Maintaining quality consistency with Geosynthetic product and application

By Edit Team | October 30, 2021 8:39 pm SHARE

“Environmental concerns and government initiatives had eased the adaptability of Geosynthetic applications,” Manish Barot Head – Technical Sales & Business Development M.E. (Civil) GEOTECH ENGG., B.E. Civil, Dip. Civil, TechFab India.

How do you evaluate demand for Geosynthetic products and advanced solutions in construction and infrastructure?

Demand of Geosynthetic products is foreseen based per the announcement of infrastructure projects by government bodies like, MoRTH, NHIDCL, NHAI, PMGSY, NFR, RAILWAYS, etc. Major part of total consumption of Geosynthetics products are used in the infrastructures works related to roads and railway. Apart from that, there are also other applications in water resources, irrigations, flood protection works, landfills, power plants, marine applications where Geosynthetics can be used.

Which kind of Geosynthetic applications, products and materials are primarily used for this sector?

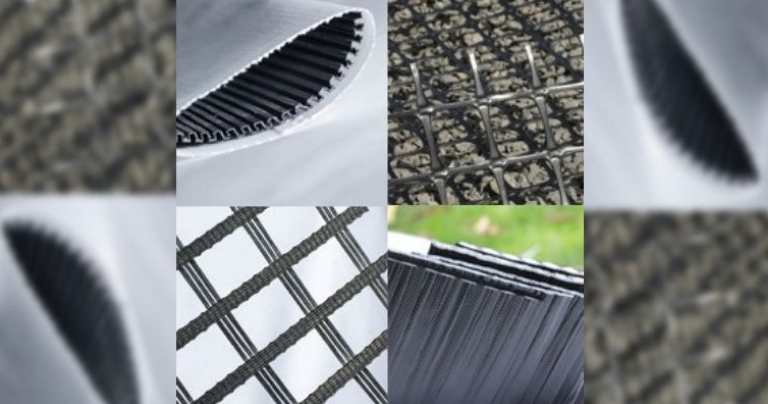

Major applications Geosynthetics in infrastructure sector are ground improvement, soil stabilisation, soil reinforcement in reinforced soil wall and slopes, separation and filtration, subsurface drainage, soil erosion protection and primary materials used are Geotextiles, Geogrids, Geostrips, Geocells, Drainage Composites, PVDs.

What are the major differences between conventional solutions and Geosynthetic solutions?

The major difference between the conventional and geosynthetic solutions is that the latter minimises overall cost, time of the project and use of natural resources thereby minimising the carbon footprint on the environment. Further these Geosynthetic products are factory made and hence the consistency in quality of the work can be maintained unlike conventional solutions.

What are challenges being faced while application of Geosynthetic products in construction engineering?

Yes, there have been challenges faced over a period of time in adoption of these products as an alternative to conventional applications due to lack of expertise, unavailability of Indian Standards etc. But with advancements in Indian expertise, availability of Indian codes and guidelines for the design and execution of these products and growing scarcity of natural aggregates/stones, concerns of environmental pollution and various initiatives of government of India has eased to certain extent the adaptability of these applications as an alternative to conventional solutions.

However, the challenges of proper execution of these materials at site with quality control and competing with low standard Chinese products still remains and needs to be tackled.

What are your latest and upcoming offerings into this segment?

Techfab India has emerged as the leading manufacturer of geosynthetic products in India having widest range of product portfolio with highest manufacturing capacities among the competitors. In continuation to this, we have ventured into new segment of geohazard mitigation wherein we have started our manufacturing facilities for high tensile rhomboidal rope netting, slope stabilization mesh and soil anchors. With this we plan to explore opportunities in the hill road infrastructure which is of major demand in northern and north-eastern part of India.

How do you see growth prospects for Geosynthetic products and solutions in India?

With the present roadmap of Ministry of Road Transport in construction of expressways, highways with limited timelines and growing scarcity of natural aggregates/stones, the future growth prospects of Geosynthetic applications looks bright. We are optimistic that the adaptability of these applications will grow in future and Techfab India aims to further grow the market share in these applications

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.