Global collaboration fuels Timken’s R&D triumph

By Edit Team | December 5, 2023 11:22 am SHARE

Timken’s expertise goes beyond one-size-fits-all solutions. In this exclusive interview, Sanjay Koul, President – India and South East Asia and Managing Director – India, Timken, discusses how the company has developed precision-engineered bearings tailored for aerospace, automotive, railways, mining, renewable energy, and more and how Timken’s industry-specific solutions ensure reliability, safety, and performance across diverse applications.

“Timken’s industry- specific bearing solutions play a crucial role in maintaining performance, reliability, and safety across a wide range of applications.”

What are the latest innovations in Timken’s engineered bearings for improved aerospace and industrial machinery performance?

Timken has been at the forefront of innovation in engineered bearings for over 120 years. This expertise and innovation also extend to the aerospace and industrial machinery sectors. The company made significant developments in engineering and advanced materials, including utilising high-performance steels to enhance the durability and performance of its bearings. Timken prioritises customised solutions tailored to specific applications, meeting the unique demands of the aerospace industry with bearings designed for high- speed, high-temperature environments and providing specialised solutions for various industrial machinery. We have developed advanced sealing technologies to protect bearings from contaminants, prolonging bearing life and reducing maintenance needs.

Timken’s commitment to research and development extends to lubrication technology, which aims to reduce friction, enhance efficiency, and extend bearing operational life. Timken has explored “smart” bearings with integrated sensors for real-time performance monitoring and predictive maintenance. Additionally, the company has responded to the growing emphasis on energy efficiency by designing bearings that reduce energy consumption in industrial applications. In aerospace, focusing on light- weighting has led to innovative bearing designs that minimise weight without compromising load-carrying capacity and performance.

How is Timken adapting bearing technology for emerging industries like electric vehicles and renewable energy?

Timken bearing technology caters to the unique requirements of emerging trends, including electric vehicles, lightweight, miniaturisation, and renewable energy. There are a variety of configurations for electric vehicles, each of which has unique challenges and benefits. To meet the demands of electric vehicles, Timken’s high-efficiency bearings minimise friction, contributing to improved battery range and overall vehicle efficiency. Additionally, the company designs bearings with minimal maintenance needs, a critical feature for applications such as wind turbines in renewable energy, where maintenance accessibility can be challenging and costly. Customised bearing solutions are another key aspect. Timken collaborates closely with manufacturers to create bearings tailored to specific industry needs, whether withstanding high torque loads in electric vehicle drivetrains or operating in harsh environmental conditions in renewable energy systems. Furthermore, Timken is researching advanced materials to enhance bearing durability and performance, integrating sensors for real-time monitoring in electric vehicles, reducing noise for quieter operation, and prioritising environmentally responsible manufacturing and materials sourcing to align with the sustainability goals of these burgeoning industries. In sum, Timken’s efforts aim to enhance the efficiency, performance, and sustainability of electric vehicles and renewable energy systems, playing a pivotal role in their success.

What industry-specific bearing solutions has Timken developed?

