JK Tyre debuted its latest OTR tyres for the mining industry at Bauma Conexpo 2024, displaying long-lasting, high-performance products and smart tyre technology designed for heavy-duty, difficult terrain operations.

JK Tyre & Industries, an Indian tyre company and pioneer of OTR tyres, unveiled its latest innovation in Off-the-Road (OTR) tyres, created exclusively for the mining sector, at Bauma Conexpo 2024 India, adding to its full OTR portfolio. The new offers include the 17.5-25 VEM 63 L5 wheel loader, the 16.00-25 VEM 99D E3 wide-body dump truck, the 12.00-24 VEM SMOOTH L5S load haul dumper, the 300-15 JET LIFT forklift, and the 10/75-15.3 MPT117 self-loading concrete mixer.

The products were introduced by Anuj Kathuria, President (India), and Debasis Khuntia, OTR Head of JK Tyre & Industries. The newly developed tyres are intended to provide a remarkable lifespan and better performance even in the most difficult terrains.

JK Tyre, the pioneer of introducing smart tyre technology – Treel (tyre pressure and temperature monitoring systems) to the country, has also displayed this cutting-edge innovation built exclusively for OTR tyres at the Expo. This groundbreaking technology improves efficiency in heavy-duty operations, reinforcing the company’s commitment to developing smart mobility solutions for the construction and mining industries.

At the inauguration, Anuj Kathuria, President (India), JK Tyre & Industries, says, “JK Tyre consistently pushes the boundaries of innovation in the OTR tyre segment, delivering solutions that are both robust and specifically designed to boost productivity in its sector. Our latest OTR tyres are engineered to excel in the most challenging terrains, offering unparalleled durability and efficiency for heavy-duty machinery in the mining sector. As a front-runner in the segment, we are dedicated to advancing performance, setting new standards in tyre technology, and enhancing the overall productivity in OTR industry.”

JK Tyre’s substantial research and technologically advanced manufacturing capabilities enable the company to meet the diversified needs of the mining industry with these advanced products. The VEM 63 (L5 Pattern) has an extra-deep tread for longer service life, a sidewall protector, wide lugs for stability, and a robust nylon casing for load capacity. The VEM 99D (E3 Pattern) provides greater handling with its chevron pattern, improved heat dissipation, and exceptional cut resistance.

The VEM SMOOTH L5S provides long tread life, stability, and great load endurance, making it ideal for hard mining situations. With a strong shell and a silica-based substance, the JET LIFT offers outstanding stability and durability. The MPT 117 provides exceptional mileage, increased durability, and a large load capacity for both on-road and off-road applications.

From being pioneers of manufacturing India’s largest tyre size- 40.00-57, 12 ft. in diameter, weighing approximately 3700 kg’s, to entering the Limca Book of Records for the largest off-the-road tyre — the VEM 045 measuring 12 feet in height and weighing approx. 3.4 tons, JK Tyre has been the leader in the Ultra large OTR tyre category. With a robust and comprehensive product range, JK Tyre continues to cater to industrial and mining applications’ diverse needs and requirements, delivering quality and dependability.

For more information, visit: https://www.jktyre.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Tata Hitachi displayed its electric EX 210LC excavator and creative solutions at BAUMA Conexpo 2024, emphasising sustainability, sophisticated technology, and next-generation machinery for India’s rapidly changing construction equipment sector.

The Minister of Road Transport and Highways, Government of India, visited the Tata Hitachi exhibit at bauma CONEXPO 2024 and unveiled their indigenous 20-tonne electric excavator idea EX 210LC Electric.

Tata Hitachi, a pioneer in India’s construction equipment business, proudly opened its pavilion at BAUMA Conexpo 2024 with an impressive display that included an indigenously created 20-ton electric excavator concept, the EX 210LC Electric. This cutting-edge electric machine meets the changing needs of infrastructure development while remaining focused on significantly lower operations and maintenance costs and the environment. It also demonstrates a strong commitment to sustainability and environmental responsibility.This unprecedented step demonstrates Tata Hitachi’s constant dedication to innovation, sustainability, and nation-building, as illustrated by the theme “Aao Kartavya Nibhaye, Chalo Desh Banaye.”

Tata Hitachi is happy to present the EX210 Value+ machine, which demonstrates our commitment to providing value-driven solutions to our clients. This machine is designed to meet the ideas of a circular economy by optimising performance and efficiency while reducing environmental impact. The EX210 Value+ provides great reliability and cost-effectiveness, backed by Tata Hitachi’s industry-leading warranty support, giving our customers peace of mind and unrivalled operating value.

The Tata Hitachi exhibit proudly displays a series of next-generation machines developed to meet a variety of industry needs. Highlights include:

New CEV-5 models: The 3.5-tonne TL340H Prime, the 5-tonne ZW 225, and the SHINRAI CEV-5 Prime Backhoe Loader. These machines are designed for improved performance, operator safety with features such as Roll Over Protection (ROPS) and Falling Object Protection (FOPS), higher fuel efficiency, and conformity to the most recent emission standards.

Designed to be versatile and reliable. The range consists of the ZAXIS 38U, NX 50, NX 80, EX130 Prime Tunnel, and EX350LC Prime models.

– The EX130 Prime Tunnel is designed expressly to satisfy India’s tunnelling needs, including crucial connection, hydro-irrigation, and power generating projects.

– The EX350LC Prime, a long-awaited addition to Tata Hitachi’s lineup, is intended to redefine productivity and efficiency by providing an optimum blend of power, agility, and cost-effectiveness to meet the industry’s increasing needs. A powerful 35-tonne excavator engineered to suit the needs of a wide range of industries and applications. This powerful equipment is designed for adaptability and will flourish in a variety of industries, including construction, mining, and infrastructure building.

These excavators are outfitted with innovative hydraulic systems, excellent operator comfort features, and strong engineering, allowing them to efficiently address the construction industry’s increasing difficulties.

A variety of tried-and-true models, such as the NX30, EX 215LC Prime, and ZAXIS 220LC Ultra, complement these new offerings. Together with customised attachments, these machines cement Tata Hitachi’s position as a market leader.

A collection of innovative attachments designed to increase versatility and efficiency in a variety of applications. These include the Tapered Ditch Bucket, which is ideal for precise ditching operations; the Jaw Bucket, which is designed to grip and handle materials with ease; the Trencher – MT600, which is ideal for digging narrow trenches for utilities or drainage systems; and the Backfill Blade, which streamlines backfilling tasks for increased productivity. Each attachment demonstrates Tata Hitachi’s dedication to innovation and satisfying a variety of operational requirements.

Visitors to the Tata Hitachi pavilion will also be able to try out cutting-edge telematics solutions like ConSite and InSite (which track and monitor machine performance and location in real time), as well as the eDost digital platform, which is an innovative, single-point solution that seamlessly integrates sales, service, and parts requirements for construction equipment customers. This complete platform improves interactions among customers, dealers, and manufacturers, increasing overall efficiency and production.

Sandeep Singh, Managing Director of Tata Hitachi, commented on the launches. “Through our customer-centric philosophy and industry expertise spanning over six decades, Tata Hitachi has built one of the largest customer-facing networks in India’s excavator segment. Our comprehensive portfolio now extends to Backhoe Loaders and Wheel Loaders, making us a trusted one-stop solution provider.”

Addressing the showcase of the EX 210LC Electric concept, he adds, “This electric excavator is a testament to our technical prowess and our commitment to sustainable solutions. By integrating innovation with ecoconscious practices, we are creating solutions that serve both the market’s needs and the environment.”

Emphasising the overarching theme of Tata Hitachi’s participation, Mr. Singh remarked, “Our presence at BAUMA Conexpo 2024 underlines our commitment to nation-building, a spirit embodied by our philosophy of ‘Aao Kartavya Nibhaye, Chalo Desh Banaye.’ This vision unites industry leaders and citizens under a shared goal of driving India’s progress through innovation, responsibility, and pride.”

For more information, visit: https://www.tatahitachi.co.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

TIL Limited (NSE: TIL), India’s leading material handling and infrastructure equipment manufacturer, introduced the Snorkel A62JRT articulating boom lift at Bauma ConExpo India 2024, marking the company’s strategic debut into India’s aerial work platform market.

The introduction, which took place on day one of Bauma ConExpo India 2024, Asia’s biggest construction equipment expo, at the India Expo Centre in Greater Noida, demonstrates TIL’s commitment to growing its product line following its recent cooperation with Snorkel Europe Limited. The event, which has gathered over 600 exhibitors from 26 countries and thousands of industry professionals, is an excellent opportunity for TIL to demonstrate its enlarged portfolio and technological capabilities.

