Road Making goes hi-tech with Smart Machines

By Edit Team | June 19, 2018 7:31 am SHARE

Compulsion and keenness of faster growth in road construction industries needs innovation in technologies, which help to construction professional to work smarter, not harder to get improve construction productivity.

Roads and highways continues to be a strong growth driver for the construction equipment industry and many big ticket projects have been announced and implemented by the government in this sector. However, ensuring timely completion of these projects not only demands the best quality output, but also creates a need for specialised, intelligent and technologically advanced construction equipment.

Technology manages project complexity

Infrastructure projects are complex and have a unique set of requirements. Contractors working on these types of projects need to be aware of regulations, safety mandates and so much more in order to succeed. According to Pankaj Udeshi, Asst. General Manager Procurement, Supreme Infrastructure India Ltd, it is important for transportation contractors to realise that with the promise of more projects, comes the expectation to deliver these projects faster and in line with increased regulations (such as safety, quality, and transparency). They will not be able to meet the increased demand and delivery expectations using the same processes and technologies they always have. This is where technology comes into play.

“Technology can help solve the challenges of managing project complexity. Software enables contractors to streamline workflows, improve operational efficiency tied directly to capital equipment and resource utilisation, eliminate paper, and move to more digital processes. All this will result in improved margins. Perhaps one of the most important tools on the construction jobsite today is the data that exists,” acknowledge Udeshi Today, technology offers contractors a wealth of information that can make construction methods more efficient. Now, it is a matter of leveraging the data to improve business processes. As the availability of data increase, the sophistication of technology will allow companies to utilise this abundant information to drive significant highway construction efficiencies.

Some of the most costly inefficiencies of the past revolve around equipment breakdowns and rework. For the 21st-century contractor using GPS (Global Positioning Software) and preventative maintenance solutions, equipment breakdowns are happening at a much lower frequency. Rework is also reduced, as the construction foremen now have access to the plans created all the way back in the estimating process. “Going forward focus will be on aligning national standards for design, construction, maintenance and operation of roads, bridges and flyovers with the global standards to bring down the cost of construction while maintaining high standards of quality through adoption of innovative technologies and materials for road construction,” says Udeshi.

Priorities are set and met by collaboration of technologies

Technology has changed the challenges of infrastructure. Technology has become a disruptive and powerful source of innovation and renewal for the industry. The way that priorities are set and met has been transformed by the collaboration of technology in road building sector. Like any other industry, the construction industry is changing and being shaped as a result of new technologies. Updates and upgrades in computer-based applications, as well as advancements in all disciplines of engineering, mean that today’s construction industry is more reliant on new technology than ever before.

There are a growing number of innovative new tools tailored for the construction industry that improve safety, enable access to plans and blueprints on the go, and help teams collaborate. Ratan Lal Kashyap, Sr. Vice President – Procurement, G R Infraprojects Ltd opines, “The technology enablers will rule the engineering, construction and operations world in the near future. The major role for technology is as an embedded technology in hard infrastructure assets (roads, railway lines, bridges). This will enable the asset owners to be continually being informed of their asset’s condition and the use of those assets. With lot of mechanisation and drastic change in construction methodology the resource manpower requirement will gradually diminish. With very fast changing technology the existing assets became outdated and there is always a challenge of procuring new assets with latest technologies to run with time. This would also lead to frequent changes on construction methodologies which would need continuous or regular training of manpower.”

Disruptive technologies result in fast and efficient equipment

Technological advancement is the need of the hour and is happening in every sector. Ajay Aneja, Brand Leader, CASE India says, “With technology coming into the picture there would be improvement in the quality of work and the cost savings and profitability would be more. Realising the importance of technological upgradation and innovation, construction equipment companies are increasingly taking action and the results are fast and efficient equipment.”

Technology ensures good quality and longer life time of roads

Ramesh Palagiri, Managing Director & CEO, Wirtgen India informs, “Relevant technology is always important for completing projects on time, and also ensuring that we have good quality and longer life time for the roads. Wirtgen Group has been involved with the road development in India since the golden quadrilateral days starting with the Mumbai – Pune Expressway. Wirtgen slipform pavers have several innovations like the automatic Dowel Bar Insertor system DBI, super smoother, central tie bar inserter, oscillating beam etc.”