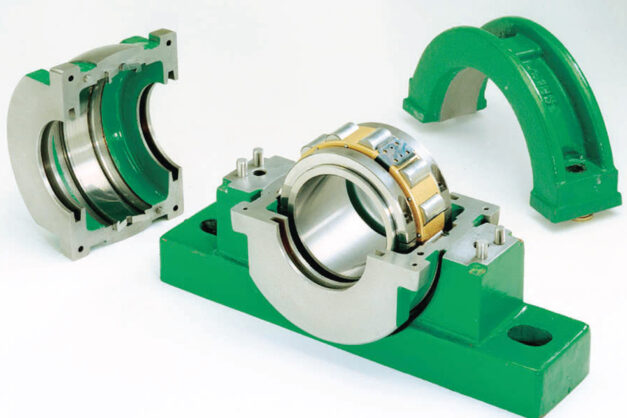

Timken has developed various industry-specific bearing solutions tailored to meet the unique requirements and challenges of various sectors. Driven by our deep R&D capabilities and engineering expertise, we deliver consistent, reliable product performance tailored for the application. With a reputation for best-in-class quality, service and design, Timken® bearings feature precision tolerances, proprietary internal geometries, and premium materials. In the aerospace industry, Timken provides precision-engineered bearings for aircraft engines, landing gear systems, and flight control systems, where precision and reliability are paramount. Timken’s specialised automotive bearings contribute to vehicle performance and longevity in applications such as wheel hubs, transmissions, and differentials. For rails, Timken offers bearings designed to withstand heavy loads, high speeds, and harsh environmental conditions in locomotives, passenger trains, and freight cars. Timken bearings endure extreme conditions in the mining and construction industry, supporting equipment such as excavators and material handling systems. In renewable energy, Timken bearings ensure the reliability and efficiency of wind turbines. The company also provides solutions for highly demanding environments, such as the steel industry, paper and pulp processing, marine applications, as well as precision requirements of medical equipment. Timken’s industry- specific bearing solutions are crucial in maintaining performance, reliability, and safety across a wide range of applications.

How does global collaboration enhance Timken’s R&D efforts?

Timken R&D invests significant time in growing expertise in friction management, materials science, and mechanical power transmission. The group surveys the fields for new opportunities and technologies, including emerging digital manufacturing and automation trends, performance modelling, heat treatment technologies, and advanced lubrication science. One of the key drivers of growth for Timken is its consistent introduction of new products. Each year, we witness a range of product launches that cater to diverse markets and applications. These launches often involve innovative solutions to address emerging needs and market needs.

Global collaboration plays a significant role in enhancing Timken’s R&D efforts in several ways. Firstly, it allows Timken to tap into a diverse talent pool and expertise worldwide. By collaborating with researchers and engineers from different regions and backgrounds, Timken can access a wider range of perspectives and innovative ideas, leading to breakthroughs in research and development. Secondly, global collaboration provides access to broader resources and infrastructure. Timken can leverage research facilities, technology hubs, and resources worldwide, enabling more extensive testing and experimentation. This can lead to quicker and more comprehensive development of new products and technologies. Additionally, global collaboration helps Timken stay at the forefront of emerging trends and technologies. Different regions may have unique market demands and regulatory requirements, and collaborating globally allows Timken to adapt its R&D efforts to meet these specific needs. It also provides valuable insights into global market dynamics and customer preferences. Furthermore, global collaboration fosters innovation by exchanging best practices and knowledge sharing. Timken can learn from the experiences and successes of its partners and apply those lessons to its R&D projects. This collaborative learning accelerates innovation and reduces the risk of reinventing the wheel.

Collaborative projects often involve multiple layers of peer review, which can enhance the rigour and quality of research. Also, collaboration can help build research capacity in developing countries by providing access to training, technology, and expertise, contributing to a more equitable distribution of research resources. Lastly, global collaboration can enhance the efficiency of Timken’s R&D efforts. By spreading the workload across different time zones, projects can progress continuously, leading to faster development cycles and quicker time-to-market for new products and solutions.

In summary, global collaboration enhances Timken’s R&D efforts by providing access to diverse talent, resources, market insights, best practices, and more efficient development processes, ultimately contributing to the company’s ability to innovate and remain competitive globally.

What steps is Timken India taking for environmental responsibility, such as reducing carbon emissions?

Timken takes pride in advancing environmental sustainability in our products and industries through increased efficiencies in our global operations. Timken India works closely with customers to repair and reuse bearings, especially in Rail and large industrial bearings, which leads to extended product life span and resource conservation.

Timken views environmental responsibility as an interconnected system of actions designed to improve the lives of individuals and communities, benefit the planet, and strengthen the business. Timken aligns its global programs with its engineering expertise to build a more efficient, resilient, and sustainable world for future generations.

The Timken Company’s Sustainable Engineering Process guides every stage of product development. In collaboration with Timken’s customers, we continually explore ways to refine existing solutions and introduce new features to make their products more efficient and sustainable.

Timken India has enhanced its environmental responsibility by implementing various strategies, including improving energy efficiency through modern technologies and practices, investing in renewable energy sources such as solar and wind power to reduce dependence on fossil fuels, collaborating with eco-friendly suppliers to ensure sustainable sourcing, and implementing waste reduction and recycling programs to minimise waste sent to landfills.

Timken regularly publishes sustainability reports to provide transparency regarding environmental targets and achievements, invests in research and development to find innovative ways to reduce carbon emissions, and collaborates with local communities on environmental projects to build positive relationships.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.