Modern structural engineers are confronted with diverse challenges, demanding innovative solutions and adaptability to navigate the complexities of contemporary construction projects.

From technological advancements to sustainability concerns, each challenge presents an opportunity for engineers to showcase their expertise and resilience in the face of evolving industry demands.

What are the modern-day challenges a structural engineer faces, and how does he overcome them?

Modern structural engineers face many challenges, each requiring unique solutions. One significant challenge is keeping pace with technological advancements. Engineers must continuously learn and leverage advanced modelling tools to stay ahead. Environmental sustainability is another critical area, addressed through green building practices and comprehensive life-cycle assessments to minimise the environmental impact of structures.

Resilience to natural disasters is essential, and engineers employ performance-based design techniques alongside advanced materials to enhance building durability. Staying compliant with evolving regulations demands a proactive approach to updating knowledge of codes and collaborating closely with regulatory bodies.

Utilising Building Information Modelling (BIM) and other project management tools facilitates effective project management, ensuring seamless coordination and execution. The rapid pace of urbanisation necessitates innovative solutions like vertical construction and modular methods to efficiently use space and resources.

Material and labour shortages are tackled by diversifying supply sources and integrating automation into construction processes. Maintaining health and safety standards involves implementing rigorous safety protocols and ergonomic design principles to protect workers and occupants.

Cost management is achieved through value engineering and thorough cost-benefit analyses, ensuring projects remain financially viable. Lastly, integrating smart technology, such as the Internet of Things (IoT) and smart building systems, helps create more efficient and responsive structures, meeting the demands of modern infrastructure.

What are the benefits of using high-strength steel as reinforcement in RCC structures?

High-strength steel in RCC structures offers benefits like increased load-carrying capacity, reduced material usage, and thinner sections, leading to lighter structures. It enhances durability, reduces construction costs, and allows for greater architectural flexibility. Additionally, it improves seismic performance and overall structural resilience.

What are the advantages of cement replacement and mineral admixture in modern-day concrete? Cement replacement and mineral admixtures in modern-day concrete offer several advantages. First, they significantly enhance concrete’s compressive and tensile strength, making it more robust and capable of bearing greater loads. Additionally, these replacements improve concrete’s durability, providing better resistance to chemical attacks and reducing its permeability, extending the structures’ lifespan.

From a practical perspective, cement replacements and mineral admixtures enhance the workability of concrete, making it easier to handle and place, which is crucial for achieving a smooth construction process. They also help in thermal control by reducing the heat of hydration, thereby minimising the risk of thermal cracking in the concrete.

Sustainability is a major benefit, as these materials often involve using industrial by-products, which reduces the carbon footprint associated with cement production. This benefits the environment and tends to be cost-efficient by lowering material costs. Ultimately, incorporating these elements improves the overall performance and longevity of concrete structures, ensuring they remain safe, reliable, and economically viable over time.

What are the common durability issues associated with reinforced concrete structures, and how can they be mitigated through construction chemicals?

Reinforced concrete structures often face several durability issues, but construction chemicals can effectively mitigate these. One common issue is the corrosion of reinforcement, which can be addressed by applying corrosion inhibitors and protective coatings to the steel within the concrete, significantly extending the lifespan of the structure.

Cracking in concrete is another prevalent problem. This can be mitigated by using crack sealants and flexible waterproofing membranes, which help maintain the integrity of the concrete and prevent further damage. Alkali-silica reaction (ASR) is also a concern, but it can be controlled by incorporating ASR inhibitors and using low-alkali cement in the mix.

Freeze-thaw damage, which can cause serious deterioration in concrete, can be minimised by adding air-entraining agents to the concrete mix, improving its resistance to freezing and thawing cycles. Chemical-resistant coatings and sealants are highly effective in protecting against chemical attacks, providing a barrier against harmful substances.

Carbonation, which can lead to reinforcement corrosion, can be addressed by applying surface treatments and carbonation inhibitors to prevent carbon dioxide from penetrating the concrete. Lastly, moisture ingress can be mitigated using water repellents and damp-proofing agents, which help keep the concrete dry and reduce the risk of damage.

How do construction chemicals impact the cost and sustainability of a concrete structure?

Concrete admixtures are essential chemicals added to concrete mixes to improve workability, enhance strength, and provide resistance to adverse weather conditions. By optimising the concrete mix, these admixtures help engineers achieve greater efficiency and cost-effectiveness in construction projects. They improve sustainability by minimising material waste, enhancing resource efficiency, and lowering the carbon footprint through a reduced need for frequent reconstruction. Concrete admixtures enhance high-volume fly ash (HVFA) and GGBS mixes by improving workability, setting time, and strength. Water reducers, set retarders, and air-entraining agents ensure optimal performance, compensating for slower hydration rates. This allows a significant replacement of Portland cement, reducing CO₂ emissions and material costs. The use of industrial by-products like fly ash and GGBS further minimises environmental impact and waste.

How critical is using corrosion-inhibiting admixtures to increase the durability of RCC structures?

Using corrosion-inhibiting admixtures is critical for increasing the durability of RCC structures. These admixtures protect the reinforcement from corrosion, significantly extending the lifespan of the structure and reducing maintenance costs. They are essential for ensuring long-term structural integrity, especially in marine environments or areas with high chloride concentrations

What is the importance of barrier coats in enhancing the service life of concrete structures, specifically for infra projects?

Barrier coats play a crucial role in enhancing the service life of concrete structures, especially in infrastructure projects. These coatings provide essential protection against moisture, chemicals, and abrasion, effectively preventing damage to the concrete. This protective layer is vital for maintaining the structural integrity of the concrete, particularly by inhibiting the corrosion of reinforcement bars, which is a common cause of structural deterioration. Using barrier coats significantly extends the lifespan of concrete structures by preserving their condition over time. This reduces the required maintenance frequency and extent, ensuring that infrastructure remains safe and functional for longer periods. Also, reducing repair and maintenance needs translates to substantial cost savings. By minimising the expenses associated with ongoing upkeep and potential structural repairs, barrier coats offer an economical advantage for infrastructure projects, contributing to a more efficient allocation of resources and better long-term financial planning.

How do you see the field of structural engineering evolving in the next decade, and how are you preparing for these changes?

In the coming decade, we anticipate significant advancements in structural engineering, driven by several key factors. First, there will be a notable integration of digital technologies such as AI, machine learning, and advanced modelling tools. This integration will streamline processes, enhance accuracy, and allow for more efficient design solutions. There will be a heightened focus on sustainability and resilience, emphasising green and resilient design practices. This shift reflects the growing awareness of environmental concerns and the need for structures to withstand increasingly severe weather events. The adoption of advanced materials will play a pivotal role in shaping the future of structural engineering. Exploring innovative materials will lead to structures with enhanced performance, durability, and sustainability.

Collaborative platforms will gradually become more prevalent, facilitating knowledge-sharing and fostering industry insights. Engaging in such platforms will be essential for staying informed about emerging trends and best practices.

Eventually, continuous learning will be paramount for professionals in the field. Staying updated with emerging technologies and trends through ongoing training and education will ensure that we remain at the forefront of innovation and adapt to evolving industry standards. As a proactive professional, I prepare for these changes by staying informed, embracing new technologies, and investing in continuous education and skill development.

With fast-paced infrastructure growth and changing construction practices, how imperative is it to create a platform where industry experts join hands to share their knowledge and experience and promote the adoption of advanced construction practices?

Yes, it’s very important to join hands in sharing knowledge and experience through the collaborative efforts of industry professionals. It facilitates adopting advanced construction practices, ensuring projects are executed efficiently, sustainably, and resiliently. By exchanging insights and best practices, professionals can navigate challenges, promote innovation, and collectively drive the industry towards more effective and sustainable solutions, meeting the demands of modern infrastructure development.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Tilara Polycarbonate Roofing Sheets are altering roofing in the industry with unrivalled quality, durability, and sustainability.

Emphasising the remarkable attributes, Brijesh Tilara, CEO of Tilara Polyplast, elaborates on their roofing sheets’ quality control, supply chain robustness, and environmental commitment.

How do you differentiate your roofing sheets in the competitive market, and what unique features or value propositions define your products?