The Snorkel A62JRT articulating boom lift is a significant improvement in aerial work platform technology, providing a larger working envelope and zero tail swing. The machine has an outstanding working height of 20.8m (67 ft. 8 in.) and the largest platform in its class, which can accommodate two operators and tools. Its short stowed length allows for easy transport between construction sites, while the oscillating front axle maintains consistent performance on uneven terrain, making it suitable for India’s different working situations.

The A62JRT is designed to be versatile and efficient, with multi-function proportional controls that allow for accurate operation and up-and-over capabilities. The machine’s powerful 4-wheel drive system, along with its rugged build, offers dependable performance over difficult terrain. With a maximum working outreach of 11.1m and a platform capacity of 227kg, the A62JRT raises the bar in the articulating boom lift category.

Sunil Kumar Chaturvedi, Chairman and Managing Director of TIL Limited, commented on the launch, says, “The unveiling of the A62JRT at Bauma ConExpo India 2024 marks a transformative moment in TIL’s journey as we expand our comprehensive material handling solutions. This machine combines robust engineering with versatile capabilities, perfectly suited for India’s diverse and demanding work environments. Backed by our eight decades of domain expertise and extensive pan-India network, this strategic expansion will contribute INR 200 crore to our topline by FY 2028.”

Alok Tripathi, President, TIL Limited adds, “Aerial work platforms have become crucial across various industries – from construction and mining to telecommunications and maintenance. The A62JRT represents our commitment to bringing world-class aerial access solutions that enhance productivity while maintaining the highest safety standards. As India’s infrastructure continues to evolve rapidly, TIL is positioned to meet the growing demand for safe and efficient aerial work platforms across diverse applications. Our partnership with Snorkel enables us to offer these cutting-edge solutions backed by TIL’s renowned after-sales support and service network.”

Further adding, Craig Revell, Business Development Director, Middle East and India, Snorkel Europe Limited mentions, “The A62JRT showcase is particularly special as it comes within months of our partnership with TIL Limited, demonstrating the swift execution capabilities of our collaboration. TIL’s extensive network and deep market understanding, combined with Snorkel’s global expertise in aerial work platforms, creates a powerful synergy that will deliver exceptional value to customers across various sectors. We are confident that this partnership will set new benchmarks in the AWP sector, bringing global standards of safety and efficiency to India’s rapidly growing infrastructure landscape.”

The Snorkel A62JRT is intended to serve a variety of sectors, including construction, maintenance, and industrial applications. It has modern features such as Snorkel Guard™ secondary guarding system, powerful hydrostatic 4-wheel drive, and an hour meter with on-board diagnostic display. The machine also has extra features like an AC generator for power tools and specialist packages for adverse weather conditions, making it suitable to a wide range of working settings across India.

For more information, visit: https://www.tilindia.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Doka, a global formwork leader, has joined the Science Based Targets program, strengthening its commitment to reducing emissions, reaching Net Zero by 2040, and pushing sustainability in the building industry.

Doka, a global leader in formwork and scaffolding, has become the first company in its industry to join the Science Based Targets initiative (SBTi). This milestone underlines Doka’s commitment to reducing emissions following the most recent scientific guidelines and helping to limit global warming to 1.5°C. By aligning its ambitions with the SBTi, Doka positions itself at the forefront of the global push to decarbonise the construction industry.

The construction sector is under increasing pressure to embrace more sustainable methods, driven by rising regulatory expectations and an urgent need to reduce its significant environmental effect. The industry accounts for over 37 percent of worldwide greenhouse gas emissions, making it an important actor in the fight against climate change. Doka sees this challenge as an environmental obligation and stimulus for developing more resilient and sustainable business models that can generate long-term success in the changing construction industry.

On the way to net zero

The commitment to the SBTi is a key component of Doka’s entire “Net Zero 2040” sustainability policy. “The transition to net zero is a complex challenge that requires both ambition and resilience. By committing to the SBTi, we are demonstrating that sustainability is not just a buzzword for us – it’s serious business,” says Robert Hauser, CEO of Doka. “We believe that sustainable practices and solutions are the key to helping our customers thrive in a futureproof, competitive construction industry.”

Ambitious climate targets as a competitive advantage

Doka has set ambitious targets for decreasing its carbon footprint. The company is committed to decreasing Scope 1, 2, and 3 emissions under the SBTi absolute reduction methodology, ensuring that Doka’s climate ambitions are consistent with the Paris Agreement’s 1.5°C trajectory. By 2030, emissions from Scope 1 and Scope 2 must be reduced by at least 42 percent. Scope 3 emissions, which include all indirect emissions created outside the company’s direct operations, must be reduced by 42 percent. Robert Hauser adds, “We are constantly collaborating with our customers and suppliers to develop safer, more efficient, and climate-friendly solutions. Our commitment to SBTi solidifies our dedication to cutting greenhouse gas emissions, not just within Doka but across our entire supply chain.”

A longstanding commitment to sustainable progress

Doka’s sustainability leadership extends well beyond its current commitment to the SBTi. Doka has already taken considerable steps to cut emissions, such as boosting the usage of renewable energy throughout its global operations. Doka’s Austrian headquarters has switched to 100 percent renewable electricity, aided by the expansion of photovoltaic installations and a green energy switch. These activities are critical to attaining the company’s long-term emission reduction targets, which are presently being validated by the SBTi, but they are only the beginning.

Furthermore, Doka’s rental model contributes significantly to the circular economy, which, like decarbonisation, is a crucial component of the company’s sustainability strategy. Doka reduces material and resource consumption by repairing its formwork after each use at dedicated service centers, allowing items to remain in circulation for longer. The company is also looking at the use of recycled, low-carbon materials in its formwork systems to reduce the environmental impact of construction projects. Doka, with a strong focus on innovation and collaboration, is constantly collaborating with top industry experts and organisations to promote sustainable practices, such as the use of intelligent heated formwork on building sites, which allows for the use of CO2-reduced concrete.

Doka has built on these efforts by pioneering the computation of the Product Carbon Footprint (PCF) for their portfolio of over 7,000 items. The company was essential in starting and co-developing the first industry-wide guidelines for determining the PCF of formwork and scaffolding, which enables evidence-based purchase decisions. These initiatives assist both the environment and Doka’s clients worldwide.

For more information, visit: https://www.doka.com/in/index

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The National Highways Authority’s SPV, DMEDL, will issue India’s first green bonds worth ₹1,000 crore, funding eco-friendly measures for the Delhi-Mumbai Expressway, advancing sustainability in the Roads & Highways sector.

Reiterating its commitment to promoting environmental sustainability and the development of green highways, the National Highways Authority of India’s fully owned Special Purpose Vehicle (SPV) ‘DME Development Limited’ (DMEDL) will issue green bonds to raise funds for the implementation of environmentally friendly measures on the Delhi-Mumbai Expressway project. The issue would be held under a closed bidding mechanism, with an aggregate total size of up to ₹ 1,000 crore and a base issue size of ₹ 500 crore.

There would be a green-shoe option for retaining oversubscription up to ₹ 500 crore. The first-ever green bond issue in the Roads and Highways sector is planned to be released in the second week of December 2024, with strict adherence to the Government of India’s sovereign green bonds framework, international conventions, and SEBI standards.

The revenues from the issuance of ‘Green Bonds’ will be used to fund operations such as avenue and median plantation, animal underpass construction, natural stormwater drainage, streetlights powered by renewable energy (solar), waste recycling and reuse, and rainfall gathering.

Commenting on this initiative NHAI Chairman, Shri Santosh Kumar Yadav says, “This initiative is a part of our vision to create greener National Highways and reiterates NHAI’s commitment towards environmental sustainability. The green bonds will help to encourage investment in eco-friendly projects, especially in the Roads & Highways sector and will facilitate long-term cost savings by reducing energy consumption and lowering the impact of vehicular emission on the environment.”

The issuance will help to improve DMEDL’s financial performance in terms of total borrowing costs while also diversifying the investor base by recruiting ‘Environmental, Social, and Governance’ minded investors. DMEDL has engaged Care Edge Analytics as the Third-Party Reviewer (TPR) to identify and certify DMEDL’s Green Activities.

