Reduces belt wear, increasing efficiency, productivity, and safety

By Edit Team | November 1, 2022 1:47 pm SHARE

Anto Sebastian, CEO of JAWS Tech Engineering, speaks about their intention to continue creating highly wear-resistant tooltips for crushing and mining applications in this product category.

Can you talk about your solutions for the mining sector?

Team JAWSTECH believes in continuous improvement and added value, so we analysed the mining industry and understood that wear and tear and the resulting failure are the biggest enemies of this sector. We approached this problem in a structured way and developed various wrades of polyurethane wear liners, crappers, skirt boards, flip flops, modular screens, other accessories,

etc. It will offer our clients guaranteed wear protection for their chutes, screens, and carry-point systems. So, it will reduce operating costs by extending service life, reducing personnel costs, and minimising downtime.

What does this added value mean?

What does this added value mean?

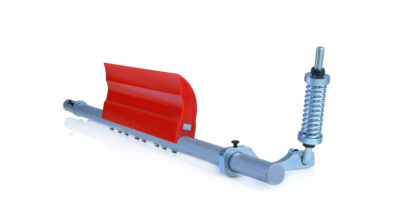

Yes, we can demonstrate this with the JAWS primary scrapper series. This is simply a scraping mechanism for conveyor systems that aid in removing carrybacks and reduces belt wear, increasing efficiency, productivity, and safety. It makes conveyor systems cleaner, safer, and more productive. It simply transforms carrybacks and spillage into marketable goods. That is what we mean by adding value to the process.

What are the major misconceptions in the industry in your aspect?

When it comes to polyurethane and related wear parts, many people believe that only one type of POLYURETHANE GRADE can be used in all relevant applications. This is a colossal blunder, and Chinese and a few Indian firms primarily promote it. We can develop this elastomer in a variety of ways and a variety of grades. All application parameters should be considered in the design, polymer selection, and formulations, or the product will fail sadly .

Except for these polyurethane-based products, what else do you offer?

We have a wide range of revolutionary tungsten carbide product lines. We created highly wear-resistant tooltips for crushing and mining applications in this product range. We concentrate on tool holder casting metallurgy and tungsten carbide powder metallurgy so we can offer a more robust product range with better TPH support. We are open to innovation; there is a general saying it will be impossible unless we try. We can say until now, we have jumped over a lot of hurdles by breaking the design and production of conventional verticals with an innovative approach. To our clients, we offer tailored solutions by analysing their pain points.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.