Tilara Solid Polycarbonate Sheets boast exceptional impact, transparency, and temperature resistance, making them a versatile glazing material for industrial and commercial applications. These sheets also possess excellent fire-retardant properties and are classified as self-extinguishing materials. Tilara Solid Polycarbonate Sheets are 250 times stronger than glass and 25 times more impact-resistant than acrylic sheets.

Tilara Multiwall Polycarbonate Sheets feature 2UV co-extruded protection to ensure exceptional UV resistance. The hollow structure, flexibility, and excellent impact resistance ensure these sheets can be deployed in various applications. The market value proposition of polycarbonate sheets lies in their combination of durability, transparency, lightweight design flexibility, weather resistance, thermal insulation, flame retardancy, chemical resistance, longevity, and low maintenance requirements. These characteristics enable various applications in diverse industries, making them an attractive material choice for many customers.

What quality control measures and testing processes ensure consistent roofing sheet quality and compliance with industry standards?

Our state-of-the-art tech lab adheres to ISI standards, ensuring that only top-quality products are delivered to our customers. Our skilled and experienced experts rigorously test every aspect of the lab. Our lab is equipped with various facilities, including falling dark impact testing, a microscope with UV coating, flame resistance testing, wall panel impact testing, transmittance and haze measurement, a micrometer, a Lux Meter, an S.S. scale, a density check meter, a colour matching chamber, and a UV light meter. This comprehensive range of testing capabilities ensures our products meet the highest quality standards.

Which measures are in place to manage potential disruptions in the roofing sheet supply chain to maintain production and meet customer needs?

Maintaining relationships with multiple suppliers helps us mitigate the risk of disruptions. We maintain an inventory of roofing sheet materials to buffer against unexpected disruptions. This helps meet customer demands even if the supply chain experiences temporary setbacks. Accurate demand forecasting allows us to anticipate material requirements and adjust our procurement strategy accordingly. We periodically audit the supply chain to identify potential vulnerabilities or improvement areas.

How do you balance roofing sheet cost-effectiveness with crucial performance aspects like durability and weather resistance?

We meticulously select materials that offer a harmonious blend of affordability and performance. Our research and development team rigorously assesses various materials to ensure they meet the required durability and weather resistance standards while keeping costs in check. We invest in ongoing research and innovation to identify new materials, technologies, and production methods that enhance our roofing sheets’ cost-effectiveness and performance.

We stand by the quality of our products and offer extended warranties that reflect our confidence in our roofing sheets’ durability and weather resistance. This demonstrates our commitment to ensuring customers’ long-term satisfaction. We conduct thorough lifecycle analyses of our roofing sheets to evaluate their total cost of ownership over their operational lifespan. This can include advanced coatings, structural reinforcements, and optimised designs contributing to durability and cost-effectiveness.

Which strategies do you follow to analyse the environmental impact of your roofing sheets throughout their lifecycle and minimise their overall carbon footprint?

We conduct rigorous lifecycle assessments to evaluate the environmental impact of our roofing sheets, from raw material extraction to manufacturing, transportation, use, and end-of-life. This enables us to identify hotspots and prioritise areas for improvement. We educate our customers about proper maintenance and care of our roofing sheets to ensure they perform optimally and have a longer lifespan, thereby reducing the need for premature replacements. Our roofing sheets are designed for long-term durability, reducing the need for frequent replacements. This extends the product’s lifespan and minimises the associated environmental impacts.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Cross-tension rubber screens from Ashar Locker provide the ideal blend of durability and noise reduction. By absorbing vibrations and decreasing noise, these screens improve operational efficiency and extend equipment life.

Ashar Locker’s polyurethane screens offer several advantages over traditional steel screens used in mining and quarrying, such as improved Wear Resistance, flexibility, Clogging and blinding reduction, and noise reduction. We offer customised aperture designs for specific operational requirements, which enhances performance and efficiency.

Overall, the wear resistance, flexibility, and reduced maintenance make Ashar Locker’s polyurethane screens a superior choice for many mining and quarrying applications.

Modular screening systems offer several benefits that significantly impact plant uptime and maintenance costs in mining and construction. These screens are designed for easy and quick replacement. Individual Panels can be replaced without the need to replace the entire deck, reducing maintenance downtime and resulting in better plant availability.

Modular panels are generally lighter and easier to handle than traditional screens, reducing the risk of injury during installation and maintenance. This safety aspect can lead to fewer accidents and associated costs.

Our modular screening system is compatible with all major screen OEMs, so the customer isn’t required to make any structural modifications to the screen deck while installing Ashar Locker modular panels.

Our screens feature a unique design that reduces the likelihood of material clogging and blinding since all the wires vibrate independently. Due to less clogging, clients have reported a reduced recirculation load on their Machines and improved tonnage. Better screening improves product quality as the mixing of the different cut sizes is significantly reduced.

Ashar Locker’s cross-tension rubber screen technology offers several advantages over traditional wire and screens, particularly in reducing noise and vibration. Rubber’s inherent properties help dampen sound, making it ideal for operations where noise reduction is a priority. Rubber screens excel at absorbing and dampening vibrations. This reduces the stress on the screen deck and supporting structures, leading to longer equipment life and less frequent maintenance.

Cross-tension rubber mesh offers a like-for-like replacement for standard wire mesh. Customers who don’t want to modify the screen and want more life and less noise compared to wire mesh can choose Ashar Locker cross-tension rubber meshes.

For more information, visit: https://www.asharlocker.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Engineered for performance, Enovation’s uControls Mobile Hydraulic Controllers are versatile, reliable, and rugged. With options to match any Off-Highway electro-hydraulic application, this range is ideal for manufacturers looking to enhance system efficiency and reliability.

The uControls range of Mobile Hydraulic Controllers is Rugged and programmable. It is designed to meet almost all the needs of the Off-Highway market in a reliable and proven package. With a wide range of Inputs and outputs for any on/off and Proportional valve control, the range has 4 well-structured I/O variants, which ensure that there is a uControls product for every size of Electrohydraulic Application.

The Powerview range of displays ranges from 3.8 inches to 15 inches and is among the most Rugged displays in the market. Completely configurable and with great environmental specifications, Murphy Powerview displays are found in the most challenging conditions, from off-Highway to Marine, from Material handling to Military equipment. These intelligent displays help build a serious amount of control and interlock capability without controllers in most applications.

Power Distribution and Wiring Harness layout efficiency is one of the most neglected parts of any equipment. The CANJ1939 PDM is a game-changer product that brings flexibility and intelligence to every piece of equipment. It is an IP67 sealed product with 20 Inputs and 12 outputs of 15A each. These outputs can be used to drive head lamps, work lamps, power sensors, wipers, motors, and hazardous lights and provide a regulated supply to several other modules on the equipment. This helps eliminate Fuses and relays and reduce wiring harness complexity. It has a diagnostic capability by which you can pinpoint the issue and assist the service team in troubleshooting.

Enovation Controls has a full-fledged Integration and Manufacturing facility in Pune, India. Our team of Application Engineers works with the OEM to understand every aspect of the equipment. This starts from sensing and displaying parameters to mapping the faults in the system to well-thought-of and engineered interlocks, ensuring that the safety of Personnel and Equipment is given prime importance. All this must be integrated using reliable and built hardware for this application. Worksite assist features, idling of the engine, data logging, in-depth analysis of parameters, and other data and control algorithms built-in provide a serious amount of data to the system and intelligence to the machine. This also ensures that the equipment is at its prime and that the operator and the maintenance team have all the necessary information to take proactive steps and keep it that way.

As India moves to Tier V (Stage 5) on engines, Enovation is at the forefront of offering solutions to our OEM customers. Building an Operator-friendly, user-intuitive, and efficient system is a primary goal in our integration process for every piece of equipment we work on. Features like work site assist and auto idling ensure that fuel is saved when the equipment is not working on the site. The end user now demands these features, and Enovation has the expertise, global experience and OEM support to make these happen.

For more information, visit: https://www.enovationcontrols.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

MMD’s patented Mineral Sizer technology offers compact, efficient solutions for mining challenges, solving space constraints, minimising downtime, lowering operational costs, and improving sustainability with low power consumption and minimal environmental impact.

