Exploring market potentials for Columbia SPM 20 Plus machines

By Edit Team | June 20, 2022 11:31 am SHARE

Ramesh Babbar, President & Director, Columbia Machine Engineering (I) Pvt. Ltd.

Columbia Machinery exhibited an impressive range of equipment at CII Excon which are enabled with latest technologies to deliver maximum uptime and efficiency. Columbia Machine is one of the world’s leading manufacturers of concrete products equipment, serving customers in over 100 countries. From mixing and batching to automatic cubing and splitting, Columbia builds a complete line of equipment to outfit entire concrete products plant. Looking at the increased investments in large scale infra projects, Ramesh Babbar, President & Director, Columbia Machine Engineering said: “As the Indian economy grows, larger machines with more production capacity are being considered.” You can read his further views on various industry shifts.

Can you elaborate on your Latest range of products and solutions?

We used to get requests for our SPM 20 Plus machine and its range of products that were popular five years ago before Covid. To meet the needs of our clients, new products are being introduced to the market today, necessitating a change in machinery. We now have a single machine that can handle a wide variety of products. As a result, we’ve been working on these devices for the past two years. Previously, our equipment could only handle pavers and blocks, but this machine can now handle tiles and tall-height products.

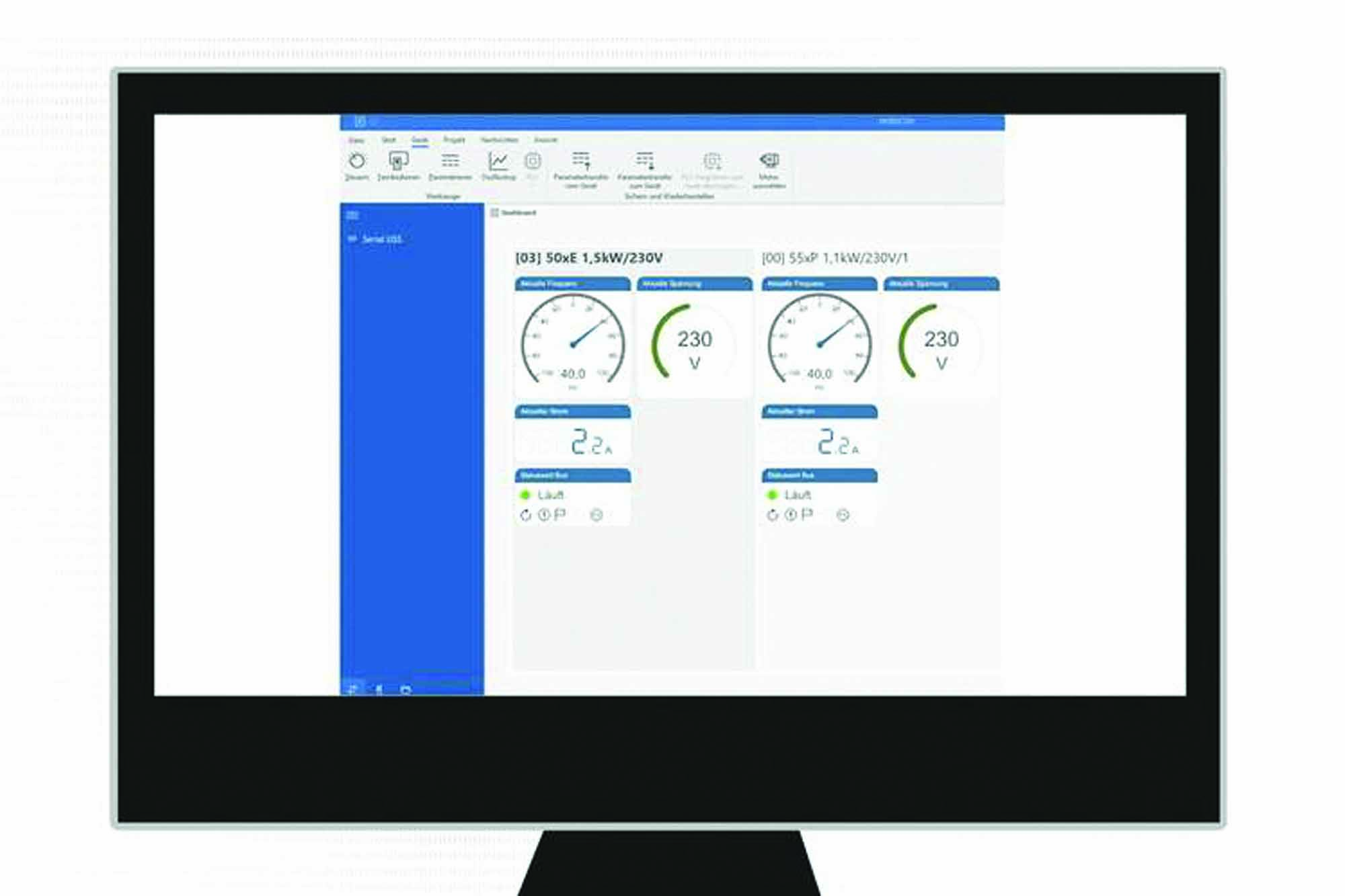

In 2021, we connected this machine to the internet of things (IoT). This machine can now be managed and maintained from our facility. This machine is designed particularly for a higher range of versatility products, and an IoT function will be released with this machine too.

SPM 20 Plus’s versatility will help large construction projects. It can produce a wide variety of items that can be used in any future construction projects. Its primary application will be on construction sites.

How do you look at the need to be fuel efficient and cost-efficient?

Cost-effectiveness is our USP, and availability of I-2 compatible motors make them fairly cost effective. Coming to the energy-efficiency aspect, I would like to highlight that our machine consume 88 kWs during operations, whereas the other machines typically consume 100 kW. Interestingly, the demand for this kind of equipment is growing since market is keen on fuel efficiency and cost factor.

What we can expect from Columbia Machine Engineering newly?

We ongoingly innovate our range of products for our customers, so they get better value for money invested. Looking at the future demand, now we are focussing on developing new products for few applications such as the planetary mixer and palletiser, along with our other product categories in the equipment range. These machines, I believe, will have increased demand in coming days. Further to this, we are also planning to expand our market in overseas by pushing exports of a wide range of machines.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.