Ecoklay LWP waterproofing membrane for protection

By Edit Team | November 1, 2022 2:56 pm SHARE

With a prosperous 60 years of experience, Ashapura GCL is a leading multi-mineral solutions provider. The company has a global footprint, having a vast network of operations in several states within India and seven other countries. The company is best known for bentonite and laminate geosynthetic clay liner manufacturers and suppliers in India.

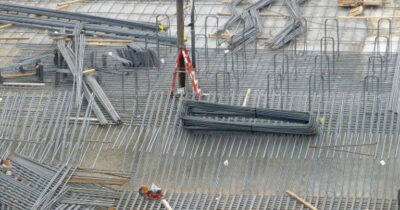

Ecoklay LWP

This is a bentonite geotextile waterproofing liner with integrated polyethene. Ecoklay LWP is a reinforced GCL consisting of a layer of sodium bentonite sandwiched between nonwoven and woven geotextile, which are needle, punched together to provide internal reinforcement with integrated polyethene. The inner reinforcement minimises clay shifting, allowing the ecoklay LWP to maintain consistent low permeability and maximum performance under various practical conditions. It is produced in the company’s state of an art manufacturing facility in Kutch, Gujarat, where the company’s own selected. Bentonite clay is used for manufacturing GCL.

Uses

It is a waterproofing membrane to protect various substrates in applications like the basement, canals, roofs, reservoirs, ponds, podiums, green roofs, and more. Advantages it has a wide range of application areas and can be easy to install. The shelf life is not affected if stored in dry, cool and dark stores. It is available in different sizes and thicknesses. The product is pre-engineered, environment friendly and has no hot work.

Surface Preparation

In preparation, the concrete and mortar surfaces must be clean and free from grease, oil, and loosely adhering particles. The steel and iron surfaces must be free from scale, rust, grease and oil. All surfaces must be as true as possible.

Applications

Lay the liner as per the required size on the prepared surface. Overlaps should be minimum of 150mm. Use the processed dry bentonite powder on the top surface of the bottom membrane at the overlap area. Seal the overlap joints using the appropriate sealant. Roll forward and press firmly to ensure the proper sealing. All angles and abutments should be sealed with extra care. The edges should be sealed well using appropriate processes like terminating into the grooves, using a terminating bar or as per the instruction of the engineer in charge.

For more details, contact:

Tel No. +91-22-66221659 , +91-22-6665 1700 +91-8291820738 WhatsApp : +91 9022251009

Email : gcl@ashapura.com

Website: www.gcl.ashapura.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.