Innovative technologies taking bridge building to new level

By Edit Team | July 8, 2017 7:45 am SHARE

Featuring some of the advanced technologies that help executing bridge construction at ease

With innovative technologies, the roads and bridges construction has come to a new level. China Railway Corporation’s giant bridge building machine – known as ‘The Iron Monster’ – has created a sensation in the field of bridge building. The construction of 1,376 km high-speed railway connecting Chengdu with Guangzhou that crosses mountainous valleys is realised thanks to ‘The Iron Monster SL900/32’.

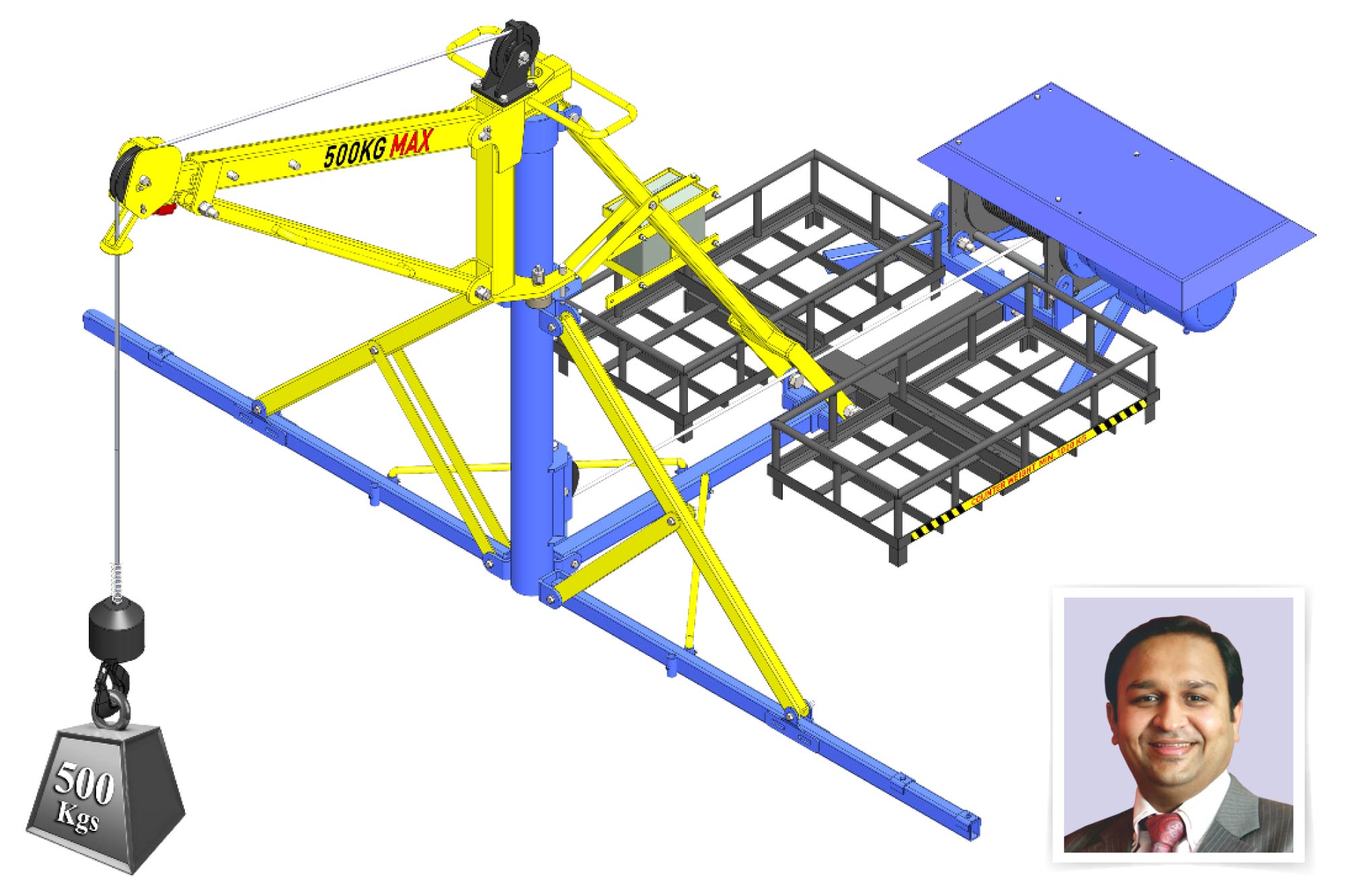

In India, crane maker ElectroMech has been involved in the execution of massive infrastructure projects. The Signature Bridge project in Delhi, Loknayak Ganga Path project in Patna, Mandovi River Bridge project, Zuari River Bridge project and Bajoli Holi Dam project are some examples of ElectroMech’s projects in recent times.

