Through rigorous testing, precise material sourcing, and a commitment to continuous improvement, Ashar Locker delivers screening media solutions that consistently perform under varied operational conditions. The company’s dedication to innovation and customer education sets it apart as a leader in the industry.

How does Ashar Locker maintain consistent global quality standards across its diverse screening media solutions?

We comply with the latest ISO quality standards to consistently maintain high product quality and customer satisfaction. We procure our wires from either Tata Steel Ltd or other equivalent wire manufacturers from around the world. Our R&D team has derived the proper chemical composition for our wires to ensure maximum efficiency. Our wires are made to our grades by our vendors. Most local suppliers don’t even buy wires. Instead, they draw their wires by melting scraps or sourcing them from suppliers. These wires are of very low quality; hence, they always offer higher wire diameters to customers under the pretext of higher life. Still, they reduce the plant’s efficiency and increase their final products. We make our customers understand the importance of screening areas, which will help them improve their plant efficiency, thus reducing costs. Therefore, when customer chooses Ashar Locker as their screening partner, they are certain they have chosen the best and most reliable supplier for their screening needs.

We use rigorous testing methods to ensure that our meshes are the best in the world regarding quality. We embrace Lean principles such as First-In-First-Out (FIFO), PCDA, Just-in-Time (JIT), Standard Work, Standard Work, Poka-Yoke, and 5S, and we practice many more lean methods and tools. These methodologies optimise efficiency, reduce waste, and promote continuous improvement throughout our manufacturing processes. We have always believed in innovation & technology; our products have been in huge demand across all the minerals in the industry. Our dedicated R&D team has always focused on developing products that create value for our customers.

What technological features or innovations differentiate ULTRA-FLEX Anti-Clogging Screens from traditional solutions?

We have always believed in innovation and technology, which has made our products in huge demand across all the minerals in the industry. Our dedicated R&D team has always focused on developing products that create value for our customers. Some of our flagship products, like the Anti-clogging screens, have enabled our customers to operate their plants during heavy monsoons.

These screens combine polyurethane with steel to make them high-flexible screens that allow each wire to vibrate individually from end to end, allowing the material to pass through smoothly even in the wettest conditions. Ashar Locker was the first to introduce this product in India, which enabled our customers to achieve high throughput screening through the monsoon. Screening in those three months of the year had been a massive pain point for the industry. Poly-Ripple is a great alternative in any application where a customer encounters blinding in traditional wire mesh. Our technology used in the production process is developed in-house and is proprietary to our group.

Can you elaborate on the specific applications where ULTRA-FLEX Polyurethane Screening excels?

Ashar Locker’s ULTRA-FLEX Anti-clogging screens have proved highly successful in the manufacture of M-sand and P-sand over the past couple of years. These handmade and uniquely designed screens efficiently utilise every motion of the screen. Each wire vibrates individually, which improves the efficiency of the plant and helps develop precise cuts needed for sand manufacturing.

The Rubber & PU meshes, when compared to the wire mesh, have a better wear life, less dust generation, less sound pollution, and are more durable. The only drawback is the reduction in open areas for screening. Non-metallic and metallic have their place and importance, and customers are guided to install the right combination of meshes to bring value to their plants. The top deck can be non-metallic, the second one metallic, and the third can be an anti-clogging screen; this can be decided with the help of the company’s expert technical team.

How flexible are you in adapting screening media solutions to unique project demands?

As a complete solution provider, we must conduct onsite audits to ensure that our customers use the right screening media at different stages to ensure maximum plant efficiency. Our meshes are customised according to the client’s requirements. Once we receive an inquiry from our customer, we visit their plant or ask for the complete flowsheet of the plant to understand the exact requirements. Based on the data, we analyse the correct type of screening media and its exact specifications to maximise the output and increase the plant’s overall efficiency. Screens are generally the most neglected part of the crushing & screening circuit and customers more often stick to the same specification of meshes supplied by their respective OEMs. It is important to understand that every crushing & screening plant is different as the end product size varies from customer to customer. Also, the nature of the mineral/rock being screened varies from quarry to quarry. Once our team analyses the complete data, we offer end-to-end screening solutions to our customers based on their requirements. Our Anti-clogging screens are in high demand worldwide, as our team of experts have successfully developed a product that helps our customers operate their plants during the monsoon season.

Most local mesh suppliers often confuse customers by offering higher wire diameters under the pretext of increasing wear life, but this reduces the overall screening area, decreasing the overall plant efficiency. We always try to educate all our customers on the importance of selecting the right wire diameter according to their desired separations, thus resulting in higher productivity and a lower cost per ton on their screenings.

Could you elaborate on how sustainable materials in your screening media benefit the environment and enhance product performance?

At Ashar Locker, we strive to ensure that our products are efficient and environmentally sustainable. For example, many of our competitors use a chemical named MOCA for manufacturing Poly-urethan panels, which is very toxic and is responsible for causing cancer to the people involved in manufacturing these panels. This is done just to save cost. Moreover, when a customer uses any such panel at their site, they are exposing themselves to harmful emissions from these panels when exposed to sunlight. We at Ashar Locker do not use any such materials that may harm our employees, customers and the overall environment.

We also believe that it is not just our responsibility but also the customers’ responsibility to ensure that they ask the right questions of their suppliers during the procurement stage to ensure that such chemicals are not being used for their products. Only then will environmentally sustainable products continue to grow on the market.

How has the demand for screening media evolved, and how is Ashar Locker adapting to meet the emerging needs?

Over the years, there has been a significant shift from customers to good-quality products. Our customers now understand the importance of products that add value to their processes, resulting in higher productivity and a lower cost per ton on their screening. Our regular onsite plant audits and performance reports help them improve their product quality per customer demand.

There is a huge demand for Screening media solutions to support the ongoing infrastructure projects in India. Moreover, the artificial sand market has taken demand to the next level, resulting in overall growth and profitability. This year, the mining market has also shown some significant growth, and hence, we expect the demand to further improve over the next few quarters.

For more information, visit: https://www.asharlocker.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

CASE India’s latest gear incorporates enhanced telemetry, eco-friendly engines, and better hydraulics, setting new performance, safety, and sustainability standards. These advancements demonstrate CASE’s dedication to cutting-edge technology and environmental stewardship.

Could you elaborate on the key technological advancements introduced in the 770NXe Series Backhoe Loaders that enhance their performance and efficiency?

We have integrated modern telemetry (SiteWatch) and remote technologies into the 770NXe Series Backhoe Loaders to improve operational efficiency, productivity, and user experience. These systems give operators and fleet owners real-time data, allowing them to evaluate equipment utilisation, track performance, and assure security. Effective monitoring and preventive maintenance lead to higher production and longer machine lifespans. Furthermore, the 770NXe Backhoe Loader features a new cabin with ROPS/FOPS to ensure maximum safety standards.

We intend to deliver innovative solutions in India inspired by successful implementations in other markets. This strategic project broadens our product offering and promises to substantially impact the construction industry, underscoring our dedication to staying on the cutting edge of technical breakthroughs.

Can you discuss the specific design features in the EX Series Backhoe Loaders and the 952 EX Double Drum Rollers that prioritise these aspects?

