Instrumentation & automation of waste treatment plant

By Edit Team | January 28, 2015 12:41 pm SHARE

Ajit Joshi of Forbes Marshall Ltd. (Pune) describes some important and mandatory instruments for waste water plants

India as a developing country has seen rapid growth of industries over last 2/3 decades. Along with economical development we are also praised with air pollution/water pollution. For many years industries have been dumping liquid as well as solid waste in lakes, rivers and open field. Now we are feeling its cumulative effect in terms of more and more unfertile land, increase in water related diseases, scarcity of drinking water, loss of aquatic life, etc.

Over the past few years concern for the environment in India has been growing. This is due to forceful execution of laws and procedures by pollution controlling authorities, also people have realised the need and benefit of treating / recycling of wastewater. Even if most of the Industries have their own ETP to treat the wastewater, ETP always gets last priority from all fronts.

Actual design and steps involved in ETP are based on the effluent load generated by that particular plant. Based on the type of effluent generated different treatment processes can be designed to take care of specific effluent generated by plant. However, people do not give due importance to know the nature of effluent. Most of the parameters like quantity of effluent generated and different chemical pollutants present are based on one time test or on mere assumption of some senior experienced person in the plant.

During actual operation of effluent treatment process also most of the people depend on off line measurement of different parameters. You can definitely save on the cost of online instruments, however you are losing much more in terms of inconsistent control over process parameters. If you are not aware of exact effluent load you would never attend stabilised control over effluent treatment. With the help of offline analysis, which will be only once or twice a day, you won’t know the ups and downs taking place in terms of effluent load on different controlling parameters such as pH/TSS/MLSS/DO/COD/BOD etc.

Some tests require the measurement to be conducted on line since the process of obtaining a sample may change the measurement. E.g. DO. Offline measurement will give lot of error because of absorption of O2 from air. Also the process by which the sample is taken, may greatly influence the result.

Developed countries are using lot of instrumentation and automation of wastewater plants. In India also most of the instruments are available. However keeping in mind Indian industry culture and their experience of instrument here we would like to discuss about some important and mandatory instruments for waste water plants.

Complete effluent treatment process is designed to treat all pollutants present in effluent. It is important to know the quality of final effluent which gets discharged out of plant. The typical parameters, which can be monitored, are pH/Turbidity/DO/MLSS/Redox/Suspended solids/COD/BOD/TOC