MMD began in 1978 and initially focused on designing and building mineral processing equipment for the UK underground coal mining sector. Our breakthrough was the Twin Shaft Mineral Sizer, which stood out for its resilience and compact design. Over the years, this innovation revolutionised material handling and processing across global mining activities. To enhance its performance in tough underground environments, we developed a customised gearbox that ensures the remarkable reliability and efficiency that Sizers are known for.

While coal was our primary focus, the Sizer’s unique capabilities soon gained recognition in other industries, such as cement, metals, energy, precious stones, and waste management. Our Sizer technology addresses challenges like space constraints by integrating seamlessly into existing setups, reducing downtime, lowering operational costs, optimising power usage, and supporting sustainability goals. It helps minimise dust, controls emissions, and reduces environmental impact, aligning with global efforts to combat greenhouse gases.

At MMD, we prioritise adaptability to meet the evolving demands of modern mining processes. Our Sizer range is highly versatile, integrating various transport and mounting solutions to handle diverse extraction needs. For instance, wheeled units are ideal for smaller Sizers in constrained environments, while Track Modular Units, powered by diesel or electricity, offer a flexible solution for larger operations. Additionally, transportable modular setups allow seamless relocation and compatibility with different transport modes, ensuring operators can tailor the system to their specific requirements.

Our Fully Mobile IPSC system takes adaptability further by combining mining shovel flexibility with conveyor cost-efficiency. Processing material directly on the mine face removes the need for haul trucks, streamlining operations and enhancing production capacity.

The Fully Mobile IPSC redefines mining efficiency by enabling in-pit material processing without haul trucks. This innovation processes material directly at the mine face, reducing operational complexity and wear on conveyor systems while boosting throughput. The system is designed for performance and reliability with a 175m³ hopper for direct feed, an adjustable MMD Apron Plate Feeder for precise tonnage control, and a discharge conveyor for optimised material placement.

Its compact, modular design ensures easy relocation and maintenance, while its robust build withstands harsh conditions and steep grades of up to 10%. With automation and remote operation capabilities, the IPSC enhances safety, simplifies management, and delivers unmatched flexibility, making it a cornerstone of modern, large-scale mining operations.

We are committed to fostering an environmental culture in our communities, including responsible use of natural resources, emission reduction, and waste reduction. We aim to improve efficiency and employ greener energy sources in our business and products. Working with our suppliers and customers, we combine our expert knowledge with new energy-efficient technology, enabling us to build products and processes that decrease our clients’ carbon footprint.

Designed to withstand impact loads and abrasive materials, they are frequently installed beneath tipping points, where their combination of dependability and durability has been shown to provide many years of trouble-free operation with minimal maintenance. The apron plates, attached to the chain, are composed of specifically rolled pieces and come in different widths to accommodate the largest volume of material that may need to be processed. These plates have overlapping edges to prevent spillage between them, and they are attached to the chains using bolts positioned between the grousers to protect the bolt heads from damage caused by the material being transported. The reduction of impact energy is important. The conveyor plates absorb the impact force, deforming within their elastic limit. The impact rails subsequently transmit the dissipated forces to the main frame construction.

The Fully Mobile Surge Loader uses cutting-edge 3D camera technology and RFID sensors to swiftly and efficiently guide trucks into position. Sensors also allow for automated start/stop delivery of material, boosting the fill factor for each vehicle. Another significant advantage is the Fully Mobile Surge Loader’s ability to load trucks with a specific desired payload precisely. These capabilities particularly piqued the customer’s interest, as they had spent the last ten years developing and implementing driverless truck fleets. Using mine automation software, a single operator may remotely deploy the Surge Loader, with instant remote control and real-time data relayed to the shovel.

We provide tailored service contracts to meet each customer’s specific demands, increasing availability by adopting preventative maintenance schedules and systems. Using our understanding of your equipment, we can cost-effectively restore your machine to its original state while maximising your return on investment. We have performed this type of exercise for all of our existing customers.

For more information, visit: https://www.mmdsizers.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

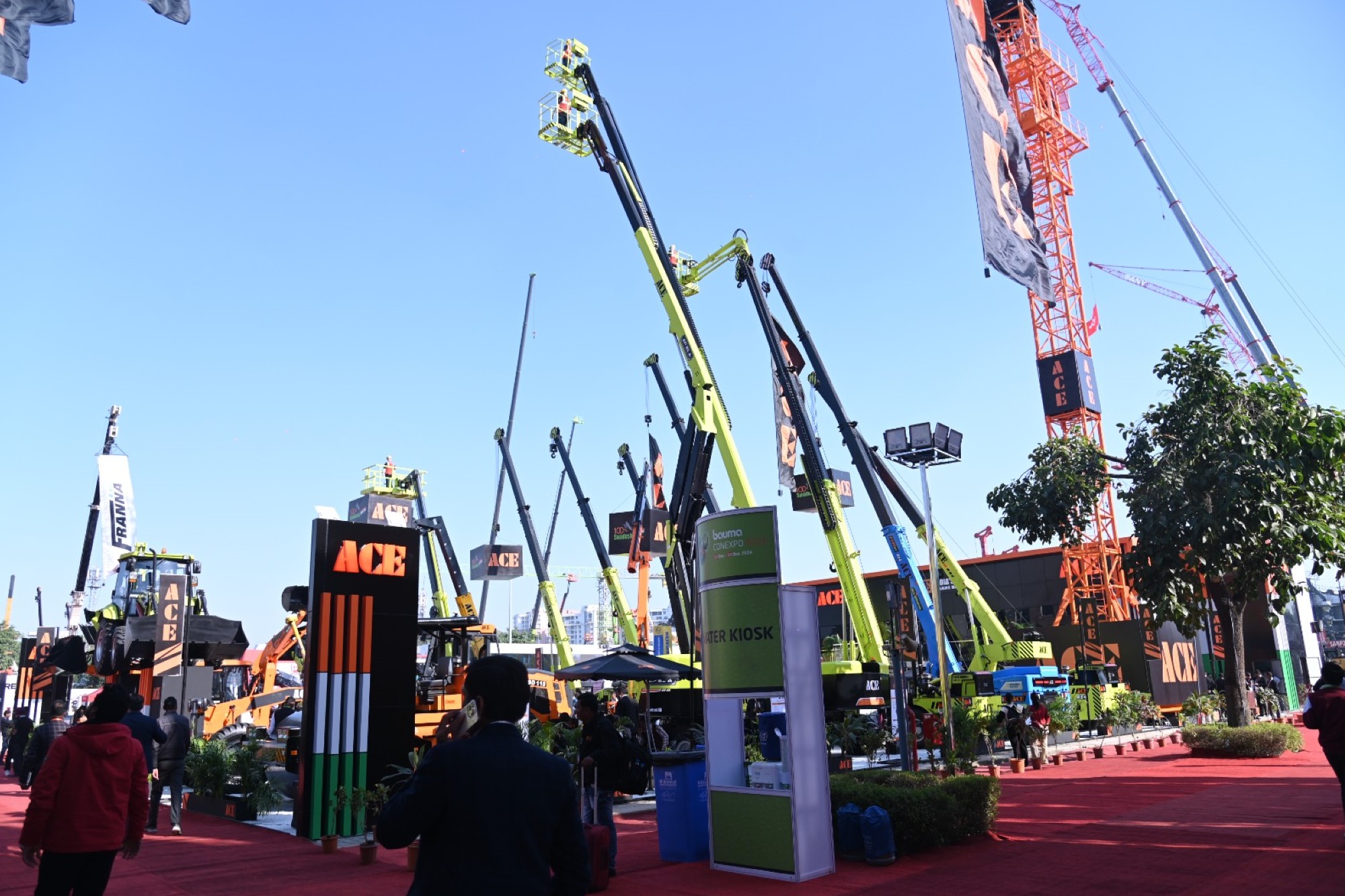

At this year’s Bauma edition, BURNER INDIA will highlight its latest advancements in energy-efficient and eco-friendly equipment while engaging with key stakeholders to address challenges and opportunities across the construction, infrastructure, and industrial sectors.

BURNER INDIA is happy to participate in bauma CONEXPO INDIA 2024, an event that brings together manufacturers, project procurement specialists, and government stakeholders in meaningful ways. The platform promotes collaboration and innovation by combining sector aims with government priorities, including infrastructure development and sustainability.

