How to make a bulk material handling site ‘smart’

By Edit Team | August 18, 2016 10:10 am SHARE

An exclusive analysis on what makes a bulk handling site smart

Bulk material handling is a common practice in several infrastructure sectors. It plays extremely important role in speeding up the overall infrastructure project. In case of mining operation as an example, here unless the bulk material abstracted from mine backwards is moved, one can’t further continue the mining operation. The key here is to move the bulk material faster to be able to continue with the mining operations. Same thing applies, in case of tunnel mucking operation as well. “The equipment used in bulk material operations can make entire operation smart with its smart features,” opines Tushar Mehendale, Managing Director, ElectroMech Material Handling Systems India Pvt Ltd. “The smartness comes from several parameters like speed of operation, energy efficiency, user friendliness, failure proof or lowest maintenance of machines, east to install and importantly safety features of the equipment.”

Y. Srinivas Reddy, Managing Director, Bevcon Wayors Pvt Ltd elaborates his understanding on ‘SMART’ bulk material handling as:

S (Sustainable): From the engineering to execution (E2E) the bulk material handling projects or products should be sustainable for life time expectations of environmental protection policies, energy conservation, people safety, financial returns etc. should create win-win situation to all the stakeholders.

M (Maintainability): Interns of low opex and good life cycle analysis of critical parts and 24/7 service support so that bulk material handling project or product is available with 100 per cent reliability for continues operations.

A (Application engineering): It is one of the most critical aspects of bulk material handling business, sometimes giving the best value proposition by showing innovative concepts and providing various solutions to the complex problems by which overall project cost and timelines can be brought under control in line with the customer expectations.

R (Revenue streams): Various revenue generating mechanisms are applied in every sale. Revenue generations can be improved by best customer service by supplying timely, qualitatively and cost effectively and more importantly closing the contract techno commercially timely is the crucial milestone in building best business relationships. The goodwill factor generated in turn enhances the credibility of the organisation. In current times ensuring effective cash flow management is most critical attribute for successful completion of the contract.

T (Total customer satisfaction): Success of business depends on total customer satisfaction means the customer should get delighted with outcome of resounding financial, business, people performances delivered by the project. This in turn leads to ‘customer for life’. To achieve this goal teams across the organisation has to work strategically with positive attitude and displaying commitment in every action.

What makes a bulk handling site “smart”?

Explaining what exactly makes a bulk handling site “smart”, Mehendale said, “To make any bulk handling site smart, we need the combination of right men and machines. Identifying the right machines by understanding the correct technical requirements related to handling operations of site makes a huge difference. It is indeed very important to put right machine for the right job.”

He adds, “Speed of operation, energy efficiency, user friendliness, low maintenance, easy to install and safety aspects needs to be taken care before selecting the right equipment.”

However, Reddy says, “All critical stakeholders should have total commitment to the objective of the project and every stakeholder should work towards creating win-win situation as and when challenges erupts.” He feels, “cost, time and commitment play most important roles in building bulk material handling site smart.”

