Let the Sun shine

By Edit Team | August 20, 2014 12:18 pm SHARE

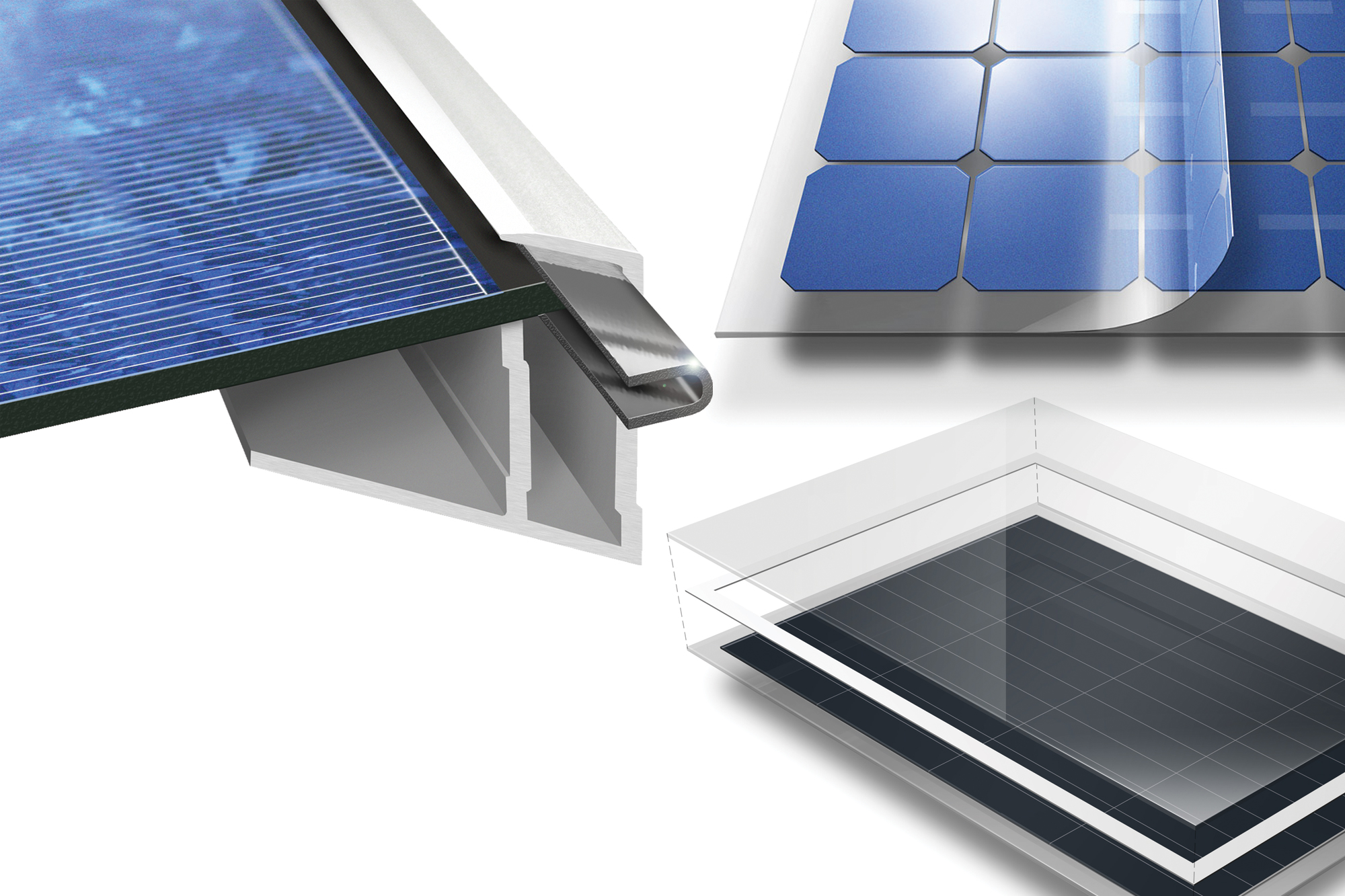

Lohmann has been servicing solar energy customers across the globe for nearly 3 decades with engineered products for applications such as frame bonding, junction box bonding, and cell fixation

Lohmann Adhesive Tapes Gmbh is a German manufacturer of engineered adhesive tapes offering solutions to multiple market segments in various ways to join components efficiently and permanently. Solar energy sector is one of them.

Lohmann has been servicing solar energy customers across the globe for nearly 3 decades with engineered products for applications such as frame bonding, junction box bonding, and cell fixation. The challenge for manufacturers within the photovoltaic industry nowadays is to increase efficiency and productivity. This is where adhesive solutions from Lohmann´s Bonding Engineers come in. The more reliably and efficiently different components are connected, the more long-lasting and cost-effective the technical solutions will need to be – irrespective of whether this is for energy production from solar systems, wind turbines and fuel cells, or for storing energy using modern battery technologies.

The company has more than 70 years of expertise in adhesive solutions, innovative developments, up-to-date production processes, quality and customer focus – worldwide.

Lohmann has been developing customised adhesive tape solutions for the solar sector since the beginning of 90s, and was one of the pioneer suppliers to enter framing application with an engineered solution. The products for solar modules have been subjected to the longest practical test ever for pressure-sensitive tapes and passed with flying colours. The customised adhesive solutions for the photovoltaic solar energy industry include several products of the DuploCOLL range, e.g. DC 9182, DC 57005, DC 9192 for frame bonding and DC 79356 for cell fixing.

According to Lohmann, these tapes guarantee highly reliable processing when bonding frame profiles to solar laminates up to fully automatic processes. To secure the laminates against mechanical loads and in order to mount them easily on the roof, these laminates are bonded to an aluminium frame by using a special pure acrylic double-sided adhesive tape. Using an adhesive tape during this procedure offers a lot of advantages to the module manufacturers. The tape has a defined thickness and therefore a defined quantity of the material between laminate and frame is always guaranteed. While the tape does not pollute the module, there is no cleaning necessary unlike liquid adhesives and sealants where usage can get messy and cumbersome.

Lohmann has presence in more than 60 countries world over. Its India manufacturing unit is based out of Chennai which is a state-of-the-art plant. It provides quality products to customers on time across the industrial locations in India.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)