Proportional directional valves for wind turbines

By Edit Team | September 16, 2023 4:19 pm SHARE

The heart of hydraulic pitch systems for blade angle control in wind energy production.

The hydraulic pitch system modulates the blade’s angle in response to changing wind conditions, ensuring maximum efficiency regardless of the wind speed.

Proportional directional valves are the key component of hydraulic pitch systems, as they must ensure accurate and high dynamic control of the blade angle in the presence of high mechanical stress, typical of onshore and offshore wind turbines.

Wind turbine: hydraulic pitch system to optimise energy production from the wind

The global push towards sustainability has led to increased interest in alternative power sources other than coal and fossil fuels. One of these sustainable sources is to exploit energy from the wind through wind turbines by converting wind movement into electrical current thanks to the rotor blades and a power generator. As the wind energy source is not constant, wind turbines are modulating the angle on the blades (“pitch angle”) to optimise their power generation in response to changing wind conditions. The hydraulic pitch system, located within the turbine hub, rotates the three variable-pitch turbine blades to precisely control the generator speed based on a feedback signal. This ensures that the electrical power required by the consumer is produced regardless of varying wind speeds, optimising the energy yield as well as reducing the mechanical load, thereby extending the wind turbine service life.

Electrohydraulic solutions for pitch control

A hydraulic pitch system provides an efficient and reliable way to control the pitch angle of a wind turbine, as it meets requirements for long-term operative life, allowing for accurate and high-performance control of the pitch angle.

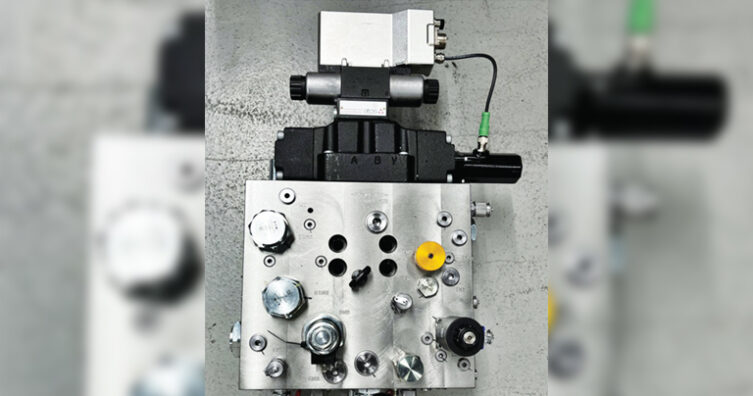

With a hydraulic pitch system, the angle of the rotor blades is changed via hydraulic cylinders: the supply source is in the fixed zone of the nacelle, while the actuator of each blade rotates with the hub.

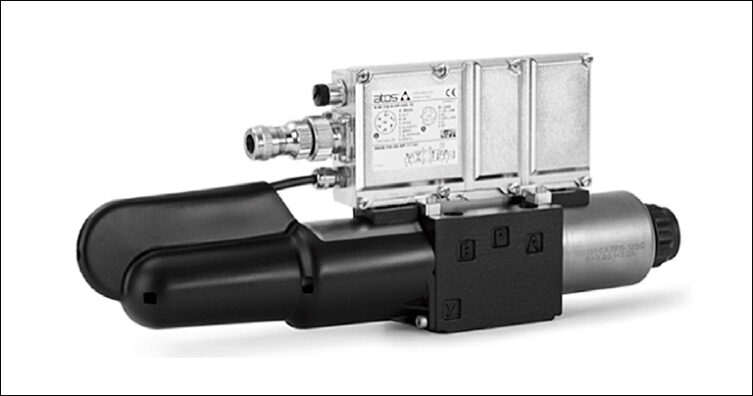

The proportional directional valves are the key component of the system, designed to ensure accurate and high-dynamic control of the actuator position. Reliability is another key factor as proportional directional valves operate in the presence of high mechanical stress. Being in the rotating turbine hub, they are exposed to heavy vibrations, shocks, and rotational forces, as well as being subjected to lightning strikes. Also, proportional directional valves must be designed to operate in critical environmental conditions, like in northern regions or marine areas characterised by low temperatures and high humidity.

Atos proportional directional valves

The key features of these valves include impressive responsiveness combined with accurate and repeatable spool position precision. They are built for robust durability, having successfully passed mechanical stress tests for both sine/random vibrations (EN 60068-2-6) and shocks (EN 60068-2-27). Additionally, they adhere to the full EMC compliance standards outlined in EN 61000-6-2, -3, and -4.

These valves also possess heightened resistance against lightning disturbances per EN 61000-4-9, as well as safeguarding capabilities against disruptions linked to medium- and high-voltage substations as per EN 61000-4-10. Classified as IP66/IP67, they offer protection against dirt, grease, and moisture.

They boast an expanded operational temperature range that can withstand temperatures as low as -40°C. With the added advantage of remote advanced diagnostic capabilities, facilitated through an integrated oscilloscope and a comprehensive alarm history, these valves provide enhanced insight into performance.

Furthermore, these valves come equipped for seamless Fieldbus communication, supporting CANopen, PROFIBUS, EtherCAT, POWERLINK, EtherNet/IP, and PROFINET protocols. Thanks to their digital electronics, these valves allow for customised flow output and performance adjustments, ensuring compatibility with a variety of turbine requirements and existing control parameters.

Atos digital proportional valves are the preferred choice for hydraulic pitch systems by several wind turbine manufacturers worldwide, who appreciate their superior performances and reliability, the results of years of R&D, and successful field experiences.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.