An event like bauma CONEXPO INDIA proves essential for developing contacts across the value chain. It allows us to display our technologies, network with procurement professionals, and communicate with lawmakers. We also meet with many OEMs to discuss their bespoke requirements and advise them on the newest trends. This connection allows us to better understand market needs, share insights, and lead collaborative efforts to address difficulties in the building, infrastructure, and industrial sectors.

We are excited to showcase various advancements at bauma CONEXPO INDIA 2024. Our oil and gas burners now have smart IOT-based control solutions that improve operational efficiency while reducing downtime. Our newest Pellet Burners and Thermic Fluid Heaters are designed for maximum efficiency and sustainability, meeting the demand for low-cost, high-performance heating solutions. Attendees can see the possibilities of these items firsthand via live demos at our booth.

Sustainability is at the heart of our design concept. Our solutions include innovative emissions control systems that meet the most stringent environmental standards. For example, our Pellet Burners use renewable biomass fuel, considerably reducing carbon footprints. Furthermore, our Thermic Fluid Heaters are designed for maximum energy efficiency, requiring little resource use during operation.

Integrating digital technologies such as AI, IoT, telematics, and automation is changing how equipment runs and interacts. Our burners and heaters now feature IoT-enabled monitoring systems that provide real-time performance data and predictive maintenance notifications. This ensures constant performance and increases equipment lifespan, lowering overall operational expenses for our clients.

Recognising the need for skilled operators, we created comprehensive training programs. By ensuring operators are well-versed in using our equipment’s innovative capabilities, we enable them to reach peak performance and safety.

The rapid growth of the equipment market offers problems in creating a strong supplier and service ecosystem. We regularly cooperate with local suppliers, providing technical support and quality benchmarks to ensure their incorporation into our manufacturing processes. In addition, our increasing service network ensures that clients in various areas receive prompt maintenance and assistance.

Our commitment to sustainability spans from design and manufacture to recycling at the end of life. Our goods are made from recyclable materials, and we follow circular economy concepts throughout our manufacturing processes. For example, our Thermic Fluid Heaters are designed to be easily disassembled, ensuring efficient recycling at the end of their lives. We also look into material science advancements that can help products last longer and reduce waste.

Visitors to our bauma CONEXPO INDIA 2024 exhibit will expect interactive demonstrations of our latest products and technology. In addition, we will hold expert-led sessions to highlight advances in energy-efficient heating solutions and the significance of renewable fuels. These workshops will provide useful information on how our technologies solve current industry challenges.

India’s dynamic construction, infrastructure, and mining regulatory framework needs ongoing innovation. Our R&D team keeps ahead by producing goods that meet current requirements and anticipate future standards. For example, our burners are engineered to satisfy prospective emission standards, assuring readiness for regulatory changes that may drive industry growth.

BURNER INDIA promotes innovation, sustainability, and efficiency in the equipment business. bauma CONEXPO INDIA 2024 is a great opportunity to exhibit our progress and work with stakeholders to create a sustainable future. We urge all participants to visit our exhibit and learn about the solutions defining the future of energy-efficient equipment.

For more information, visit: https://burnerindia.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Pradeep Kumar, Managing Director of Terraform Geotechnical Services, is driving change in India’s geotechnical landscape. With over 25 years of experience and strong alliances with international brands, Terraform is at the forefront of delivering innovative and eco-friendly technologies that reshape the country’s construction and mining industries.

Our 25+ years of experience and global partnerships with brands like Tecniwell, Dragflow, Massenza and Rockdril have greatly influenced our company’s approach to geotechnical challenges. Through these partnerships, we have gained valuable insights, access to cutting-edge technologies, and a deep understanding of industry best practices. This has allowed us to offer innovative solutions, high-quality equipment, and expert services to address the complex geotechnical challenges our clients face effectively. Our collaborations with these reputable brands have enabled us to stay at the forefront of the industry and deliver exceptional results to our customers.

Terraform Geotech is crucial in India’s infrastructure growth by providing drilling and grouting solutions for sectors like tunnelling, mining, and hydroelectric power projects. Our expertise in slope stabilisation and ground improvement techniques is essential for the success of these projects, ensuring safety and efficiency in the construction process. In this sector, Terraform Geotech’s specialised services with the client as a team are ultimately driving the country’s economic growth and progress through on-time delivery and prompt response with high-quality standards.

Data logging in grouting technology enhances project efficiency. It ensures quality and safety in applications such as tunnelling, dam rehabilitation, and ground improvement by monitoring and analysing grouting operations. This technology allows engineers to track the flow rate, pressure, and volume of grout injected into the ground, ensuring that it is applied in the correct areas and at the proper consistency. With access to this data, project managers can make informed decisions to optimise grouting operations, minimise waste, and prevent potential safety hazards such as structural instability or leaks. Ultimately, data-logging grouting technology improves overall project quality, reduces costs, and enhances the safety of projects.

Advancements in grouting and drilling technologies have made them more adaptable to diverse conditions in projects like metro construction, slope stabilisation, and bridge foundations. These advancements include developing specialised equipment and tools with grout mixtures that can cater to specific soil types and conditions and innovative drilling techniques that allow for more precise and efficient installation of anchors and piles. Additionally, improvements in equipment such as drilling rigs, special tools, grouting pumps, and accessories have increased the speed and accuracy of the process, making it easier to handle challenging geological conditions. These advancements have enhanced the overall effectiveness and safety of grouting and drilling operations in various construction projects.

Our slurry filtration systems ensure responsible water management in the construction, mining, and wastewater sectors by reducing water consumption, preventing pollution, and facilitating water reuse. Their role in solid-liquid separation not only aids in operational efficiency but also contributes to environmental sustainability. Construction sites often generate slurry from cutting, grinding, or demolition. This slurry contains fine particles, such as cement, dust, and other debris, which can harm the environment if not managed properly. In mining, slurry filtration systems separate solid minerals or other particulate matter from the liquid. This process is essential for both the recovery of valuable minerals and the protection of local water systems.

Terraform plans to expand its market presence in the Indian geotechnical market by investing in research and development to stay updated with industry trends and demands. The company will also build strong relationships with key stakeholders and clients to ensure customer satisfaction and loyalty. Additionally, Terraform will explore new partnerships and collaborations to enhance its offerings and service capabilities further. By remaining proactive and adaptive, Terraform aims to capitalise on the promising growth opportunities in the Indian geotechnical market and solidify its position as a leading provider.

For more information, visit: https://terraformgeotech.com/ws/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