Advanced technologies for Indian roads

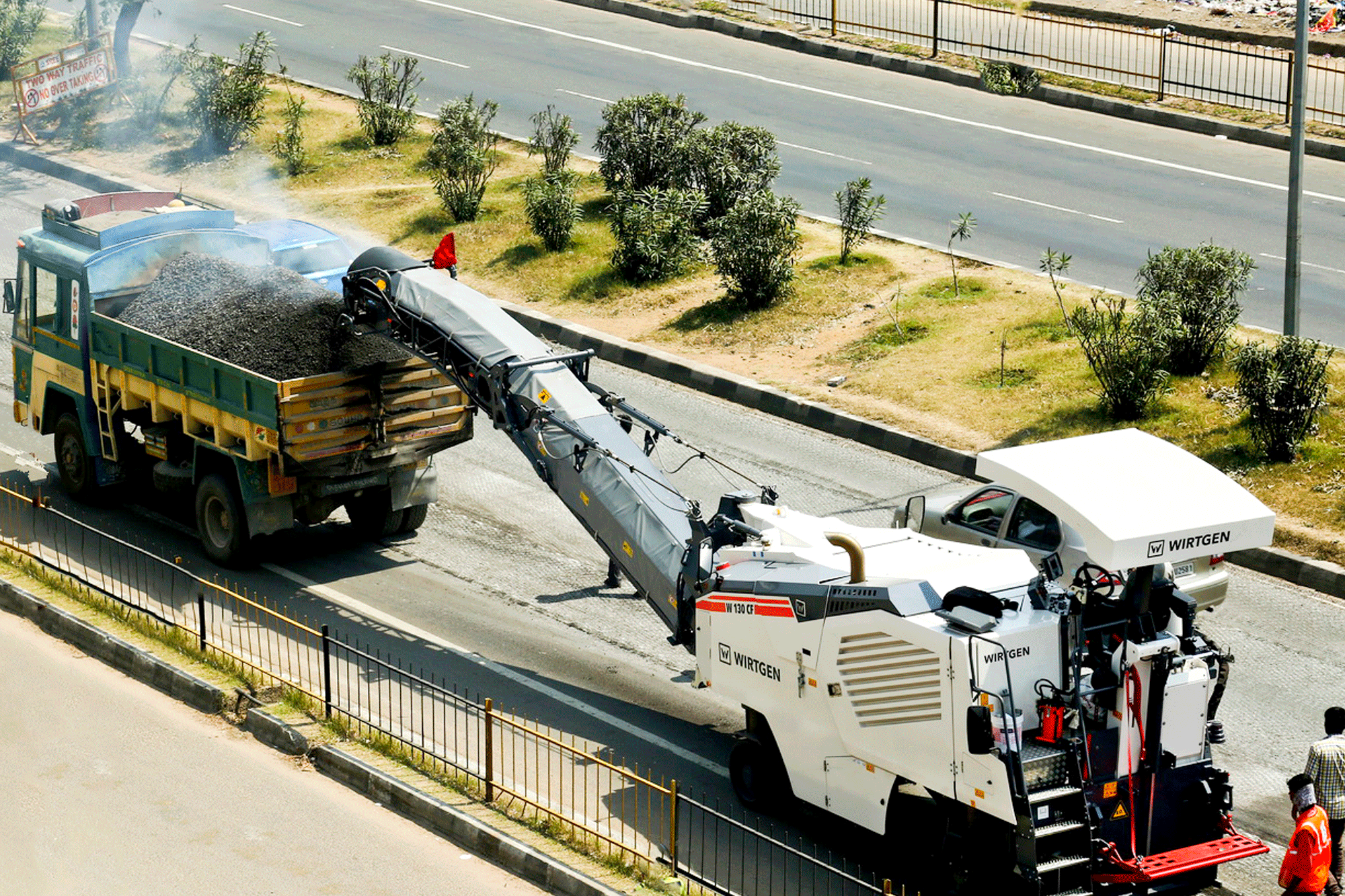

Making smart road with road milling technology

GRIL is one of the pioneers in the industry in using the latest techniques and machineries to make roads of the future. The use of new technology and construction methodology has given opportunities for construction equipment manufacturer to benchmark and introduce equipment being used in developed countries. Kashyap says, “One of the important technologies which help in making the roads smarter are introduction of road milling technology i.e. milling machine has helped use of reclaimed asphalt pavement (RAP) which was a waste and damage to environment when dumped on road side. Another technology used is the foam bitumen technology which involves bituminous paving mix recipe by injection of bitumen in the form of foam into the aggregates predominantly constituting the scrapped or milled aggregates from the existing road. Advantages of this technology are utilisation of up to 90 per cent of reclaimed aggregates, thereby reducing the fresh material requirement and reducing the carbon footprint by using cold mix and lesser emission of fumes or greenhouse gases – GHG (CO2, SO2, NOx and more).”

