Metso celebrates its 150th anniversary

By Edit Team | November 6, 2018 7:01 am SHARE

Metso celebrates its 150th anniversary this year. Since its outset as local ironworks in 1868, the company has evolved through a series of mergers, acquisitions and divestments. With its own operations in over 50 countries and over 12,000 dedicated professionals working, the company provides world’s mining, aggregates, recycling, and process industries with innovative solutions for the sustainable processing and flow of natural resources.

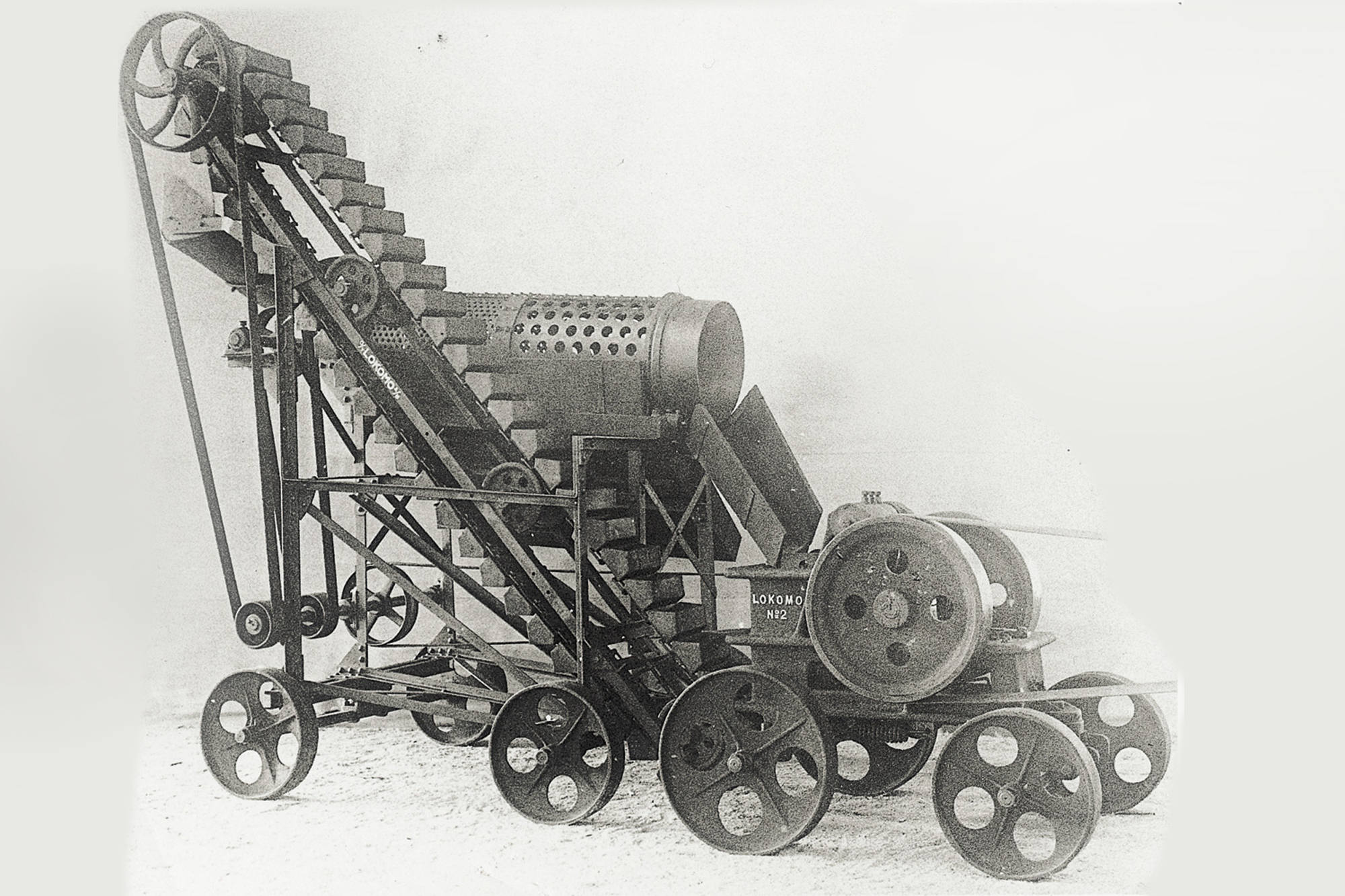

During its 150 years, the company has been in many businesses, ranging from steam engines, locomotives, car manufacturing, forest machines, and pulp and paper machines, to valves, metal and waste recycling equipment, and solutions for rock and mineral crushing and screening, to name a few.

Metso is probably the only company in the world providing equipment and services for the recycling business already for 100 years. With the increasing importance of circular economy, recycling is more important than ever. The company is in a position to provide the necessary equipment and services to handle virtually any type of waste or scrap metal. Our metal recycling offering rests on a strong platform built on the Lindemann Texas Shredder and N-Series technology, covering a wide range of efficient solutions for the fragmentation, compaction and separation of different types of metal scrap. With the acquisition of M&J Industries, now the company is also a supplier of solid waste recycling equipment.

In flow control, solutions are built on innovative Neles and Jamesbury valve solutions. Neles Oy was established by Antti Nelimarkka and Eino Santasalo in 1956. Today, various process industries – often located close to urban areas and including, for example, pulp and paper, chemicals, energy, gas processing and LNG, industrial gas, and refining – rely on our flow control products and services to run their processes safely and reliably.

Aditionally, Metso is investing in the development of its foundry capacity in Vadodara, India. The company expects to invest a total of approx. EUR 25 million to purchase the assets and to develop the foundry by 2020. With this investment, the company is responding to the global market demand by increasing production capabilities in cast wear parts for the aggregates and mining industries.

“This investment further expands our global manufacturing footprint in foundry products, improving our operational capabilities and allowing us to meet our customers’ growing needs both in terms of availability as well as reduced lead times,” says Sami Takaluoma, President, Minerals Consumables business area at Metso.

The foundry development will begin as soon as the acquisition of the foundry assets has been completed. The first product deliveries from the Vadodara foundry are expected by the end of 2019 and the production will ramp up quickly in 2020. The new foundry will be built to follow the company principles.

Celebrating 150 years

To celebrate its 150th anniversary, the company organised a photo exhibition illustrating how Metso has taken part in shaping and building the modern world.

The exhibition featured photos, stories and insights into how the world and the industry have changed over time focusing on three main themes – building urban environments, enabling the modern way of living and reaching for the future.

For any further information,

please visit www.metso.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)