High-performance concrete: Advancements and applications

By Staff Report | September 11, 2024 1:46 pm SHARE

Explore the advancements in high-performance concrete (HPC) and its impact on the construction industry. From superior strength to enhanced durability, this comprehensive article covers HPC’s benefits, challenges, and the role of cutting-edge materials.

High-performance concrete (HPC) has revolutionised the construction industry with its superior characteristics, offering enhanced durability, strength, and efficiency. Recent discussions by industry experts at the B2B Purchase Procurement Forum have provided valuable insights into the current state of HPC, its benefits, challenges, and the role of ultra-fine materials in pushing the boundaries of concrete technology. This article explores these insights in detail, highlighting how HPC is shaping the future of construction.

The rise of high-performance concrete

High-performance concrete is designed to offer enhanced properties compared to conventional concrete. Improvements in strength, durability, and other key parameters make it suitable for demanding applications in high-rise buildings, infrastructure, and specialised structures.

Rushabh Surendra Karnavat, Founder and CEO of Rushabh Surendra Karnavat Associates, emphasises the evolution of HPC: “High-performance concrete represents a significant advancement over traditional mixes. It’s not just about achieving higher strength; it’s about meeting a comprehensive set of performance criteria, including durability, workability, and resistance to environmental factors.”

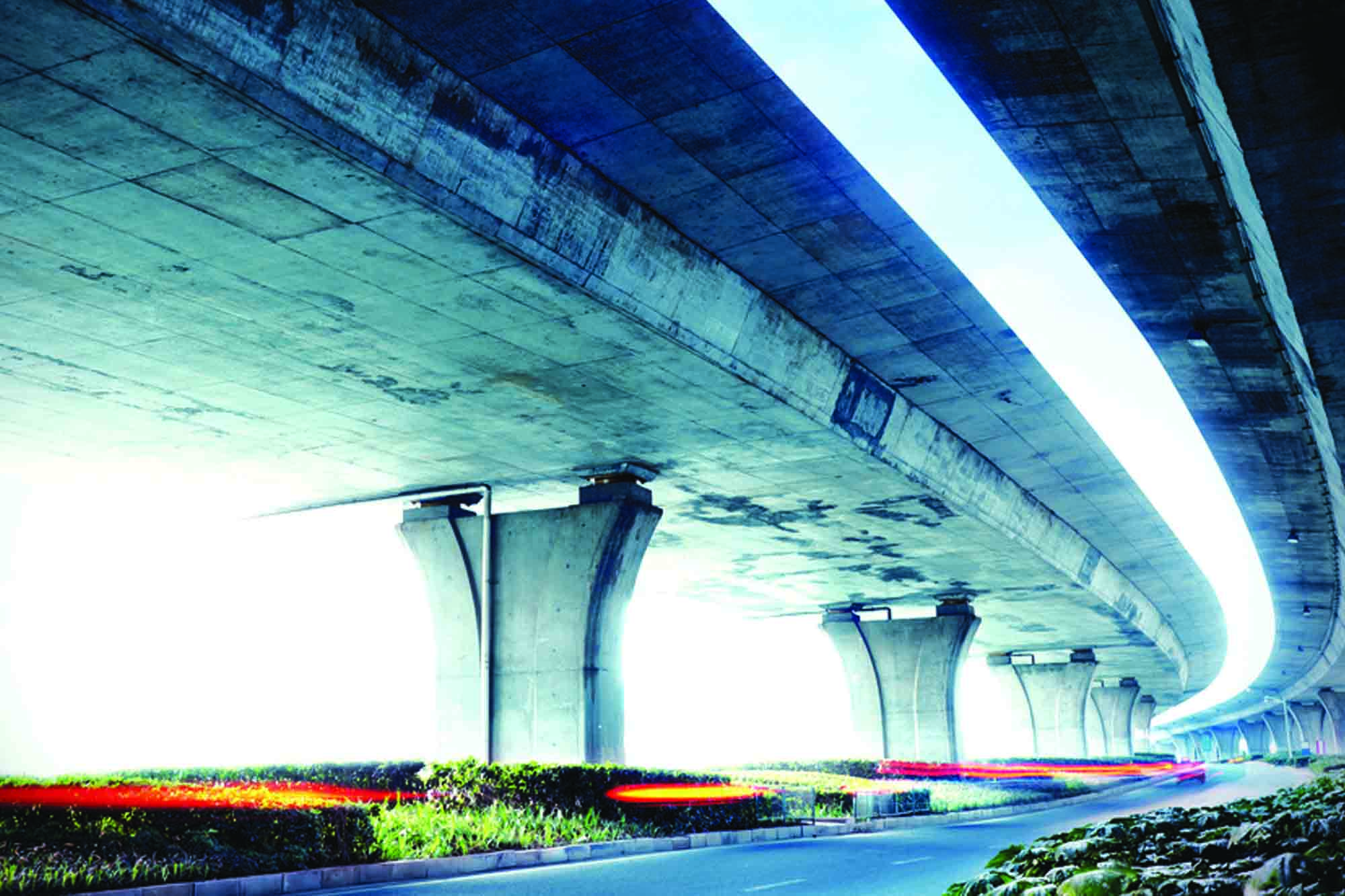

The importance of HPC is particularly evident in urban environments where space is limited. Cities like Mumbai, Chennai, and Delhi increasingly turn to high-rise buildings to accommodate growing populations. These structures demand concrete that can withstand high loads and harsh environmental conditions. HPC’s ability to deliver on these requirements makes it a preferred choice for modern construction projects.