He adds, “Soil stabilisation is another technology which is used for improving the physical properties of soil by mechanical or chemical means. It improves the load carrying capacity of soil. Warm mix technology is another technology adopted where the flexible pavement can be laid at a lower temperature without affecting the workmanship and quality of road. Fleet of future ready hot mix plants with options of producing several types of mixtures with additive dosing facilities, keeps the carbon emissions with limits with minimum emission and pollution to the environment. The problem of hauling of hot mix from distant located plants have been mitigated by use of warm mix technologies with no risk of fall of temperature of mix. Live monitoring of all the equipment deployed, GPS fitted fleet helps coordinate better logistics and mitigates any disconnect within the working ecosystem.”

CASE’s compactors: Perfect suit for Indian roads

CASE’s compactors are known for their excellent fuel efficiency, unmatched reliability, high centrifugal forces, and all round visibility. They are easy to operate, maintain and offer excellent operator comfort. With dual-drum drive technology, multiple amplitude and frequency combinations and impressive manoeuvrability. CASE compaction product range is of the top-class quality and perfectly suited for Indian roads. Aneja says, “CASE is proud to be the only company to achieve the milestone of delivering more than 11,000 Vibratory Compactors and 5,000th Vibratory Tandem Compactor. Keeping up with the previous models, CASE launched its 752 EX Vibratory Tandem Compactor in EXCON 2017.”

CASE 752 EX with new generation engine

The CASE 752 EX is equipped with a fuel-efficient 3.9-litre 4-cylinder engine, with a mechanical injection system and internal exhaust gas recirculation that delivers 76 HP at 2,200 RPM and torque of 332 Nm at 1,300 RPM. This new-generation engine is developed by CNH Industrial subsidiary FPT Industrial, one of the world-leading manufacturers of engines, transmissions and powertrains — provides outstanding performance, fast response times, and best-in-class fuel economy. The 752 EX’s operator compartment features a rotating operator seat and tiltable steering which gives excellent front and rear drum/nozzle visibility, making the drive and compaction process easier and safer. The look of the machine is enhanced by foldable canopy for ease of transportation, new fuel and water tanks and new sophisticated instrument cluster.

Cold Milling and Cold Recycling technologies

The Wirtgen Group has been consistently trying to develop products which offer better efficiency in terms of fuel consumption and this helps in sustainable development and less carbon emissions, and also the machines contribute towards reduction of use of aggregates and also in the reuse of existing bitumen with the Cold Milling and Cold Recycling technologies.

The average age of any of the Wirtgen Group products in the market is around 2 years, which means that most of the products are from the new generation and in most cases, the Wirtgen Group products are at least a generation ahead of competition. The company is introducing these new gen products to help the customers with improve productivity and reduce their operating costs.

Dual-layer concrete paving with Wirtgen slipform paver

Wirtgen Group is one of the pioneers in the field of technologies for road building, both for asphalt and as well as concrete paving. Palagiri informs, “With the focus of the current government on concrete paving we can offer Wirtgen slipform pavers with lot of innovations like the Dowel Bar Insertor system (DBI), super smoother, central tie bar inserter, oscillating beam etc. We have slipform pavers paving from a width of 1.5 metres to 16 metres and we are pleased to inform that all these are currently working in India at different project sites.” The Wirtgen slipform pavers can now offer Dual-layer concrete paving, where a single machine is used for dual layer concrete paving; the bottom layer and the top layer concrete are paved in a synchronised operation. It is additionally ensured that both the top and bottom layers are paved “Wet-in-Wet” regardless of weather or site conditions. This can be done with single paver or with two pavers where it is necessary to distribute the operating weight to two separate machines.

The Cold Recycling reuses 100 per cent of asphalt pavement material and only addition is bitumen 2-3 per cent which rehabilitates the asphalt pavement to its original properties. Hot re-cycling is an economical and environment friendly rehabilitation method for asphalt surface courses where many types of surface damages like rutting, cracking, lack of skid resistance, pavement irregularities, excessive bitumen, etc can be repaired on a large scale in a short period of time. The first Wirtgen hot recycler has arrived in India and the project would shortly start.

