Shot blasting machine for the renewable energy sector: Wind turbine parts

By Edit Team | July 25, 2022 4:08 pm SHARE

NESCO Indabrator is one of the leading manufacturers of surface preparation equipment, i.e., the Shot Blasting and Shot Peening Machine. We also have an in-house abrasive plant to manufacture steel shots and steel grits. Indabrator offers a complete range of solutions for surface preparation systems for domestic and international markets, catering to the foundry, forging, and metalworking industries.

Indabrator is one of the trusted brands in surface preparation equipment. Indabrator has executed many projects of national importance and supplied machines for various applications in Automotive, agriculture, railways, shipyards, ordnance factory etc. Indabrator has one of the largest infrastructures set up for manufacturing surface preparation equipment. To support our customers, we have sales and service branch offices in the North, East, West, and South regions.

Our product range also includes standalone machines and fully integrated systems that include spray painting and powder coating systems. It may range from compact machines to custom-designed machines or plants for a specific application. As a complete supplier, we help our customers combine machines, spares, service and abrasive media requirements that can increase productivity and economic efficiency, reduce emissions and improve logistic sequence.

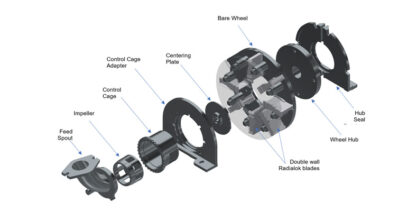

The Blast Wheel

The Radialok Wheel is furnished as original equipment on almost all high-performance Indabrator blast machines, and it’s adaptable for retrofit to most existing equipment.

The Radialok Wheel itself is of double-wall construction, made from alloy steel for true balance and hardened for long life. It is lighter, easier to handle, and less affected by ricocheting abrasives. The blades are held securely in position by the simplest method ever devised: they lock against the spacer bars. There are no pins, springs, or setscrews, and it’s impossible to install a blade incorrectly.

All wheel-assembly parts are made of an exclusive Long-Life alloy for maximum wear protection. The blast pattern resulting from the Radialok curved blade distributes abrasives more uniformly throughout the blast zone, for more rapid and thorough cleaning. Moreover, the control cage is securely locked into position to eliminate potential “drifting” and shift of the abrasive coverage area.

The Radialok Wheel unit is also available with a direct drive for specific blasting applications.

For more details, contact – NESCO Limited – Indabrator Division Nadiad Petlad Road, Vishnoli, Dist. Anand 388130 +91 7043935577 / indabrator.sales@ nesco.in Shot Blasting I Shot Peening I Painting System I Abrasives

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.