‘DME Development Ltd.’, incorporated in August 2020, is NHAI’s wholly owned Special Purpose Vehicle (SPV) for the funding, building, and operation of the Delhi-Mumbai Greenfield Expressway and has got AAA ratings from CRISIL, CARE, and India Rating. DMEDL seeks to generate approximately Rs. 48,000 crore from banks and the financial markets through loans and bonds and has already raised approximately ₹ 42,000 crore for the Delhi-Mumbai Expressway project.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

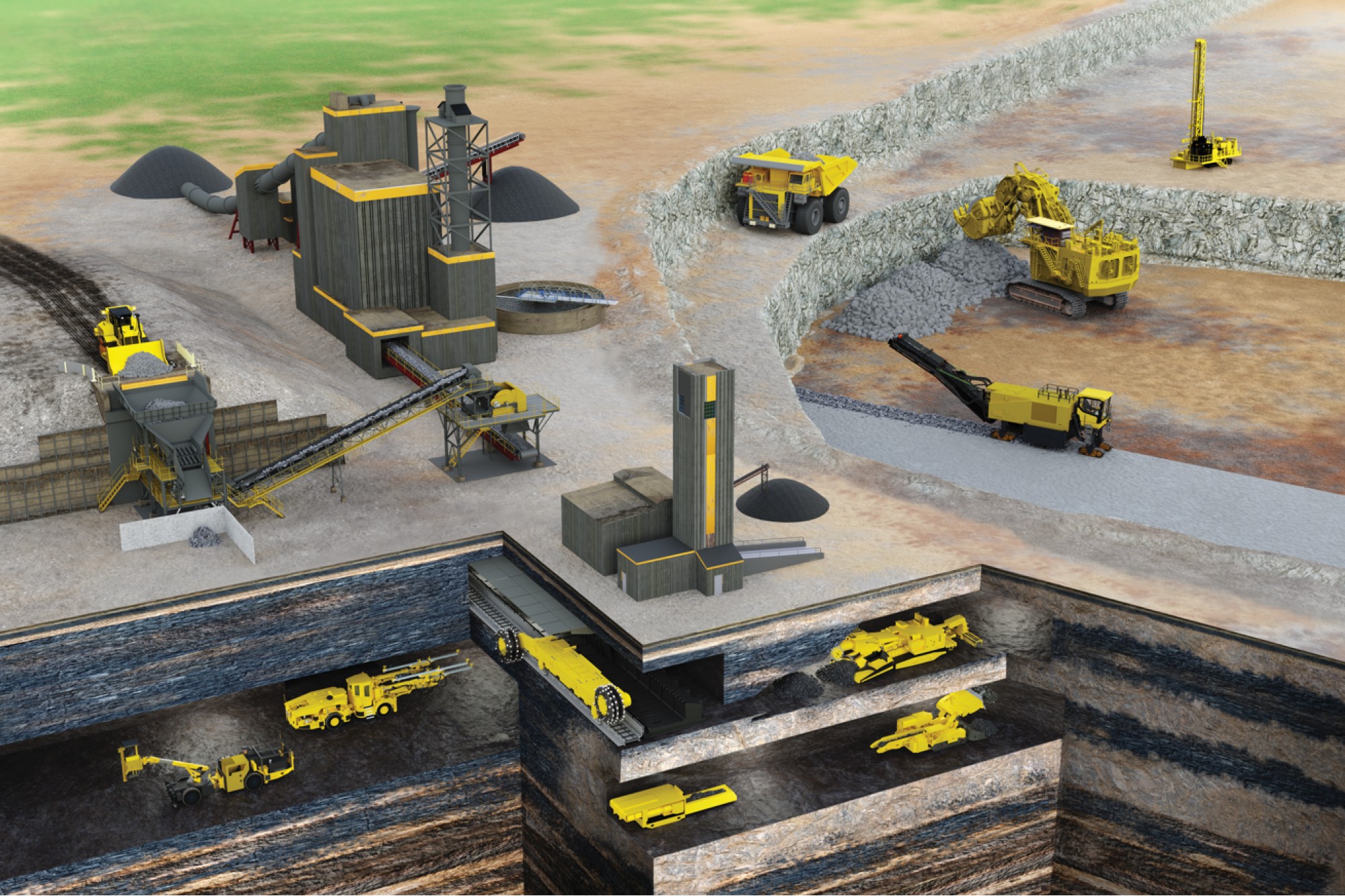

Kennametal India will present novel drilling, mining, road rehabilitation, and wear protection solutions at bauma CONEXPO 2024, with an emphasis on increasing productivity and performance to meet India’s growing infrastructure needs.

Kennametal India Limited will exhibit a comprehensive range of innovative foundation drilling, road rehabilitation, surface mining, trenching, and wear protection solutions at bauma CONEXPO 2024, one of the region’s leading trade fairs for the construction machinery, building material machine and mining machine industries, which will take place from December 11 to 14 at the India Expo Centre in Greater Noida.

MT Swamy, Regional Leader – APAC, Infrastructure Business, Kennametal India Limited says, “In line with rising infrastructure development in the country, our customers demand higher productivity and performance from their equipment. Kennametal’s offerings in road rehabilitation, mining and trenching are developed to perform in the toughest conditions while delivering optimum efficiency. We look forward to partnering with customers on their growth journeys and transforming how everyday life is built.”

Kennametal’s Road King™ tool line is ideal for road rehabilitation due to its exceptional milling machine performance. Visitors will be able to see the RK31, RK32, RK43, and RK54 models, which feature new design improvements such as improved body, washer, and retainer design for optimal carbide tip usage, better rotation, and reduced axial play, all of which improve holder protection and retention in the current generation of tool holders. Road King’s design components extend tool life while making tooth changes simple and efficient for operators.

Kennametal will showcase its premium 38/30mm shank series conical tools and concomitant holders for hydraulic rigs and diaphragm wall cutters, as well as the KF Series quick change flat cutters, weld on teeth, and flat teeth with TC buttons, which are known for increasing productivity and overall performance. Kennametal will also demonstrate its 25mm-shank conical tool portfolio and holders, as well as a ‘core barrel ring’ built by in-house experts based on customer specifications.

Our foundation drilling conical tools with extra-tough grade KHE16, which can penetrate even the toughest rocks, will also be on show. In tests comparing it to our standard construction grade, this innovative pick features a tapered tungsten carbide tip that wears evenly with the pick’s steel body; provides increased chipping and fracture resistance as well as improved thermal properties; maintains cutting efficiency over a longer period; reduces downtime required to inspect tools and replace damaged picks; and saves money by extending the life of the machine’s holders and drilling tools.

Finally, in the surface mining solutions category, Kennametal will showcase its conical tools with the industry’s first taper tip for surface miners, which deliver new levels of performance and productivity, as well as KenCastTM wear protection solutions, which extend wear part life by up to 6X, ultimately benefiting customers by avoiding costly repairs and downtime.

For more information, visit: https://www.kennametal.com/in/en/home.html

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

DPIIT collaborates with Moglix to develop a 12-month Manufacturing Incubation Program, providing coaching, resources, and finance to 25 growth-stage businesses, thereby strengthening India’s innovation-driven manufacturing and aligning with Atmanirbhar Bharat.

The Department for Promotion of Industry and Internal Trade (DPIIT) has signed a Memorandum of Understanding (MoU) with Moglix, Asia’s top B2B e-commerce platform, to establish a manufacturing incubation program. This alliance represents a critical milestone in India’s manufacturing journey, bolstering the vision of a Viksit Bharat. The initiative’s goal is to provide growth-stage entrepreneurs with tools, resources, and chances to accelerate their success and stimulate innovation in the manufacturing sector.

The program will help over 25 growth-stage entrepreneurs in industries such as chemicals, automotive, infrastructure, and green energy. These entrepreneurs will take part in a 12-month program that includes access to Moglix’s large mentor network, supply chain infrastructure, and financial help through Credlix, the company’s NBFC subsidiary. DPIIT will expand the program’s reach by leveraging the Startup India ecosystem to facilitate adoption, resource sharing, and nationwide exposure.

Sanjiv Singh, Joint Secretary of DPIIT, remarks, “Startups are catalysts for India’s economic and technological progress. This MoU with Moglix underscores our commitment to fostering innovation, nurturing entrepreneurship, and building a resilient manufacturing ecosystem aligned with India’s vision of self-reliance.”

Rahul Garg, Founder and CEO of Moglix, adds, “This collaboration is a transformative step for India’s manufacturing sector. By combining Moglix’s technological expertise with DPIIT’s strategic guidance, we aim to build a sustainable, innovation-driven manufacturing economy that empowers entrepreneurs and aligns with India’s vision of becoming a global manufacturing hub.”

Aligned with Atmanirbhar Bharat’s goal, this program will empower startups with collaborations, funding possibilities, and resources to produce globally competitive goods. It also intends to boost India’s manufacturing contribution to GDP and assist entrepreneurs in entering foreign markets.

This agreement demonstrates Moglix’s dedication to enhancing supply chains while solving the problems that growth-stage manufacturing businesses confront. It is consistent with India’s national aims of increasing the manufacturing sector’s GDP contribution and establishing the country as a worldwide industrial leader.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

As India strives for economic growth and infrastructure development, the construction equipment sector prioritises innovation, sustainability, and global competitiveness to provide safer, more efficient, cost-effective solutions for nation-building.