Advantages of high-performance concrete

HPC offers several advantages over conventional concrete, which are crucial for the design and longevity of structures.

One of the most significant advantages of HPC is its high strength-to-weight ratio. Avijit Chaubey, Head Technical, RDC Concrete Ltd, illustrates this with a recent competition among engineering students in Maharashtra: “We supported a project where students aimed to achieve the highest strength relative to the weight of concrete cubes. Our team’s approach led to a winning design with outstanding strength while maintaining a manageable weight. This underscores HPC’s ability to provide high strength without proportional increases in weight, which is critical for high-rise and other load-bearing structures.”

In practical terms, this means that HPC can support greater loads while using less material, reducing the structure’s overall weight. This property is particularly advantageous in high-rise buildings where minimising weight is essential to reduce foundation costs and structural load.

High durability is another key benefit of HPC. It is designed to resist environmental factors such as moisture, chemicals, and temperature fluctuations. Manish Mokal, Joint General Manager (Quality Excellence Cell), AFCONS Infrastructure Ltd, notes, “HPC is not just about high strength; it also offers improved durability. It can withstand harsh environmental conditions and requires less maintenance over time. This makes it a cost-effective choice for long-term projects.”

Durability is critical for infrastructure projects such as bridges, roads, and tunnels, where exposure to the elements can lead to significant wear and tear. HPC’s resistance to such conditions extends the lifespan of these structures and reduces maintenance costs.

HPC typically has a higher modulus of elasticity compared to conventional concrete. This means that it is more resistant to deformation under stress. Rushabh Karnavat explains, “A higher modulus of elasticity translates to better performance under load. It allows for more efficient design and greater safety margins in structural applications.”

This property is particularly beneficial in high-rise construction, where minimising deformation is crucial for maintaining structural integrity.

Challenges in high-performance concrete

Despite its advantages, HPC presents several challenges that must be addressed to realise its full benefits. HPC often requires a low water-cement ratio to achieve its desired strength. However, this can result in high viscosity, complicating the mixing and pumping processes. Avijit Chaubey describes this challenge: “The low water-cement ratio required for HPC leads to high viscosity, making it difficult to pump and work with. This issue is exacerbated in large-scale projects where efficient placement is crucial.”

The high viscosity of HPC can lead to problems such as increased pumping pressure and difficulty in achieving consistent quality throughout the mix. To address this, it is essential to develop solutions that balance high strength with improved workability. In large-scale applications, such as high-rise buildings or massive infrastructure projects, the heat of hydration from cement can lead to cracking. Sajin Noorjahan, Director of Conmach Solution, highlights this issue: “During the construction of certain sections of the bullet train project, we encountered problems with high heat of hydration leading to cracks. This resulted from high cement content and the associated heat generation.”

To mitigate this issue, strategies that manage the heat of hydration, such as incorporating supplementary cementitious materials or optimising the mix design, are necessary. HPC can be more expensive than conventional concrete due to the high cement content and advanced materials used. Manish Mokal remarks, “While HPC offers numerous benefits, it also comes with a higher cost. This is primarily due to the increased cement content and the use of advanced materials. Finding ways to optimise costs while maintaining performance is a key challenge.” Developing cost-effective HPC solutions involves balancing performance requirements with budget constraints, ensuring the benefits outweigh the additional costs.

The role of ultra-fine materials

Ultra-fine materials, such as Ground Granulated Blast Furnace Slag (GBFS) and micro silica, enhance HPC. These materials help improve hydration, reduce the water-cement ratio, and enhance overall performance. Avijit Chaubey explains the benefits of these materials: “Ultra-fine materials can fill the pores in concrete, improving hydration and increasing strength. They act as nucleation sites for forming CSH gel, contributing to the concrete’s strength.” Rushabh Karnavat adds, “These materials are often 10 to 100 times smaller than cement particles, providing a high surface area that enhances the durability and performance of HPC. They allow us to achieve higher strength with a lower cement content, which also helps reduce costs and manage the heat of hydration.”

Incorporating ultra-fine materials can significantly improve concrete performance. By optimising the mix design and using these advanced materials, high strength and durability can be achieved while addressing common challenges associated with HPC.

High-performance concrete represents a major advancement in construction technology, offering enhanced strength, durability, and functionality. While high-performance computing (HPC) offers numerous benefits, it also presents challenges that must be addressed to harness its potential fully. Integrating ultra-fine materials is critical in overcoming these challenges, providing a pathway to improved performance and cost-effectiveness. As the construction industry evolves, HPC will remain a key component in developing resilient and efficient structures, meeting the growing demands of urbanisation and infrastructure development.

By addressing the challenges and leveraging the benefits of HPC and ultra-fine materials, the industry can advance toward building stronger, more durable, and sustainable structures for the future.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)