Mining 4.0

By Staff Report | November 21, 2024 6:43 pm SHARE

The mining sector in India is undergoing a digital transformation thanks to Industry 4.0, bringing groundbreaking technologies that promise to enhance efficiency, safety, and environmental stewardship. Yet, the road ahead is fraught with challenges such as capital costs and cybersecurity risks that need addressing.

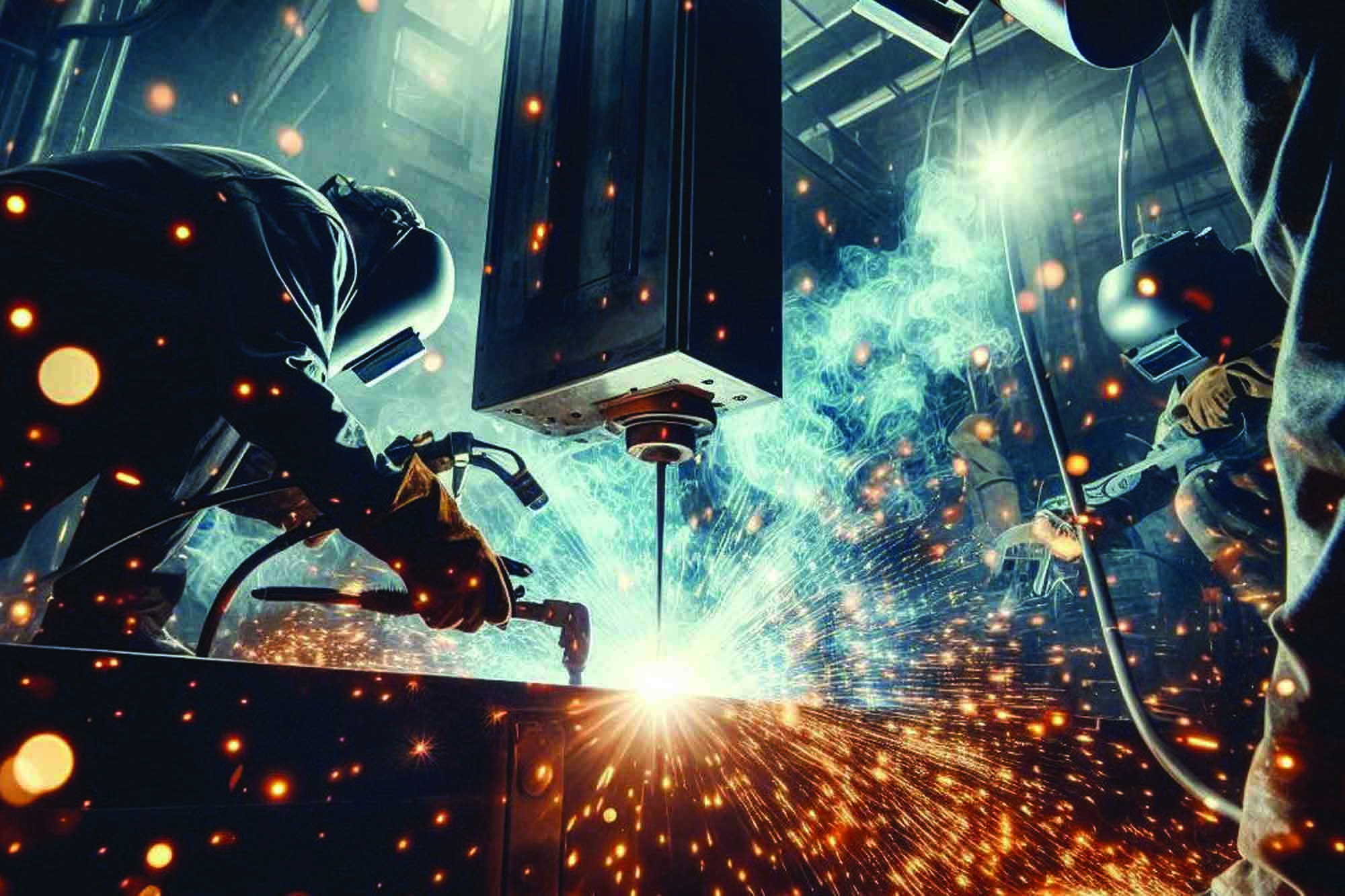

In the depths of India’s mines, a digital revolution is underway. The arrival of Industry 4.0 technologies—automation, robotics, AI, IoT, and data analytics—is transforming mining operations from labor-intensive practices to streamlined, intelligent systems. Sensors predict equipment failures before they happen, robots tackle hazardous tasks, and AI fine-tunes resource extraction for peak efficiency. These advancements aren’t just boosting productivity; they’re enhancing safety and driving sustainability through pollution monitoring and waste reduction.