How do your innovations tackle challenges in large-scale infrastructure projects, boosting speed and cost-effectiveness?

India is on track to become the world’s third-largest economy by 2030, with a 5.1 percent proportion of global GDP up from 3.5 percent today. This will rise at a CAGR of almost 9 percent during this time. This expansion will be part of our goal of achieving a Viksit Bharat by 2047, and infrastructure development will be the cornerstone, bringing significant opportunities for the Construction Equipment sector.

This opportunity comes with its own set of challenges and responsibilities. We understand that our products must deliver high-duty cycles, productivity and economy, safety for users and people in the vicinity, durability of equipment, and a cleaner environment. All these aspects are at the core of our design and manufacturing goals, and we are confident that with each new development, we can deliver superior products that meet each of these customer requirements.

Our equipment line is frequently growing to meet the changing needs of the construction industry. Load safety is linked to telematics, ensuring it is well-monitored at major infrastructure sites. IoT is also assisting us in creating smarter machines that are connected to customers, hence increasing connectivity and efficiency. This is why we are our customers’ preferred partner for nation-building.

How is your company reducing energy use and emissions and incorporating green technology in its equipment?

Sustainability is vital to human life, and we are focused on it from the start, from designing equipment to using less fuel per unit of work done. The materials we and our suppliers utilise adhere to all guidelines and best practices. We implement energy-efficient technology in our equipment to reduce environmental effects while improving operating safety. For example, compliance with CEV stage V is a major step towards lowering carbon footprint. Our new products are more fuel efficient than previous models because of innovative solutions supplied in our hydraulic and engine systems, reducing energy demand. Our manufacturing plant is energy- and water-efficient, as we generate solar electricity and harvest water.

What strategies help your company stand out globally and tackle challenges like pricing, tariffs, logistics, and local regulations in export markets?

Our unwavering commitment to understanding the demands of worldwide customers and our improved goods with the most up-to-date emission and safety standards are expanding global acceptance of our products. The gap between items from established and emerging markets is gradually closing, and new products are becoming more acceptable due to India’s low-cost basis. For example, our newly built export digger loader, which includes features such as an extended dipper, rock crusher, multiple bucket options, AC/HVAC and compatibility for extreme subzero climates, is significantly improving our position in worldwide markets. Our distribution is expanding, and our firm spans more than 20 nations.

How are you optimising manufacturing and supply chain processes to reduce costs while maintaining quality and delivery timelines?

Through the introduction of the Kubota Production System (KPS), our plant has rapidly adopted efficient operations. This also boosted capacity to meet future demand and offer high-quality results while minimising waste.

Our supply chain has undergone a comprehensive procurement review exercise and supplier quality upgrades to ensure process and delivery uniformity. A Kaizen Community, which includes professionals from Kubota Japan, wworkson theme-based projects to reduce costs, increase production, and improve operational efficiency at our suppliers.

Capacity enhancement for essential suppliers is also underway, and investments are being made to match the industry’s predicted future levels.

How are you upskilling to ensure quality component production?

The MSME sector is important to the construction equipment supply chain. We are collaborating closely with these industries to upskill MSMEs so that they can take the next step in manufacturing high-quality components.

We provide technical help to MSMEs by establishing our standards/processes and encouraging the implementation of international quality standards such as ISO 9001 and TS16949. This can help MSMEs build a reputation for quality and dependability, increasing their appeal to OEMs and other consumers. This can help them implement best practices, optimise manufacturing processes, and enhance product quality.

Recommending that they participate in or engage with government agencies, industry associations, and so on through various ICEMA/CII activities. These programs concentrate on quality control, lean production, and applying innovative technologies.

This flagship program is driving the “Make in India” movement, seeks to boost Indian manufacturing and encourage MSMEs to participate in the global supply chain.

What support is needed to attract multinational investment in high-quality component manufacturing?

The government’s ongoing focus on the Construction Equipment industry and its faster reaction to industry challenges through ICEMA has produced an environment where customers benefit from innovative products and solutions. The government’s objective of energy self-sufficiency and climate change is pushing the industry to create fuel-efficient, carbon-neutral products. While manufacturers must invest in these technologies, their efforts must be bolstered by targeted PLI or other incentives to accelerate investment. Adoption of carbon-neutral technology will also require external environmental backing, which will necessitate measures from both the government and the industry.

How can industry-government partnerships improve operations and foster innovation?

Industry and government have collaborated in various ways, and we have witnessed the evolution of the entire industry. However, there are issues that we must recognise and solve, as they may become a priority given the rate at which we are moving in infrastructure development.

One such area to focus on would be the implementation of common standards across all types of equipment used in terms of emission, safety, registration rules, and so on, as well as a 10-year roadmap that will guide manufacturers in planning capacity and capex requirements.

The infrastructure industry, including manufacturers, faces a growing challenge in skilled workforce availability. While various government and private agencies are making credible efforts, these efforts must be coordinated by design and outcome to meet specific standards.

How does your participation at Bauma India 2024 reflect the ‘Innovation for Nation Building’ theme?

Our participation in Bauma Conexpo India 2024 is aligned with the theme ‘Innovation for Nation Building,’ our key priorities remain safety, productivity, and efficiency. We’re offering improvements focusing on energy saving, operator safety, automation, and real-time monitoring. These achievements demonstrate our commitment to ensuring India’s infrastructure growth is safe and sustainable. All of our new products are CEV V compliant and CEV II Safety legislated, with different unique features to meet the varying needs of our customers, whether for captive or rental applications. Our product range accounts for 55 percent of the CE industry by volume, and we are always focused on our role in leading innovations and solutions for our clients.

For more information, visit: https://www.escortskubota.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

At bauma CONEXPO INDIA 2024, Caterpillar is set to showcase its latest innovations. Amit Bansal, Director of Sales & Marketing, outlines how the company is leading the way with advanced technology, autonomous machinery, and sustainable solutions to drive India’s infrastructure forward.

What latest innovations will you be showcasing at bauma CONEXPO INDIA 2024?

India is poised for growth, and this era is the golden era for Indian infrastructure, with so many projects being planned and implemented by the government. We are fully ready to support our customers with our latest technologically advanced machines and solutions and play an important role in building a new India.

At Bauma CONEXPO this year, our primary objective is to showcase Caterpillar’s extensive product solutions, featuring a wide range of Cat and other Caterpillar brand equipment. We aim to highlight our latest offerings, aftermarket services, and financial solutions designed to support our customers. Additionally, we will focus on technology and solutions that enhance productivity, efficiency, safety, and profitability for customers in the Indian construction equipment industry.

Digital transformation, including AI, IoT, telematics, and automation, is a driving force in the industry. How are these technologies integrated into your products?

Advanced technologies create a game-changing customer experience, improving profitability, efficiency, safety, and sustainability. We are committed to understanding customers’ needs and delivering pioneering products, with a focus on digital-enabled solutions and the aftermarket.

When it comes to autonomous technology, Caterpillar is leading the way. We currently have the largest autonomous truck fleet in the world, with over 580 machines in operation, and that number continues to grow each year.

In alternative fuels, we are helping customers reduce lifecycle greenhouse gas (GHG) emissions by offering equipment that can operate on lower-carbon intensity fuels like biodiesel, renewable diesel, and biogas. While tailpipe emissions remain similar to traditional fuels, the overall lifecycle GHG emissions are significantly reduced. For instance, all Caterpillar diesel engines can run on 100% Hydrotreated Vegetable Oil (HVO).

Connectivity is another area in which Caterpillar has been a pioneer for over 20 years. We have connected more than 1.5 million assets through telematics, enabling us to generate valuable machine insights. This data allows customers to operate their fleets more efficiently, optimising productivity while conserving essential resources like fuel.

We are also focused on electrification and committed to delivering powerful electrified products and solutions. Our initial battery-powered equipment gave us valuable experience, and with more battery-powered machines and chargers under development, we are helping our customers achieve their climate-related objectives. Our electric drivetrains and hybrid powertrains, using electric drive transmissions, are designed to improve energy efficiency and productivity.

India’s equipment market is growing rapidly, but this brings challenges in building a robust component supplier and service provider ecosystem. How are you addressing these challenges?

India is an important global manufacturing hub, and we recognise this, having invested significantly in our local operations. We have an intricate network with hundreds of suppliers, serving not just our Indian customers but also catering to global demands. Along with our subsidiary brands, we envision a more interconnected, efficient, and sustainable India.

Regarding services, our long-standing Cat dealers, Gainwell Commosales India Pvt Ltd and Gmmco Ltd, are strategically located across the country to serve and support our customers efficiently. They are always ready to respond quickly to any needs. We offer tailored plans throughout the product lifecycle to enhance the ownership experience for our Cat customers, ensuring they get the most out of their equipment.