Our EX Series Backhoe Loaders and 952 EX Double Drum Rollers take a comprehensive approach to operator safety and comfort, with innovative design characteristics dedicated to these requirements. To enhance operator safety, we have integrated advanced telematics for real-time monitoring, an audio-visual warning system with over 25 alarms to inform operators of potential concerns, and an engine protection shutdown to decrease downtime by preventing damage during failures. We built roomy cabins with excellent sightlines, ergonomic seats, and straightforward controls to improve comfort and productivity.

Features like Eco Mode and Auto Idle improve fuel efficiency and reduce noise levels, making long shifts more manageable. Furthermore, increased swing frame height improves manoeuvrability, demonstrating our commitment to both safety and convenience of use. These characteristics illustrate our commitment to providing operators with a safe, comfortable, and efficient working environment.

Your products highlight the FPT S8000 Engine and the CASE Intelligent Hydraulic System (CIHS). Could you explain how these systems contribute to the overall performance and reliability of the 770NXe Series Backhoe Loaders and the CX220C Crawler Excavators?

The 770NXe Loader Backhoe, which features a cutting-edge Electro-Hydraulics variable displacement pump and the tried-and-true FPT S8000 engine, excels in demanding loader applications by providing faster response times and fuel efficiency. This innovative technology saves up to 24 percent on fuel, has a 26 percent lower maintenance cost, and increases output by more than 10 percent. Meanwhile, the CASE CX220C LC Crawler Excavator, driven by a powerful FPT engine, has excellent productivity and 8 percent better fuel efficiency. It is suited for hard activities such as stone quarries, road building, and general construction.

The CASE Intelligent Hydraulic System (CIHS) offers precise and efficient hydraulic performance, which improves the machines’ durability and effectiveness in various applications. These innovative features work together to improve the performance and dependability of the 770NXe Series Backhoe Loaders and CX220C Crawler Excavators, making them excellent alternatives for various construction demands.

How does CASE India address this through improved fuel efficiency and eco-friendly features in your equipment?

At CASE, we prioritise energy efficiency and environmental responsibility in our equipment to meet the construction industry’s growing demand for sustainable practices. Our machines are powered by highly fuel-efficient engines that meet BS-CEV IV emission standards, significantly decreasing pollutants and minimising environmental effects. Furthermore, we are prepared to upgrade our machinery to the most recent emission standard, BS-CEV V, which is expected to be implemented in January 2025, guaranteeing that we remain ahead of industry requirements.

We offer construction equipment that reduces energy consumption while also promoting a cleaner, more sustainable environment. Our equipment combines great fuel efficiency, productivity, and adherence to tight emission standards. Our company’s ethos is built around a commitment to sustainability and innovation.

For more information, visit: https://www.casece.com/en/india

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

By integrating superior engineering, rigorous testing, and innovative technology, RD Infra Equipment ensures that its machinery stands up to the toughest challenges and delivers unmatched reliability and performance.

What ensures the reliability and performance of your products in challenging environments?

In today’s industrial landscape, we know that the efficiency and safety of complex operations, like those in quarries and construction sites, rely heavily on dependable equipment. We are proud to be a leading name in the construction and infrastructure sector, delivering products that ensure consistent performance even in the most challenging environments. Our focus on innovative design, rigorous testing, and unwavering commitment to quality means we provide solutions that meet the demanding needs of heavy-duty applications.

The foundation of our success lies in superior engineering and robust design. We know operators’ specific challenges, including severe weather, abrasive materials, and long operational hours. That’s why each of our products is made using materials meant to withstand wear and tear in these kinds of environments. For example, high-tensile parts and reinforced frames are common in our machinery to lower the possibility of breakdowns that could result in expensive downtime.

Quality assurance is a critical part of our manufacturing process. Every piece of equipment undergoes rigorous testing to ensure it meets international standards. This thorough quality control helps us identify and address potential issues before our products reach the market, ensuring you receive reliable and consistent equipment that performs in the toughest conditions.

We integrate advanced technology to enhance the reliability and performance of our products. Features like telematics systems provide real-time monitoring and diagnostics, allowing operators to track equipment performance, receive maintenance alerts, and optimise operations through data analytics. This approach minimises unexpected breakdowns and maximises uptime, crucial in environments where productivity is directly tied to profitability.

Understanding that every operational environment presents unique challenges, we offer customisation options to meet specific client needs. This ensures that our equipment is reliable and perfectly suited for the tasks at hand.

Our comprehensive support and maintenance services further enhance reliability, ensuring you can depend on your equipment throughout its lifecycle. This commitment to excellence is reflected in the high levels of satisfaction reported by our clients, who praise the durability, efficiency, and customer service we provide.

What features of the RDJC4436 and RDJC4236 enhance their aggregate production and mineral processing efficiency?

Machinery choice is crucial for operational efficiency in aggregate production and mineral processing. The RDJC4436 and RDJC4236 models stand out with their impressive horsepower and adjustable closed-side setting (CSS) ranges, enhancing crushing performance across various rock types. Understanding these specifications helps operators optimise workflows, reduce costs, and boost output.

The RDJC4436 and RDJC4236’s high horsepower ratings determine their operational capacity. Increased torque at the crusher’s jaw allows these machines to crush larger and denser materials efficiently. This capability is essential when processing tough rock types like granite, basalt, or quartzite, which require more power for effective fragmentation. A crusher with higher horsepower maintains efficiency under heavy workloads, ensuring a consistent feed rate, reducing downtime, and enhancing productivity.

The adjustable CSS of the RDJC4436 and RDJC4236 is vital for adaptability and product quality. CSS is the smallest distance between a crusher’s fixed and movable jaws when closed. Adjustable CSS capabilities let operators specify the desired output size. This flexibility allows crushers to handle various materials effectively. For softer rocks, a wider CSS enables quicker processing cycles without compromising performance, while a tighter CSS enhances efficiency for harder materials by producing a more precise output size. This adaptability improves final material quality and can eliminate the need for additional processing stages.

How do RD screens deliver effective and reliable mining and materials processing performance?

Our RD screens are key players in mining and materials processing. They are designed to handle a wide range of materials, from limestone to gabbro. Their success comes from our innovative design and advanced technology.

We have built RD screens, or “Resilience Design Screens,” to withstand the tough demands of processing various minerals. They feature robust construction with high-quality materials, like reinforced steel frames and wear-resistant screen media, ensuring durability and a long lifespan. Their modular design allows us to easily customise and maintain them, adapting to different material types and processing needs.

Our RD screens are more effective with efficient screening media options like woven wire mesh, rubber, or polyurethane. These are optimised for different materials, improving separation efficiency and throughput. Adjustable incline angles help us customise the screening process to reduce material clogging and enhance flow, especially for heavier materials like gabbro.

Technological innovations further boost the performance of our RD screens. Electromechanical drive systems provide precise control over vibration, improving separation and reducing energy use. Intelligent control systems offer real-time monitoring and predictive maintenance, helping us prevent unexpected downtime. Additionally, advanced vibration control algorithms ensure consistent processing, leading to better material recovery and less waste. Our modern RD screens also incorporate dust and noise suppression technologies, promoting a safer and more environmentally friendly working environment.

Please deliberate on the sustainability practices integrated into RD Infra Equipments’ manufacturing and operations.

We are proud to lead the shift towards eco-friendly crushing and screening machinery practices. We integrate innovative design principles and sustainable methods to tackle environmental concerns while boosting productivity and efficiency.

