Galvanising process: frequently asked questions

By Edit Team | July 2, 2015 7:03 am SHARE

Promtech Group is one of the largest aerosol products and metal pre-treatment chemicals manufacturing company in India. Promtech started with metal finishing chemicals and aerosol paints for powder coating and painting touchup, offering their aerosol paint cans since 1994. Today supplying products such as zinc rich paints, zinc bright sprays, galvanising of mild steels, the following is a list of frequently asked questions about hot-dip galvanising and cold galvanising of mild steel.

How is steel protected from corrosion by galvanising?

Zinc metal used in the galvanising process provides an impervious barrier between the steel substrate and corrosive elements in the atmosphere. It does not allow moisture and corrosive chlorides and sulfides to attack the steel. Zinc is more importantly anodise to steel . This means it will corrode before the steel, until the zinc is entirely consumed.

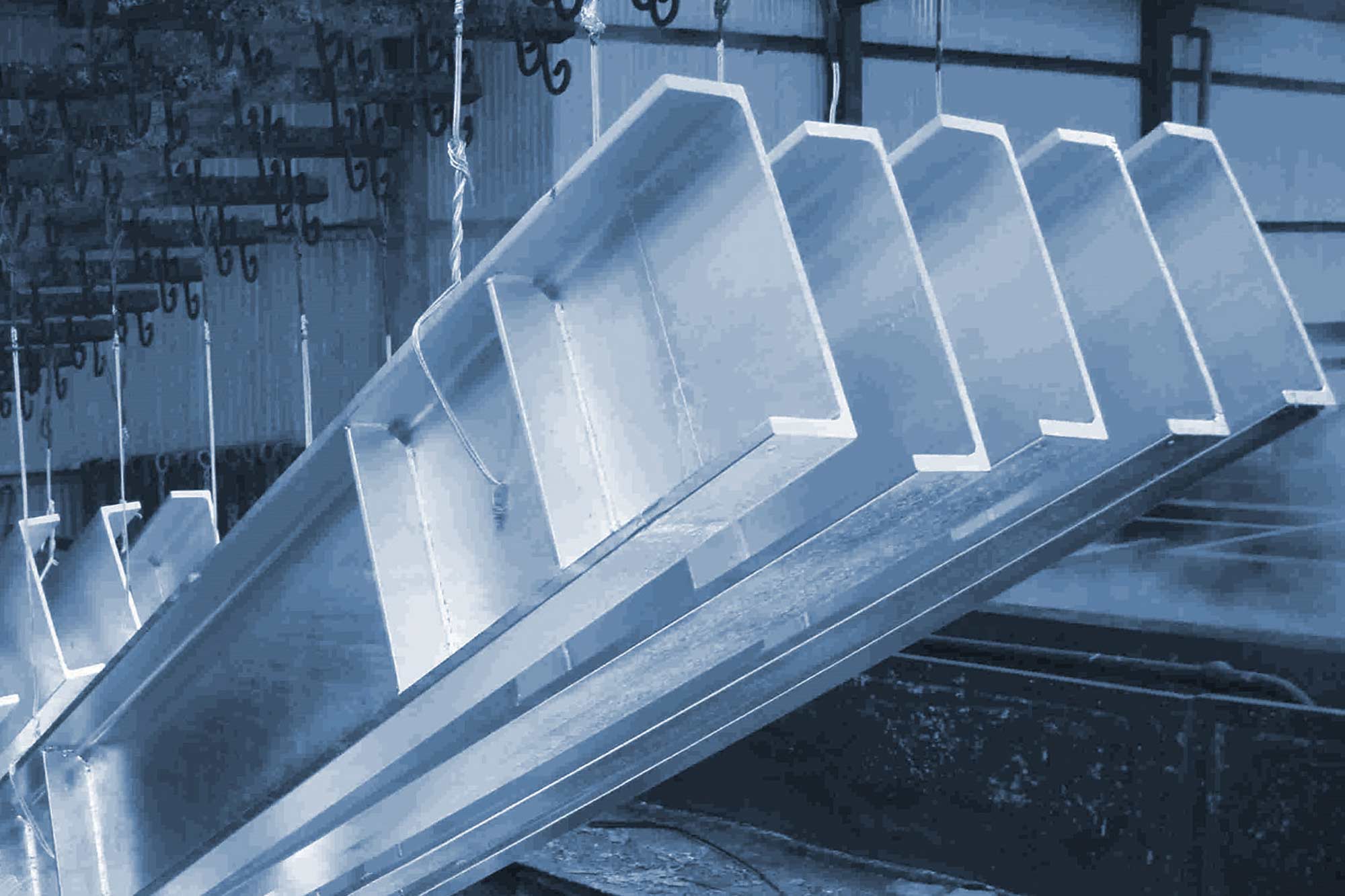

What are the steps in the galvanising process?

