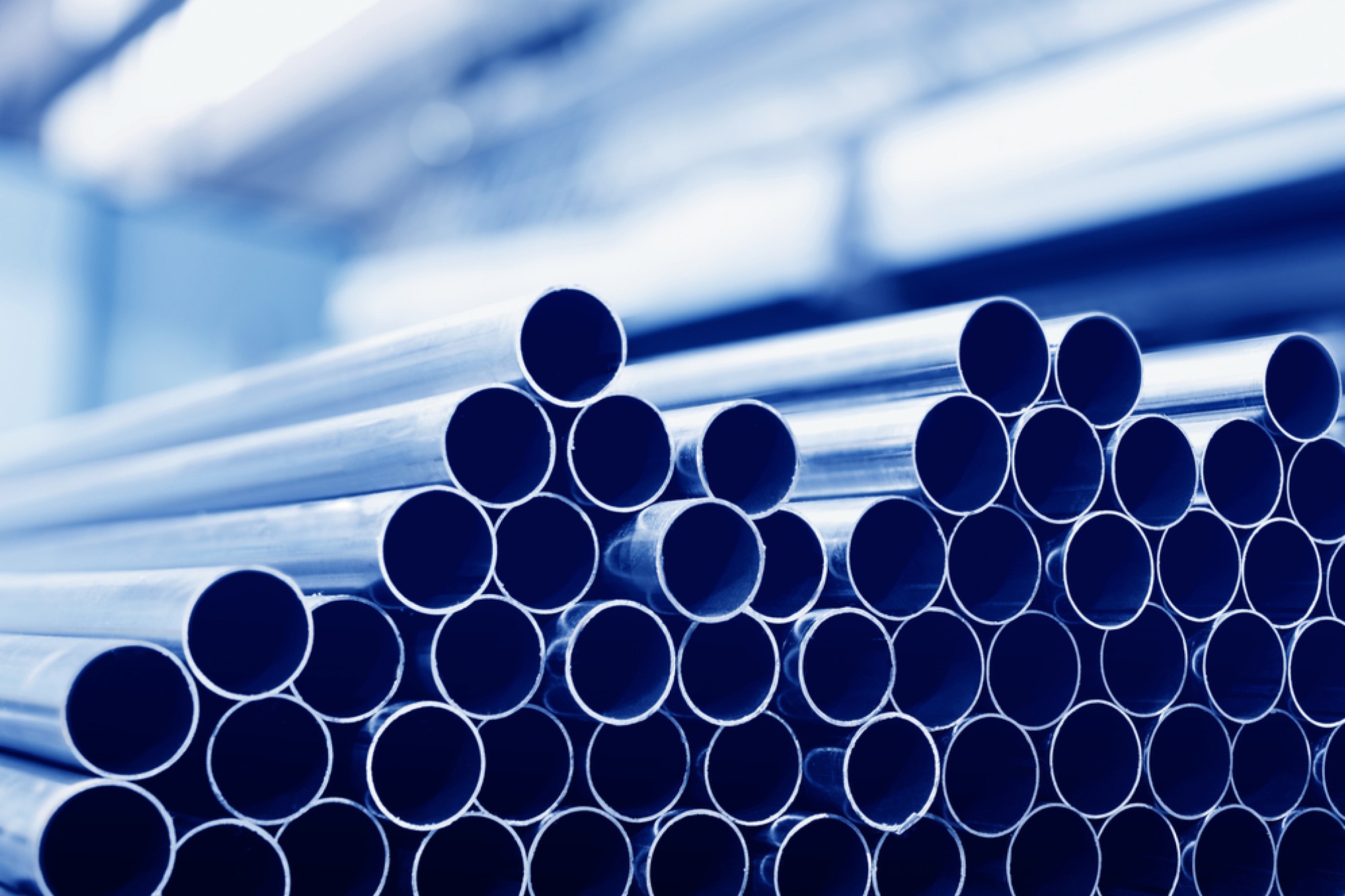

Non-corrosive pipes with excellent tensile properties for industrial applications

By Edit Team | June 20, 2022 4:50 pm SHARE

Siddharth Bansal Director, Skipper Pipes in an interview with B2B Purchase

Innovations and R&D in industrial pipes to withstand critical environment

Skipper Pipes conduct regular and thorough check-up as per the prescribed BIS standards. Below mentioned are some highlights our R&D activities:

- Opacity test to control bacterial formation caused by exposure to sunlight.

- Impact test to check the strength against external load its bearing capacity

- Tensile test to check the elongation at high & low critical temperature

- Reversion test to check the expansion & contraction.

Products and services for civil infrastructure

Skipper provide uPVC Plumbing; SWR pipes and fittings for civil and industrial infrastructural purposes. Our UPVC pipes have an economical installation uptake, down-take lines, terrace looping, and concealed pipe work. Made of thermoplastic material welded by solvent cement, these fire-resistant products do not contaminate water passing through them. Being 100 percent lead-free ensures overall hygiene. Our UPVC pipes and fittings are anti-fungal and anti-algae. Their smooth surface prevents scaling and deposition, while their UV stability makes them ideal for outdoor application. These non-corrosive pipes with excellent tensile and impact strength are a smart substitute for GI pipe systems. These pipes are made as per ASTM D 1785, and also comes in SCH 40 and SCH 80.

We also offer various problem-solving techniques by experts who provide in depth technical demonstration & complete training at the point of installation.

uPVC pipes for industrial activities

Besides uPVC & CPVC, we also offer HDPE & PPR pipes & fittings for the industrial segment. Skipper HDPE Pipes are safe durable and cost-effective solution for various applications. Strength tests on raw material & finished goods assists to provide the quality as per standard IS:4984-2016.

Few Key features of HDPE Pipes

- Excellent resistance to Corrosion, Abrasion & Chemical;

- High Ductility & Toughness;

- Excellent resistance to Water Hammers;

- Excellent Weldability;

- Low Installation Cost;

- Durable & Cost Effective;

- High flow characteristics;

- Minimum friction loss.

Skipper Poly-propylene Piping system is safe, durable, high performance and cost-effective solution for various Heating-Chilling and Hot-Cold water applications. Pipes & Fittings are usually joined together by Poly-fusion welding. PPR-C Pipes are recommended for a maximum water temperature up to 950 C.

Few Applications of our PPR – C Piping system

It includes other products like Connection Heating & Cooling, Wall Heating a Chemical Transport, Geothermal, Liquid Food Transportation, Effluent Treatment Plant, RO & DM Water Supply Lines, Solar Water Heating System, Pharmaceutical & Food Grade Application, Ship Building & Swimming Pools, Compressed Air & Vacuum Pipelines

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.