A key part of our approach is using sustainable materials in our manufacturing processes. We prioritise recyclable materials, such as steel sourced from recycled content, to minimise waste and reduce our reliance on virgin resources. This helps lower our carbon footprint and supports a more circular economy. Additionally, we employ advanced manufacturing technologies, like precision engineering, to cut energy consumption and waste. By investing in energy-efficient machinery and adopting lean manufacturing practices, we ensure minimal environmental impact during production.

Energy efficiency is also a major focus in the design of our machinery. We incorporate cutting-edge technologies, such as variable frequency drives (VFDs) and optimised hydraulic systems, to significantly reduce energy usage and operational costs. These innovations also cut down on greenhouse gas emissions. Moreover, our equipment is built for durability, extending its operational lifespan and reducing the need for frequent replacements, further minimising environmental impact.

We are also committed to reducing noise and emissions. We integrate sound-dampening technologies to lower noise levels, enhancing site safety and operator comfort. Our equipment meets global emission standards, minimising harmful exhaust emissions. We also work closely with clients to optimise operational practices for further emission reductions.

Our commitment to sustainability extends to the end of a product’s life. We design our machinery for easy disassembly, refurbishment, and recycling, promoting resource recovery and reducing landfill waste. This not only improves the environment but also provides our clients with decreased disposal costs and the opportunity to reuse items.

We also collaborate with clients to support sustainable practices. Providing training and workshops on eco-friendly operations, we help operators make informed decisions that enhance productivity and environmental responsibility.

What are your key focus areas or upcoming innovations in crushing and screening technology?

We are committed to developing energy-efficient equipment that reduces carbon footprints and improves material recycling. By integrating smart technologies like IoT and AI, we offer data-driven insights that boost efficiency and predict maintenance needs, minimising downtime.

Our modular crushing and screening solutions are designed for versatility and customisation, allowing easy adaptation to various project requirements and maximising productivity. As urban projects evolve, we invest in portable technology that combines performance with easier transport and setup.

Safety remains a top priority, and we’re continually improving ergonomics, control systems, and safety features to protect operators. Additionally, we’re exploring renewable energy integrations to lower operational costs and emissions.

By focusing on these areas and collaborating with industry stakeholders, we aim to meet today’s challenges and seize future opportunities in the crushing and screening sector.

For more information, visit: https://rdgroupindia.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Schwing Stetter India’s latest excavators and wheel loaders, featuring advanced engine and hydraulic technologies, deliver exceptional efficiency, precision, and operator comfort, driving productivity and sustainability in mining operations.

What engine technology and hydraulic system advancements have been implemented in your XE20U and XE250LC-K hydraulic excavators?

We ensure that our hydraulic excavators, including models such as the XE20U and XE250LC-K, are outfitted with the most recent improvements in engine technology and hydraulic systems through a continuing dedication to research and development. Our engines are engineered to fulfil strict emissions criteria while delivering maximum power and fuel efficiency. We use modern hydraulic systems that provide precise control and increased longevity. These systems feature cutting-edge components such as variable displacement pumps, load monitoring capabilities, and modern filtering systems.

Can you elaborate on the benefits of the Variable Horse Power Technology (VHP) in your excavators and how it enhances operational efficiency and adaptability in diverse mining conditions?

Variable Horse Power Technology (VHP) in our excavators provides substantial benefits by automatically altering the engine power output to meet operating needs. This technique optimises fuel economy while reducing engine wear and tear, resulting in lower operating costs and longer equipment life. VHP improves versatility in various mining conditions by providing the power required for complex jobs while conserving fuel during lighter operations. This assures consistent performance and efficiency across various workloads, allowing operators to manage various mining scenarios with ease and precision. VHP also contributes to a lower environmental imprint by reducing excessive fuel consumption, which aligns with sustainable mining methods.

What are the key features of your excavator and wheel loader cabins that contribute to operator comfort and safety?

Our excavators and wheel loaders’ cabins are designed with operator comfort and safety in mind, with numerous critical features to boost productivity in tough mining settings. These include an ergonomic design with adjustable seats, simple control layouts, and plenty of legroom to prevent operator fatigue and improve comfort throughout long hours. Advanced HVAC systems ensure a comfortable working environment, regardless of the weather. Large, strategically positioned windows and high-resolution cameras improve visibility, situational awareness, and safety. Soundproofing materials and anti-vibration technology reduce cabin noise and vibrations, resulting in a quieter, more comfortable office. ROPS/FOPS certification, seat belts, and emergency stop buttons are all integrated safety measures that ensure operator safety. These features collectively improve operator well-being, reduce fatigue, and enhance focus, increasing productivity and efficiency in demanding mining operations.

How do the increased payload capacities of the ZL33FV, ZL48GV, and ZL55GV wheel loaders boost productivity and efficiency in large-scale mining projects?

The enhanced payload capacity of our ZL33FV, ZL48GV, and ZL55GV wheel loaders leads to increased productivity and operating efficiency in large-scale mining projects, allowing for larger amounts of material movement in each cycle. This minimises the number of cycles required to execute a task, lowering overall cycle times while increasing throughput. The increased cargo capacity also enables greater use of haul trucks, which can be loaded more effectively. This leads to fewer delays and improved operational continuity. Furthermore, the loaders’ sturdy construction and powerful hydraulic systems ensure they can manage larger weights without sacrificing performance or reliability, contributing to increased productivity and efficiency in mining operations.

How do your wheel loaders’ 160-bar and 185-bar main relief pressures enhance precision and performance in complex mining operations?

Advancements in hydraulic systems, such as the 160 Bar and 185 Bar main relief pressures in our wheel loaders, considerably impact precise movement and overall performance in complex mining operations. Higher main relief pressures allow the hydraulic system to produce more force, which enhances the loader’s lifting and digging capabilities. This precision enables operators to accomplish activities with better accuracy and control, which is critical for negotiating the challenging conditions of mining sites. The improved hydraulic systems also provide a smooth and responsive operation, lowering cycle times and increasing overall efficiency. These hydraulic systems help to handle huge loads and complex manoeuvres efficiently, which is critical for sustaining high productivity levels in mining operations.

What role does load-sensing technology play in the performance of your hydraulic excavators and wheel loaders?

Load sensing technology improves the performance of our hydraulic excavators and wheel loaders by adjusting hydraulic power distribution based on real-time operational demands. This system continuously analyses load needs and changes the hydraulic flow and pressure as needed. Load sensing technology provides greater precision by supplying the appropriate amount of hydraulic power when and where required, improving the precision of movements and operations and enabling more accurate and efficient task execution. This adaptive power management minimises energy waste, decreasing fuel usage and operating expenses. Load sensing technology reduces wear and tear on components by eliminating excessive hydraulic pressure and flow, increasing equipment lifespan and lowering maintenance requirements. Load sensing ensures hydraulic systems run at maximum efficiency regardless of load, resulting in consistent and dependable performance in various mining circumstances. Overall, load-sensing technology increases operational precision and resource management, making our equipment more efficient and cost-effective in harsh mining settings.

For more information, visit: https://www.schwingstetterindia.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

ENSO Group collaborates with Gazpromneft Lubricants to provide high-performance products that improve mining equipment efficiency, extend lifespan, and reduce downtime through innovative engine oils, hydraulic fluids, and other components.

Could you elaborate on the specialised lubricants you provide for mining equipment?