There are four steps:

Pre-inspection – where the fabricated structural steel is viewed to ensure it has, if necessary, the proper venting and draining holes, overall design parameters which are necessary to yield a quality galvanised coating

Cleaning – steel is immersed in a caustic solution (degreasing solution ) to remove oil from grease, dust and dirt. This is followed by dipping in an acid bath (hydrochloric) to remove mill scale, rust, and finally dipped in bath of flux that promotes zinc and steel reaction, retards further oxidation (steel will not react with zinc unless it is perfectly clean)

Galvanising – the clean steel is dipped into a kettle containing 450 degree C molten zinc where the steel zinc metallurgically reacts to form three zinc-iron intermetallic layers and one pure zinc layer

Final inspection – the newly galvanised steel is sight-inspected, followed up by measurement of coating thickness with a magnetic thickness gauge.

When compared with paints, how does the cost of hot-dip galvanising compare to other corrosion protection systems?

When compared with paint systems, hot-dip galvanising after fabrication has comparable initial application costs. In fact, the lower life-cycle costs of a hot-dip galvanised project makes galvanising the smart choice for future.

How long can it be expected for galvanised steel project to last in service?

Hot-dip galvanised steel resists corrosion in numerous environments extremely well. It is not uncommon for galvanised steel to last more than 70 years under certain conditions.

Does the galvanised steel coating of zinc resist abrasion?

The three inter-metallic layers that formed by fusion bonding between iron and zinc metals during the galvanising process are all harder than the substrate steel and have excellent abrasion resistance.

What causes wet storage stain and how can it be prevented?

Zinc on newly galvanised steel is very reactive and wants to form zinc oxide and zinc hydroxide corrosion products on exposure to air, UV radiation and moisture and water vapours in the atmosphere. This eventually becomes the stable zinc carbonate. When galvanised steel is tightly stacked or stored in wet boxes that don’t allow for free flowing air, the zinc forms excessive layers of zinc hydroxide, otherwise known as wet storage stain. Most wet storage stain can be easily removed with a cleaner or nylon brush. To prevent wet storage stain, store galvanised steel indoors or block it so that there is ample free flowing air between each galvanised article.

Can galvanised steel in service withstand high temperatures for long periods of time ?

Constant exposure to temperatures below 390 degree F (200 degree C) is a perfectly acceptable environment for hot-dip galvanised steel. Good performance can also be obtained when hot-dip galvanised steel is exposed to temperatures above 390 degree F (200 degree C) on an intermittent basis.

Why should galvanised steel be painted?

Called duplex coatings, zinc and paint in combination (synergistic effect) produce a corrosion protection approximately 2 times the sum of the corrosion protection that each alone would provide. Additionally, duplex coatings make for easy repainting, excellent safety marking systems, and good colour-coding. Painting over galvanised steel that has been in service for many years also extends the life of the zinc coating.

Is galvanising more expensive than paint?

Depending on the product mix, square feet per ton, and condition of the steel surface, galvanising is often less expensive on an initial cost basis. However the lifetime costs should be considered when making a project decision on the corrosion prevention system to utilise. And, with galvanising, the life-cycle cost, i.e. the cost per year to maintain, is almost always less than any conventional painting system. Paint systems require maintenance, partial repainting and full repainting several times over a 30-year project life. The costs can be staggering, making the decision to paint a costly one in the long run.

What is the difference between hot-dip galvanised fasteners and zinc-plated fasteners ?

Hot-dip fasteners generally have about 10 times as much zinc on the surface and are suitable for use in all exterior and interior applications. Zinc-plated fasteners will provide a dis-satisfactory anti-rust performance if used outside, especially when used to connect hot-dip galvanised structural steel members.

How long will hot-dip galvanising protect the steel from corrosion?

The corrosion rate of zinc and how long it will provide protection is a function of the coating thickness and the amount of corrosive elements in the atmosphere. For example, in rural settings where there is less automotive/truck exhaust and plant emissions, galvanised steel can easily last for 100 – 150 years without maintenance. Industrial and marine locations contain significantly more aggressive corrosion elements such as chlorides and sulfides and in such a condition, galvanised steel may last for 50 – 100 years.

Where are galvanised steel products used?

The variety of things galvanised is broad. Structural steel (angles, channels, wide-flange beams, I-beams, H-beams), grating, expanded metal, corrugated sheets, wire, cables, plate, castings, tubing, pipe, bolts and nuts. The industries that utilised hot-dip galvanised steel range from infra and EPC projects, water and wastewater treatment plants, architectural steel structures (canopies, facades, exposed structural steel, lentils, reinforcing steel for concrete decks, exposed structural steel columns and barriers, pulp and paper plants (structural steel, walkways, handrail), motor housings, electrical cabinets, frames, heat exchanger coils): Transmission towers, distribution poles, substations, wind turbine poles, signal antennas, cell towers, rail transportation (poles, switchgear, miscellaneous hardware), chemical/petrochemical plants, Off-shore constructions,(pipeline hardware manufacturing buildings, storage tanks, walkways) silos, tank farms, chemical and steam pipelines, (fence poles, boats, trailers, stadiums, arenas, road crash guards, racetrack fences) Pre Engineered Metal Buildings and almost every mild steel fabrications.

