Revolutionising shot-blasting equipment for industries

By Edit Team | July 12, 2023 2:33 pm SHARE

We provide customised solutions optimising shot blasting, boosting efficiency and effectiveness for our valued customers.

Shot blasting is crucial in several industries, including foundries, automotive, railways, power, construction, and agriculture. In India alone, there are approximately 5500 to 6500 foundries, with 85 percent classified as small and medium enterprises. These foundries produce a staggering 13 million tonnes of castings, positioning India as the second-largest global market after China.

Comprehensive shot blasting solution with quality and reliability

Indabrator, a renowned manufacturer of shot blasting machines and surface preparation equipment in India, has established itself as a trusted provider of comprehensive Surface Preparation solutions. With over five decades of experience, the company is known for its commitment to quality, reliability, and customer satisfaction. Indabrator’s robust machines, rigorous testing procedures, and comprehensive after-sales support have solidified its position as a leading player in the industry.

Versatile application benefits of shot blasting machines

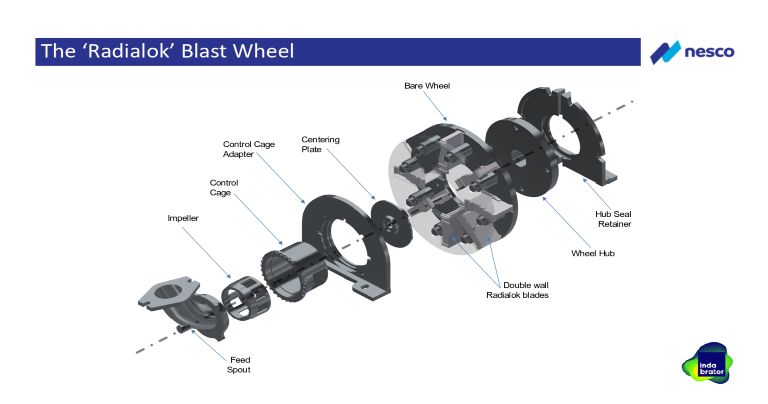

Our extensive range of shot-blasting machines is designed for various applications and industries. Our product portfolio includes airless shot blasting machines, wheel blasting machines, and tumble blasting machines. Each machine is engineered to deliver efficient surface cleaning, peening, deburring, or finishing by propelling abrasive media at high velocities. Indabrator’s diverse product lineup ensures that customers can find the ideal solution to meet their specific needs, whether it’s for small-scale operations or large-scale industrial applications.

Commitment to quality and innovation

Our commitment to delivering top-quality products is evident in its operations. The company utilises robust materials and employs rigorous testing procedures to ensure its machines’ optimal performance and durability. By maintaining strict quality control measures, Indabrator consistently meets and exceeds industry standards, instilling confidence in customers that their equipment will deliver exceptional results over the long term.

We understand the importance of providing comprehensive after-sales support to its customers. The company goes beyond the initial purchase by offering maintenance services, spare parts, and technical assistance. The availability of prompt support and expertise from Indabrator’s service team enhances the overall ownership experience, strengthening customer relationships and fostering trust in the brand.

Indabrator innovations in R&D

Indabrator’s expertise extends across various industries, including automotive, foundries, steel fabrication, aerospace, railways, and shipbuilding. Our ability to customise solutions to meet specific requirements has made it a preferred choice across these diverse sectors. By understanding each industry’s unique challenges and needs, we deliver tailored solutions that optimise the shot blasting process, resulting in enhanced efficiency and effectiveness for its customers.

Innovation is at the heart of our operations. We at Indabrator invest in research and development to stay ahead of emerging trends and technological advancements in shot blasting. By harnessing the latest technologies and innovative approaches, Indabrator continuously introduces cutting-edge solutions that push the boundaries of surface preparation. These advancements not only improve the performance and efficiency of the machines but also contribute to reducing environmental impact and increasing sustainability in the industry.

Indabrator’s long-standing presence and commitment to excellence have solidified its position as a leading manufacturer of shot-blasting machines and surface preparation equipment in India.

This article has been authored by Nirav Lad, General Manager – Sales, Indabrator

For more details, visit: http://www.indabrator.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.