Dynamic syncrystallisation technology: safe and durable

By Edit Team | January 22, 2016 12:43 pm SHARE

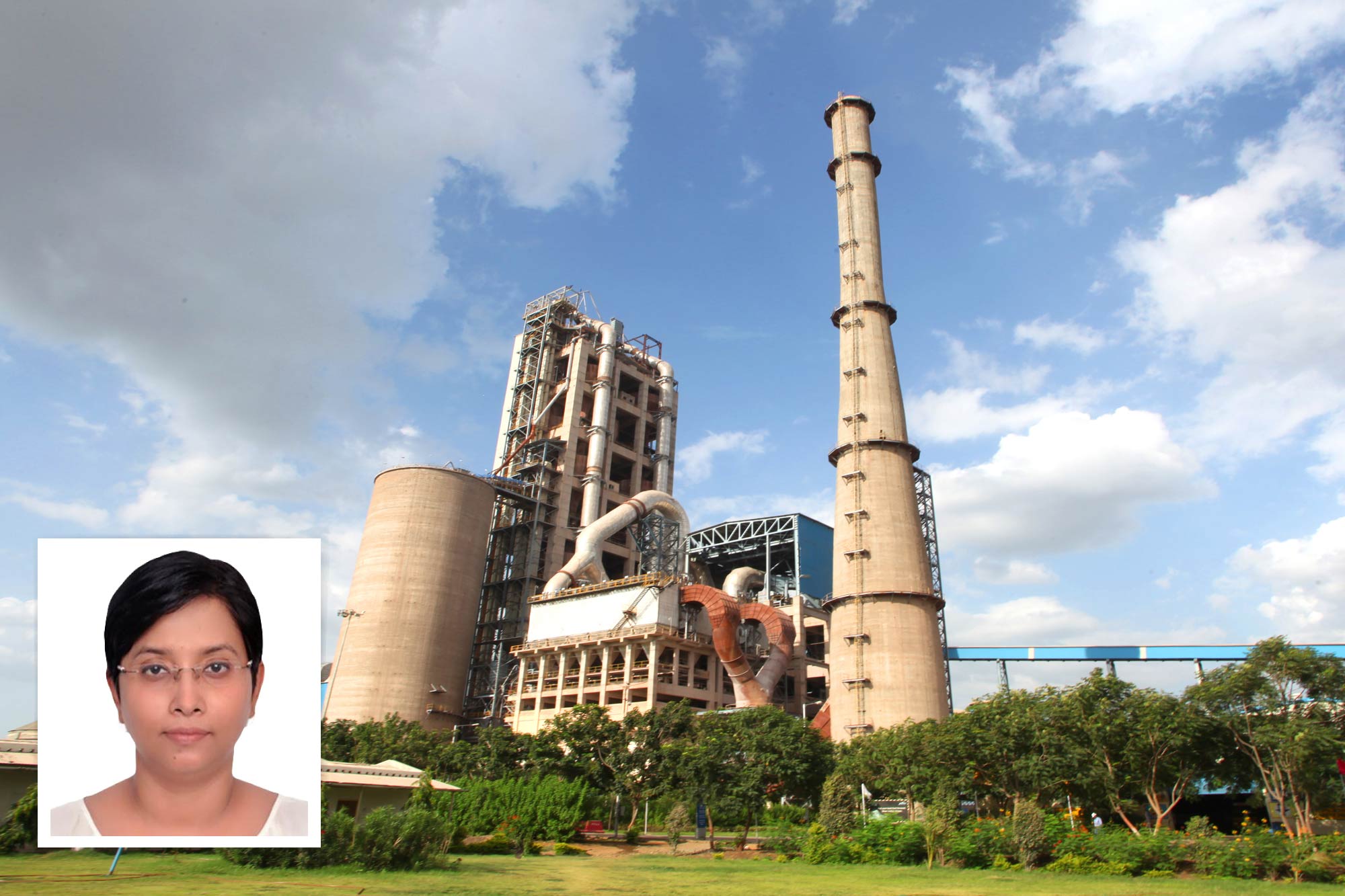

Our MC-Special DM using the dynamic syncrystallisation technology has helped address concerns of safety and durability to make the concrete impermeable.

The construction segment in India is now at a mature state of development. There are a few technologies, inspired from the west, but adapted to India. The new developments are more “Evolutionary, rather than Revolutionary”.

“We are at a stage, where we understand material technology and their interactions with each other. Be it admixtures, waterproofing systems, tile adhesives, grouts, repair systems or protective coatings, we are constantly improving our range,” says Sunny Surlaker, Head Admixtures Division, MC-Bauchemie (India) Pvt Ltd.

