Layher Allround scaffolding boosts cement industry efficiency

By Edit Team | July 11, 2024 6:38 pm SHARE

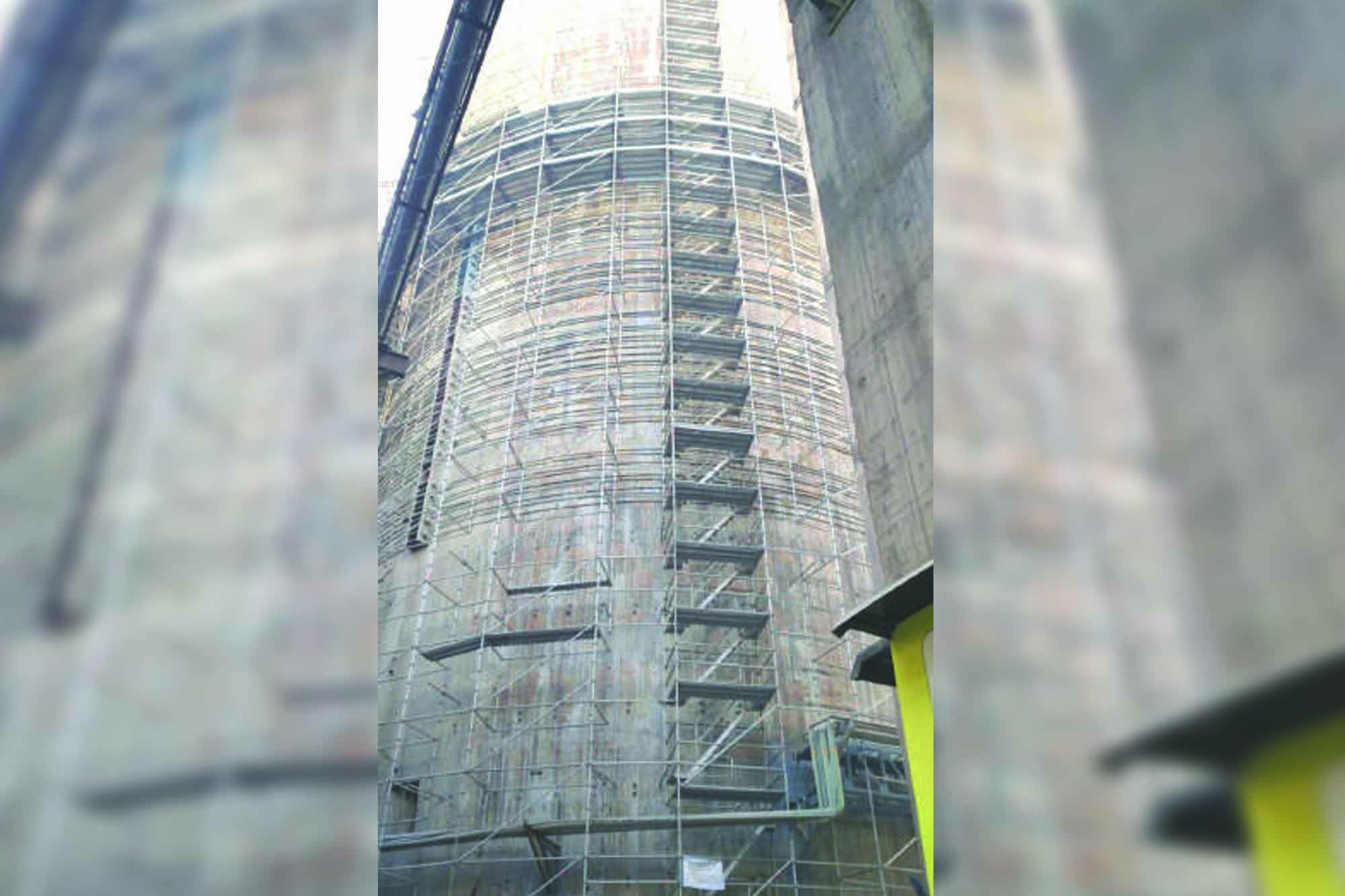

Layher’s Allround Scaffolding improves cement industry efficiency by providing strong support for silo maintenance and industrial heights, maintaining reliability in a variety of settings.

Layher has been producing high-quality scaffolding systems in Germany for over 75 years. Layher operates more than 45 subsidiaries around the world. The items are used in construction, cement plants, chemical plants, power plants, shipbuilding, and offshore applications.