Our dealers provide 24/7 support through a dedicated network of almost 4,000 people, all backed by Caterpillar experts. This extensive service network is a key advantage, helping our customers receive immediate assistance whenever required.

Cat Financial offers various financing and leasing options and extended protection packages to support our customers further. Whether customers are looking to invest in new or used Cat machines or need funding for repairs and rebuilds, Cat Financial helps them make informed decisions that best suit their business needs, regardless of size.

Maximising machine performance is crucial, and that’s where our Customer Value Agreements (CVAs) come into play. These agreements offer hassle-free service at any point in the machine’s lifecycle, ensuring maximum performance and utilisation. With CVAs, customers receive support from dealer technicians, genuine Cat parts for scheduled maintenance, and fluid health management to identify potential issues before they lead to downtime. It’s an all-in-one plan designed to maintain machine health and ensure longevity, making equipment ownership easier.

Our Cat Rebuild and Cat Reman options are sustainable and cost efficiency solutions. Cat equipment is designed to be rebuilt, offering the ability to restore used machines to like-new performance at a fraction of the cost of new equipment. Our certified rebuild options breathe new life into machines, extending their useful life while reducing the need for new resources. This supports customer demand and contributes to a circular economy, aligning with global sustainability goals.

We have also embraced digital solutions to facilitate business. Our eCommerce platform, www.Parts.Cat.Com, and dealer-specific mobile applications simplify Cat equipment’s ownership, operation, and maintenance. Customers can access everything they need to manage their machinery efficiently at the click of a button.

Can you share your approach to sustainability throughout your products’ lifecycle, including any innovations in materials, recycling, or circular economy initiatives?

Caterpillar contributes to a reduced-carbon future by investing in new products, technologies, and solutions to help customers meet their climate-related objectives. Our portfolio includes advanced technology solutions to support our customers’ needs in their sustainability journey.

Over the past 20 years, we have invested over $30 billion in R&D to deliver best-in-class innovation, including autonomy, alternative fuels, connectivity and digital and electrification (AACE) technologies.

We integrate the energy technologies developed by our Energy & Transportation (E&T) segment into machines manufactured by our Resource Industries (RI) and Construction Industries (CI) segments, providing an advantage to our customers as we help them achieve their objectives. Our construction equipment helps build the infrastructure for the energy transition. Our mining equipment supports the increased demand for critical materials, such as copper, lithium, nickel, and cobalt, required for electric vehicles, battery storage, wind and solar power, and grid modernisation and stability. We offer machines and engines capable of operating on alternative fuels such as hydrogen, biogas, hydrotreated vegetable oil (HVO) and biodiesel while continuing to develop technologies for the future.

One of our leading innovations is in autonomous technology. Caterpillar has one of the largest autonomous truck fleets in the world, with more trucks being launched each year. This technology revolutionises the industry, improving safety, efficiency, and productivity.

We are helping customers reduce lifecycle greenhouse gas (GHG) emissions by offering products that run on lower-carbon intensity fuels like biodiesel, renewable diesel, and biogas. While tailpipe emissions are similar to traditional fuels, the overall lifecycle GHG emissions are reduced significantly. For instance, all Caterpillar diesel engines can run on 100% Hydrotreated Vegetable Oil (HVO).

For more than twenty years, Caterpillar has also been a leader in connectivity. We connected over 1.5 million assets using telematics, generating valuable data insights. This helps our customers operate their fleets more efficiently, optimising productivity and conserving critical resources like fuel.

Electrification is another key area where Caterpillar is making significant strides. We’ve already introduced battery-powered equipment and continue developing more battery-powered machines and charging solutions. These advancements will support our customers’ climate-related goals by improving energy efficiency and productivity through electric drivetrains and hybrid powertrains.

In terms of sustainability, our Cat Reman program plays a crucial role. Caterpillar has been remanufacturing for 50 of its nearly 100 years in business, and today, remanufacturing is central to our strategy for building a more sustainable world. Through the Cat Reman process, used components are returned, cleaned, inspected, salvaged, and remanufactured to meet original factory specifications. This ensures like-new performance with the added benefit of relevant engineering updates. Using state-of-the-art salvage techniques and strict quality controls, Cat Reman offers affordable, high-performance products that support the circular economy while carrying a same-as-new warranty. This way, we give materials a new life and help our customers achieve their sustainability goals.

With India’s changing regulatory framework in construction, infrastructure, and mining sectors, how is your company adapting to ensure compliance while innovating?

Infrastructure is key to India’s economic growth, and our mission is more than just being a machinery supplier; we aim to be a key partner in India’s infrastructural expansion. As growth in mining, transportation, captive power generation, and infrastructure construction accelerates, the demand for efficient, state-of-the-art machinery escalates. We are committed to addressing this demand with innovative solutions, and from every road to every skyscraper, you will find a touch of Caterpillar.

In recent years, our dedicated focus in India has centred around elevating R&D investments, aligning with evolving regulatory benchmarks. This includes the transition from CEV 3 to CEV 4 in 2021 and the impending leap to CEV 5 emission standards, as well as our steadfast commitment to compliance and progress.

For more information, visit: https://www.caterpillar.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

A live demonstration of the BF90.3 Crusher Bucket with the MB-S18 Screening Bucket demonstrates efficiency and sustainability in construction.

MB Crusher, a global pioneer in crushing and screening solutions, will take part in BAUMA CONEXPO INDIA 2024 at the India Expo Centre in Greater Noida, Delhi NCR. From December 11 to 14, 2024, MB Crusher will provide a live demonstration of two of its flagship products, the BF90.3 crusher bucket and the MB-S18 screening bucket, at stall O.F10. This event will highlight MB Crusher’s dedication to increasing productivity, decreasing waste, and encouraging sustainable practices in building and demolition.

They are excited to be a part of BAUMA CONEXPO INDIA 2024. With India’s rapidly increasing construction sector, this event provides a perfect chance to showcase the capabilities of our BF90.3 and MB-S18 machines. Their live demonstration will allow visitors to observe firsthand how MB Crusher’s solutions may help businesses save money and improve project efficiency.

Bringing industry-leading solutions to India’s growing construction market

The BF90.3 crusher bucket is one of MB Crusher’s most popular models, designed to crush a variety of materials such as concrete, granite, stone, and demolition debris. This equipment allows businesses to recycle waste on-site, considerably lowering transportation and disposal costs. The BF90.3 is well-known for its durability, making it ideal for demolition, road building, and mining operations that prioritise sustainability and cost savings.

The MB-S18 screening bucket is versatile, allowing you to sort and separate items like soil, gravel, and rubble. This methodology improves productivity in a variety of areas, including landscaping and garbage recycling, allowing project managers to maximise efficiency and reduce operational costs.

Demonstrating innovation and efficiency at BAUMA CONEXPO INDIA 2024

MB Crusher’s live demo at BAUMA CONEXPO INDIA 2024 will provide delegates with an immersive experience of the BF90.3 and MB-S18, demonstrating their cutting-edge features and operating advantages. The expo is expected to attract hundreds of industry professionals looking for creative solutions in construction and mining, and MB Crusher is ready to demonstrate how its technology can improve jobsite operations.

In addition to the demonstration, MB Crusher experts will be accessible throughout the event to discuss various projects. Attendees will have the opportunity to hear about the environmental benefits of on-site crushing and screening, which reduces waste while producing sustainable, reusable aggregate.

Key benefits of MB Crusher’s machinery:

Join MB Crusher at BAUMA CONEXPO INDIA 2024, Stall O.F10.

MB Crusher invites all industry professionals, project managers, and enthusiasts to visit its booth O.F10 from December 11 to 14, 2024, to see the future of crushing and screening technologies. Don’t pass up this opportunity to understand how MB Crusher’s equipment may help you achieve improved efficiency, profitability, and sustainability in your projects.

To learn more about MB Crusher’s involvement in BAUMA CONEXPO INDIA 2024 or to organise a meeting with our team, please contact:

MB Crusher India Private Limited

Email: info@mbcrusher.com

Phone: +91 22 4970 6759

Website: http://www.mbcrusher.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

BharatBenz introduces AMT technology, proven globally in Daimler Trucks, to its heavy-duty vehicles, enhancing productivity and fatigue-free driving. A bulk order of 80 units for the mining segment highlights its demand.

Daimler India Commercial Vehicles (DICV), a wholly-owned subsidiary of Daimler Truck AG (“Daimler Truck”), announces the market launch of the BharatBenz heavy-duty truck (HDT) range equipped with the globally proven 12-speed Automated Manual Transmission (AMT) by receiving the first order of 80 3532CM mining tippers from a single customer. BharatBenz, known for its extremely capable construction and mining heavy-duty range, expanded its product offering by introducing ‘Torqshift’.