Some key offerings

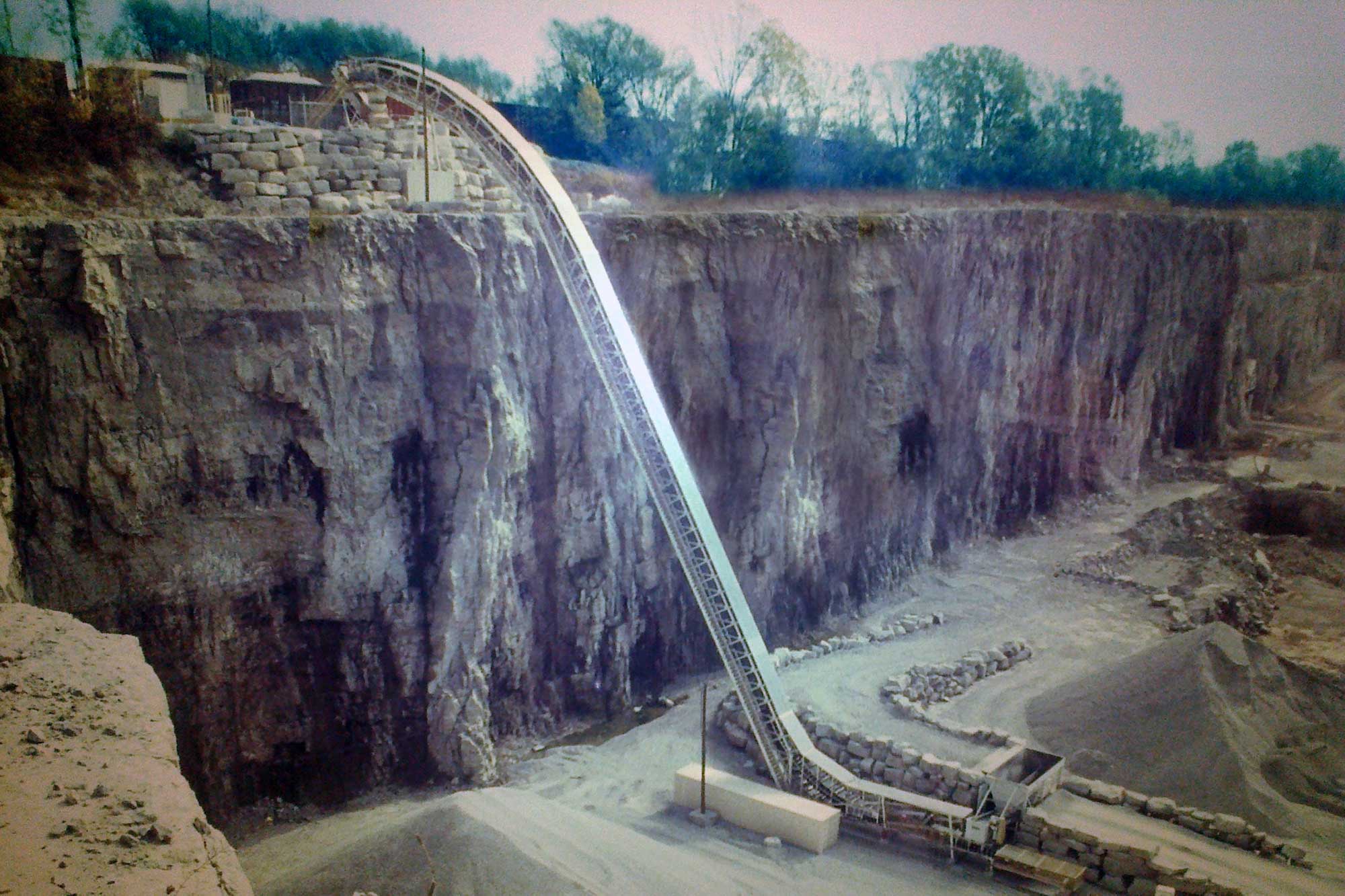

ElectroMech has developed a unique and cost effective bulk material handling system for extraction and disposal of overburden generated during construction of tunnels. This system can very efficiently remove overburden generated during construction of deep shafts as well as the overburden generated during the tunnelling operation itself.

Briefly the system consists of:

• High speed, high lift winch located at ground level

• Support structure complete with columns and gantry girder and rails

• Motorised trolley atop the gantry girder

• Lower block from which a self-dumping bucket is suspended

• Heavy duty, side dumping rectangular or square cross section bucket

• Self-dumping station where the laden bucket is emptied of the overburden into dumpers for onward transportation to dump site

• All the associated electricals.

These systems can be used where shafts and tunnels are constructed like water supply projects, surge shafts for dams, etc. Several such systems designed and manufactured by ElectroMech are operational at various construction sites of construction majors like HCC, Patel Engineering, Jaiprakash Industries, Unity, IVRCL, Soma Enterprises, etc. “Such a system is extremely economical compared to the deployment of mobile cranes for mucking operations on account of higher throughput and cheaper running costs,” claims Mehendale.

To become sustainable, innovation, technology upgradation and continuous learning play a major role. “At Bevcon execution excellence is paramount which is achieved by enrolling of all critical stakeholders’ customers, consultants, suppliers and internal teams to deliver the right results, right time and most cost effectively,” said Reddy.

Bevcon has demonstrated consistently for the last two decades of existence in bulk material handling business. Execution of many first of its kind projects like Tata Steel – 90-degree Steep Angle Conveyor for conveying two 500 TPH Petcoke from wagon unloading area to storage silo, JK Cement – 90-degree High or Steep Angle Conveyor for conveying 1,650 TPH Clinker from Wagon unloading area to storage area, Shree Cement – Pipe Conveyor for conveying 3,190 TPH limestone from mine to process plant with 1.4 kms conveying length etc, are few testimony of Bevcon strengths.

Bevcon Wayors provides concept to commissioning solutions and execute turnkey and EPC projects for all material handling applications for various industry segments such as thermal power, steel, cement, sugar, mining, pharma, chemicals, paper, port, food, fertilisers, and aggregate sectors.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)