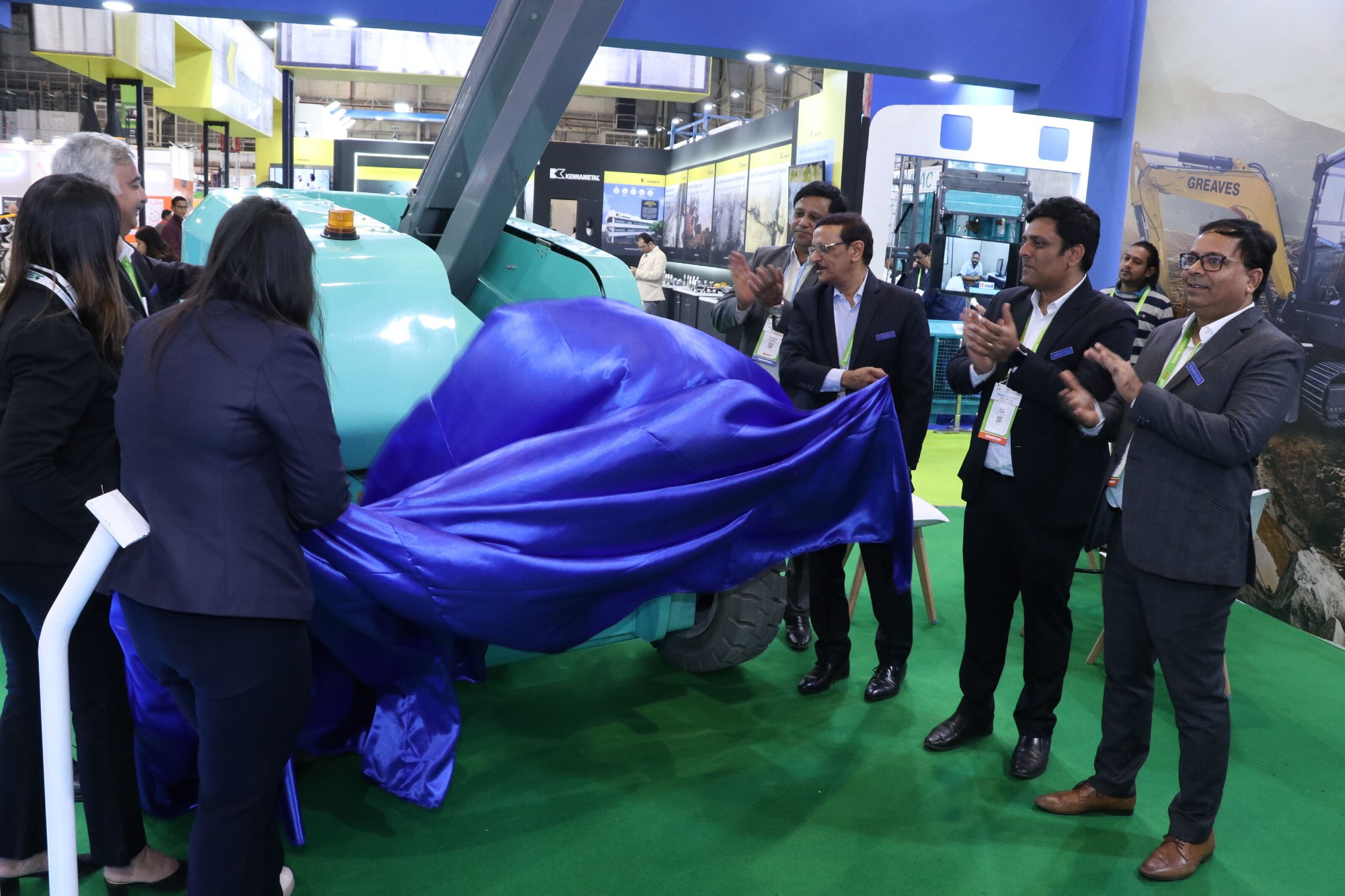

Piero Guizzetti, CEO of MB Crusher India Pvt. Ltd., emphasises the importance of bauma CONEXPO INDIA in encouraging industry-wide collaboration. MB Crusher will highlight its dedication to sustainable and efficient material processing solutions through live demos of the BF90 crusher bucket and the MB-S18 screening bucket.

At bauma CONEXPO INDIA 2024, we are excited to present a live demo of our latest BF90 crusher bucket and MB-S18 screening bucket, two leading solutions in on-site material processing. The BF90 crusher bucket allows for powerful on-site crushing, significantly reducing waste and transport costs by transforming materials into reusable aggregates. The MB-S18 screening bucket offers adaptable and efficient on-site material separation, suitable for diverse materials like soil, sand, and gravel. These innovations demonstrate our commitment to enhancing productivity, sustainability, and cost-efficiency for our customers, offering versatile solutions tailored to India’s growing infrastructure needs.

Our eco-friendly approach focuses on reducing emissions, minimising fuel consumption, and improving operational efficiency in our equipment. For instance, our products are designed to work directly on-site, which cuts down on transportation needs and associated emissions. Additionally, our machines don’t consume more fuel than what would be used for normal base machine operations while delivering high-performance results, ensuring that less energy is needed to achieve optimal outcomes. This approach is part of our commitment to responsible manufacturing and energy efficiency.

Attendees at bauma CONEXPO INDIA 2024 can expect an engaging experience at our stall, with live demonstrations of our BF90 crusher bucket and MB-S18 screening bucket. Our live demo allows visitors to witness these machines’ efficiency, power, and versatility in action. Our team of experts will be available for consultations to discuss how our solutions can be tailored to various project needs. We also want to share insights on how our equipment can help companies align with sustainability and productivity goals. For those interested in the future of on-site material processing, these demonstrations offer a unique opportunity to explore industry-leading technology up close.

Events like bauma CONEXPO INDIA are crucial for building a collaborative ecosystem within the construction, mining, and infrastructure sectors. By bringing together manufacturers, procurement experts, and government stakeholders, bauma CONEXPO INDIA creates a platform for a 360-degree exchange amongst all stakeholders, bringing together the different perspectives and strategic interests at one table. It also fosters partnerships and enables innovative solutions to showcase how they can address sector-wide challenges more tangibly. It is an unparalleled opportunity for us to connect with project decision-makers and stakeholders, explore regulatory updates, and align our offerings with market needs and sustainable goals. This event is invaluable in supporting our shared objectives in the current climate, where infrastructure development is accelerating.

We look forward to showcasing our innovations and engaging with industry stakeholders at bauma CONEXPO INDIA 2024, where we aim to demonstrate how MB Crusher aligns with India’s construction and sustainability goals.

For more information, visit: https://www.mbcrusher.com/es/es/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

As industries face growing water scarcity and environmental compliance challenges, Kärcher India is pioneering solutions that help businesses save water, reduce waste, and increase productivity. From recycling water on construction sites to introducing AI-powered autonomous cleaners, Kärcher is shaping the future of industrial cleaning with a clear focus on sustainability and innovation.

Water scarcity is an increasing concern, particularly in industries like mining and construction. Kärcher’s water treatment and recycling systems are designed to tackle this issue by greatly reducing water consumption. We collect used water from cleaning processes and store it in a designated tank. From there, the water goes through a multi-stage filtration process that typically involves sedimentation, filtration, and oil-water separation to remove contaminants like dirt, debris, and oil. Once treated, the water is recycled and reused in cleaning applications, reducing the need for fresh water.

These systems are vital for ensuring environmental compliance. By recycling water, businesses can significantly reduce the amount of wastewater they discharge, thus minimising their impact on local water resources. In regions with strict water usage and wastewater discharge regulations, Kärcher’s systems help companies meet regulatory requirements and avoid penalties. On a broader level, our water treatment solutions promote sustainability by helping businesses conserve water and reduce their environmental footprint, showing their commitment to responsible water management.

Kärcher Wheel Wash Systems are designed to prevent dirt and debris from construction sites and mining operations from being tracked onto public roads. This is essential for maintaining road safety, preventing environmental contamination, and protecting nearby communities. When vehicles or equipment leave the site, they drive over a ramp with high-pressure nozzles. These nozzles spray water at high velocity to effectively clean mud, dirt, and other contaminants from the wheels and undercarriage.

The system is designed to recycle water efficiently. It collects the used water, filters out contaminants, and recycles it for reuse, reducing water consumption and minimising the system’s environmental impact. Built for heavy-duty applications, these systems feature robust nozzles that deliver powerful water jets to tackle the toughest grime typically found in mining and construction environments. Advanced filtration allows for the reuse of up to 85% of the water, making the system both eco-friendly and cost-effective.

The systems are also highly customisable and modular, ensuring they meet specific site requirements. Durability is key, with the equipment built from industrial-grade materials to withstand harsh operating conditions and provide long-lasting performance. Many of our systems are fully automated, requiring minimal manual intervention, which ensures consistent efficiency and reliability on the job site.

The KIRA CV 50 marks a significant advancement in autonomous cleaning technology. This AI-powered vacuum sweeper is engineered to provide exceptional cleaning performance with a strong focus on efficiency and sustainability. It operates autonomously, navigating complex environments and performing cleaning tasks without human intervention. Thanks to its advanced sensors, the KIRA CV 50 can detect obstacles highly, ensuring safe and reliable operation. It also adapts to different environments, from large open spaces to tight corners, optimising its cleaning path for maximum coverage.

The machine features a user-friendly interface, making it easy to program, monitor, and control. It is also designed to minimise water and energy consumption, contributing to significant cost savings and reducing its environmental impact. Its long-lasting batteries and energy-efficient technologies further enhance sustainability. For businesses aiming to streamline their cleaning processes while achieving sustainability goals, the KIRA CV 50 is the ideal solution.