The 12-speed Automated Manual Transmission (AMT), known as ‘Torqshift’ for the BharatBenz range, has been used in hundreds of thousands of Mercedes-Benz trucks throughout the world. The gearbox, known for its ease of use, will be available in the latest BharatBenz models, including the 4032T, 5532TS, 5532T, 2832CM, and the flagship 3532CM.

Sreeram Venkateswaran, President and Chief Business Officer comments, “Heavy-duty Construction and Mining (CM) trucks are one of our strengths and we have considerable presence in this space. With the new 12-speed AMT in our CM portfolio, the customers will see a significant benefit in productivity improvement in their operations and notable savings as the overall fleet efficiency will go up. The deliveries for the 3532CM BharatBenz Torqshift trucks have started and vehicles are already being deployed in operations. We will offer AMT in Tractor Trailers (TT) as well, which will not only enhance the productivity of the vehicles, but play a critical role in improving road safety as well. This is a segment we foresee growing steadily and with road infrastructure rapidly shaping up, BharatBenz Torqshift range will add a lot of value to our long-haul logistics customers. Our AMT technology, adapted from Mercedes-Benz trucks, delivers consistently on the total cost of ownership equation. It is ideally engineered to suit Indian conditions to offer incredible value through our Mining Tippers, Surface Tippers and Tractor Trailers.”

The BharatBenz Torqshift series provides greater driving comfort with smooth, jerk-free gear shifting and much faster shift times, improving the vehicle’s drivability. The integration of the shift lever into the steering column not only enhances interior ergonomics, but it also helps to isolate noise and heat, resulting in a more comfortable drive.

Pradeep Kumar Thimmaiyan, President and Chief Technology Officer, Daimler India Commercial Vehicles says, “The 12-speed AMT is a big triumph for us at India Product Engineering as we achieved our goal to introduce this transmission in our BharatBenz portfolio after meticulous planning and adaptive engineering, ensuring minimal cost of development. A global technology like the Mercedes-Benz AMT, seamlessly integrated in our BharatBenz Torqshift range of trucks, keeps in mind our customers’ needs in the market. This technology is designed to reduce driving stress and to ensure a faster turnaround with significantly higher fuel efficiency. Torqshift is engineered to minimize maintenance, significantly improving the total cost of ownership for our customers. This aligns perfectly with our intent to deliver not only well-engineered and safe products, but also ones that add tremendous value to our customers’ businesses.”

Engineered to accommodate heavy-duty requirements in the Indian construction and mining segments and long-haul, the Torqshift range has a wider selection of gear ratios and higher input torque capacity, making the BharatBenz trucks ideally suited for handling gross combination weights (GCW) from 28 to 55 tonnes. This strong performance is complimented by a revolutionary design that removes the need for synchromesh components, increasing reliability and eliminating the need for frequent overhauls. Its compact and lightweight aluminium enclosure provides excellent installation and power-to-weight ratio. The Torqshift’s fuel-efficient design is optimised for specific operational situations, resulting in a lower total cost of ownership. Safety is also a significant aspect, with software-controlled powertrain protection technologies that limit the possibility of driveline component damage in harsh operating situations. Furthermore, the best-in-class shifting system allows for extremely smooth gear changes, supporting optimal driving comfort and safety throughout different driving modes, including auto, manual, power, and eco.

For more information, visit: https://www.bharatbenz.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

BEML Ltd and MDL have collaborated to develop refined marine technologies, combining engineering and shipbuilding experience to increase India’s self-reliance in defence, in line with the “Aatmanirbhar Bharat” goal.

BEML Ltd and Mazagon Dock Shipbuilders Ltd (MDL) have signed a strategic Memorandum of Understanding (MoU) to collaborate on research and development of cutting-edge marine technologies. The signing ceremony occurred at BEML’s Delhi office and was attended by the company’s CMD, MDL’s Director (Shipbuilding), and senior officials from both organisations.

MDL is India’s only shipyard with a proven track record of manufacturing frigates, destroyers, and submarines. MDL has been participating in the indigenisation of its platform and is actively seeking partners to attain its goal of creating platforms entirely in India.

BEML Ltd has created robust research capabilities in various sectors, including platform designs for heavy defence utility vehicles, missile systems, metro and rail components, mining equipment, and defence system modernisation. As part of its strategy to broaden its expertise in the field, BEML intends to use its cooperation with MDL to develop cutting-edge solutions for future marine applications.

This collaboration demonstrates BEML’s dedication to improving its research skills and driving innovation in the defence and maritime sectors. The cooperation aims to capitalise on new opportunities in the maritime sector and contribute to India’s vision of “Aatmanirbhar Bharat” and technical self-reliance in crucial military technologies by combining its established engineering competence with MDL’s extensive understanding of shipbuilding.

Welcoming the partnership, Shri Shantanu Roy, CMD of BEML Ltd, states, “We are delighted to join hands with MDL to advance the nation’s maritime sector through enhanced research and the development of indigenous technologies. This collaboration underscores our commitment to reducing dependency on imports for the defence forces while strengthening our manufacturing capabilities and contributing to India’s self-reliance in the defence and maritime domain.”

Shri Sanjeev Singhal, CMD (MDL) states,“The MoU between MDL and BEML is an important step in the right direction. This collaboration is a testament to the shared vision of both organisations to drive innovation and technological advancement in Marine applications. This partnership is not just a milestone but a small yet decisive move towards the realisation of self-reliance in Defence production under the “Aatmanirbhar Bharat” initiative. I am confident that this partnership shall pave the way for meaningful indigenisation in the Defence sector and reinforce our commitment to the nation’s security and progress.”

BEML will contribute its substantial knowledge to this MoU by providing technical guidance for the design and manufacture of important marine-specific equipment. The company will also concentrate on creating and optimising manufacturing processes to meet the specialised needs of the maritime industry.

MDL will lead its indigenisation initiatives in conjunction with BEML, using BEML’s established track record of localising production for defence, rail, and mining equipment. This collaboration is a crucial step towards increasing self-sufficiency in critical marine technology while decreasing dependency on imports.

To facilitate this collaboration, MDL will provide BEML’s research team with dedicated facilities for the development, testing, and validation of novel technologies and systems. Together, the two organisations hope to stimulate innovation and produce cutting-edge solutions that line with India’s vision of Atmanirbhar Bharat (self-sufficient India) and boost the country’s maritime capabilities.

For more information, visit: https://www.bemlindia.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

MYCRANE, the first global platform for online crane leasing, has expanded its offering by launching a new Marketplace to ease the international sale and purchase of lifting equipment.

The Marketplace, which was officially launched at bauma China, builds on the strengths of the MYCRANE crane rental platform, which is already well-established in highly active buying markets such as India and the Middle East, with over 1,500 registered crane rental companies offering more than 12,000 cranes.

MYCRANE users and other interested parties worldwide can now buy and sell used and new lifting equipment on the MYCRANE Marketplace. This promotes a movement from low-volume and pricey trades and towards numerous, cost-effective sales transactions. There are no subscription costs; only competitive fees are due after a sale.

The MYCRANE Marketplace sells lifting equipment such as mobile, crawler, tower and specialist cranes, as well as aerial work platforms and other equipment.

“Just as we’ve made crane rental easy and accessible for all, we now want to democratise the equipment sales process, by supporting fast, global trading and providing access to a wide range of keenly-priced equipment,” says Andrei Geikalo, MYCRANE founder and CEO.

“The MYCRANE Marketplace is particularly valuable to individuals and small and medium-sized enterprises (SMEs), who will be empowered by the ability to source the right equipment at the right price – wherever they are, internationally.

“The goal is to streamline the buying process, increase transparency and choice, and create a robust trading platform for the benefit of the entire industry.”

The MYCRANE Marketplace, which can be reached at market.my-crane.com, provides verified crane documentation, choices to filter lifting equipment by age and condition, and the ability to receive inspection results.

Finally, MYCRANE may provide logistics and transportation services, from the sales process to final delivery at the customer’s project site anywhere in the world, as well as insurance and leasing (financing) to support the purchase.

For more information, visit: https://my-crane.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

BEML Limited secures a ₹ 246.78 crore order from Central Coalfields Limited for 48 BH60M Rear Dump Trucks, showcasing its dedication to creative, reliable, and high-performance solutions in mining operations.

BEML Limited, a premier Public Sector Undertaking under the Ministry of Defence, Government of India, has bagged a significant order worth ₹246.78 crore from Central Coalfields Limited. The deal includes the delivery of 48 cutting-edge BH60M Rear Dump Trucks, as well as parts and consumables for 1+4 years and full after-sales service support.