Ideal solution for rehabilitation of heavily travelled roads

For asphalt paving, Wirtgen have the new generation Dash 3 pavers with features like the Ergo plus operating system, Pave dock assistant, Autoset plus and multiplex. For Cold milling technology the company have the new machine W 130 cf, also all the milling machines are equipped with level pro system which ensures perfect levelling quality at high operating speed and a quick change tool holder system HT 22. The VOGELE – In Line paving where the binder and surface courses are paved “hot on hot” in a single pass, greatly accelerating activities on a job site. In addition, it is not necessary to completely close down the road: the three machines – a paver for the binder course, a paver for the surface course and a material feeder – work “In-Line”, one behind the other, leaving one lane open to traffic. The process is both economical and highly eco-friendly, the layer thickness can be reduced in “hot on hot” paving, thus lowering consumption of the costly surface course mix.

The innovative VÖGELE SprayJet technology is helpful where bitumen emulsion can be sprayed and overlaid with an asphalt surface course .The special advantages of the innovative VÖGELE SprayJet technology lie in its cost-efficiency and excellent environmental credentials. The process optimises the placement of thin, resource-saving and low-noise asphalt layers.

Palagiri says, “We have introduced the Cold Milling and Cold Recycling technologies and these two technologies are reasonably well accepted in the market. Soil stabilisation is also becoming very popular and all these technologies result in saving resources, faster construction and cost economical solutions. The Cement Treated Base or Sub Base (CTB or CTSB) not only reduces aggregate requirement, but also ensures stronger foundation and reduces layers.”

Building next gen infrastructure with JCB’s smart machines

JCB introduced a wide range of innovative and intelligent such as a digitally advanced 11-tonne Soil Compactor, 5-tonne Wheeled Loader, 38-tonne Tracked Excavator and a Backhoe Loader with many world’s first features. This range of smart machines exhibits a blend of technology and digital innovation to meet the demand for world-class machines to build India’s next gen infrastructure.

For instance, during Excon 2017, the largest exhibition in South Asia for the construction equipment industry, JCB introduced Compaction Monitoring System integrated with Livelink in its 11-tonne Soil Compactor – the JCB 116. This has been introduced for the first time in the Indian construction equipment industry. This innovative system provides relative compaction value which helps in achieving consistent and uniform compaction throughout the patch. JCB Compaction Monitoring System digital display shows high or low frequency and amplitude values for compaction control. This versatile system is suitable for both asphalt and soil surface. Similarly, the 455ZX Wheeled Loader, the Loader Productivity Management System (LPMS) helps in real time monitoring of individual weight of loaded bucket, total accumulated weight, tare weight and number of loaded buckets.

JCB’s Livelink: Advanced Telematics technology

JCB introduced the iconic JCB Backhoe Loader with 30 new innovative features, including 15 industry firsts and five World’s first including an AMT which is an Automated Manual Transmission called Easy Shift. Apart from this, this world class machine comes with as an SOS switch, Economy and Power Mode, Guide me home, and Smart App machine Diagnostics. JCB has further strengthened its position in the excavator segment by introducing an all new 38-tonne Tracked Excavator with two variants – the JCB 380LC Xtra and the JCB 380LC Quarry Master (QM). This is JCB India’s largest Made in India Excavator.

Jasmeet Singh, Head Corporate Communications and External Relations, JCB India explains, “JCB is fully embracing the convergence of digital and traditional technologies and is pioneering the way. It is leading the integration of Internet of Things and Big Data in its products and services through an Advanced Telematics technology called JCB Livelink.”

He adds, “JCB LiveLink not only gives users the location of their equipment at all times, but also relays back all machine related information to the customer. This technology aims to deliver constructive, real-time information to increase productivity and efficiency. Users, dealers and JCB get SMS alerts on their phones regarding the service, operations and security of their machine. JCB India is the first manufacturer in the Indian construction equipment industry to introduce Internet of Things at this scale.” Today, over 75,000 Livelink enabled machines are working successfully in India. To monitor these machines in real time, the company has set up a world class command centre at Ballabgarh facility. JCB’s dealerships have also set up similar Livelink command centres to ensure that real time support is provided to the customers as they can now plan for service schedules and also engage with users and customers in preventive maintenance.