The industrial cleaning landscape is rapidly evolving, especially in the mining, construction, and infrastructure sectors. One major trend is the increasing demand for sustainable solutions that minimise water and energy consumption, reduce waste, and promote environmental responsibility. This is closely aligned with initiatives like the Swachh Bharat Mission. Automation is gaining momentum, with autonomous cleaning technologies offering improved efficiency and enhanced safety. Additionally, digitalisation plays a big role, with IoT-enabled devices and data-driven solutions becoming essential for remote monitoring, predictive maintenance, and optimising cleaning operations.

We are focused on staying at the forefront of these trends. We invest heavily in research and development to create cutting-edge solutions that meet the changing needs of our customers. Sustainability is a core focus, and we are dedicated to developing eco-friendly products that help our customers achieve their sustainability goals. We are also expanding our portfolio of autonomous cleaning solutions to improve efficiency and productivity. We aim to provide valuable insights and optimise cleaning performance by integrating IoT and data analytics. Combining German engineering excellence with local market insights, Kärcher will continue to deliver innovative and sustainable solutions that exceed our customers’ expectations in these industries.

For more information, visit: https://www.kaercher.com/int/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

From energy-efficient machines to AI-driven automation, SCHWING is committed to driving innovation while ensuring compliance with India’s evolving regulatory landscape.

bauma CONEXPO INDIA is an important forum for bringing together major stakeholders in the construction sector and encouraging collaboration and innovation. This event allows us to demonstrate our leadership, interact with project procurement professionals and government authorities, and match our creative solutions with the expanding demands of infrastructure development. These events help to establish alliances and pave the way for technological advancement in the sector.

At bauma CONEXPO INDIA 2024, we will launch ground-breaking innovations demonstrating our commitment to innovation. Among the highlights are our Crushers, intended to handle different aggregates and materials efficiently, our improved Stationary Pumps with energy-saving features, and our adaptable Self-Loading Mixer (SLM), which provides on-site concrete production efficiency. These goods demonstrate our commitment to merging innovative technology and practical solutions for the Indian market.

Our operations are built on the foundation of sustainability. Our equipment integrates cutting-edge pollution control and energy-saving technology that meets or exceeds international environmental standards. We prioritise energy efficiency by incorporating low-emission engines into our Boom Pumps and Stationary Pumps and using CNG-powered equipment to reduce reliance on fossil fuels. Furthermore, our recycling units for concrete waste demonstrate our dedication to environmental care throughout the construction process.

We have embraced digital transformation to increase operational efficiency and customer value. Our IoT-enabled machines support real-time performance monitoring, predictive maintenance warnings, and seamless project management integration. Our technology allows users to monitor and optimise equipment utilisation remotely. Automation in our Boom Pumps improves precision in operations while increasing safety and decreasing personal involvement.

We value operator training highly to guarantee that our innovative machinery is utilised to its greatest capacity. We have trained over 15,000 operators nationwide through dedicated Batching Plant and Concrete Pump programs. Collaborations, such as those with the NSDC and IESC, as well as more than five Memorandums of Understanding with various state government skill development authorities, help to boost our training activities. We aim to bridge the technological and operational expertise gap by integrating theoretical knowledge with hands-on experience.

We have built a comprehensive support network to meet the expanding demands of the equipment market. Our ecosystem includes over 30 service facilities and a dedicated team of more than 250 service engineers across India, ensuring that customers receive prompt and reliable support. Collaborations with reputable local suppliers improve our supply chain skills, while in-house manufacturing of crucial components maintains the quality and dependability of our equipment.

We take a lifecycle approach to sustainability, beginning with the design phase and including lightweight materials to improve fuel efficiency. We use green manufacturing principles to reduce environmental effects in our production operations. Our machines are outfitted with low-emission and energy-saving technologies during the utilisation phase. After their existence, technologies like concrete recycling factories encourage circular economy principles by decreasing waste and reusing resources. This comprehensive strategy illustrates our dedication to environmental stewardship at all stages.

bauma CONEXPO INDIA 2024 attendees may expect an immersive experience at our booth. Live demonstrations of major items, such as all-new crushers, self-loading mixers, and excavators, will demonstrate their capabilities in realistic circumstances. Interactive seminars with technical specialists will provide deeper insights into our solutions, while an exclusive preview of upcoming breakthroughs will demonstrate our forward-thinking approach to the sector.

SCHWING remains proactive in adapting to India’s evolving regulatory framework. Our equipment meets the latest compliance standards, from emissions norms to operator safety guidelines, ensuring reliability and trust. Anticipating future shifts, such as increased emphasis on sustainability, we invest in cleaner technologies like CNG and electric machinery. These advancements comply with regulations and position SCHWING to support accelerated growth in construction, infrastructure, and mining sectors driven by government initiatives.

For more information, visit: https://www.schwingstetterindia.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The new motto driving change in the construction sector is green, smart, and skilled. The increasing demand for highly skilled individuals to manage cutting-edge technology brought about by electrification and automation is setting in motion a more sustainable, efficient, and dynamic future in construction.

Electrification, automation, and skilling are now necessary and not optional in the construction industry, which is at a turning point. A trained workforce is becoming increasingly important as companies seek to incorporate the latest technologies into their operations. Working with the government, academic institutions, and industry leaders will ensure that the sector develops effectively and sustainably.

One thing is certain as the construction sector undergoes further change: machines powered by energy, data, and highly competent human hands will build the future. Let’s look at how they are converging to redefine the construction landscape.

Among the most significant stimuli in the construction sector is electrification. Electric gear is becoming increasingly necessary as governments throughout the world pledge to reduce their carbon footprints. For instance, with its hybrid powertrains and electric drivetrains, Caterpillar has spearheaded the movement to increase energy efficiency. Amit Bansal, Director of Sales and Marketing at Caterpillar India, states, “Our electric-powered machinery and hybrid vehicles are part of a larger commitment to help our customers meet their climate-related objectives.”

Due to integrating electric technologies, the industry is also shifting towards equipment that runs on renewable energy sources. According to the World Green Building Council, this shift is critical as construction accounts for approximately 39% of global energy-related carbon emissions. Caterpillar’s electric machines drastically reduce lifecycle greenhouse gas emissions by using up to 100% hydrotreated vegetable oil (HVO) instead of conventional diesel fuels. Achieving the industry’s decarbonisation objectives requires such solutions.

Automation has changed how tasks are performed at construction sites, making it much safer, more accurate, and more efficient. From bricklaying to excavation, complicated operations that previously required human interaction are now completed by AI-powered machines. Real-time data from IoT-enabled equipment enables predictive maintenance, ensuring machinery runs as efficiently as possible.

“Our Magni Telehandlers are equipped with IoT and telematics, which allow for real-time equipment monitoring and predictive maintenance,” highlights Vikram Rana, Director of Abhay Rana Infra Services Pvt. Ltd. “AI-enhanced features such as smart load balancing ensure that we improve operational productivity while keeping safety at the forefront.”

One of the standout innovations is Caterpillar’s telematics system, which connects over 1.5 million assets worldwide and provides critical insights into fleet performance, fuel usage, and machine health. This data-driven approach improves efficiency and reduces downtime and maintenance costs, keeping projects on schedule and within budget.

Automation has also made a mark in material handling solutions. Nandan GSE, led by Dr. Raghunandan Jagdish, MD and CEO, uses IoT-enabled systems in their equipment to monitor real-time performance and predict equipment failure. “This constant monitoring ensures that machines perform at their best while lowering operational expenses,” Dr. Jagdish explains.

While automation and electrification transform the machinery landscape, skilling is essential to ensure these technologies reach their full potential. The integration of advanced technologies calls for a well-trained workforce capable of operating modern equipment. Many construction firms, recognising this need, have initiated comprehensive training programs.

Abhay Rana Infra Services provides specialised training programs for operators and technicians. “We offer hands-on training, certification courses emphasising safety, and digital platforms with interactive modules. This ensures our operators have the right skills to utilise our Magni equipment to its fullest,” says Vikram Rana.

This focus on skilling extends across the industry. Columbia Machine Engineering offers comprehensive training programs for its operators, as President and Director Dilip R. Sharma points out. “We recommend our customers employ skilled personnel with ITI or diploma certificates and train them thoroughly in machine settings, mould changes, and process optimisation.” This ensures that equipment is operated safely and efficiently, minimising breakdowns and extending its lifespan.