The BH60M Rear Dump Truck is a high-performance vehicle equipped with a Cummins engine providing 480 kW (644 FHP) at 2000 rpm with a sophisticated Allison gearbox. With a payload capacity of 54,500 kg, this truck is designed to withstand the harsh conditions of mining operations. Its ergonomically built cabin provides operators with improved comfort and control, while Orbitrol full-time power steering and a shortened turning radius provide exceptional manoeuvrability.

The BH60M Rear Dump Truck, which is primarily constructed at BEML’s Mysuru plant, is outfitted with cutting-edge innovations that improve safety, efficiency, and operator comfort. These include a 360-degree back camera for increased visibility and safety, an Automatic Fire Suppression System for emergency preparedness, and an Auto Lube System for easy maintenance. The air-conditioned cabin creates a comfortable working environment, while the Driver Fatigue Monitor System and Productivity & Health Monitoring System improve operational efficiency and equipment health, making it a cutting-edge solution for current mining operations.

These attributes make the BH60M an excellent choice for efficient and safe overburden transportation in mining operations. The truck meets ISO standards and the most recent safety regulations outlined in DGMS circulars dated October 2018 and February 2020. Once the equipment passes the final inspection, deliveries will begin as soon as possible, while adhering to the highest quality and timing requirements.

Commenting on the development, Shri Shantanu Roy, Chairman and Managing Director of BEML Ltd, says, “This order is a testament to our enduring partnership with Central Coalfields Limited and highlights BEML’s unwavering commitment to delivering innovative, reliable, and high-performance mining solutions. We take immense pride in being a trusted partner to the mining sector, providing cutting-edge equipment that meets the evolving demands of the industry. This milestone further strengthens our resolve to contribute to India’s growth by supporting critical sectors like mining with sustainable and advanced technologies, aligning with the nation’s vision of self-reliance and global leadership in industrial innovation.”

With this order, BEML cements its position as a reliable partner in the mining and infrastructure industries, underlining its commitment to fostering innovation, quality, and nation-building.

For more information, visit: https://www.bemlindia.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

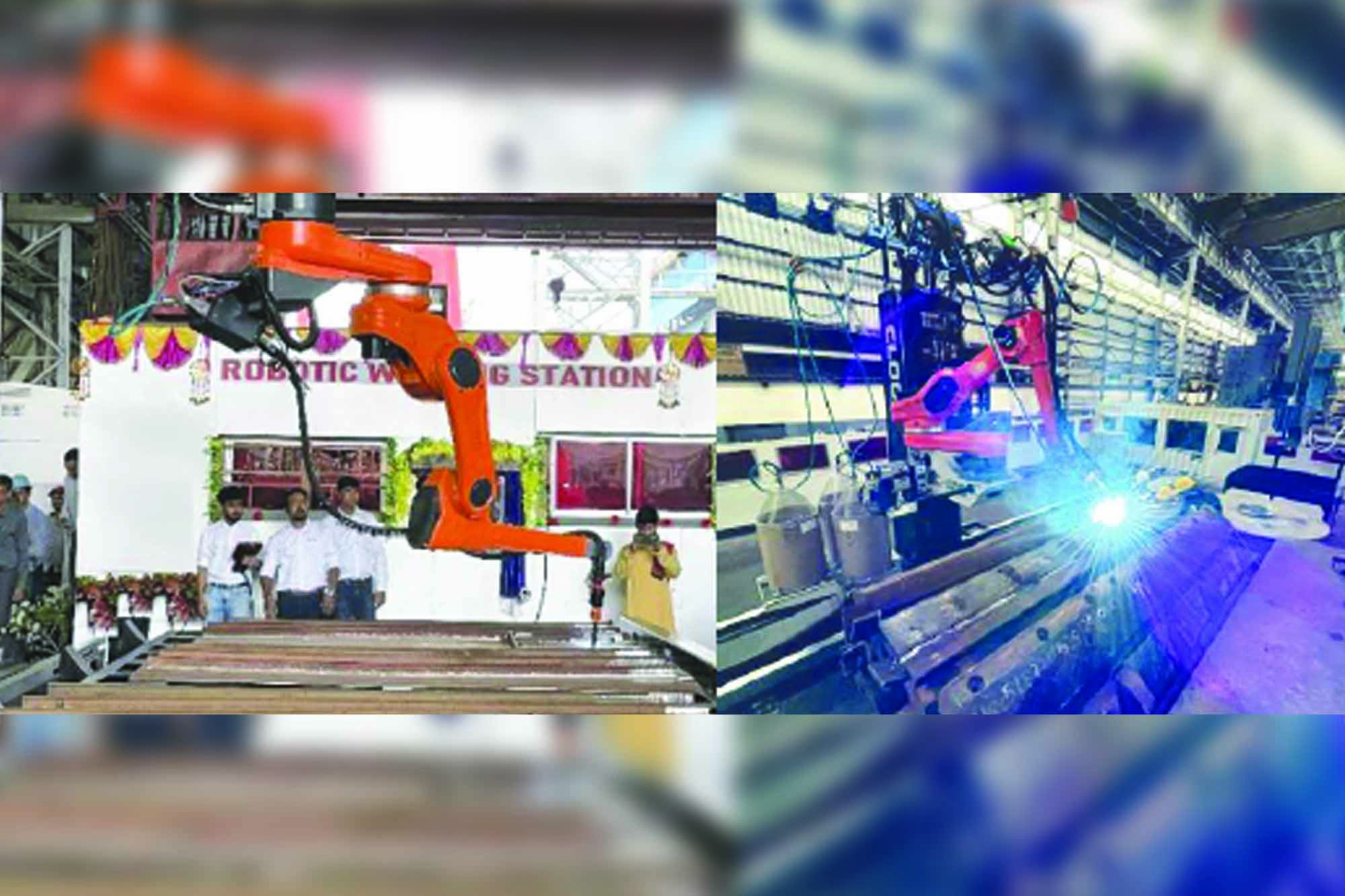

CLOOS’s customised single-source welding technology solution has been redefining the industry for a decade. Sumon Mitra, COO of Cloos India Welding Technology, affirms that CLOOS is at the forefront of innovation with its comprehensive solutions.

Cloos successfully installed a robotic welding and cutting solution for Larsen & Toubro’s crusher rotor. Cutting technologies play an essential part in modern manufacturing. As with welding, the need for it is steadily expanding. Cutting systems must become faster and more accurate. The machining time for a component will be reduced, while the material will be used efficiently and with optimal production quality. At the same time, usability, production dependability, and energy efficiency are critical. Innovative cutting technologies are in high demand to meet rising efficiency and quality standards. When choosing a cutting system, it is critical to ensure it is precisely suited to the task at hand and consider future projects.

CLOOS provided Larsen & Toubro Robotic with a cutting solution that included an automatic tool changer, addressing the issue of manual cutting quality and time. Oxy-fuel flame cutting was used to cut a star plate with a thickness ranging from 80 to 120 mm. On average, adopting robot technology for cutting reduces manufacturing costs by 25 to 30 percent while significantly improving quality. Cloos provides the best machining technology for any welding and cutting application.

CLOOS welding solution

Larsen & Toubro rely on CLOOS as a single source provider for welding the crusher rotor, which entirely transforms their three-stage welding process. They also benefit from CLOOS Tandem Weld technology, which provides maximal deposition with less heat input and an automatic tool changer for critical welding seams using a single torch.

Transformer tank welding at Crompton Greaves

CLOOS successfully implemented a robot welding solution for transformer welding at Crompton Greaves. Cloos has long provided robotic welding solutions to the transformer industry. Crompton Greaves relies on Carl Cloos Schweisstechnik GmbH for transformer tank welding competence. The new welding system is about 22 meters long and consists of two stations and a Cloos 7-axis robot (QIROX QRC-410-E). It enables flexible processing of various components, improving the efficiency and quality of hall manufacturing.

If you wish to modify your current Transformer tank subassembly and full assembly welding process, count on CLOOS’s superior welding technology and tailored Robotic welding solution, backed by their 105 years of experience!

Speed Weld

CLOOS stable all-round Innovative welding process Speed Weld completely changed welding quality in the many sectors’ low- or high-capacity range. Speed welding is employed in every aspect of metal machining. The voltage-controlled MIG/MAG pulsed arc method allows for extremely high arc pressure even under extreme conditions. The intense arc in Speed Weld allows you to achieve high welding speeds. It provides exceptional weld quality due to the deep penetration. Users can avoid significant reworks because spatters and undercuts are low.

Benefits:

• High welding speeds due to the powerful arc

• Excellent welding quality because of a deep penetration

• Reduced rework thanks to the pulsed arc technology with regulated drop separation.

