By Edit Team | May 8, 2021 6:15 pm SHARE

What we need to see is the coated metal, plastic or wood parts, when touched by a Covid patient, should not retain its virus to affect the person who has accidentally touched it, says Prof. AS Khanna, Chairman, SSPC India.

When it comes to the application of protective coatings, what are some of the important points to be noted to choose the right fix?

The most important factors, which must be taken into account during application of protective coating are:

• Suitable specification of the location where coating is to be applied

• Suitable formulation which assures the protective property suitable for that location

• Proper surface preparation, including level of cleanliness and anchor profile

• Application technique used

• Supervision and Quality assurance

The protectiveness of the coating is not dependent on the paint formulation alone but is dependent on its proper specification, surface preparation. Even a good paint system may not perform on a poorly cleaned surface and with low or no anchor profile. Anchor profile gives a kind of anchoring the paint to the surface. Application technique also assures protectiveness. Though, brush and roller application is cost-effective, it is not practical for larger areas. Airless spray with a high impact of paint droplets gives a high protectiveness. Supervision during application where at each step, the surface condition, drying of paint is measured and a proper recoating interval is maintained, also assures long productivity of the paint coating.

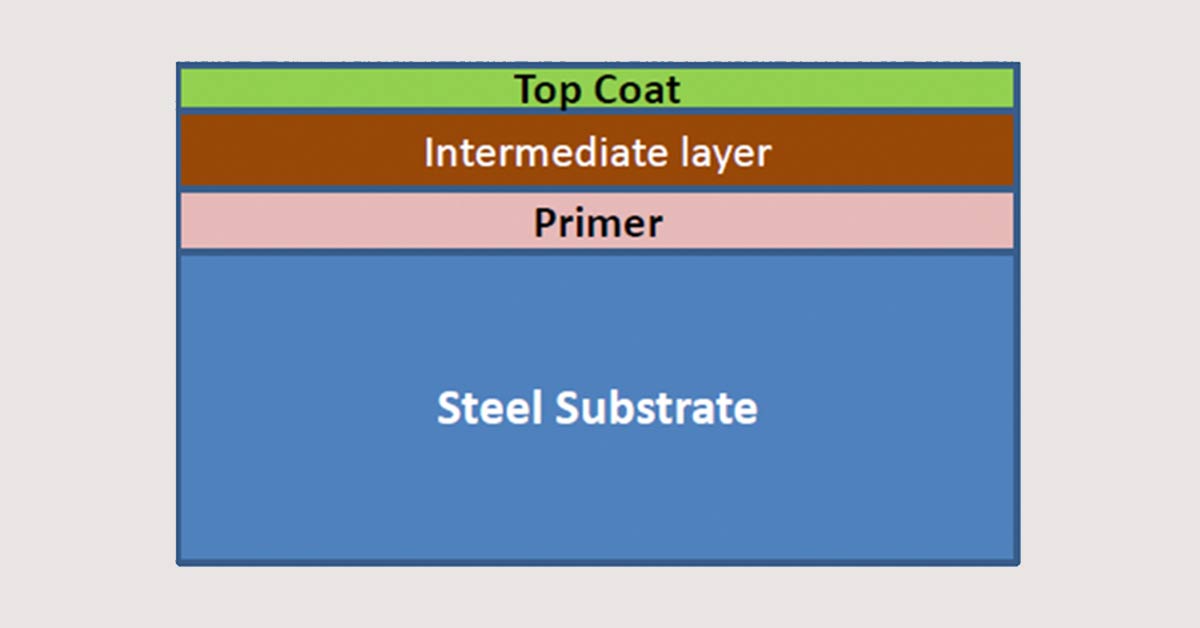

Figure 1: A simple model of protective coating with a primer layer, intermediate coat and top coat.

What is the durability of these protective coatings? What should be the frequency of re-application to ensure all-round protection throughout the year?