The need for skilled operators is even more pressing in the heavy machinery, where machine sensitivity and precision are critical. Suretech Infrastructure’s Chairman and MD, Sunil Newatia, highlights the importance of upskilling. “Our operators undergo rigorous training, not just in operating the equipment but also in understanding soil dynamics, which is critical for sensitive equipment like pile drivers,” he explains.

As technology advances, companies are turning to digital tools for training. Digital learning platforms, VR simulations, and remote assistance are becoming the norm, ensuring that even geographically dispersed teams can stay updated with the latest technologies.

Despite the benefits, electrification and automation bring significant challenges. Companies must overcome high upfront costs, integration difficulties, and the need for a supportive ecosystem. Rana says, “Establishing a robust supplier and service provider network is key. We focus on developing local partnerships to ensure we have the right infrastructure to support our technology.”

Skilling also poses a challenge, particularly in regions with lower levels of technical education. The industry’s transition to electrification and automation could widen the skills gap if training programs keep up with the technologies being introduced. Companies must work closely with educational institutions and governments to address this gap through apprenticeship programs, certifications, and on-the-job training.

But the journey is only getting started. The construction sector will significantly shape a greener, smarter, and more efficient future as long as companies keep investing in R&D, skilling programs, and sustainable technologies.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Interarch Building Products and Jindal Steel & Power have joined forces to improve India’s urban infrastructure by pushing steel for multi-story buildings and major developments using sustainable, high-performance solutions and innovation.

Interarch Building Products Limited, a pioneer in Pre-Engineered Building (PEB) solutions, has formed a strategic alliance with Jindal Steel & Power Ltd (JSPL), a leading steel manufacturer. This collaboration aims to transform India’s urban infrastructure by promoting steel as the preferable material for multi-story buildings, data centres, and large constructions.

This collaboration will combine Interarch’s expertise in design, engineering, production, and project management with JSPL’s cutting-edge manufacturing facilities for heavier structures, allowing the development of high-performance steel solutions. The two companies hope to drive innovation in the building industry by promoting sustainable and efficient urban development approaches. Steel is becoming the preferred material for modern urban building due to its speed, strength, adaptability, and sustainability. The partnership between Interarch and JSPL aims to meet these demands by combining the former’s PEB building expertise with the latter’s superior steel production capabilities.

Arvind Nanda, Founder and Managing Director of Interarch Building Products Limited, says, “Our partnership with Jindal Steel & Power marks a significant step in transforming India’s urban landscape. By enhancing the sustainability and efficiency of construction, we aim to support India’s vision for smarter, safer cities.”

Ajay Agarwal, EVP, Construction Material Business, Jindal Steel & Power Ltd, adds, “This strategic partnership with Interarch underscores our commitment to transforming India’s urban infrastructure. By integrating our high-quality, innovative steel solutions with Interarch’s engineering expertise, we aim to set new benchmarks for sustainable, future-ready construction practices that meet the demands of a rapidly evolving nation.”

This collaboration is a significant step towards improving India’s urban infrastructure and meeting the growing demand for sustainable and long-lasting construction solutions.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Combilift has been voted Company of the Year at the 2024 Business & Finance Awards, its ninth significant achievement in three months, demonstrating its global leadership and innovation in material handling.

Combilift, a global leader in material handling systems, has been named Company of the Year at the renowned Business & Finance Awards 2024, presented by KPMG Ireland. This incredible result is Combilift’s ninth big victory in the previous three months, cementing its position as the industry leader.

The Company of the Year award, presented to Combilift CEO Martin McVicar by Seamus Hand of KPMG at the 50th Business & Finance Awards ceremony in Dublin, demonstrates the company’s substantial impact on the Irish economy and the global market. Combilift, with an annual revenue of more than €500 million, thrived because of its export-focused business model, with 98 percent of its activities supplying overseas markets.

Since its inception in 1998, Combilift has established a global reputation as the largest manufacturer of multi-directional, articulated, and sideloading forklifts, as well as heavy material handling equipment such as straddle carriers, with over 85,000 units in use in 85 countries. The company’s dedication to innovation, sustainability, and research and development has been critical to its rapid expansion, establishing it as a true leader in the material handling sector.

Martin McVicar, CEO of Combilift, says, “This award reflects the bold vision and relentless drive that has been at the heart of Combilift since Robert Moffett and I started in 1998. Every forklift, every innovation, and every milestone reflects our commitment to pushing boundaries and transforming material handling worldwide. This moment belongs to our employees, our dealers, and our customers, who rely on us to deliver quality material handling solutions to optimise their warehouse space.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Michelin, the world’s top tyre technology company, has expanded its presence in the Delhi-NCR region by launching two premium next-generation stores.

These sophisticated outlets, strategically positioned in South Delhi’s Lajpat Nagar and Noida’s Sector 52, mark a significant step forward in Michelin’s commitment to providing unmatched customer experiences and growing its footprint in India.

These openings are part of Michelin’s larger goal to expand its reach in India. Michelin intends to strengthen its position as a leader in the Indian tyre market by focusing on innovation, premium client experiences, and sustainability. Michelin’s latest initiatives in Delhi-NCR emphasise the company’s dedication to providing the best tyre solutions while expanding connections with valued partners such as BK Tyres and Resham Tyres. Together, they are laying the groundwork for a new level of excellence in tyre retail.

Speaking on the occasion, Shantanu Deshpande, Managing Director of Michelin India, says, “The opening of these new dealerships underscores Michelin’s unwavering commitment to expanding its footprint in India and delivering exceptional tyre solutions. Our focus remains on partnering with dealers who share our vision of innovation and excellence. These new dealerships in South Delhi and Noida stand as testaments to Michelin’s dedication to quality, innovation, and customer satisfaction. We are excited to continue growing our presence and bringing world-class experiences to Indian consumers.”

The South Delhi showroom, run by BK Tyres, covers an astounding 1,500 square feet and represents a significant transition for one of Michelin’s oldest and most reputable dealers. With a 50-year history, BK Tyres has evolved into a modern store tailored to the premium needs of high-value clients. This beautiful outlet, conveniently located in Lajpat Nagar, provides a selected variety of Michelin’s world-class tyre portfolio, premium alloy wheels, and specialised 4×4 tyre options. The store’s modern design and customer-focused layout represent Michelin’s commitment to providing a smooth and upgraded experience for today’s discerning vehicle owners.

Michelin’s new dealership in Sector 52, Noida, in conjunction with Resham Tyres, is intended to meet the needs of modern car owners with cutting-edge technology and competent service. This dealership provides full tyre services such as alignment, balancing, and fitting, as well as cutting-edge equipment and a diverse selection of premium tyre brands, to ensure the greatest fit for each car. The Noida location intends to create a standard for tyre retail by combining technical perfection with world-class customer service.

For more information, visit: https://www.michelin.com/en/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Columbia Machinery will showcase its latest innovations in concrete block production, energy-efficient technologies, and the Made-in-India Columbia Wil-El-Mil Wet Press, which has revolutionised the industry with cutting-edge sustainability practices and digital integration.

At major exhibitions worldwide, we consistently receive much attention from our large client base. Our huge number of visitors in India keeps us active most of the time. Beyond strengthening connections with existing clients, we are broadening our reach to include key stakeholders in infrastructure and construction. Our focus includes infrastructure firms, subcontractors, building material suppliers, and companies specialising in soil stabilisation.

We use the Vertical Mould Vibration method, which benefits our customers by allowing them to produce concrete blocks with outstanding strength and perfect dimensional precision. This improved method minimises the quantity of cement used and decreases water absorption in the blocks, resulting in higher quality and economic efficiency.

In addition, we have started manufacturing the Columbia Wil-El-Mil Wet Press at our Columbia Machine India factories. This development is a game changer for the factories, particularly for prominent Wet cast manufacturers, because it gives them access to the world’s best-wet press technology at a reasonable cost. By manufacturing this cutting-edge technology in India, we enable our customers to attain outstanding product quality while supporting sustainable practices.

