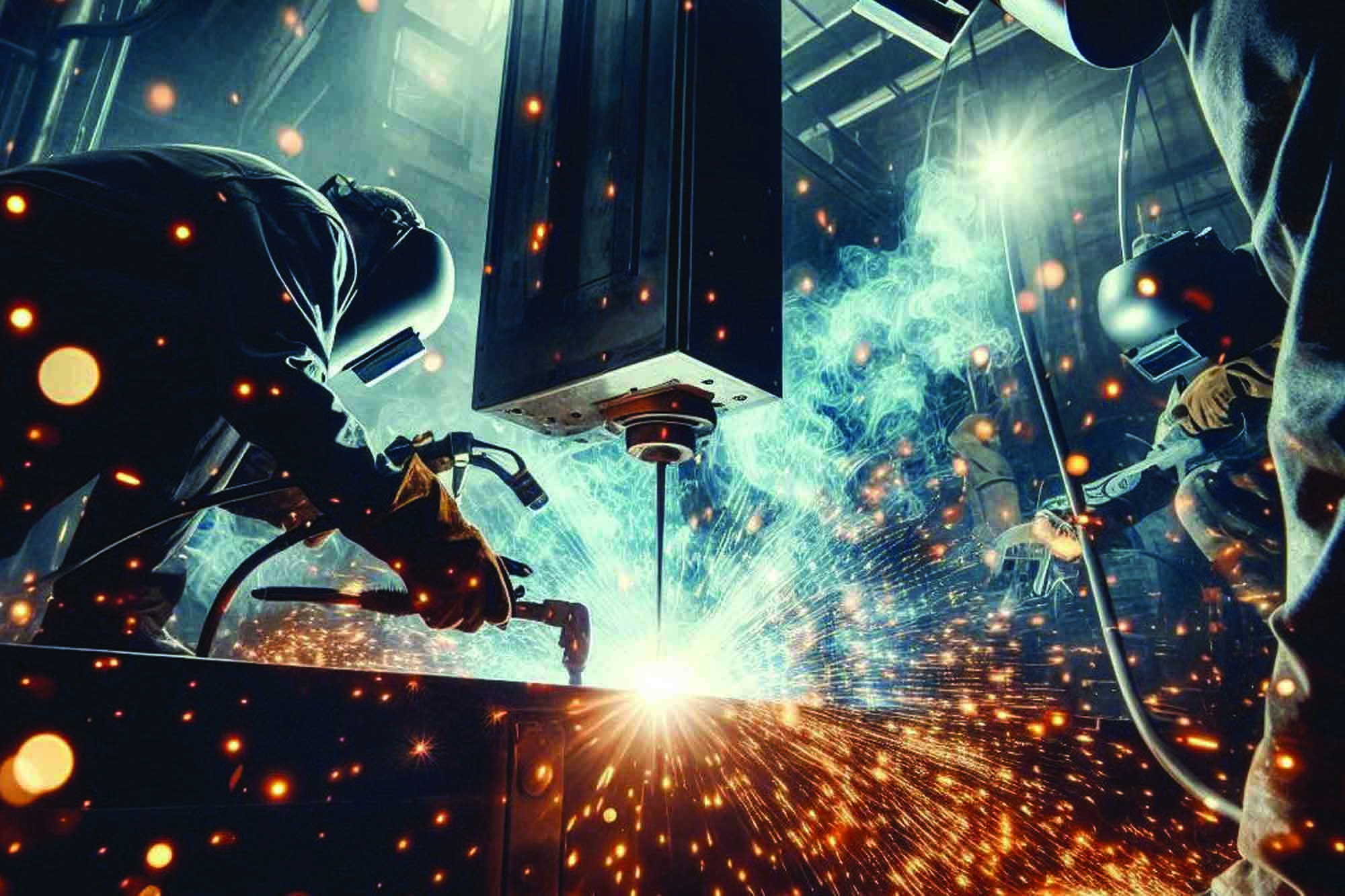

Ironclad innovation: The new era of metal structures in modern construction

By Staff Report | January 14, 2025 6:36 pm SHARE

Steel is at the heart of modern construction innovation, from prefabricated buildings to advanced corrosion protection. Industry leaders discuss how steel’s adaptability enhances design, sustainability, and efficiency in large-scale infrastructure projects.

What if the very foundation of construction—steel and metal—could do more than just support? Imagine these materials not only holding up structures but transforming how we build, design, and innovate. As we step deeper into Industry 4.0, steel and metal are evolving to meet new challenges, redefine efficiency, and embrace sustainability. These shifts were at the heart of the thought-provoking webinar, “Ironclad Innovation: The New Era of Metal Structures,” where a panel of experts explored how these materials are shaping the future of construction. From tackling high-temperature corrosion to driving the rise of prefabricated steel structures and addressing gaps in engineering education, the discussion highlighted the untapped potential of steel in reshaping the infrastructure landscape.