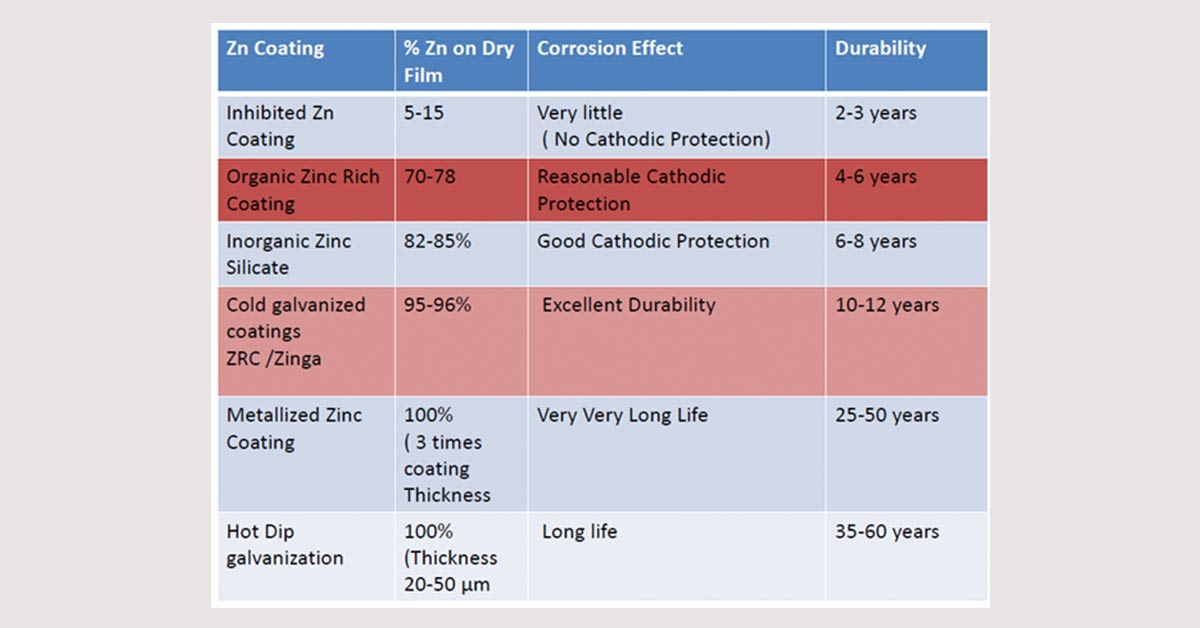

Durability of paint coating also depends on several factors. In addition to the factors mentioned above, choice of various paint coatings in a multicoat system is equally important. A pure organic coating when applied with all precautions as mentioned earlier will not have a long durability as such a coating provides only barrier effect, in case any damage by impact will immediately cause corrosion to the substrate. Hence, longevity of external structures depends upon using a suitable primer coating below the main organic paint coating to provide an additional mechanism of corrosion protection to the substrate in addition to the only barrier protection. There are various kinds of primers like zincbased and aluminium-based, which when applied on substrate below the organic coating can give long durability. Let me illustrate the effect of zinc-based primer on the durability of the structures:

Let us take a very common paint system usually applied on an external steel structure, a zinc-based primer, intermediate epoxy coat of 100 microns and a top aliphatic polyurethane of 50 microns as shown in Figure 1. The Figure 2 explains how a zinc primer with varying concentration of zinc will enhance the life of the coating. A 10-15 per cent Zn in epoxy just enhances the life of epoxy coating a minimum while as the concentration of Zn enhances the life can go from 2 to 3 years to 6 to 8 years to even 25-50 years. So the role of a primer is very important to provide durability to a protective coating.

Figure 2: Effect of zinc-base primers on the durability of protective coating.

Also, for a fixed primer coat, doubling the thickness of the intermediate epoxy coat will also enhance the life of the coating.

Usually, if the application of a coating has been done as per precautions stated in answer one and a suitable primer has been used for a fixed durability then no recoating is expected before the design life is achieved. Yes, mechanical damage may cause deterioration of coating at some localised areas which can be repaired by normal method of recoating by choosing same parameters.

As we are dealing with the second wave of Covid-19, how can protective coatings help in keeping the surface germ-free?

Covid is not causing any corrosion damage to the components. What we need to see is the coated metal, plastic or wood parts, when touched by a Covid patient, should not retain its virus to affect the person who has accidentally touched it. So, we need to apply a suitable anti-bacterial and anti-virus coating on the surface which is being touched several times by everybody whether a corona patient or a normal person. For this, many companies have come up with special coatings which reduce the bacteria count and they also affect the RNA virus, in which category the coronavirus comes. There is a flood of such paints in market. Many such coatings which are transparent can be applied on the existing components without changing their appearance and look. One of the most important ingredients in these coatings is the zinc or copper organometallic additives or nano-silver. We also have made such a formulation and we are ready to share and sell the technology if anybody is interested.

What kind of consultancy and certification courses does SSPC India provide?

SSPC is a 19-year-old professional body, working on the education of paint coatings and consultancy services. We conduct training programs onpaint coating inspection and quality control Level1 and Level2. Since 2003, we have conducted more than 200 courses and trained several young persons and entrepreneurs.

In addition, we also conduct courses on other topics such as:

• Pipeline corrosion/coatings

• Pipeline integrity

• First level of cathodic protection

• Fundamentals of corrosion and its protection

• Advanced coatings including smart, functional and nanocoatings

• Surface engineering

• Alternative methods of coatings: Thermal spray, PVD, laser-based and metallic coatings

We are also doing online courses on paint coating inspections and QA level 1. In addition, we have a paint testing laboratory called SECC. It is a reliable paint testing laboratory and NABL accredited laboratory.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.