The benefit of CLOOS Arc Seam Tracking

The sensor precisely measures the torch’s position relative to the specified path during welding. This allows for automated adjustment in the event of any discrepancies, resulting in constant, high-quality welding. Because measuring and welding occur simultaneously with the arc sensor, time loss is minimal. At the same time, workpiece distortion, such as from thermal expansion, is directly adjusted for. The CLOOS arc sensor, therefore, combines productivity with high quality.

The first robotic welding system in the Indian shipping industry

GRSE trusted CLOOS and installed the first robotic welding system in the Indian shipping industry. CLOOS’ offline Roboplan software solves the problem of non-repetitive ship panel welding. Using the TEACH procedure takes less time than developing a new program in the robot system. As a result, system utilisation increases, the manufacturing process is streamlined, and welding production becomes more adaptable.

Cloos successfully welded Radiators, PF condenser Charge Air coler, and Barplate radiators by Cloos innovative welding process Cold weld.

CLOOS This achieve excellent results when welding challenging materials using the directionally stable MIG/MAG AC pulsed arc. Cold Weld combines a pulsed arc with AC technology. Due to the adjustable AC part you can individually control the heat input into the component. Cold Weld enables higher welding speeds by increasing the deposition rate while maintaining an optimal heat input, which positively impacts the component and material characteristics. The reduced heat input preserves the original material properties, minimising distortion and the need for extensive rework. Additionally, Cold Weld can compensate for material tolerances thanks to its excellent gap-bridging ability.

Contact:

Cloos India Welding Technology Private Limited

Ground & 1st Floor,Plot No. 114/1/3,

General Block, Midc Bhosari, Pune,

Maharashtra 411026 India

Website:- http://www.cloos.de

Email :- contact@cloos.in,

Mobile:-7003545907 / 9168383939

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Everest Industries’ extension of Pragati Infra’s Palwal facility exemplifies sustainable industrial design by combining energy efficiency, natural lighting, and adaptable spaces to accommodate changing production requirements and enable long-term growth.

Pragati Infra, a renowned industrial manufacturing company, has tasked Everest Industries with expanding its Palwal, Haryana facilities to increase production capacity. The project included the construction of three unique buildings, each designed to fulfil the company’s evolving operational demands. This case study will examine the facility’s architectural, structural, and sustainable elements. We will focus on the novel engineering solutions, tonnage, and area specifications that make this industrial complex unique in modern architecture.

Overview of the project

The Pragati Infra Palwal extension project comprises three buildings, each built for a unique operational purpose but linked by cutting-edge engineering solutions offered by Everest Industries. The facility’s overall tonnage is 1,000 metric tonnes (MT), and each structure includes modern amenities, optimised workstations, and sustainable elements designed to fulfil the company’s growing needs.

Building specifications

Block A2

Block A2 is the complex’s largest structure and exemplifies modern industrial architecture. With a tonnage of 495 MT and a plinth area of 11,580 square metres, this structure is intended to handle a high operational capacity while ensuring energy efficiency and worker comfort.

·Daylight Polycarbonate: 647 square metres of daylight polycarbonate panels built into the roof help flood the room with natural light, eliminating the need for artificial lighting and improving the overall working environment.

·Insulation: The roof has 4 mm thick air bubble insulation and covers 11,700 sq m. This insulation helps to regulate internal temperatures by limiting heat loss in the winter and keeping a cool indoor climate during the hot summer months.

·Louvres: 278 square metres are strategically arranged to provide effective ventilation and improve air quality throughout the structure.

·Mezzanine Area: A 590 sqm mezzanine level improves the building’s storage and operations capacities while not increasing its overall footprint.

Block A1—Part 1

Block A1 is divided into two portions, each built for a specific function within the industrial complex. Part 1 has a plinth area of 3,980 square metres and a tonnage of 220 tonnes.

·Daylight Polycarbonate: 300 square metres of polycarbonate panels allow plenty of natural light, minimising the need for artificial lighting and increasing energy efficiency.

·Insulation: The roof is insulated with 4mm thick air bubble material that covers 4,203 square metres, delivering consistent thermal performance year-round.

·Louvres: 255 square metres of louvres are installed to improve ventilation and ensure excellent air circulation and comfort.

·Mezzanine Area: A 340 sqm mezzanine adds extra space for operational purposes, storage, or future expansion.

Block A1 – Part 2

Part 2 of Block A1 is the largest of the two pieces, weighing 285 tonnes and covering an area of 5,800 square metres.

·Daylight Polycarbonate: This part has 435 square metres of polycarbonate panels, which allow natural light to permeate the interior while reducing energy use.

·Insulation: The roof is insulated with 4mm thick air bubble material, which covers 6,067 square metres and ensures efficient temperature regulation.

·Louvres: 337 square metres are fitted to improve air circulation and eliminate the demand for mechanical cooling systems.

·Mezzanine Area: This section’s 481 sq m mezzanine provides additional storage or operational space and allows for future growth.

Sustainable features and efficiency

Sustainability was a top emphasis during the facility’s design and construction. The strategic use of daylight polycarbonate panels across all buildings reduces dependency on artificial lighting, lowering energy consumption and improving the internal environment for workers.

The air bubble insulation utilised in the roofing system considerably improves the facility’s energy efficiency by maintaining ideal inside temperatures all year. This minimises the demand for HVAC systems, resulting in cheaper energy bills and a more environmentally responsible operation.

Furthermore, the buildings have louvres that allow for natural ventilation, which minimises mechanical cooling and improves indoor air quality, critical for worker health and productivity.

Futureproofing through mezzanine spaces

Each block has a mezzanine area varying in size from 340 to 590 sqm, which provides flexible space for future storage, operations, or equipment. These mezzanine floors help to future-proof the building, allowing it to accommodate Pragati Infra’s rising needs as the firm grows.

Everest Industries’ Pragati Infra extension project in Palwal exemplifies modern industrial construction that integrates sustainability, energy efficiency, and functional design. Everest Industries has designed a facility that suits Pragati Infra’s current operational needs while providing long-term adaptability for future growth.

This project supports Pragati Infra’s expanding operations and establishes a new standard for industrial buildings in the region. It showcases Everest Industries’ ability to deliver high-performance, sustainable industrial facilities.

For more information, visit: https://www.everestind.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Schmalz’s innovative mGrip finger gripper offers a game-changing solution, combining a hygienic design with exceptional flexibility and precision.

Schmalz’s innovative mGrip finger gripper is constructed in a hygienic design and meets the highest cleaning standards. Its unusual design lets it pick up delicate things like vegetables or baked goods precisely and gently. This enables food manufacturers to automate their handling operations while maintaining process reliability.

Sensitive surfaces, sometimes soft, sometimes fragile, spherical or flat—food products come in a variety of shapes, making automated solutions difficult to implement. However, they all have one thing in common: the handling must be completely hygienic and hence safe. With its numerous configuration choices, Schmalz’s mGrip finger gripper always provides the best solution. Strong grasping is made easy with circular or parallel finger modules.

In contrast to mechanical solutions, the pneumatically controlled mGrip handles sensitive products with remarkable precision. Baked items, fruits, and vegetables, for example, can be safely placed in trays and removed for quality check. The gripper can safely pick up food in a variety of shapes and forms, including chicken drumsticks, thanks to its flexible structure. Companies outside the food business that want to pick up nets or sacks full of small parts benefit as well. This means that rapid picking can be implemented around the clock without the need to retain workers on standby for order picking.

Excellent process stability

The closed system maximises process dependability. The innovative finger gripper also meets the strictest cleanliness standards. They are simple to clean from the outside and meet the standards of CIP (Cleaning in Place) and COP. Schmalz has removed extra drives from the design, and the pneumatic circuit is closed. The sanitary design reduces the danger of contamination. The lightweight design makes mGrip ideal for use on cobots and other lightweight robots.

The gripper’s modular design, which includes different finger sizes and varied placements, opening angles, and forces, allows it to be easily customised to any task. This provides enterprises the greatest flexibility when processing various foods, particularly for usage in high-speed processes. As boring jobs are automated, they may deploy their workforce more efficiently. This reduces expenditures while also improving the application’s efficiency and quality.

For more information, visit: https://www.schmalz.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Sensor integration is reshaping how commercial vehicles operate. From improving fuel efficiency to ensuring driver safety, sensors play a crucial role in predictive maintenance and fleet management, setting new standards for the future of transportation.

As commercial vehicles (CVs) become more connected and automated, sensor technology plays a key role in their evolution. These sensors are now a critical component of modern CVs, helping improve safety, efficiency and performance. From monitoring speed and tyre pressure to tracking engine health and external conditions, sensors drive the shift toward smarter, safer and more efficient vehicles.

The growing importance of sensors in commercial vehicles