Enso Oils and Lubricants offer various high-performance products from Gazpromneft Lubricants, Russia, specifically designed to satisfy the demanding needs of mining operations. These items improve equipment performance, increase lifespan, and save downtime. Heavy-duty engine oils are engineered with increased thermal stability, a high viscosity index, and modern additives such as detergents and dispersants to reduce engine wear, lengthen equipment lifespan, and reduce downtime by lowering engine failures and extending oil change intervals. Hydraulic fluids have exceptional anti-wear qualities, thermal and oxidative stability, and good water separation and filtration, which protect hydraulic components and provide reliable operation while reducing maintenance and failures. Gear oils containing extreme pressure (EP) additives and corrosion inhibitors protect gears and bearings against wear and corrosion, increasing their life and saving downtime. Greases with excellent adhesion, water resistance, and anti-wear additives protect vital components like bearings and joints from wear and corrosion, decreasing the need for regular maintenance. Compressor oils, noted for their low volatility and thermal stability, as well as anti-wear additives, reduce wear on compressor components, lengthen their lifespan, and require less maintenance as oil life increases.

How do ENSO Group cater to the performance demands of these sectors?

Enso Oils and Lubricants provide high-performance products from Gazpromneft Lubricants, Russia, specifically for construction, infrastructure, and mining machinery. These lubricants are designed to withstand large loads, with sophisticated additives that increase load-carrying capacity and minimise wear, increasing machinery life under adverse conditions. Extreme Pressure (EP) additives create a protective layer on metal surfaces, preventing metal-to-metal contact and enabling smooth functioning. Anti-wear technology further decreases friction and wear, hence increasing equipment reliability.

These lubricants thrive in demanding settings because of their thermal stability, which allows them to maintain viscosity and performance across a wide temperature range. They also provide oxidation resistance, which prevents the production of sludge and varnish, and water resistance, which ensures efficacy in wet and humid settings while also protecting against rust and corrosion.

Furthermore, the lubricants are intended to control impurities by repelling dust and dirt and are compatible with various filtering systems to ensure smooth operation. Its improved lubricity improves the life of bearings, gears, and hydraulic systems, whereas anti-corrosion additives protect metal surfaces in wet or chemically exposed settings.

Can you discuss the impact of high-performance and synthetic lubricants on the machinery’s energy efficiency and thermal management in mining operations?

High-performance and synthetic lubricants improve energy efficiency and thermal control in mining operations. For energy efficiency, these lubricants decrease friction and wear. High-performance lubricants with modern additives enable smoother operations and lower energy consumption, while synthetic lubricants provide stable lubrication due to their homogenous molecular structure. It also increases the viscosity index, ensuring appropriate thickness across temperatures and lowering energy loss. Furthermore, they improve load-carrying capacity with extreme pressure additives and the ability to take larger loads without failure, resulting in reduced mechanical losses.

High-performance lubricants carry heat away from important components, whereas synthetic lubricants provide superior thermal conductivity for efficient heat dissipation. Their oxidation resistance minimises sludge and varnish formation, ensuring thermal control. Their long lifespan and resistance to thermal degradation eliminate the need for frequent replacement. They also reduce operating temperatures by minimising friction and wear, resulting in more consistent performance and cooler machinery.

These benefits improve machinery performance by providing smoother and more reliable operation, cost savings from reduced energy use and extended lubricant life, increased equipment lifespan, and reduced downtime due to fewer breakdowns and maintenance requirements, all leading to higher productivity.

How do you foresee enhancing support and services for the construction equipment and mining sectors in lubrication needs and technical support?

The partnership between ENSO Group and Gazpromneft-Lubricants aims to improve lubrication solutions and provide technical support for the construction and mining industries. This collaboration broadens the product portfolio with high-performance lubricants like engine oils, hydraulic fluids, gear oils, and greases, leveraging Gazpromneft’s R&D expertise to create unique formulas that provide improved protection and efficiency. It improves supply chain and distribution by implementing effective logistics and local warehousing, resulting in prompt delivery and easy access to items. The cooperation focuses on sustainability and compliance by conforming to local and international standards. A dedicated helpline for technical support, emergency assistance, and a comprehensive feedback mechanism for continual improvement demonstrate a customer-centric attitude. Additionally, the collaboration will involve participating in industry events to educate and create awareness about the most recent goods and technology. This collaborative endeavour seeks to provide enhanced lubrication solutions, improve equipment performance, and increase operating efficiency in the construction and mining industries.

How do you ensure lubricants comply with environmental regulations and sustainability standards, particularly in sensitive environments such as mining sites?

Enso Oils and Lubricants are committed to ensuring that its products, which Gazpromneft Lubricants supply, are environmentally safe, especially in sensitive locations like mining sites. The lubricants comply with local and international environmental requirements, such as ISO 9001, 14001, and 45001 standards. They come in bulk packaging to reduce waste, and suitable disposal instructions are supplied to prevent contamination. We also invest in R&D to reduce environmental effects during production and disposal. The corporation prioritises training teams in optimal environmental standards and spill response protocols. In addition, we work with industry leaders and environmental organisations to stay current on rules and implement best practices.

What role does tribology play in reducing wear and friction in critical components of mining machinery?

Tribology, or the study of interacting surfaces in relative motion, is critical in reducing wear and friction in mining machinery, which improves efficiency, reliability, and lifetime. Understanding various wear mechanisms, such as abrasive, adhesive, fatigue, and corrosive wear, allows the selection of materials with optimal hardness, toughness, and corrosion resistance. Lubrication science contributes by using lubricants to build protective coatings, distribute heat, and remove pollutants; modern lubricants, such as synthetic oils and those with EP and anti-wear additives, provide improved protection. Surface engineering enhances wear resistance with hard coatings and surface texturing, whilst material composites with integrated lubricants increase durability. Friction reduction controls sliding, rolling, and fluid friction by carefully selecting and applying lubricants. Tribological testing and monitoring, which includes lab simulations and field tests, validate performance and detect early wear indicators using wear particle and vibration analysis. The tribological design prioritises optimising component geometry and bearing selection, integrating lubrication systems, and utilising sophisticated seals to prevent contamination. Economically, these techniques cut maintenance costs, lengthen component life, reduce downtime, and improve energy efficiency, resulting in lower operational expenses.

For more information, visit: https://www.ensogroup.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

As India’s mining industry evolves, BKT’s Earthmax tyres lead the way, providing unrivalled durability and efficiency for surface and underground operations.

How would you describe the current state of the mining industry in India, particularly in terms of surface and underground mining?

India’s mining sector is expanding rapidly, owing to rising mineral demand and technological developments. Surface mining, which includes open-pit and strip mining, remains the most popular method due to its low cost and efficiency. However, underground mining is increasingly popular, particularly for obtaining minerals found farther underground, such as uranium, zinc, and copper.

Speaking of technology, how are you contributing to the mining industry in India, particularly with your Earthmax products?

Our Earthmax line of all-steel OTR radial tyres is developed for heavy-duty surface and underground mining machines. Earthmax tyres are designed to handle hard mining conditions with high durability, traction, and cut resistance. We customise these tyres to meet the individual needs of each mining site, assuring optimal performance and safety.

Can you elaborate on how BKT tyres are customisable for different mining sites?

Each mining site has distinct terrain, mineral types, and operating challenges. At BKT, we collaborate closely with mining operators to understand their conditions and tailor our Earthmax tyres accordingly. Our representatives continually assess site circumstances and adapt to changes in haul distance, loading patterns, terrain, and equipment. If the present condition changes, the existing tyres may no longer be the best fit for the task, which is when we come in with new recommendations that meet your updated needs.