At the exhibition, we will debut our Made-in-India Concrete Wet Press. Given the large amount of concrete and space required for its functioning, a live demonstration of this plant on the exhibition floor is impossible. However, attendees will be able to delve further into this powerful technology’s advanced features and benefits, emphasising its potential for efficient and high-quality concrete production. We are also asking potential purchasers to visit our existing client sites and factory to see the plant in operation and conduct production demonstrations.

We began employing energy-efficient motors because we are devoted to minimising our clients’ environmental footprint and operational costs. This unique technique significantly reduces energy use and greenhouse gas emissions, helping to create a more sustainable future.

Our proprietary Vertical Mould Vibration Technology maximises energy efficiency when combined with modern hydraulic and pneumatic systems. By reducing electric power use, we help our customers lower their carbon footprint while saving money.

Digital transformation, including AI, IoT, telematics, and automation, is a driving force in the industry. How are these technologies integrated into your products? We have integrated IOT into the panels of Concrete Block Plants and Batching Mixing Plants. This will enable our clients to access input on raw material usage, production, and plant efficiency. This will also allow us, as equipment producers, to access them with online support.

To ensure the best performance and longevity of our equipment, we recommend that our customers use professional personnel with ITI or diploma certificates in electrical and mechanical engineering to run the block and batching mixing plants. Furthermore, we recommend appointing civil engineering diploma or BE graduates as plant managers or quality control engineers.

We welcome this team to our facility for a comprehensive 3-5-day training program that will cover the theoretical and practical elements of our equipment. This training provides operators with a solid understanding of technology and equipment.

Our experienced Service Engineers impart training on assembly, erection and commissioning. Finally, customer operators receive on-site training covering production processes, machine settings, mould changes, mix design, and machine parameter optimisation.

The equipment market is growing rapidly, but this brings challenges in building a robust component supplier and service provider ecosystem. How are you addressing these challenges? Our cutting-edge manufacturing facility in Vadodara allows us to manufacture a wide range of equipment in-house, including batching and mixing facilities, handling systems, and moulds.

We get our outsourced components from reputable vendors with long-term connections, resulting in a strong and dependable supply chain. This strategic approach creates a robust supplier ecosystem.

We adhere to the patented design of Columbia Machine Inc., USA, a firm known for its unique designs. Our machines rely on their tried-and-true procedures, which have been used since 1937. We improved our tried-and-true designs, ensuring machines endure longer and offer higher-quality results. We are committed to quality and only utilise the best materials; no recycled products here!

Our strategic acquisition of Wil El Mil, the global pioneer in Wil El Mil technology, in October 2022 has strengthened our position as a leading provider of sophisticated production solutions for concrete wet press technology. Building on our two years of excellent experience providing Columbia Wil El Mil technology from our UK facility, we are pleased to announce the start of domestic manufacturing of the Columbia Wil El Mil Wet Press in Baroda.

This critical milestone allows us to provide cost-effective and innovative solutions to our valued customers. We are excited to display our ‘Made in India’ machinery at baumaConexpo, where we will provide detailed insights into the technology and manufacturing process. We are not conducting a live demo due to space constraints and the large quantity of concrete required.

The Indian government’s infrastructure programs, particularly statewide highway construction, have greatly raised the demand for high-quality concrete block machines to manufacture retaining wall blocks and high-strength concrete pavers. This rise has resulted in our company’s highest-ever order book.

Furthermore, government mandates to use fly ash bricks near thermal power stations to reduce environmental effects have increased demand for high-quality fly ash bricks. We are happy to be fulfilling orders from quality-conscious customers who use our cutting-edge concrete block equipment to create these eco-friendly bricks.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

With growing environmental regulations, Nandan Petrochem (NPL) is providing a critical solution for the mining sector. Their premium AdBlue solutions ensure reduced nitrogen oxide emissions, while their commitment to compliance with international standards and reliable supply keeps equipment running smoothly under the toughest conditions.

We ensure that our VELVEX range of lubricants meets the performance and durability standards required for mining and construction equipment through a comprehensive approach. Our VELVEX range includes hydraulic oils, engine oils, transmission oils, and greases, all designed to withstand extreme conditions like heavy loads, dust, moisture, and vibrations. We conduct thorough laboratory and field testing to assess properties such as wear protection, heat stability, and corrosion resistance. Our lubricants adhere to global industry standards, including API, SAE, and OEM specifications, ensuring reliable performance and extending the lifespan of your equipment. Additionally, we customise VELVEX lubricants to meet the specific needs of different machinery types and continuously monitor their performance through client feedback, ensuring ongoing optimisation.

NPL Bluesky Automotive has established itself as a leader in India’s DEF/AdBlue market, helping companies in the infrastructure and mining sectors meet stricter emission norms while maintaining operational efficiency. AdBlue has become essential with the growing emphasis on reducing nitrogen oxide (NOx) emissions, especially in mining. NPL produces high-quality AdBlue that complies with ISO 22241 and OEM specifications, ensuring it is pure and free of impurities, which is critical for the optimal performance of Selective Catalytic Reduction (SCR) systems. We also ensure a reliable supply of AdBlue, preventing disruptions in industries like mining, where equipment operates for long hours under demanding conditions. We actively monitor regulatory changes, ensuring AdBlue solutions comply with the latest environmental standards.

NPL Bluesky Automotive is recognised as a pioneer in providing high-quality DEF/AdBlue and environmentally friendly solutions, with a strong focus on sustainability and performance. We ensure our AdBlue solutions meet international standards by using premium raw materials and adhering to ISO 22241, optimising the performance of Selective Catalytic Reduction (SCR) systems to reduce nitrogen oxide (NOx) emissions. Our commitment to sustainability goes beyond emissions reduction, as it uses Post-Consumer Recycled (PCR) containers to minimise plastic waste and support the circular economy. We balance performance and sustainability by developing environmentally friendly lubricants using biodegradable components, which help reduce pollution risks. Our AdBlue solutions also comply with BS IV norms and other regulatory standards, enabling industries to stay compliant with evolving environmental regulations. Through continuous innovation and investment in research and development, we ensure our products deliver exceptional performance while supporting the global shift toward sustainable practices.

We recognise the importance of efficient procurement in ensuring the quality and availability of lubricants, which are essential for large-scale infrastructure projects. By sourcing premium raw materials, adhering to industry standards, and cultivating strong relationships with reliable suppliers, we guarantee the timely delivery of high-quality products. Our approach includes bulk purchasing and optimised inventory management, helping us control costs while maintaining supply efficiency. Additionally, we implement risk management strategies like supplier diversification to enhance the resilience of our supply chain. These measures collectively ensure a consistent supply of lubricants, keeping production cost-effective and reliable.

We strategically leverage digital technologies to optimise product performance, streamline distribution, and enhance customer engagement. Our WhatsApp Chatbot enables retail customers to place orders effortlessly, ensuring faster processing and availability. Our customer portal simplifies order placement for OEMs and distributors and provides real-time tracking, from billing to delivery. Additionally, we plan to implement a demand forecasting tool to gain better visibility into order fulfilment. At the same time, our Vendor Management Inventory (VMI) system will ensure smooth management of packaging materials at vendor locations, contributing to more efficient logistics and timely deliveries.

We are committed to expanding our product portfolio and manufacturing capabilities to meet the evolving regulatory standards in the automotive and mining sectors. For FY25 and beyond, we plan to innovate in lubricants and DEF formulations, invest in sustainable manufacturing practices, and further strengthen our distribution network across India. In the mining sector, we plan to introduce advanced lubricants designed for harsh conditions, including FA-4 oils that offer improved fuel efficiency and enhanced wear protection. As the shift to electric vehicles (EVs) accelerates, we prepare to develop specialised products such as battery coolants, EV transmission fluids, and greases. Sustainability remains central to our strategy, driving our investments in green manufacturing technologies, eco-friendly packaging, and biodegradable ingredients. To ensure our products are accessible even in remote areas, we are strengthening our distribution network across India and exploring international markets to meet the growing global demand for high-performance lubricants and DEF solutions.

For more information, visit: https://www.velvex.in/nandan-group-of-companies

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Despite rapid advancements in construction technology, Indian contractors remain hesitant to adopt electronics, AI, and IoT, preferring manual controls. High costs, unskilled operators, and shrinking project margins further hinder tech adoption, highlighting the need for a shift in mindset and market readiness.