More possibilities – Layher products and services

Layher’s current product attributes and services assist customers in achieving long-term success and increasing the profitability of their businesses. The Layher Allround Scaffolding has become synonymous with modular scaffolding on the market. It is extremely versatile and can be utilised in various applications, including construction sites, the chemical industry, power plants, aeroplanes, shipyards, the event sector, theatres, and arenas.

Application of Layher Allround scaffold in cement industries

Cement silos can be used in the production process in integrated cement plants or as a crucial component in distribution terminals. These storage silos are critical to the cement industry because they allow for continuous production while cement dispatch can be intermittent. The largest cement storage silos in the cement industry have diameters of up to 30 m. In contrast, normal silos for storing up to 20000 metric tonnes of cement have diameters ranging from 16 to 30 m and heights of 72 m. Such silos require efficient and trouble-free emptying. As a result, total plant reliability and almost 100 percent availability are the greatest requirements. To achieve high availability, flow problems must be strictly eliminated. According to the principle of flow in silos, this can only be accomplished by mass flow. For cement silos, the central cone design has been the most popular. On the one hand, the central cone serves as a displacement function for the material in the silo; on the other hand, numerous configurations, particularly those with several compartments, become viable. Multi-compartment silos are used to make speciality cement from a variety of primary and secondary cement components.

The building’s shape, as well as the surface of the façade, resembled a crystal. To attach the Local Scaffolder, the Layher Scaffolding and Technical team worked to fit the scaffold to the building’s slope with various brackets inside, then pushed it inwards by one scaffold width. The scaffold was anchored using Layher Anchoring technology, allowing larger wind loads to be transferred without putting extra strain on the structure.

Wind pressure makes it difficult to create scaffolding for silo repair. The use of support systems (scaffolding with a permanent structure) to eliminate blockages caused by brackets or cable trays around the silo. Layher Allround Scaffolding systems offer a unique, bolt-less connection technology; the patented Allround joint has superseded the traditional scaffolding technique, particularly in the construction of Scaffolds for Silos up to 54 metres. Allround Scaffolding can withstand all forms of heavy loads and is an excellent system for all types of support scaffolding. Allround scaffolding effectively addresses all obstacles, whether they involve fake work at extreme heights or round inner scaffolding.

It must be erected in a modular scaffolding system for the maintenance of silos and high-rise industrial structures. Cement plants are located near the seashore, so wind force must be considered.

Anchoring is critical for scaffolding stability and must be installed continuously as the scaffolding assembly progresses. Only provide anchoring on sufficiently robust components, and if necessary, test the anchoring surface using pull-out tests. A check is unnecessary if appropriate load-bearing capability can be calculated based on professional knowledge and the service value of the anchoring force is at most 1.5 KN or, in the case of reinforced concrete.

Connect the horizontal ledger. With two standard couplers and particularly wide scaffolding constructions, anchoring using a horizontal ledger must be necessary. The anchoring design is chosen based on the bay width, the load on the scaffolding, the live load, the wind load, and the structural height of the scaffolding. As the scaffold’s weight increases, the anchoring configuration must get denser to transfer the force to the anchoring surface safely. The more dense the anchoring structure, the less force will be applied to the individual wall ties.

Landing–type aluminium Stair Access

Layher Modular stair towers provide access alternatives that always fit and match the system. The landing-type Aluminium stair tower makes it simple to build a 4-standard stairway tower, either integrated into scaffolding or as a free-standing access structure anchored to the building. Using aluminium landing-type stairs makes it possible to work on scaffolding without difficulty. Furthermore, access structures that are built into the scaffolding are distinguished from those that are separate and fixed to the silo. An aluminium stair tower’s highest permissible load-bearing capability is 2.5 KN/m2. Because of the minimal weight of the components, it is simple to build up to 54 metres in height. Attach the required anchoring as needed, following structural standards. Unlike external platform stairway access, the platform stair tower cannot interfere with work inside the scaffolding while individuals ascend or descend.

Allround Scaffolding is straightforward to erect around curved surfaces thanks to the Allround connector’s eight distinct connectors and varied angle options. Possible connections and variable angle choices allow curved surfaces to be easily enclosed with scaffolding. The widest potential bay widths must be considered when designing cost-effective large-diameter scaffolding. Two kinds of system solutions using Allround equipment have proven useful in practice: the first employs solely system bays, while the second uses intermediate bays. In both circumstances, it is advised that the last bay be designated as an equalising bay.

For more information, visit: https://layherna.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.