Volvo P5320B ABG: Tracked sensor paver

“Road building contractors are being pressurised to increase productivity both in the size of the roads they build and the speed with which they complete them. At Volvo Construction Equipment (Volvo CE) we are pleased to be introducing advances in our own technology for road building machines. Our company is widely regarded as one of the leading innovators in the field of Construction Equipment and we aim to maintain this position into the future,” informs Dimitrov Krishnan, Vice President and Head of Volvo CE India. Vovlo CE’s latest product for the road building industry is the P5320B ABG paver. Innovations on the unit include load-sensing hydraulics so that hydraulic output is perfectly matched to all components. An automatic hydraulic track tensioner delivers smoother operation while simultaneously reducing wear and downtime and there are a host of other innovative features and benefits on the unit.

The P5320B ABG pavers, along with the P4370B ABG are both manufactured at Volvo’s plant in Bangalore. Both models deliver maximum paving widths of 7 metres, a paving output of 600 tonnes per hour and are powered by an 88 kW engine, which delivers high power with minimal noise and low fuel consumption. The P5320B ABG is a tracked sensor paver which delivers a basic paving width of 4.5 metres, while the P4370B ABG is a wheeled sensor paver which delivers a basic paving width of 2.5 metres. Volvo CE has an advanced research and development program that has built up over the years and is demonstrated in the industry leading productivity and fuel efficiency levels the company delivers. This superior productivity and fuel efficiency is helping drive advancement in the road building industry.

CareTrack designed to enhance customers’ businesses

CareTrack is a telematics system that gives equipment owners access to a wide range of machine monitoring information that can help save time and money. The system generates a wide range of reports with data on aspects such as fuel consumption, operational hours, geographical location and more. These reports are available via a web portal or can be received via SMS or email alerts. CareTrack can also be used to manage machine servicing and wear parts. This allows fleet managers to reduce fuel costs, optimise machine and operator performance, as well as proactively manage service and maintenance to maximize uptime. CareTrack is offered not as a standard practice but as specialised packages designed to enhance customers’ businesses.

According to Krishnan, “Customers say they like the insight CareTrack provides, which supports them with maintenance, invoicing, fleet management and operator training. With CareTrack, customers can monitor load efficiency, number of cycles, overload percentages and identify operator training needs. For example, CareTrack can tell owners what time the machine operation starts, takes a break, and ends. What’s more, CareTrack allows owners to tap into a wealth of actionable data including fuel consumption, idle time, machine location, fluid levels and service alerts. With the time and labour savings CareTrack offers, customers say they view it as an investment rather than extra costs.”

As owners are pushed to deliver more with less, CareTrack is a great way to proactively manage machines and increase uptime by planning service and maintenance requirement in advance, avoiding potential problems. It’s also possible for Volvo CE dealers to troubleshoot faults remotely minimising service and downtime. Krishnan opines, “Into the future, it’s difficult to say exactly how new technology will change the industry but in broad terms Volvo’s pursuit of electrically-driven vehicles could be a game changer. Recently, our company unveiled the world’s first fully-electric compact excavator, the EX2, which is equipped with electric drive systems and electromechanical linear actuators.”

He adds, “Our work on autonomous machines has also produced very positive results and could have serious ramifications for the road building industry. In 2016, we introduced the HX1, a concept loader that laid out our vision for the future. With so many duty cycle operations in road building it stands to reason that some form of autonomous operations could benefit this field in future.”

One of the most important tools on the construction jobsite today is the data that exists.

Pankaj Udeshi, Asst. General Manager Procurement, Supreme Infrastructure India Ltd

The technology enablers will rule the engineering, construction and operations world in the near future.

Ratan Lal Kashyap, Sr. Vice President –Procurement, G R Infraprojects Ltd

Realising the importance of technological upgradation and innovation, construction equipment companies are increasingly taking action and the results are fast and efficient equipment.

Ajay Aneja, Brand Leader, CASE India

Relevant technology is always important for completing projects on time, and also ensuring that we have good quality and longer life time for the roads.

Ramesh Palagiri, Managing Director & CEO, Wirtgen India

JCB is fully embracing the convergence of digital and traditional technologies and is pioneering the way.

Jasmeet Singh, Head Corporate Communications and External Relations, JCB India

Our work on autonomous machines has also produced very positive results and could have serious ramifications for the road building industry.

Dimitrov Krishnan, Vice President and Head of Volvo CE India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.