SigmaWeld Accelerated TIG (S.W.A.T): Making TIG Faster

By Edit Team | March 21, 2022 8:12 pm SHARE

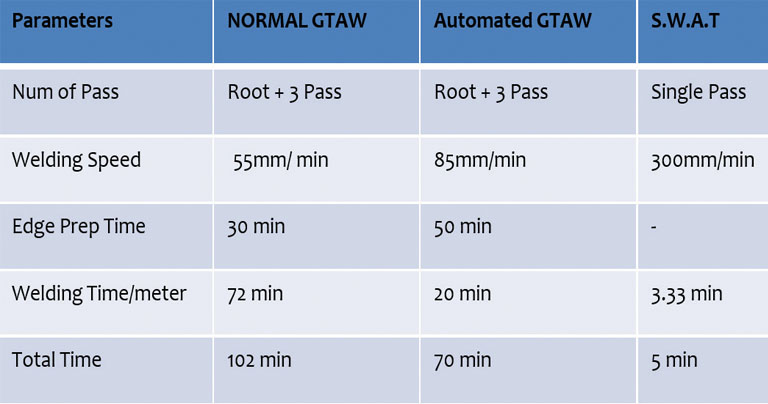

Productivity Comparison Manual GTAW Vs Automated GTAW Vs S.W.A.T

Today, if you have to manufacture stainless steel, alloy steel, or titanium vessels that are 8 to 12 mm thick, the material needs to be welded in multiple passes. First of all, the surface needs to be edge prepared. That means grinding or beveling of the plates throughout the length, then the fit-up, root pass, hot pass, and multiple passes till the capping is achieved. Even when we weld this in automation, we have to keep the inter-pass temperatures in mind and allow enough time in between passes to ensure the temperatures do not exceed the interpass limit.

This means a typical 8mm thick; 1 metre to 1 metre long weld seam would take approx. Edge prep and welding take 100 minutes. Imagine if we could do the same in minutes.

Sigmaweld Weld Accelerated TIG (S.W.A.T) is a GTAW process that does not require edge bevelling, uses as little as 10% of the gas normally required, and produces highly repeatable, x-ray quality welds with excellent cap and root aesthetics.up to 10 mm can be welded in a single pass without edge preparation. This means that the time taken for edge preparation plus the multi-pass welding can be reduced to a single pass. A typical 102-minute job (edge preparation and welding multi-pass) can be done in minutes.

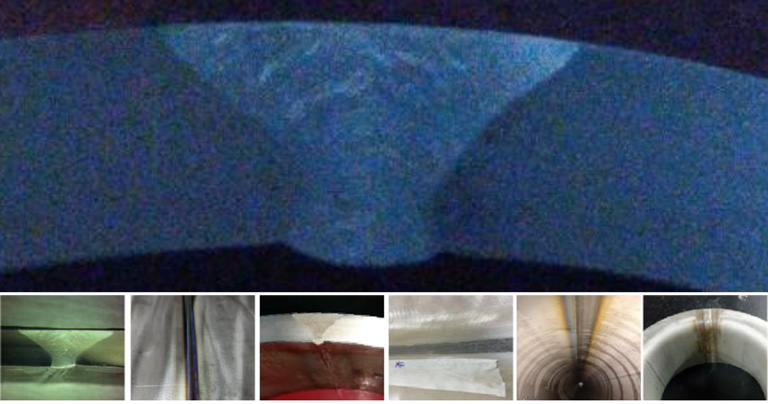

Penetration Profile of 8.5mm thick tube single pass welding with S.W.A.T

The fundamental principle behind this process is an intentional increase in arc pressure to the point where it extends the crater to the bottom of the pool. The surface of the weld pool will become anchored to both the top and bottom surfaces to form a stable structure. This stable arc is moved along the weld path as a keyhole. The arc is supported by Purging Gas on the back side and Shielding Gas from the torch.

For example, in tube mills, where a typical thickness of 8.5mm is used, use a PT (Plasma–Tig) combination and speeds of up to 75mm/minute. This process was replaced with S.W.A.T. (SigmaWeld Accelerated TIG), a variant of the KeyHole GTAW process. Using only the TIG torch, with the new process, mill speeds of 400 mm/ minute were easily achieved.

The production was more than doubled, only one power source was used for S.W.A.T (GTAW) and filler wire consumed during the process was less than half of the Plasma – TIG combination.

Similarly, for Nickel Alloy plates of 8mm, up to 3 passes were needed to be welded using standard GTAW process. With S.W.A.T this could be done in a single pass.

As shown in the table, 8mm plate welding could be done within 5mins using SWAT compared to the standard GTAW manual welding time of up to 100 minutes, and 50 minutes when welded in Automated GTAW with Cold Wire Feeding.

As shown in the table, 8mm plate welding could be done within 5mins using SWAT compared to the standard GTAW manual welding time of up to 100 minutes, and 50 minutes when welded in Automated GTAW with Cold Wire Feeding.

Coupon plates of SS304 of thickness 2.72mm, 4.12mm,6.0mm and 8.0mm were made and subjected to required ASME IX tests to check for RT, Macro, Tensile 1, Tensile 2, Micro (On Weld), Micro (On PM& HAZ), Hardness, Root Bend 1, Root Bend 2, Face Bend 1 and Face Bend 2.

The samples passed the acceptance criteria for each of the above tests. Further trials have been conducted on Cobalt Alloys, Titanium, Nickel Alloys up to 8mm thickness. The results are very high speed welds with exceptional quality.

For thicknesses above 8mm and up to 14mm can be welded with added filler wire.

Electronics Devices Worldwide Pvt. Ltd. 31, Mistry Industrial Complex, Cross Road ‘A’, MIDC, Andheri East, Mumbai -400093, INDIA,Tel: +91-22-45410600 Mob +91-9820785022 Email: nchinoy@edmail.in, sigmaweld@edmail.in URL:www.sigmaweld.com

Expertise shared by: Nimesh Chinoy, Marketing Director, SigmaWeld

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.