How is BKT differentiating itself from other industry players?

We have the most SKUs in the Off-Highway tyre market and are manufactured in India, so our customers receive timely deliveries and don’t have to worry about stocking up on tyres. Our local production decreases wait times and keeps costs low for our clients. We are additionally, being close to customers results in more prompt after-sales care. With one of the industry’s largest R&D teams and an in-house mould facility, we can offer new patterns and compounds quickly – from concept to market introduction.

Could you elaborate on the benefits Earthmax tyres offer for mining operations?

Earthmax tyres offer several advantages to mining operations. Because of its durability and high traction, the Earthmax SR 53 for wheel loaders provides a longer tyre life and reduces downtime. The Earthmax SR 55 for LHD machines improves stability and manoeuvrability in underground mines, increasing overall safety and efficiency. The Earthmax SR 46 rigid dump truck tyre has excellent cut resistance and tread durability, making it perfect for surface mining’s severe conditions. Our Mineforce bias tyres for rigid dump trucks and Earthmax OTR radials provide solid performance and reliability in the most demanding settings. These customised solutions improve mining operations’ efficiency, safety, and production.

Furthermore, our tyres are engineered to improve driver comfort while reducing tiredness, making workdays safer and more productive, particularly on tough terrain. We are the only company in India that manufactures all-steel radial tyres and offers ASR and bias tyres for earthmoving, contributing significantly to the industry’s migration to radial tyres. All major equipment manufacturers trust us, and our products include some of the world’s largest tyres, such as the Earthmax SR 468, designed specifically for Indian coal mines.

How do you see the future of mining in India evolving, especially with the advancements in tyre technology and other innovations?

The future of mining in India is bright, emphasising sustainable and efficient operations. Implementing automation, AI, and IoT in mining operations will boost production while lowering environmental impact. At BKT, we are dedicated to assisting the industry’s progress by constantly inventing and developing solutions that suit mining’s ever-changing demands. BKT is prepared to respond to emerging improvements in off-highway equipment.

For more information, visit: https://www.bkt-tires.com/in/en/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Geospatial World’s new paper, “Evolving Role of National Mapping Agencies,” explores how NMAs are transforming by adopting Geospatial Knowledge Infrastructure to enhance their impact on national and global development.

It emphasises the value of collaboration between NMAs and the private sector, demonstrating how these collaborations are transforming geospatial capabilities in different economic sectors. Effective collaboration combines the skills and resources of public and commercial partners and promotes the creation of cutting-edge geospatial solutions. To ensure successful partnerships, it is critical to implement strong mechanisms that include specific actions, policies, and strategies that facilitate effective cooperation, as well as to adopt appropriate partnership models that establish the structural frameworks and types of relationships between the collaborating parties.

The report describes several public-private partnership (PPP) approaches, strategic alliances, and data-sharing agreements, all of which are important in improving NMA capabilities. PPPs are cooperative partnerships between one or more public-sector bodies and private-sector enterprises that combine their strengths to create substantial advances in geospatial technologies. For example, the Alberta Data Partnership (ADP) is recognised as a significant example in the geospatial sector, to use the capabilities and resources of both public and private institutions to improve geospatial data accessibility, quality, and utility across a wide range of applications.

Strategic alliances are formal agreements between independent organisations to work together and exploit each other’s strengths, resources, and talents to achieve certain goals while remaining distinct entities. These relationships can help NMAs and industries exchange geospatial data, technology, and knowledge. A significant example is SwissTopo’s strategic partnership with Hexagon, which modernised mapping systems by incorporating sophisticated surveying technologies such as LiDAR and photogrammetry, enhancing data accuracy and processing speed.

Data-sharing agreements are critical for maximising the use of geographical data. These formal agreements establish explicit standards, access mechanisms, and usage rights for sharing geographic data between parties, thereby increasing transparency and efficiency. For example, the Australian Government collaborated with Geoscape Australia to provide licensed access to proprietary datasets for commercial and academic purposes.

Hitesh Kumar Makwana, IAS, Surveyor General of India, Survey of India, India, highlighted the achievements under the National Geospatial Policy 2022: “In line with National Geospatial Policy 2022, Survey of India has commenced collaboration with the industry. The Government has advanced from traditional methods of procuring data to collecting accurate geospatial information and developing applications that can solve problems in real-time. All of this has happened due to private-public partnerships.”

His statement reflects a growing realisation of the value that public-private partnerships offer to the geospatial sector, allowing NMAs to be more dynamic and impactful in tackling national problems.

Sanjay Kumar, CEO of Geospatial World, spoke about the industry’s key transition: “The transition to Geospatial Knowledge Infrastructure represents a pivotal moment for National Mapping Agencies and the entire geospatial industry. This high-level thought leadership report underscores the importance of evolving our data frameworks to enhance collaboration and drive sustainable development. By integrating advanced geospatial technologies within a cohesive digital ecosystem, we are advancing our capabilities and contributing to global resilience and growth.” His findings underscore the vital necessity for NMAs to adapt to a quickly changing technology context in order to remain at the forefront of geospatial innovation.

The research goes on to discuss the expanding role of NMAs, which is being pushed by technological breakthroughs such as Artificial Intelligence (AI), Machine Learning (ML), and Digital Twins. These technologies are transforming the geospatial landscape, allowing NMAs to provide more precise and actionable data that is critical for decision-making in fields such as urban planning, infrastructure management, and environmental monitoring. The integration of these technologies improves data accuracy and broadens the scope of NMA capabilities in supporting complicated decision-making processes.

Furthermore, the research highlights the emerging trend of public-private partnerships (PPP) as critical to encouraging innovation and strengthening NMA capacities. NMAs are better positioned to assist economic growth, sustainable development, and capacity building in various sectors by utilising industry experience. These collaborations are cited as critical in ensuring that NMAs can keep up with the changing demands of the geospatial sector, making them more nimble and responsive to new issues.

Other collaborative approaches discussed in the paper include collaborative R&D consortia, technology transfer agreements, and outsourcing and contracting, all of which play important roles in the advancement of geospatial technologies. For example, a cooperative initiative between the German Federal Agency for Cartography and Geodesy (BKG) and the Fraunhofer Institute resulted in the development of novel geospatial data processing methods, illustrating the capacity of collaborative research and development to drive innovation.

The paper finds that as NMAs evolve, their contributions to national and global development will become more important. The incorporation of modern geospatial technologies, as well as the increase in collaborative activities, will position NMAs as critical to the future of geospatial knowledge and its use across a wide range of sectors. This progression is projected to enable NMAs to take a more proactive role in determining the future of geospatial intelligence, resulting in global innovation and sustainability.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Srinivasan

AGM, Schwing Stetter India

Topic: Empowering Operators with Advanced Training and Safety Measures

Mr. Srinivasan M is a seasoned professional trainer with more than 20 years of expertise. He is an expert in hydraulics, pneumatics, and concreting machine technology, with numerous industry qualifications. Mr. Srinivasan, known for his extensive knowledge and practical approach, has trained several experts and operators to improve their technical abilities and industry readiness.

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mark McConway

Managing Director, WEB Systems International

Topic: New Trends in Mobile Access Towers and Platforms

Mark McConway, the Managing Director at Scotland-based WEB Systems International, which partners with India, holds a first-class Honours Degree in Business and Legal Studies. He has led various industries, notably Construction, Universal Design, and Manufacturing. Since 2013, Mark has driven innovation in working-at-height safety solutions at WEB Systems International, focusing on underdeck access for bridges, oil and gas facilities, steel plants, and more. His passion lies in reducing worker time at heights and fostering a global network to enhance safety and efficiency. Mark’s career is marked by his commitment to improving industry safety standards and operational processes.

