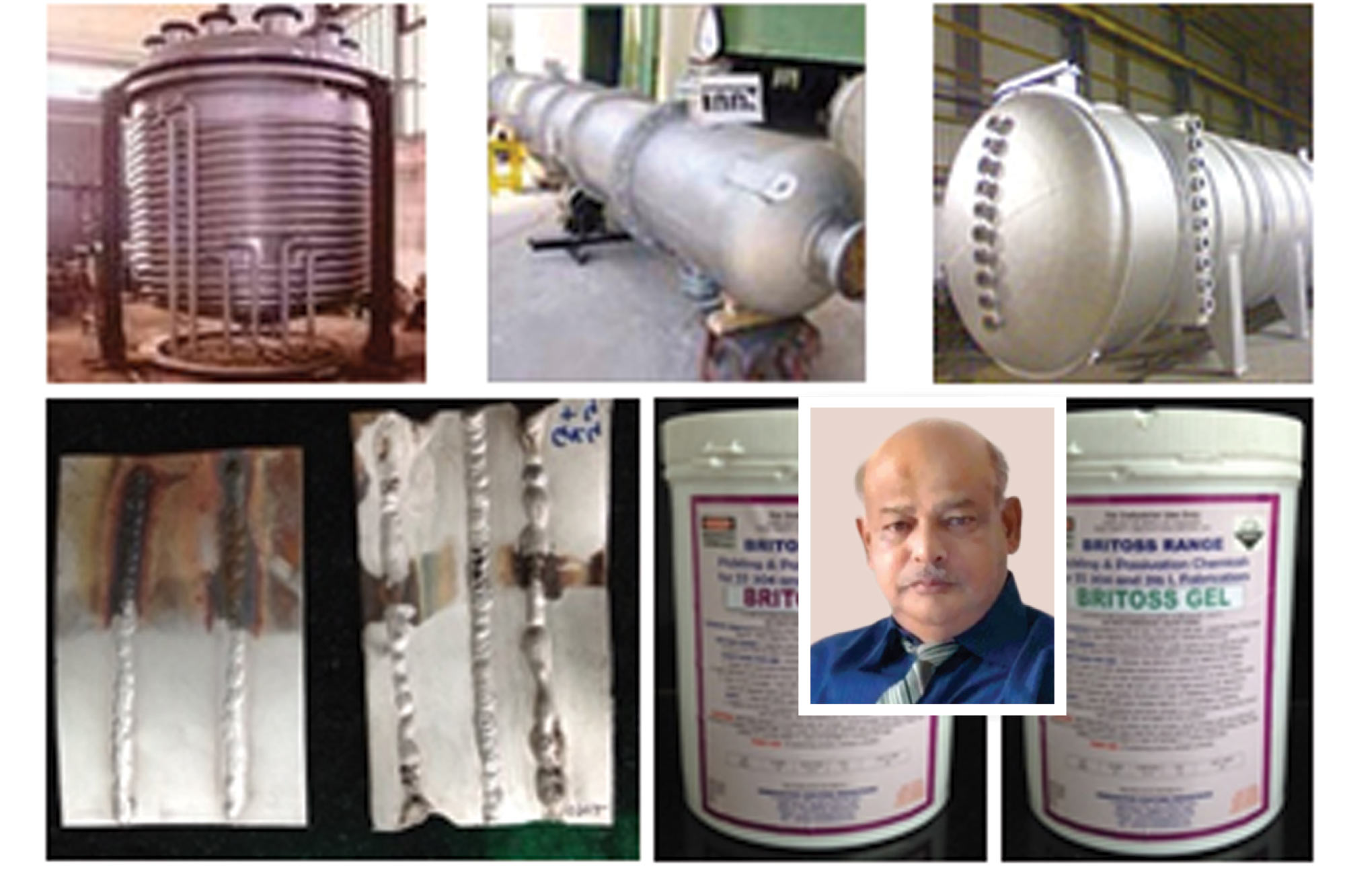

FAQs on Britoss range products

By Edit Team | March 15, 2018 12:11 pm SHARE

Can one touch, handle and use Britoss range products by hand?

No. Britoss range products contain strong acids and oxidising chemicals. These products must be handled after wearing all the safety equipments.

Which tools /means of application are recommended for use Britoss range products during cleaning?

Use any plastic spray bottle available for spraying Britoss spray. Use face-shield during the spray. For application by brushing, use 1 or 3 brush with nylon bristles. Always dip brush in water after use this increases the utility and life of brush.

Does one need a ventilation system to use Britoss range products in the plant?

Britoss range chemicals are acidic and fuming in nature. The use of these chemicals shall be done in open area or highly ventilated areas. One should not use these products in hot sun light or beyond 45 C.

What is the recommended shelf life of Britoss range products?

For best and optimum results and performance, use Britoss products within six months from the time of purchase keep the containers tightly closed with inner and outer lids store in a cool and dry place .

Does one need to pre-clean fabricated equipment parts?

It is utmost necessary to remove light oils or dirt on the parts. Britoss products are excellent cleaners and can handle light grease and oils. However, stainless steel alloys high in sulfur or carbon usually require a pre-treatment in an alkaline bath such as Cleensol- SS Degreaser. Wiping with 7-10 per cent solution of Cleenol SS will remove Surface oil and Grease.

Can Britoss range products be used on metals other than stainless steel?

Britoss range may be used to remove surface iron from nearly any metal, including titanium, aluminum, hastalloy, inconel, cobalt chrome, etc. It is also works as a good brightener for copper, brass, and bronze. Users are well advised to take a small trial to establish suitability before Production scale usage.

Are Britoss range products not compatible with any other metals?

Britoss range products will cause damage to the surfaces of concrete, mild steel; carbon steel, zinc, and galvanised steel. Avoid exposure of these materials to Britoss range and rinse immediately if there is an inadvertent spill onto these materials. We recommend extra dilution and room temperature operation. PVC pipe and fittings made from copper, brass, or bronze are not recommended for long term use with Britoss range products.

Will Britoss range products remove rust from mild steel fabrications?

Britoss range products are not recommended for mild steel fabrications. Innovative Coating Industries offer RUSTOGEL 1406, PHOSGEL and GALVAPREP for derusting MS and GI fabrications. These are used as pre-treatment for MS; GI steels are especially formulated for faster rust removal. For removal of rust on SS 304 and 316L, regular Britoss range products are the only recommended products.

Contact:

Pradeep Vaidya, CEO,

Innovative CoatingIndustries

MIDC, Pune

Thane: B-7 / 701, Vedant Complex, Vartak Nagar Naka,

Thane (West) –400606

Mobile: 09820181738

Email: puvpromtech@gmail.com

Sonia Vaidya, Tech Mktg Executive, Thane

Tele: +91-22-25883265,9819813015

Email: soniavaidya30@gmail.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.