Oorja Udyog: The Stud Welding Specialists

By Edit Team | April 8, 2016 11:25 am SHARE

Shear stud welding machines, supply and fixing of shear studs

• Extensive experience in shear stud welding for thru deck stud welding and beams for almost all the leading PEB and bridge manufacturers in India.

• Can supply almost every available size of shear connector.

• Large fleet of stud welding machines in India.

• Experienced team of site supervisors and trained welders.

• Quickest service when it comes to supply of shear connectors or the full installation welding package.

Applications

• Pre-engineered buildings

• Steel bridges

• Steel buildings

• Heavy fabrication

• Railways.

Shear stud welding machines and fixing shear studs

Oorja Udyog has extensive experience when it comes to shear stud welding. The company is one of the leading players in India when it comes to manufacturing stud welding machines and shear stud fixing, having welded lakhs of shear connectors to a hundreds of metal deck projects, bridge beams and a variety of base plates.

Oorja Udyog is able to offer a range of stud welding machines for all applications ranging from welding 3 mm diameter studs onto thin sheets to say 25 mm studs onto thick base plates used in metal deck projects, bridge beams, boiler pipes, transformer tanks and also panel fabricators.

The company also offers almost every available size of shear connector and can boast of having the largest fleet of shear connector welding machines in India and an experienced team of site supervisors and trained welders. With the help of this, Oorja Udyog can supply services of shear connectors or the full installation welding package at earliest.

The need for shear connection

The shear flow between steel beam and reinforced concrete deck slab is a natural consequence of the requirement for composite action. If there were no connection, a beam and slab would bend as illustrated diagrammatically below. The presence of a shear connection prevents the slip between the two components and achieves a much stiffer and stronger beam.

When there is shear connection, the two components behave as one.

Drawn arc stud welding process

Drawn arc stud welding is a process by which a metal stud is joined to a metal work piece by heating both parts with an electrical arc. The advantage of this process is that the fastener is attached to the work piece without marring the other side while providing maximum weld penetration and reliability.

Advantages of drawn arc stud welding

• Shear connection prevents the slip between the two components (steel beam and reinforced concrete deck slab).

• High weld strength – full cross-sectional weld. The bond is stronger than surrounding metal.

• The one-sided fastening process permits greater design versatility.

• Tamper proof.

• Increased productivity.

• Economic advantages – savings on labour and fabrication costs.

• Machine is simple to use

• Requires very little skilled labour.

Applications:

• Pre-engineered buildings

• Heavy fabrication

• Steel buildings

• Steel bridges

• Railways.