Steel as the pillar of modern architecture and infrastructure

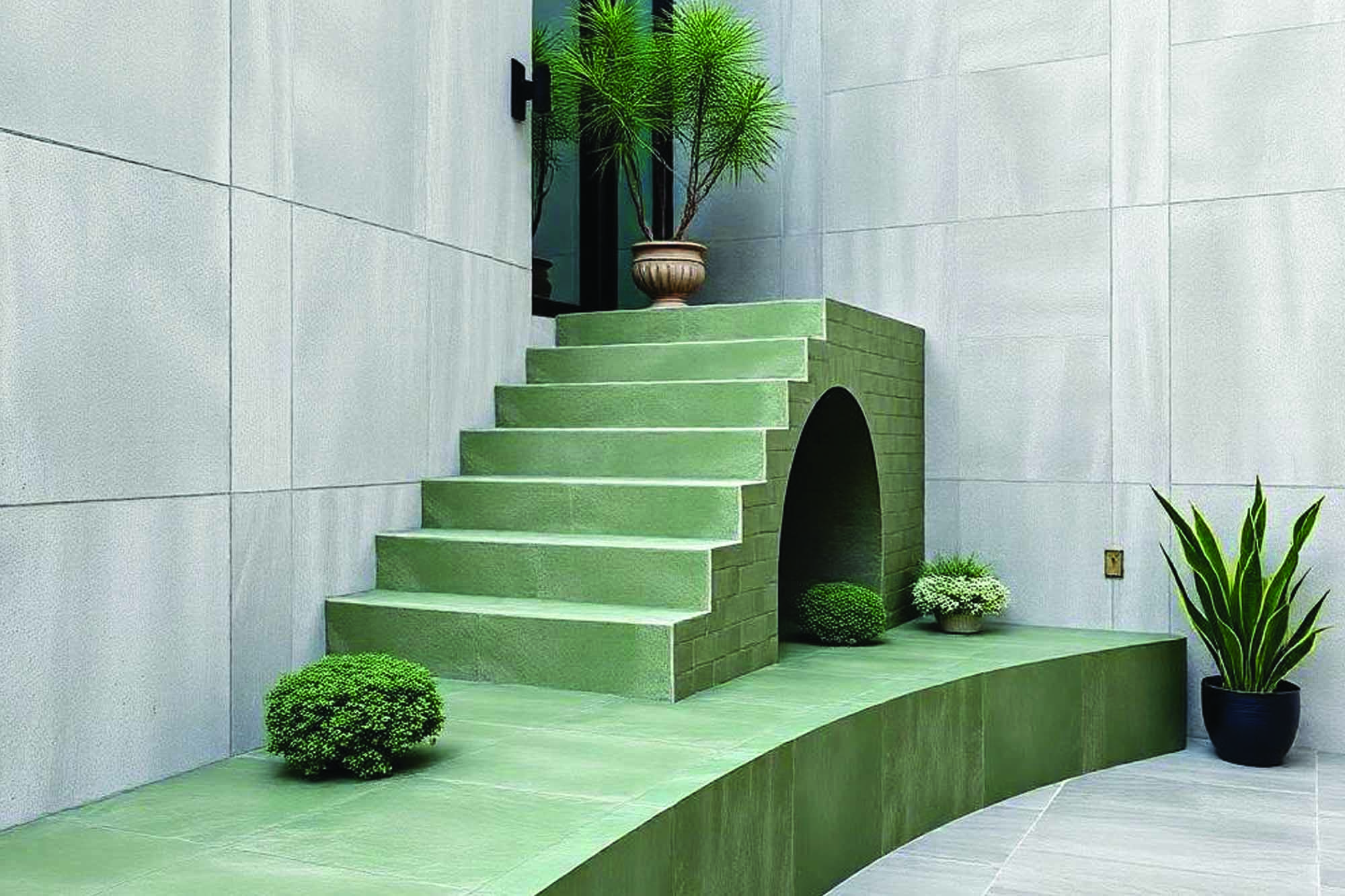

An examination of steel’s role as a fundamental component in developing contemporary infrastructure kicked off the discussion. Although steel is still a crucial structural design component, Prof. A S Khanna, Chairman, SSPC, stressed that the challenges have evolved. “Steel continues to be one of the most essential materials for creating robust structures. However, selecting the right type of steel and incorporating effective protection systems are key to ensuring long-term durability,” he stated. Ar. Prashant Deshmukh, Principal Architect, Prashant Deshmukh & Associates further echoed this, noting that the rise in steel quality and advanced coatings have made steel an increasingly attractive option for architects.

Steel’s ability to create large, flexible spans with minimal support is revolutionising how architects design public and private buildings. “Steel allows us to design creative, efficient spaces that would be impossible with concrete,” explained Deshmukh. He cited initiatives such as renovating Indian railway stations, which are being turned into cutting-edge, steel-driven architectural wonders. Software developments that allow for complex and dynamic design possibilities, such as soaring cantilevers and broad arches, further enhance this versatility.