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Anubhav Roy

Marketing Manager, Abhay Rana Infra Services Private Limited

Topic: Preventive Maintenance: Key to Longevity of Access Equipment

Anubhav Roy is a computer science engineer with a PGDM in Marketing Management, bringing four years of digital marketing experience and a background in the construction industry. With firsthand experience in implementing IoT applications, Anubhav skillfully blends technical and marketing expertise. Currently, he is focused on promoting Magni Telehandlers, leveraging his dual expertise to drive brand growth.

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Dr. Raghunandan Jagdish (Dr. Raghu)

MD & CEO, Nandan GSE Pvt Ltd

Topic: Safety Protocols for Working at Height in Urban Areas

Dr. Raghunandan Jagdish, also known as Dr. Raghu, is the MD and CEO of Nandan GSE Pvt Ltd, where he leads a team of 250 experts dedicated to solving material handling challenges across the Aviation, Aerospace & Defense, and Manufacturing industries. With a PhD from Robert Sobourn University and a Master’s in Mechanical Engineering from Texas A&M University, Dr. Raghu is a renowned thought leader in material handling. His expertise spans Planning, Kaizen, Lean methodologies, World-class manufacturing, and Vertical Factory design. Based in Navi Mumbai, Dr. Raghu travels extensively for business, continually expanding his knowledge and influence in the field.

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Kobelco Construction Equipment India Pvt Ltd introduces the SK80 Excavator in Chennai. Takemichi Hirakawa, Managing Director of Kobelco Construction Equipment India Pvt Ltd, proposes the Made-in-India 8-ton mid-segment excavator in front of channel partners.

The SK80 Excavator has various new features, including superior technology, a sophisticated hydraulic system, fuel efficiency, operator comfort, durability, maintenance, and versatility, which distinguish it from competitors and demonstrate its dedication to sustainability. The SK80 Excavator is equipped with a variety of attachments that allow it to execute a wide range of jobs, including digging, lifting, and grading.

Sharing more details about the new product, Takemichi Hirakawa, Managing Director, Kobelco Construction Equipment India Pvt Ltd, says, “The launch of the SK80 Excavator is a significant milestone in the 17-year journey of our company in the Indian CE industry and is a testament to the company’s ongoing commitment to innovation, excellence and to the Make in India drive. We have a long-standing reputation for delivering high-quality excavators that meet the growing demand of Indian customers. The SK80 Excavator will also address the need for advanced machinery that can handle diverse tasks with ease and efficiency. The cutting-edge technology and robust engineering of the SK80 Excavator will be a game changer in the mid-category excavator market.”

The excavator is equipped with a Yanmar engine that reflects Japanese technology and seeks to give a best-in-class performance. The environmentally friendly engine decreases fuel consumption and pollutants, saves operating costs, and has a minimal environmental impact. The advanced hydraulic system ensures smooth and precise operation. This technology increases the machine’s digging and lifting capabilities, making it suitable for various applications. The SK80 excavator features a roomy and ergonomic cabin with adjustable seating, a touchscreen colour monitor, and straightforward controls to assure the operator’s safety and comfort. The machine’s strong design makes it the ideal choice when operating conditions are the most difficult. The SK80 Excavator requires low maintenance and provides high uptime and productivity.

Kobelco Construction Equipment India Pvt Ltd is a subsidiary of Kobelco Construction Machinery Co., Ltd. (part of the Kobe Steel Group), the world’s leading manufacturer of construction equipment. Kobelco’s product line comprises excavators and cranes, all of which are engineered to provide exceptional performance and dependability.

For more information, visit: https://www.kobelcowelding.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Tembo Global Industries Ltd. has established two new divisions, Tembo Global Infra Ltd. and Tembo Defence Products Ltd., to improve project execution and contribute to India’s “Make in India” drive.

Tembo Global Industries Ltd. has announced the formation of two separate firms targeted at altering the landscape of their respective industries. This news is a key milestone for Tembo Global Industries Ltd. as it brings together the new businesses – Tembo Global Infra Ltd. and Tembo Defence Products Ltd.

The first of these initiatives establishes Tembo Global Infra Ltd. as the primary project executor, greatly expanding the company’s portfolio. This division, which operates under the overall direction of Tembo Global Industries Ltd, is intended to improve and streamline project execution efficiency. With a continuous dedication to providing excellence, the division is positioned to be the driving force behind the company’s future projects, committed to innovation and upholding the highest quality standards.

Tembo Global Industries Ltd.’s strategic decision to establish this division demonstrates its commitment to company adaptability in a changing commercial landscape. With a team of experienced professionals and recognised experts, the division intends to capitalise on specialised expertise by concentrating project execution inside its operations. This strategy ensures that each project receives personalised attention, tailored solutions, and meets the highest levels of delivery excellence.

Furthermore, as part of its strategic integration, Tembo Global Industries Ltd. launches its second division, Tembo Defence Products Ltd. This project is motivated by rising production demands and demonstrates Tembo’s commitment to supporting the “Make in India (Atmanirbhar Bharat)” campaign. This move furthers the country’s larger goal of promoting self-reliance in defence manufacture.

Speaking on the launch of the divisions, Sanjay Patel, Managing Director at Tembo Global Industries Ltd, comments, “The introduction demonstrates our company’s dedication to growth and marks the beginning of a new era of innovation and excellence in project execution and diverse business ventures. Our company’s divisions are examples of our strategic vision and commitment to setting the standard in their respective fields.”

This groundbreaking programme highlights Tembo Global Industries Ltd’s dedication to optimising its organisational structure, boosting operational effectiveness, and stimulating innovation across all of its businesses. With these two divisions hitting the stage, Tembo Global Infra Ltd. and Tembo Defence Products Ltd., the business retains its position as a forward-thinking leader in the field, ready to handle any challenges that may come while providing incomparable value to its stakeholders.

For more information, visit: https://www.tembo.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