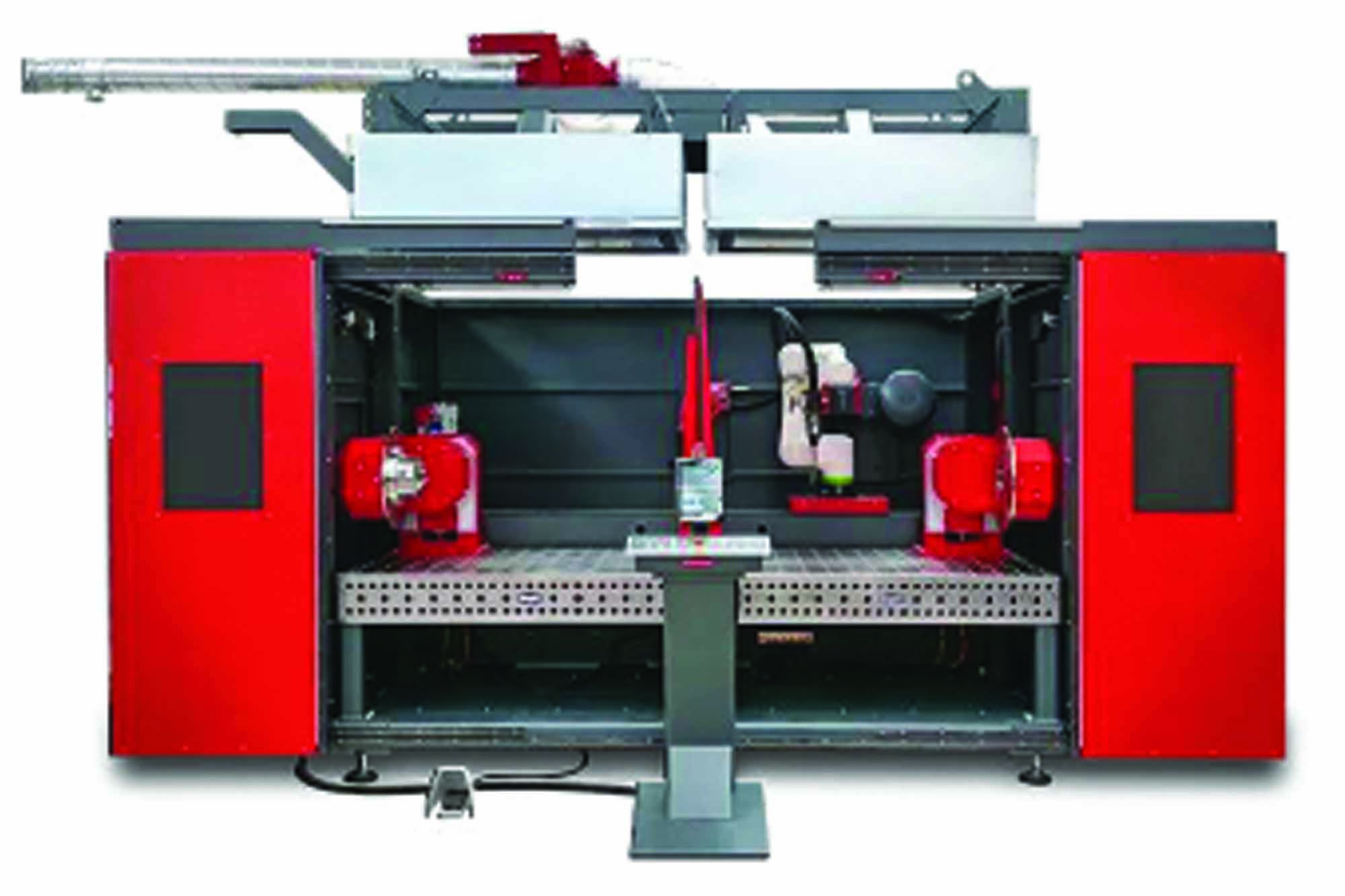

Oorja-make drawn arc stud welding machines

Oorja Udyog is a manufacturer of stud welding machines and following models are available:

• OUE – 16: Suitable for welding studs up to 16 mm diameter

• OUE – 19: Suitable for welding studs up to 19 mm diameter

• OUE – 25: Suitable for welding studs up to 25 mm diameter.

Oorja headed shear connector studs and onsite fixing services

Oorja-make headed shear connector stud can be used for welding flat surfaces, inside/outside angles, and thru deck.

Headed shear connector studs are designed to interconnect (tie) the concrete slabs to the load bearing steel beams. A stud that transfers shear stress between metal and concrete in composite structural members in which the stud is welded to the metal component. This composite construction resists shear loading between the concrete and the steel beam and increases the loading capacity in steel buildings, bridges, column, etc.

Oorja Udyog manufactures studs as per IS standards. The company can provide test reports for the materials used. The products meet all applicable standards and the company can supply studs of almost any size, shape and configuration of thread.

Standard headed shear stud range: The headed shear studs are made to order as per clients’ requirements. Standard sizes are made available ex-stock. The common sizes shear connector studs are in diameter 16 mm, 19 mm, 22 mm, and 25 mm.

Oorja Udyog also offers onsite fixing services of shear connectors studs or thru deck welding of shear connector studs on mezzanine floors.

Contact:

Oorja Udyog Enterprises

No.42/1,1st Cross,

Kariobanahalli Main Road,

Peenya Second Stage,

Bengaluru – 560058

Tele: +91-9890084085,

080-32993799, 080-32323799

Email: sales@oorjaudyog.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.