Promtech offers technical know-how to professionals and students

By Edit Team | October 28, 2014 11:13 am SHARE

Promtech Consultancy provides required assistance and turnkey technical know-how for setting-up aerosol paints and products filling facility

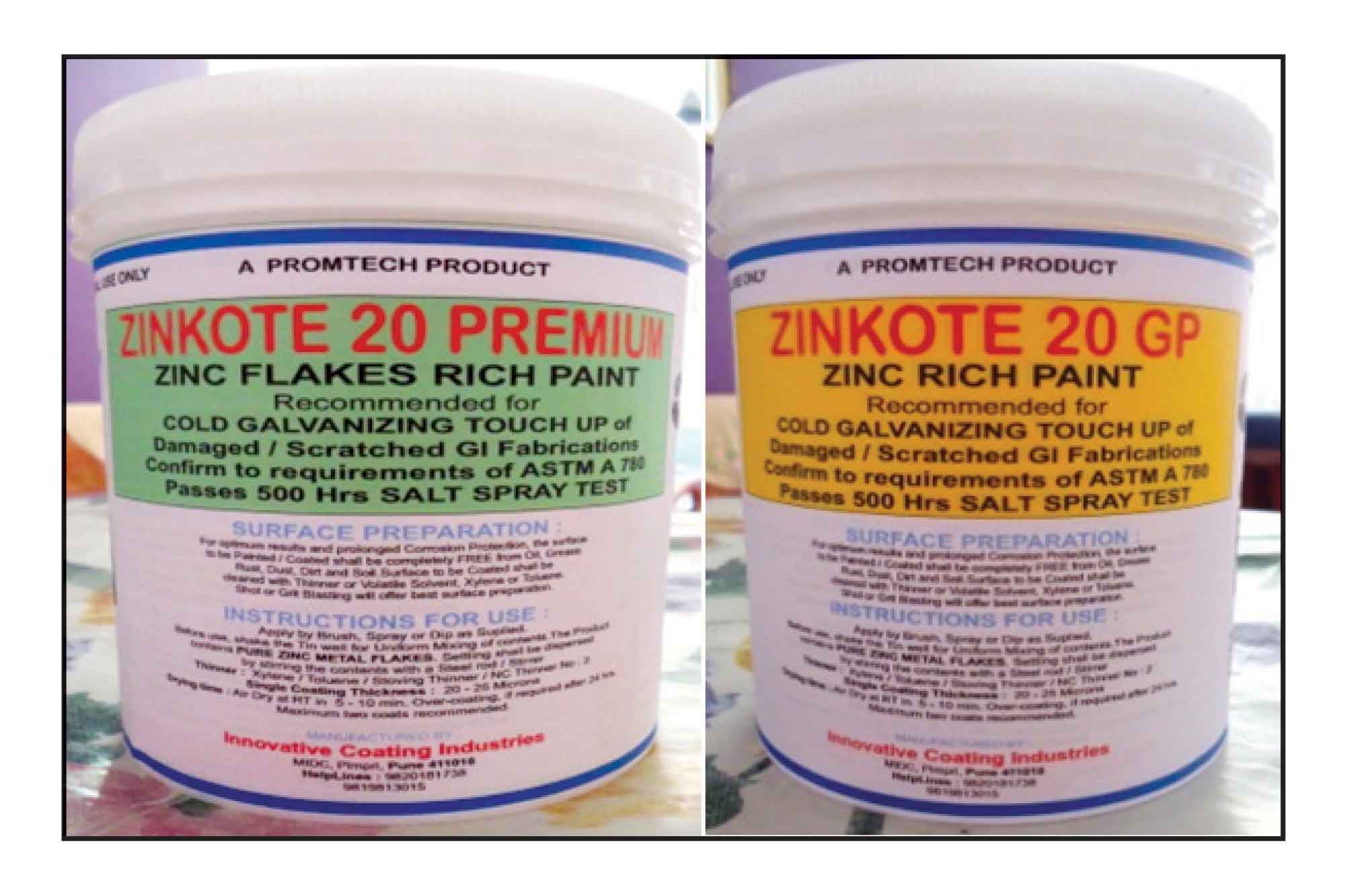

Promtech Consultancy offers manufacturing formulations and complete technical know-how for manufacture of metal pre-treatment chemicals. Having started with aerosol paints for powder coating and painting touch-up and offering their aerosol paints cans from the year 2002, Promtech has achieved phenomenal growth over the years. In the process Promtech has added to its range nearly 45 different types of aerosols, covering a range of industrial applications.

Purpose of offering products manufacturing know-how

Promtech products range includes the several high demand industrial products having a continuous demand in almost every industrial sectors. The company plans to educate and assist young graduates and technocrats in every industrial area across the country to localise manufacturing and supplying aerosol products. This will eliminate freight, forwarding, delays and damages, VAT, LBT, local govt. taxes as well as bring convenience to buyers.

Who can avail this

• Powder and paints manufacturers

• Aerosol marketers (Indian or foreigners)

• Powder distributors or dealers

• Aerosol products manufacturers looking for expansion and for additional products

• Foreign firms want to set-up their manufacturing facility in India.

Product areas

• Zinc metal sprays for cold galvanising

• Zinc plating and passivation touch-up sprays

• Zinc rich COL galvanising paints

• Aluminium and 600 C HR aluminium paints

• Stainless steel 316L sprays for SS fabricators

• PTFE blend teflon plus acrylic sprays

• Metallic finishes: copper, bronze, gold, silver, aluminium, chrome, zinc aluminium finishes

• 600 C heat resistant aluminium sprays

• Rust looseners, rust preventives, lubricants

• Complete car care range products

• Peel off coating or vinyl spray for anti-corrosion

• Electrical contact cleaners: PCB coating sprays

• Battery terminal coating sprays

• Paint, varnish and gasket remover sprays

• Dye, developer and cleaner sprays for NDT

• Black magna ink and white background paint for MPI.

Space and other infrastructure requirements

To set up a production facility, an area of around 5,000 sq.ft. is required for storage of raw materials, finished goods, processing area, despatch station, R&D or analytical and QC lab etc. However, an area of around 500 sq. ft. is adequate only for trading activity.

Power-related requirement for aerosol filling plant

• Compressor: 5 HP

• Other pneumatic machine: 5 HP

• Flame-proof electrical fitting.

Promtech services of know-how transfer includes:

• Raw materials sourcing details

• Paints and thinners, additives sourcing details

• Formulation techniques and formulating details

• Plant setting up and 1 day trial production run

• Troubleshooting techniques for plant machinery

• Techniques for overcoming formulation problems

• Supply of its approved raw materials

• Technical and laboratory training when needed

• Promtech Consultancy also offers marketing assistance through b2b portals, email marketing.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.