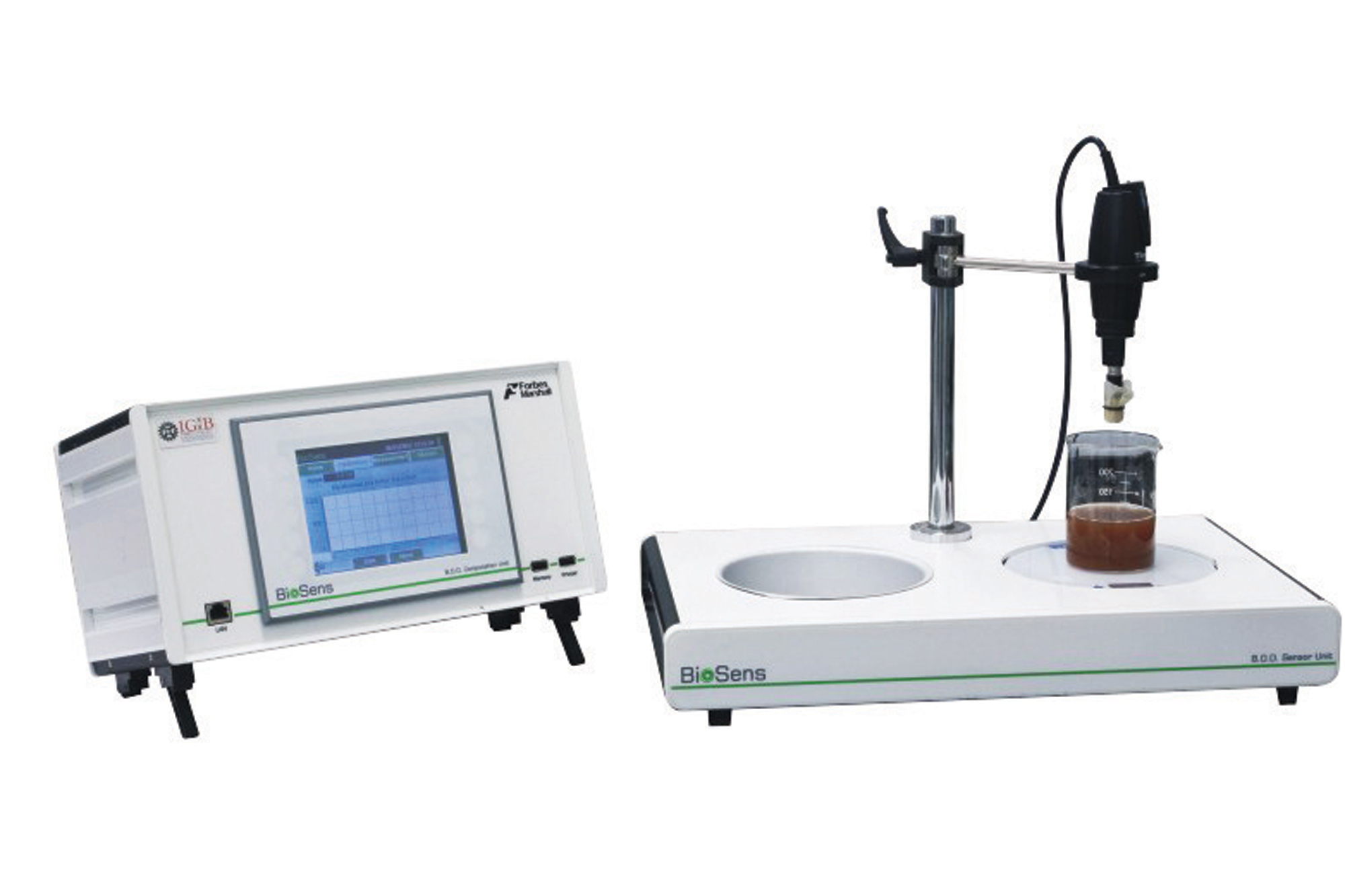

Most of the above measurement s are global measurements. There are some chemical constituents, which need cross checking before discharge of effluent out of the plant. Major parameters out of this are ammonia, sulphide, nitrate, phosphate, and chromium. Today titration based on line analysis of these parameters is possible.Organic load is another major pollutant which needs complete conversion before discharge. High concentration of organic load means consumption of more DO. Regular practice is to monitor BOD/COD levels to know the oxygen demand. With todays technology it is possible to monitor COD/BOD on line. Even there are some lab techniques available which can monitor true BOD in 40 minutes in place present BOD3 or BOD5 method.

In India many industries have started using on line analysers for wasterwater plants. Online analysis will provide a clearer understanding of process variability and provide a rapid response to change in the process. On line analysers optimise process performance and indicate operational problems. It also improves knowledge of treatment processes and indicates long term performance trends as well as conformity with environmental regulations before discharge.

Total instrumentation available today includes water quality parameters such as pH, redox, DO, turbidity, suspended solids, sludge profiler, sludge level indicator, MLSS, ammonia, nitrate, sulphide, phosphate, TOC, COD, BOD, oil and grease, phenol, water in oil analyser, magnetic flow meter, ultrasonic level indicators, dosing pumps, and VFD.

We must appreciate that responsible and efficient effluent management is the future of all water consuming industries and effluent from well controlled plants can be recycled only if you monitor your process. Unmonitored treatment of wastewater is just wasted water.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.