MCI®-2026 Floor Coating for Concrete Longevity: when and why?

By Edit Team | May 23, 2022 11:49 am SHARE

It’s important to understand when and why to choose a product like MCI®-2026 Floor Coating to achieve concrete longevity.

Extending concrete service life takes a multifaceted approach, but the underlying principles are always the same:

- Properly understand the conditions and environment

- Select the appropriate treatment

- Appropriate application of selected solution to obtain best results. Cortec’s line of MCI® Technologies has several outstanding options but every treatments are equally suited to all the application. Therefore, it is important to know when and why to choose a product like MCI®-2026 Floor Coating to achieve for concrete longevity.

Selecting the right product for application

Selecting a product to extend service life is by considering the structure and its environment, is the very first step towards selecting the right product for application. For example, an engineer planning a new parking ramp in a harsh winter environment where deicing salts are used, could extend the service life by specifying Migrating Corrosion Inhibitor™ admixtures for the concrete mix.

Selecting a product to extend service life is by considering the structure and its environment, is the very first step towards selecting the right product for application. For example, an engineer planning a new parking ramp in a harsh winter environment where deicing salts are used, could extend the service life by specifying Migrating Corrosion Inhibitor™ admixtures for the concrete mix.

Workers performing concrete repairs can help the repair last longer by incorporating MCI® Mini Grenades into repair mortars. Facility managers can ward off corrosion on existing structures through periodic application of surface applied corrosion inhibitors (SACIs) such as MCI®-2020.

While these products could also be used for concrete floors, often the biggest concern in an industrial environment is the risk of external concrete damage from heavy traffic and exposure to harsh chemicals. It is chiefly after this kind of damage that corrosion is more likely to occur by allowing corrosives to enter the substrate. MCI®-2026 Floor Coating is an excellent first line of defense against these problems.

Benefits of MCI®-2026 Floor Coating

There are three main areas where MCI®-2026 Floor Coating is especially helpful:

- Applications with strict VOC limits

- Federally inspected plants

- Areas with heavy traffic and/or chemical spillage

MCI®-2026 Floor Coating addresses the first concern by being a 100 percent solids, and two-component novolac epoxy coating, with zero VOCs. This is perfect for maintaining VOC compliance, and offer a great advantage for workers applying the coating. In the second case, MCI®- 2026 meets all USDA/FDA guidelines for use in federally inspected facilities. In regard to the third case, MCI®- 2026 Floor Coating achieves a high degree of physical and chemical resistance while maintaining excellent adhesion to properly placed primers.

In so doing, it protects concrete surfaces from aggressive industrial environments, and prevent the intrusion of corrosive elements that can potentially cause further concrete deterioration at the reinforcement level.

MCI®-2026 Floor Coating can be used alone as a body/ basecoat or as a topcoat if additional internal moisture resistance is needed by priming the floor below.

Best practices for good concrete coatings performance

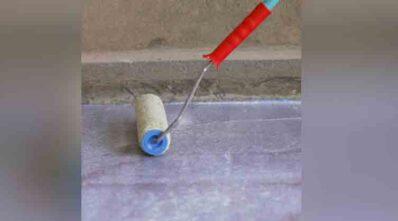

Next in importance to choosing an appropriate technology, is applying it properly. As for any coating, good surface preparation is critical to ensuring the best performance possible.

Before applying MCI®-2026 Floor Coating, workers should make sure that the concrete floor is clean and sound with a minimum surface profile of CSP-2. Existing coatings should be removed to ensure proper adhesion. As a two component product (a feature that allows crosslinking for an overall stronger coating chemistry), MCI®-2026 Floor Coating should be properly mixed and applied at the right temperatures per manufacturer’s instructions to work as designed.

Choosing physical and chemical durability for concrete floors

By choosing to apply MCI®-2026 Floor Coating, facility owners and managers are left with concrete floors with a high degree of physical and chemical resistance. These qualities make the floor more durable and help it last longer primarily by protecting against physical and chemical damage and secondarily by blocking the intrusion of corrosives in an aggressive environment.

All this is achieved with a low VOC coating that can be used in federally inspected facilities.

Contact Cortec® to see if MCI®-2026 Floor Coating is the right choice for your industrial concrete floor application: https://www.cortecmci.com/contact-us/

Keywords: Cortec, From Grey to Green, MCI, extend service life, concrete deterioration, concrete damage, low VOC coatings, concrete longevity, concrete coatings, concrete floor durability

For more details, visit: www.cortecadvertising.com

Cortec Website: http://www.cortecvci.com Phone: 1-800-426-7832

FAX: (651) 429-1122

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)