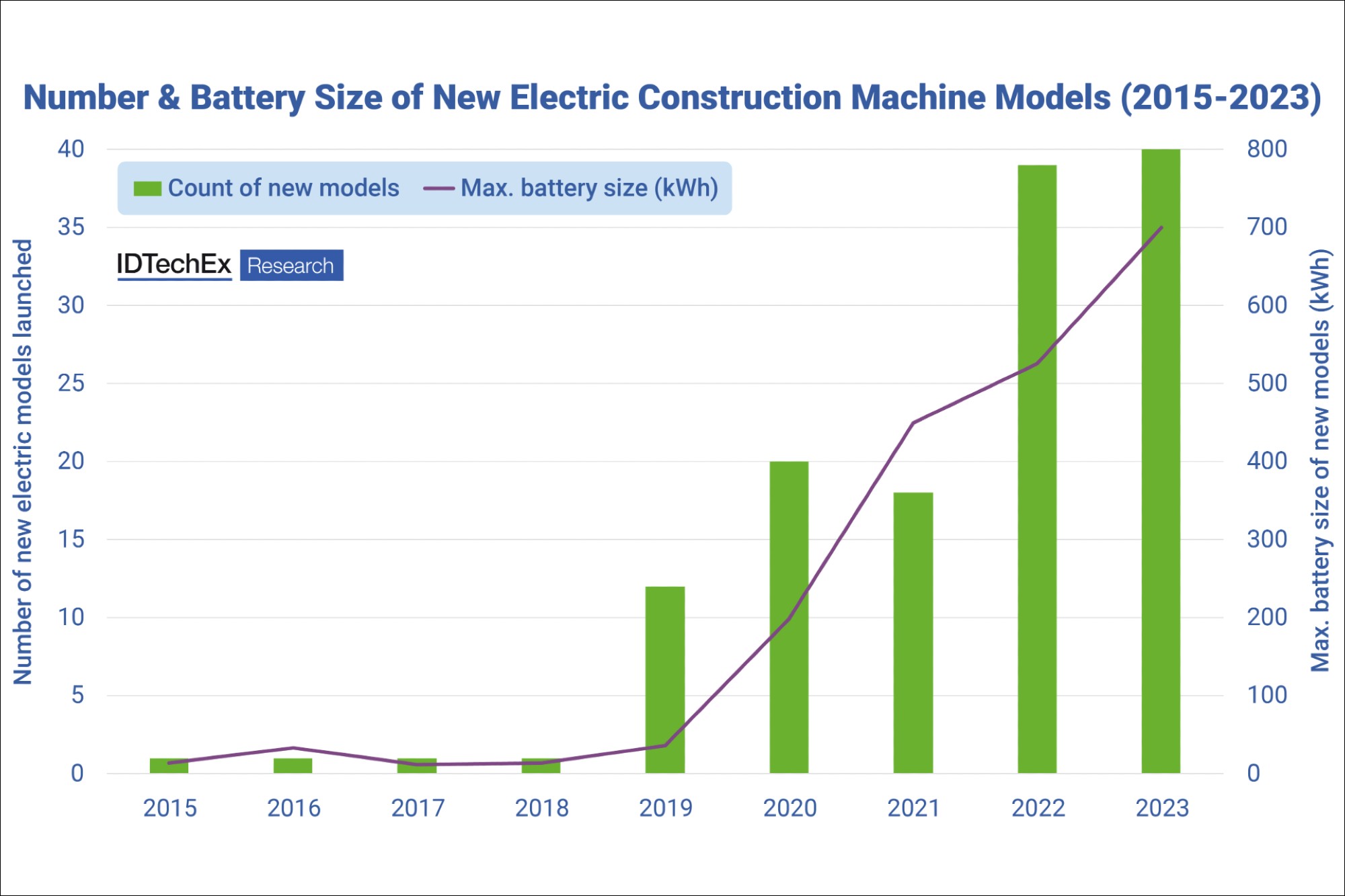

The construction machinery industry is fast evolving, with improvements in machine size and performance. IDTechEx’s analysis anticipates a market value of more than US$126 billion by 2044, emphasising this transformational shift.

The construction machine sector is still in the early phases of electrification, with the first tiny electric machine entering the market in 2015. However, IDTechEx’s new report, “Electric Vehicles in Construction 2024-2044: Technologies, Players, Forecasts,” demonstrates how today’s electric machines are larger and better than their counterparts from less than a decade ago. OEMs worldwide are accelerating the development of electric machines, and IDTechEx predicts that the market will be valued at more than US$126 billion by 2044.

Machine performance continues to increase

Mini excavators were the first electric machinery to appear on the scene. Their smaller sizes and lower workloads made them suitable trial grounds for construction electrification. Many construction businesses were concerned about whether these electric machines could survive the pressures of the job site while providing comparable performance to diesel engines.

According to IDTechEx’s latest assessment, electric mini-excavators have advanced to the point where they can compete with diesel in almost every significant measure. EVs provide comparable or even superior power than diesel machines, with models from Kato and Wacker Neuson capable of producing 30-60% more digging force than the average diesel machine of the same size. These machines’ runtimes have also improved significantly. Whereas the earliest machines on the market only lasted 4 to 6 hours on a single charge, current devices may operate for up to 8 hours (a full workday) as standard. Persistent battery development has played a significant role in this growth, and IDTechEx anticipates runtimes to reach 9 to 10 hours.

Large excavators and loaders are coming to the fore

While mini-excavators dominated the early stages of electric construction machine growth and remained the market’s largest segment, development efforts have shifted to giant excavators and wheel loaders. These two machine types accounted for 35 percent of total equipment sales in 2023 and are among the most significant emitters of greenhouse gases on the job site, accounting for more than half of all construction machine emissions. Their electrification is thus critical to accelerating the decarbonisation of the worldwide construction industry.

As the number of new electric machine types entering production increased from 2019 to 2023, so did the size of these machines. Whereas 3-tonne mini-excavators were previously the pinnacle of electric machine technology, many OEMs today offer huge excavator models weighing 20 tonnes or more. In 2023, the Chinese OEM Know-How began building a 52-tonne electric excavator, the largest. Wheel loaders have reached a similar point, with new 20-tonne machines now the standard for electrification.

Larger machines require larger and more complex battery systems, and the rise of electric excavators and wheel loaders has resulted in a significant increase in battery sizes in construction over the previous five years. The maximum battery size installed in newly produced models has increased from ~30 kWh in 2018 (used in mini-excavators and similar tiny machines) to over 500 kWh by 2023. The Know-How 52-tonne excavator is outfitted with a massive 700 kWh battery, which IDTechEx says would cost $210,000 on its own and weigh more than 3.5 tonnes.

What’s next for EV construction machines?

Many of the larger machines that are now on the market have already followed in the footsteps of mini-excavators by matching the performance of diesel rivals. OEMs have reached the point where achieving performance parity is no longer a challenge, and they are focussing on expanding their EV portfolios to include larger machines and new equipment types. Chinese OEMs have been market leaders in this regard, manufacturing larger excavators and wheel loaders while also pioneering the electrification of mobile cranes weighing hundreds of tonnes.

Battery developments will play a significant role in defining the future of the electrical construction industry. OEMs are now charging far higher prices for batteries than the automobile sector, but increasing the scale of EV production and establishing dedicated supply chains will help to reduce costs. At the same time, increasing the efficiency of existing battery technologies and incorporating more modern Li-ion and future battery technologies will broaden the range of machines that can be electrified and improve their performance.

The new IDTechEx paper “Electric Vehicles in Construction 2024-2044: Technologies, Players, and Forecasts” delves deeper into the future of the electric construction machine industry. It predicts that the market will increase at a 21 percent CAGR to US$126 billion in value by 2044.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Hilti’s new DDS platform, which leverages the power of IoT, enables real-time access to tool park management, insights into cordless tool battery condition, and functions as a virtual customer service centre.

Hilti India Private Limited announces the launch of its groundbreaking Data Driven Services (DDS). This innovative solution provides cutting-edge tool park and warehouse management, as well as battery health services. This strategic approach intends to revolutionise business tool management while increasing on-site productivity and efficiency.

Hilti India has been in the forefront of bringing technologies that promote productivity, safety, and sustainability to Indian construction sites since its inception. Hilti India debuted Nuron in July 2023, a single 22V cordless platform that delivers performance and safety to all tasks, from light duty drilling to heavy duty breaking.

Hilti India has made its Nuron platform smarter and more agile by integrating information and connection into all equipment. Hilti’s revolutionary “Data Driven Service (DDS)” is an integrated IoT solution that offers superior tool park management and real-time insights into battery health services.