Yet, as India’s mining sector embraces this high-tech shift, challenges remain. High initial costs, a shortage of skilled labour, and cybersecurity concerns keep progress uneven. Still, leading players are forging ahead, envisioning a future where smart practices redefine mining for the modern age. To understand why this shift is crucial, we spoke to industry experts, gathering insights on the current landscape and the path forward for India’s mining evolution.

The driving forces behind Mining 4.0

Sajal Ghosh, Business Head, Softweb Technologies Pvt Ltd, highlighted the key forces driving the shift towards Mining 4.0, particularly in India. He explained that mining companies are at a crossroads, caught between the traditional practices of Mining 2.0 and the more advanced, technology-driven Mining 3.0 and 4.0. “There are progressive leaders in the mining industry who are willing to embrace new technologies, recognising their potential to solve existing challenges while preparing for future demands,” he said.

A mix of necessity and opportunity powers the push towards Mining 4.0. The industry is grappling with rising operational costs, administrative inefficiencies, and safety concerns. However, the integration of advanced technologies, such as AI, IoT, and automation, has made it possible to optimise operations, reduce costs, and enhance decision-making. Through real-time data collection and analytics, companies can now make proactive decisions that reduce downtime, improve asset utilisation, and drive overall productivity.

As Sajal put it, “Mining 4.0 is not just about automation; it’s about interconnection. All devices, machines, and processes are linked together, allowing for the continuous flow of data and real-time insights. This interconnectedness enables predictive maintenance and proactive decision-making, ultimately leading to more efficient and sustainable operations.”

Vasim Pradhan, Sales Head – EMEA and APAC, SymX.AI, echoed these sentiments, emphasising the growing role of IT and AI in mining operations. He noted that just a decade ago, fleet management and fuel consumption tracking were cumbersome tasks reliant on paper-based systems. Today, with the use of real-time tracking and analytics, companies can instantly identify inefficiencies and make adjustments on the fly. “Now, with just a few clicks, you can monitor your entire fleet, pinpoint underperforming machines, and even track fuel consumption, reducing waste and optimising performance,” he explained.

The role of cybersecurity in the digital mining landscape

As mining operations become increasingly digital, cybersecurity has emerged as a critical concern. With data being stored and processed in the cloud, ensuring its security is vital to the success of Mining 4.0. Sajal Ghosh pointed out that large corporations are particularly sensitive about their data, recognising its value as a strategic asset. “In the digital age, data is currency. Losing or compromising it can have catastrophic consequences for a business,” he said.

Both experts agreed that the industry must invest in robust cybersecurity measures to protect against potential threats. As mining companies rely more heavily on digital systems to monitor equipment, track resources, and manage operations, the risk of cyberattacks grows. Establishing strong data protection protocols will be essential to maintaining trust and safeguarding critical information.

Leveraging digital technologies for sustainable mining

Another key aspect of Mining 4.0 is its potential to reduce the environmental footprint of mining operations. As the industry faces growing pressure to meet sustainability targets and reduce carbon emissions, digital technologies can provide significant solutions. Vasim Pradhan’s company, SymX.AI, is focused on helping mining operations achieve their carbon-neutral goals through smarter, more efficient plant management. “By improving plant efficiency and reducing waste, we can help companies lower their carbon footprint,” he explained.

Ghosh added that while sustainability is still a relatively new concept in Indian mining compared to Europe or other developed regions, there is growing awareness. “Mining companies must be climate-conscious, not just to comply with regulations but because it’s the responsible thing to do. Technology can help monitor emissions, optimise resource use, and even facilitate carbon trading to generate revenue,” he said.

Future milestones for Mining 4.0

Looking to the future, both experts are optimistic about the continued evolution of Mining 4.0. As technologies become more advanced and integrated, mining operations will become increasingly autonomous, efficient, and sustainable. The next major milestone will be the widespread implementation of AI-driven predictive maintenance, advanced automation, and smart resource management systems.

Ghosh believes that just as doctors today rely on sophisticated diagnostic tools to understand a patient’s condition, the mining industry will increasingly rely on digital tools to understand and optimise every aspect of its operations. “The mining industry is moving toward a more data-driven, AI powered future where real-time data and predictive analytics inform decisions,” he said.

For Pradhan, the next big leap will be the integration of AI across all aspects of mining, from fleet management and crushing operations to safety monitoring and environmental management. “AI is already playing a significant role in monitoring the mining process, ensuring that the right kind of rock is fed into crushers and detecting any irregularities in machine operations before they result in costly accidents,” he said.

Mining 4.0 is not merely a fad; it is the direction that the industry is taking. As digital technologies continue to evolve, the potential for smarter, more sustainable mining operations grows. By embracing these advancements, mining companies can optimise their resources, reduce their environmental impact, and position themselves for long-term success in a rapidly changing world. The question is no more whether the sector should embrace Mining 4.0, but how soon it can do so to remain competitive and satisfy the expectations of a more sustainable future.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)