Gantry cranes with unique design

ElectroMech has supplied 60-tonne SWL modular gantry cranes for the Signature Bridge project and the Loknayak Ganga path project. According to Tushar Mehendale, Managing Director, ElectroMech Material Handling India Pvt Ltd, “The unique feature of SWL modular gantry cranes is their ability to be configured in four different combinations of spans and heights of lift. This unique design allows the end user to use these cranes across different areas of the project as well as different project sites,”

ElectroMech cranes are also making possible the construction of the 3rd bridge over the river Mandovi in Panjim, Goa. The company has supplied two 125-tonne gantry cranes in the precast yard of the project. These cranes have a span of 30-metre and are used for handling precast segments and for loading these onto trailers for transportation to the construction site. At the bridge construction site, ElectroMech has also supplied a specially designed 150-tonne Gantry crane that is mounted on the launching girder. This 150-tonne crane has a height of lift of 35-metre and is used for lifting the segments from the low bed trailers and hoist them into position for the bridge construction. According to Tushar, the unique feature of this crane is its ability to precisely position the segment within a tolerance zone of 1 mm on account of its unique hydraulic cross travel mechanism.

ElectroMech has also provided three nos. of 100 / 20-tonne Gantry cranes for the upcoming iconic Zuari Bridge project in Goa. These cranes have spans of 25-metre and 18-metre and will see action in the precast yard.

Earlier several smaller pre-cast segments were put together for a single span during bridge construction. But now, with newer design and R&D advancements, larger width segments are cast beforehand (horizontally wider to accommodate more lanes). This means that for Indian contractors’ cranes that can handle 120-tonne to 150-tonne of precast segments vis-à-vis 60-tonne segments, which were a standard previously, have become the need of the day.

Cranes that can accommodate such larger requirements along with newer configurations for auxiliary hooks, etc. are also needed. These cranes must be able to handle the weight requirements while being safe and effective.

Soil compactor with advanced features

With a focus on building new highways, compactors, wheel loaders and graders are in high demand for quality road construction. Equipment manufacturers are trying to innovate and adapt to latest technologies while improving the efficiency of the machines as time-bound projects need reliable machines.

CASE has introduced 1107EX soil compactor that ensures powerful, fuel-efficient performance. CASE 1107EX features a new FPT Industrial S8000 3.9-litre engine that delivers 100 HP at 2,200 RPM and torque of 435 Nm at 1,300 RPM.

“The soil compactor is also available with advanced features such as the compaction meter and Eagle Eye Telematic System, a real time vehicle tracking and communication based on GPS technology that helps deliver better value for money,” explains Shalabh Chaturvedi, Head of Marketing, CASE India.

Crawler dozers with hydrostatic transmission technology

CASE India has recently launched new models of crawler dozers ranging from 13-tonne to 20-tonne of operating weight with “Hydrostatic Transmission” technology, powered by a 6.7-litre 6-cylinder engine engineered by FPT Industrial. This Tier III FPT Industrial engine introduces new features and upgrades that raise the bar on performance, and deliver market leading fuel economy and power. “The turbocharged engine with an air-to-air intercooler features a well-proven multi-injection technology to maximise torque back-up under load. The result is consistent performance, higher pulling capacity and an ability to work with high torque at lower engine rpm reducing long term engine wear,” Chaturvedi said while explaining the unique features of CASE India’s new crawler dozers.

Plastic formwork systems

In bridge building, though a lot of innovation took place in the machinery segment, Ashesh Mittal, Marketing Director at Wonder Mold Plast Pvt Ltd believes the innovations are mainly in the precast structure, steel structures and suspending bridges. He adds, “In case of cast-in-situ, it is majorly to do with the supporting system of the formwork, so that the system can provide the best support which ensures utmost safety and which is also easy and faster to install.”

Explaining the advantages of plastic formwork systems, he said, “Nova plastic formwork is easy to use and easy to remove after casting. The main issue arises with conventional formwork is the weight of the formwork due to which it becomes difficult to de-shutter after casting.”

Wonder Mold Plast offers plastic formwork systems which are light weight and can be used with the existing supporting system used by the contractors. The company also provides supporting system as per the requirements of the projects. “We provide plastic formwork which gives the ease in fixing as well as deshuttering,” adds Mittal.

Tushar Mehendale, Managing Director, ElectroMech Material Handling India Pvt Ltd

The unique feature of SWL modular gantry cranes is their ability to be configured in four different combinations of spans and heights of lift.

Shalabh Chaturvedi, Head of Marketing, CASE India.

The soil compactor is also available with advanced features such as the compaction meter and Eagle Eye Telematic System, a real time vehicle tracking and communication based on GPS technology that helps deliver better value for money.

Ashesh Mittal, Marketing Director, Wonder Mold Plast Pvt Ltd

Nova plastic formwork is easy to use and easy to remove after casting. The main issue arises with conventional formwork is the weight of the formwork due to which it becomes difficult to de-shutter after casting.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.