Reliable joints in precast with Dextra’s Unique GROUTEC Coupler Solution

By Edit Team | May 24, 2023 4:48 pm SHARE

In the article that follows, it is discussed how crucially important it is to use GROUTEC coupler solutions in precast structures to get solid joints.

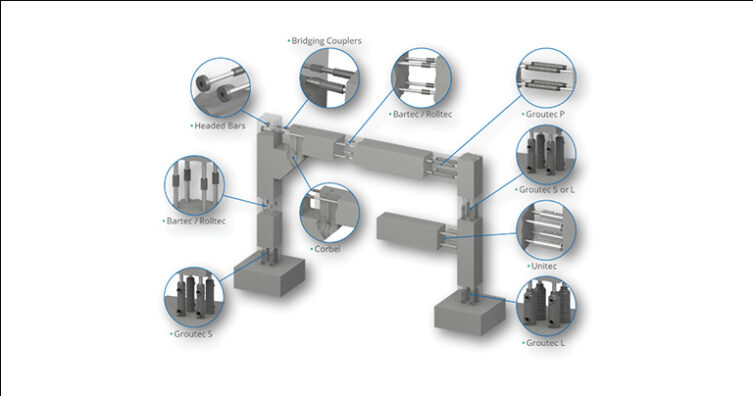

In Dextra’s customer-centric, innovative, and customengineered product portfolio, yet another efficient product has been qualified and tested successfully over the years in several major infrastructure projects. With the ongoing development and changing the momentum in the Indian precast industry, we are seeing an increase in the application areas of precast construction methods in construction infrastructure projects, including residential or commercial buildings, data centres, process plant pipe racks, mass housing projects, and many others. One of the key factors contributing to the success of precast construction is connection joints, where Dextra Groutec Coupler has a significant role. Below are some of the key features of the Dextra Groutec Coupler:

Groutec is a mechanical splicing system specially designed to connect two precast elements. Moreover, it doesn’t require in situ wet concrete to join.

GROUTEC Couplers

Groutec is designed and manufactured in compliance with Eurocode 2, BS 8110, ACI 318, IBC, and AASHTO, and is available in three variants:

• Groutec L: It has a larger tolerance that allows a greater axial misalignment in the cast.

• Groutec S: Its slim body facilitates easy installation with slim columns and panels.

• Groutec F: It is fully grouted and does not require any threading on the rebars.

All of the above mentioned products can be used with non-shrink grouts that are readily available from major manufacturers. Additionally, all couplers are marked with a code that is primarily used to trace all information related to the projects, such as material certificates, inspection and test reports, and mould numbers, among others.

The design files are compatible with CAD & BIM tools.

Pipe rack application

Pipe racks are a convenient way of routing overhead piping. It is a very popular solution in the oil and gas industry to support pipes carrying various gases and liquids. Owing to the high cost of steel construction, made even higher by fireproofing requirements and increased time, precast concrete pipe racks are the talk of the town in processing plants. The superstructure of a pipe rack is mainly composed of columns and traverse beams, making prefabrication the ideal solution for fast and inexpensive construction and installation.

Case Study – RIL Jamnagar Refinery Execution methodology

Installation on Reinforcement In this project, Groutec couplers were specifically used to connect precast elements vertically, composing the H frames of the pipe racks.

The couplers were installed on the reinforcement bars in the precast yard itself.

Couplers are then cast in concrete after the formwork is closed.

These precast elements were then carried to the site, where further erection took place. The top element was positioned over the bottom one.

The next step is to pour the grout (Sika grout in this case) into the couplers. When we start lowering the top element, its protruding bars get inserted into the cavities of the coupler and make the grout overflow. This assembly is then temporarily maintained with braces until the grout is dry.

Couplers were certified by IAPMO, which was a mandatory specification in this project.

Key benefits of GROUTEC

• At least 3x faster construction cycles compared to cast-in-place.

• Reduced grout consumption with desired results in fewer man-hours

• Safe. Only short protruding bars.

• Engineered shape for an optimal concrete bond.

• Cope with bar misalignment.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.