Innovative technologies

Innovation and new developments are the key to today’s technical and market development. Surlaker informs that MC-Bauchemie, Germany invests 10 per cent of manpower and resources in R&D.

“By virtue of being collaborated we are immediately exposed to new technologies. In recent years we have contributed several innovative technologies, like acid resisting concrete, dense packing concretes based on quantz technology and very low pore volume thick coatings for drinking water and waste water industry based on dynamic syncrystallisation to name a few. These processes developed in our labs find application in day-to-day concrete technology as well,” says Surlaker.

Dynamic syncrystallisation technology finds application not only in concrete improvement and permeability reduction, but also in mineral based protective coatings, plasters, waterproofing systems and many similar cement-based applications requiring a very dense, impermeable, mineral system.

Sustainable, green technology

Impermeability to water and other deteriorative factors is a key requirement in Indian construction. Despite technological advances in material systems, the deterioration rate for concrete remains quite high and is evident by the extent of leaking or dilapidated structures. Surlaker feels, with the extreme requirements on concrete today, along with paucity of high quality raw materials, makes the production of impermeable concrete structures quite difficult.

“Our MC-Special DM using the dynamic syncrystallisation technology has helped address concerns of safety and durability to make the concrete impermeable. By making its application simple opens up doors for use of this innovation in a wide range of applications, where water ingress, as a problem is critical. At the same time, there was the need to make this innovation local, sustainable and green,” explains Surlaker.

Using MC-Special DM technology in public utility infrastructure projects increases the durability of the structures, reducing rework and rehabilitation. Reduced expenditure on rehabilitation means the government can effectively use funds for new developments. The same applies to construction in the private sector and home-owners as well. Therefore society at large is benefitted.

The product has been used across a varied cross section of projects such as metro railways, water treatment plants, residential, commercial construction as well as concrete dams.

MC-Special DM for concrete integral waterproofing

When asked if he has incorporated MC-Special DM in its projects, Surlaker says, “We are using MC-Special DM technology primarily in our concrete integral waterproofing. Our innovation is that this integral waterproofing additive makes concrete water-impermeable and therefore more durable and sustainable using dynamic syncrystallisation technology.”

The dynamic syncrystallisation technology also finds way into waterproofing coatings, repair technology, special mortars.

Features of MC-Special DM

MC-Special DM provides integral waterproofing properties by combining three characteristics into one specially designed product. Surlaker explains in detail about these innovative characteristics:

Reduction of capillary pores

Special additives in MC-Special DM make the concrete more workable at the same w/c ratio or provide a reduction in w/c at the same workability levels. This property helps concrete achieve excellent compactability thereby reducing capillary pores. Less capillary pores means less transport of water through the cement matrix, giving the treated concrete an excellent first line of defense against water ingress.

MC’s dynamic syncrystallisation (DySC) technology

MC-Special DM uses advanced micro-fine latent hydraulic and pozzolanic nanoparticles to affect a structure of densest packing in the cement matrix on a nano-scale. The cement matrix is thus densified by a complex process called dynamic syncrystallisation (DySC).

The strength and permeability of a cement-based material is based on hydration of the clinker components, to form Calcium Silicate Hydrate (C-S-H) gel and free-lime. Our special nano-particles use this free lime, in presence of water, to recrystallise and form new more stable, impermeable C-S-H and Calcium Aluminosilicate Hydrate (C-A-S-H) phases. One gram of our crystallising nano-pozzolan can react with more than 1,000 gm of free lime in the concrete, which means its reactivity, is higher than most pozzolans and its densification property too is much higher. Therefore the most porous part of the cementitious matrix, (free lime), is converted to very impermeable and stable hydration crystals.

This crystalline mineralisation process continues over time in presence of water, and the structure of the matrix becomes more refined, overall porosity decreases, micro-cracks are sealed and pore volume is minimised. This DySC process thus makes concrete watertight.

Hydrophobic pore blocking mechanism

MC-Special DM has special additives, which on one hand causes contraction of capillaries and on the other hand converts the water-absorbing capillary forces into water repellant capillary forces due to the hydrophobic effect of the constituent. Thus water is pushed out of the capillary pores and the concrete is kept dry. MC-Special DM is specially formulated and designed to prevent the passage of water through pores and capillaries of the concrete. This hydrophobic pore blocking mechanism gives concrete the third and final line of defence against water ingress.

The effectiveness of these properties has been verified in accordance with DIN 1048: part 5, which tests, water penetration into the concrete by application of pressure upto 5 bars. “Results indicate that depending upon the concrete mix-design the absorption of water into the concrete is reduced by up to 60 per cent. In addition, similar tests for co-efficient of permeability for concrete treated with MC-Special DM was reduced by up to 67 per cent as compared to control concrete,” Surlekar claims.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)