Why is the galvanised coating is shinier in someplace compared to others?

The galvanised coating appearance may either be bright and shiny resulting from the presence of an outer layer of pure zinc, or duller, matte gray as the result of the coating’s inter-metallic layers being exposed. Performance is not affected. Coating appearance depends on the amount of zinc in the coating. Shining also results on the percentage of aluminium in the galvanising bath as well as the composition of flux.

Is the zinc coating’s thickness consistent over the entire piece?Coating thickness depends on the thickness, roughness, chemistry, and design of the steel being galvanised. Any one or all of these factors could produce galvanised coatings of non-uniform thickness.

Can galvanised be painted over its coating?

If so, what procedure should be followed?Galvanised coatings can be easily and effectively painted, not only for aesthetics but also to extend the structure’s service life. The age and extent of weathering of the galvanised coating dictate the extent of surface preparation required to produce a quality paint system over galvanised steel.

How much weight will my material gain from galvanising?

As an average, the weight of the article will increase by about 2 to 3 per cent due to zinc picked up in the galvanising process. However, that figure can vary greatly based on numerous factors. The fabrication’s shape, size, and steel chemistry all play a major role, and other factors like the black weight, the different types of steel that get welded together, and the galvanising chemistry can also have an effect.

What is the reason for incorporating venting and drainage holes into a project’s design?

The primary reason for vent holes is to allow otherwise trapped air and gases to escape; the primary reason for drain holes is to allow cleaning solutions and molten zinc metal to flow entirely into, over and throughout the part, and then back into the tank or kettle.

If stiche-weld takes place, will there be uncoated areas after galvanising?

When stitch-welding is used, there is a possibility of gas release between gaps, which will prevent the galvanised coating from forming in these areas. By leaving at least a 3/32 inch (2.4 mm) gap between the contacting surfaces, gases are allowed to escape and cleaning solutions and molten zinc are allowed to flow in between the surfaces for a complete and uniform coating.

What is “white rust” and how can it be avoided?

“White rust” is the term mistakenly applied to wet storage stain, which actually is a milder corrosion product than white rust. Wet storage stain can be avoided by properly stacking freshly galvanised articles, avoiding unprotected exposure to wet or humid climates, or by using a surface passivation treatment (dip in very dilute dichromate solution) after galvanising. Wet storage stain typically weathers away once the part is in service. White rust is most commonly associated with galvanised cooling towers structures and marine, Off-shore fabrications.

Is it a concerned matter when galvanised steel comes in contact with other metals?

Zinc is a noble metal and will sacrifice itself (i.e. corrode, give up its electrons and create a bi-metallic couple) to protect most metals. So, it is recommended to insulate galvanised steel so that it does not come in direct contact with dissimilar metals. Rubber or plastic, both non-conductive, are often used to provide this insulation.

Is a salt spray test in a laboratory appropriate to estimate the corrosion rate of zinc coated steel?

In order for zinc to develop its protective patina of zinc carbonate that is very stable and non-reactive, it requires a wetting and drying cycle like that produced by nature. Salt spray tests keep the zinc wet and essentially wash the zinc corrosion products off as they develop, inflating corrosion rate of zinc. This lab test is not reflective of real-life performance of zinc coatings.

What is “Cold Galvanising”?

There is no such thing as cold galvanising. The term is often used in reference to painting the mild steel fabrication or damaged galvanised structure or object with 99 per cent pure zinc-rich paint. Galvanising by definition means a metallurgical reaction between zinc and iron to create a metallic bond between the zinc and the steel of approx 3600 psi. There is no such reaction when zinc-rich paints are applied and the bond strength is only several hundred psi. Application of zinc rich paints will completely seal the exposed, scratched, weldedc, damaged surface (resulting from removal of zinc layer on mild steel. Such damaged surfaces are virgin and are much more prone to atmospheric corrosion. Corrosion and rusting are a sub-surface phenomenon and will propagate under the galvanised zinc coating layer. Hence it is customary and mandatory to coat such areas with zold galvanising zinc rich paints.

For all further technical details and supplies of zinc rich paints, zinc bright sprays:

Please call Innovative Coating Industries:

Production wing Promtech Consultancy Group:

Thane B-7 / 701, Vedant Complex,

Vartak Nagar Naka, Thane West- 400606

LL:022 25883265.

Pradeep Vaidya, CEO.

Mobile: 09820181738

Email:puvpromtech@gmail.com

www.promtechaerosol.com

Sonia Vaidya, Technical Marketing Executive.

Mobile: 09819813015

soniavaidya30@gmail.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)