SABIC launches new LNP™ compound offering easy plating with lds

By Edit Team | May 23, 2022 12:04 pm SHARE

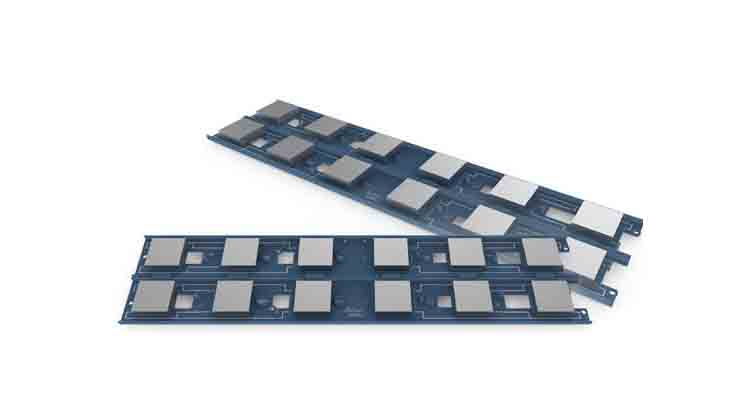

SABIC, a global leader in the chemical industry, today introduced LNP™ THERMOCOMP™ OFC08V compound, a material well suited for 5G base station dipole antennas and other electrical/ electronic applications. This new compound can help the industry develop lightweight, cost-effective, all-plastic antenna designs that facilitate deployment of 5G infrastructure. In an era of increasing urbanisation and smart cities, broad availability of 5G networking is urgently needed to provide fast, reliable connectivity for millions of residents.

LNP THERMOCOMP OFC08V compound is a glass fiber reinforced material based on polyphenylene sulfide (PPS) resin. It features excellent plating performance using laser direct structuring (LDS), strong layer adhesion, good warpage control, high heat resistance, and stable dielectric and radio frequency (RF) performance. This unique combination of properties could enable an injection moldable new dipole antenna design, offering advantages over traditional printed circuit board (PCB) assembly and the selective electroplating of plastic.

Across-the-Board Performance Benefits The new LNP THERMOCOMP OFC08V compound is formulated for potential use in metal plating using LDS. The material offers a wide laser processing window and both ease of plating and uniformity in plating line width to help ensure stable and consistent antenna performance. Strong adhesion between the plastic and metal layers avoids delamination, even following thermal aging and lead-free reflow soldering. Improved dimensional stability and lower warpage compared to competitive glass-reinforced PPS grades help achieve smooth fixation of the metal plating during LDS, as well as accurate assembly.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.