The emergence of prefabrication is one of the key trends propelling innovation in steel structures. Dr. Ganesh Vishwakarma, Ex-Director (Projects & Business Planning), Steel Authority of India Limited, who has spent over four decades in the steel industry, shared his insights into the evolution of prefabricated structures, particularly in the industrial and healthcare sectors. “Steel’s adaptability to prefabrication has unlocked massive potential for quicker, cost-effective, and durable construction. Today, we see prefab steel structures in industrial plants, hospitals and fire stations,” he said.

The demand for versatile steel applications

These prefabricated structures have several benefits compared to conventional building techniques. They maintain excellent durability standards while saving substantial time and money. “Initially, prefabricated buildings were considered temporary solutions, but advancements in steel engineering have made them just as robust, if not more so, than conventional structures,” added Saurabh Bhardwaj, Deputy General Manager, Epack Prefab Technologies Limited. Prefabricated steel reduces project timelines and allows for greater design precision, significantly reducing the margin for error.

Addressing high-temperature corrosion

The problem of high-temperature corrosion, which impacts steel in industries that function in harsh environments, was one of the more technical topics covered in the webinar. Temperatures in places like steel mills and power plants can rise far above the point at which normal corrosion takes place. Although power plants are susceptible to high-temperature corrosion, Prof. Khanna clarified that most buildings and infrastructure projects hardly ever experience this problem. “When steel structures are exposed to temperatures above 500°C, special fire-resistant coatings are applied to protect them,” he stated. These coatings insulate the steel, preventing it from weakening during fires or extreme heat scenarios, thus preserving the structure’s integrity.

Meanwhile, Dr. Ganesh explained how refractory materials protect steel used in high-temperature settings, such as steel plants, from scorching heat and molten metal. These safety precautions make designing steel structures under such circumstances more difficult, but they are necessary to keep steel functioning well in challenging conditions.

Educational gaps and the need for innovation in the curriculum

As the demand for steel and metal construction rises, the industry needs skilled professionals. Prashant Deshmukh brought attention to this serious and regrettable flaw in the educational system: “Modern steel construction techniques are not adequately covered in most academic curricula. Students are not exposed to the latest tools and materials that are shaping the steel industry today. ” This disparity impedes the growth of a skilled workforce that can fully exploit steel’s potential in the building industry.

He advocated the inclusion of advanced steel design software, material treatments, and modern construction techniques in architectural and engineering programs. If academic programs are aligned with industrial practices, future professionals will be better prepared to push the limits of design and innovation in steel construction.

Greenfield vs. brownfield projects

When discussing the challenges of integrating steel and metal structures into different projects, Dr. Ganesh shared his experience working on Greenfield and Brownfield projects. “The challenges of Greenfield and Brownfield projects are vastly different. While Greenfield projects provide the opportunity to design and build from scratch, Brownfield projects are often constrained by existing infrastructure,” he explained.

In a Greenfield project, such as setting up a steel plant, the planning and construction processes are more straightforward, albeit demanding. Dr. Ganesh recalled the challenge of pouring 8,000 cubic meters of concrete in a single operation while managing extreme temperature variations. “In places like Jagdalpur, where the ambient temperature was close to 40°C, we faced unique challenges, such as sourcing hundreds of tons of ice to cool the concrete,” he said.

On the other hand, Brownfield projects present a different set of difficulties. Integrating new steel structures into existing buildings or sites requires careful planning to avoid disrupting operations. Dr. Ganesh noted that the biggest challenge in Brownfield projects is managing confined spaces and coordinating shutdowns to ensure construction proceeds smoothly without interfering with the existing infrastructure.

The growing demand for modular structures

Steel’s role is becoming increasingly more significant as the need for prefabricated and pre-engineered buildings, especially in the industrial sector, keeps growing. According to Saurabh Bhardwaj, the use of prefabricated steel and modular buildings is growing at a pace of 8–10% each year. The government is also driving this change by encouraging quicker and more effective building techniques for major infrastructure projects, in addition to architects and consultants. “The government’s push for modular construction is helping steel construction gain traction in sectors where speed, cost, and durability are paramount,” Saurabh stated.

Engineers and architects now have more opportunities to experiment with creative uses of steel because of the growing modular construction trend. This method enables quick building deployment without sacrificing safety or quality. Indeed, it is expected that a greater emphasis on prefabrication, which allows for faster turnaround times and cost savings, will define the future of steel buildings.

Forging a steel-strong future

Steel plays an increasingly important role in determining the future skyline as the construction sector develops. From providing design flexibility to enabling rapid, cost-effective construction, steel and metal structures are at the forefront of architectural and engineering innovation. However, the future success of steel in construction will depend on overcoming challenges related to high-temperature corrosion, expanding the use of prefabrication, and bridging the gap between academia and industry.

The webinar panellists’ perspectives emphasised the vital significance of continuous research, technology development, and education in optimising the use of steel and metal in buildings. As the industry develops and evolves, steel will continue to serve as the cornerstone of contemporary infrastructure and architecture, pushing the envelope of what is conceivable in the construction field.

Steel’s full potential is only just emerging, and as these developments materialise, a new era of construction is dawning, one that is more dynamic, sustainable, and efficient than ever.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.