DDS introduces a number of new capabilities, the most noteworthy of which is power tool position tracking, which allows the user to track the site where the tools are located. In addition, DDS provides real-time information on the utilisation of power tools, including idle assets and the time the tool was idle. The third feature offered by DDS is a proactive health monitoring system for tool batteries, which provides proactive notifications and replacements in the event of a failure, assuring continued operations.

Hilti has introduced “ON! TRACK 3”, a single app for controlling all Hilti assets, to make it easier and more convenient to access this collected information. In addition to offering access to all of its functions, the app serves as a virtual customer support centre. Users, for example, can use the app to retrieve all important product specifications, examine tool maintenance costs, and even arrange repairs.

Speaking about the launch, Ashish Markande, Director of Marketing, at Hilti India Pvt Ltd, says, “At Hilti, our constant endeavour is to streamline our customers’ tool ownership experience and ensure their convenience in using our products and services. In line with this vision, we have designed the Data-Driven Services (DDS) platform to empower customers to focus on their core business and manage tools. By addressing the key pain points, DDS optimises operational efficiency and purchase processes, serving as a one-stop solution for all their tool-related needs.”

DDS is India’s first power tool-specific service. It works smoothly with Hilti’s ground-breaking Nuron platform, collecting data from all cordless instruments during each charge cycle. Using the app, organisations can harness tool park analytics, enhance productivity, and make educated decisions. Hilti India’s new solution intends to provide data-driven consultancy and services, keeping its pledge to be the best partner for productivity, safety, and sustainability for its customers.

India is going through a digital transition, especially in the construction industry. Construction 4.0, which is powered by new technologies and data-driven solutions, marks a substantial transition. BIM, IoT, AI, ML, robotics, and automation are major technologies driving this paradigm change. It is good to see India’s willingness to embrace innovation and work towards higher production.

For more information, visit: https://www.hilti.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

TIL Limited (NSE: TIL) has signed an agreement with Snorkel Europe Limited to become an official Sales and Service partner in Northern and Eastern India, the Andaman and Nicobar Islands, Nepal, and Bhutan.

Snorkel will supply its vast product line, as well as knowledge and support, as part of this new cooperation while TIL will use its large network of customers in India, Nepal, and Bhutan to provide high-quality aerial work platforms, tele handles, and material lifts.

TIL has established itself as a powerful participant in the material handling, mining, construction, and defence sectors by offering individually developed solutions. TIL’s defence sector offerings have been employed for decades in India’s defence establishment’s three services. The company is well known for its retail equipment, which includes Reach Stackers, Rough Terrain Cranes, Truck Mounted Cranes, and Pick and Carry Cranes, among others.

This new relationship will allow TIL to expand into a new product area while also leveraging its large consumer base. This will expand TIL’s offerings to customers in India across a variety of industries.

Sunil Kumar Chaturvedi, Chairman and Managing Director of TIL Limited, and Craig Revell, Snorkel Europe Limited’s Business Development Director for the Middle East and India, signed the cooperation agreement. This is another milestone for TIL as it seeks to extend its product options to meet India’s growing need for bespoke equipment.

Speaking about the new partnershi Craig Revell, Business Development Director, Middle East and India, Snorkel Europe Limited says, “We are excited to have TIL Limited as our Sales & Service partner in India, Nepal and Bhutan. The brand’s legacy in the AWP sector, coupled with its highly experienced team make it the ideal partner for Snorkel in this region. We look forward to reaching new customers across TIL’s territory and bringing them the robust products that both Snorkel and TIL are known for.”

“TIL Limited is delighted to embark on this partnership with Snorkel in India, Nepal and Bhutan. Our customers have known us for highly reliable and robust products that can perform in different and demanding working environments safely. The products that Snorkel has to offer to Indian Customers are known globally for the same quality and dependability. We feel this partnership is a natural fit and fulfils the Indian markets demand for safe, powerful and versatile aerial work platforms.” mentioned Alok Tripathi Director and President of TIL Limited.

TIL’s relationship is another step towards meeting the diversified needs of its clients who are involved in the nation’s construction and defence. The move is also consistent with the company’s objective of becoming a worldwide trusted provider of technical solutions that provide long-term value to people’s and the planet’s lives. The new product line is expected to increase TIL’s revenue by approximately INR 200 crore by FY 2028.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The fischer bolt anchor FAZ II Plus establishes a new standard for anchoring systems by providing high tensile strength, adaptability, and European standard certifications.

This revolutionary steel anchor is designed to withstand the most extreme conditions, delivering strong and dependable performance in a wide range of demanding applications. With its outstanding capabilities, the FAZ II Plus is an essential instrument in sectors such as railways, tunnels, airports, highways, renewable energy projects, energy, and industries.

Speaking about the groundbreaking capabilities of the FAZ II Plus, fischer India MD Mayank Kalra highlighted the anchor’s unparalleled performance and adaptability. “The FAZ II Plus represents a significant leap forward in anchoring technology. Its high tensile strength, combined with easy and quick installation, makes it a game-changer for numerous critical infrastructure projects. We are proud to offer a product that meets the stringent demands of modern construction and engineering. The FAZ II Plus is more than just an anchor—it’s a cornerstone of modern engineering, offering unparalleled performance and reliability for projects that shape the future. “

The FAZ II Plus has much higher tensile strength, resulting in fewer fastening points and improved construction. It has a wide range of substrate material approvals, including various concrete grades, steel fibre concrete, and solid sand-lime brick. It is approved for dynamic loads in diameters ranging from M16 to M24, making it excellent for lifting platforms, conveyor belts, and pumps as it provides instantaneously loadable attaching points. Installation is quick and simple, with no drill hole cleaning required for diameters ranging from M8 to M24. The FAZ II Plus provides fire safety by ETA evaluation and other testing and can handle heavy loads even during a fire. It has a verified service life of up to 120 years, which makes it suitable for long-term applications. It can withstand high seismic loads with diameters ranging from M10 to M24, which is critical for earthquake-prone areas. Its diverse functionality allows for a variety of installation options, including millimetre-accurate load adjustments.

The FAZ II Plus alters crucial parts by enabling secure anchoring for various applications. Mr. Kalra emphasised that it maintains the stability of railings, cable trays, and other components in railways, hence improving infrastructure safety and reliability. In tunnel construction, its high tensile strength and fire safety approvals ensure long-term stability under harsh conditions, distinguishing it from other solutions. For airports, its quick and effective construction enables dynamic applications like as lifting platforms and conveyor systems, assuring operational efficiency and safety. The FAZ II Plus is also perfect for highway infrastructure, as it can withstand high loads and seismic stresses, allowing for strong guardrail and signpost installations. Its extended service life and high load-bearing capability make it ideal for renewable energy projects like wind turbines and solar panel arrays, ensuring durability and reliability. In the energy and industrial sectors, it provides strong anchoring for large gear and equipment while ensuring operational integrity and safety.

The fischer FAZ II Plus bolt anchor is a powerful and adaptable solution designed to meet the most stringent requirements in different critical infrastructure applications. Its high tensile strength, diverse approvals, and ease of installation make it an excellent choice for engineers and construction experts. Whether for railways, tunnels, airports, highways, renewable energy projects, or industrial applications, the FAZ II Plus provides dependable, long-lasting, and secure anchoring solutions.

For more information, visit: https://www.fischer.in/en-in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

ICRA expects operating leverage to help buffer growing competitive pressure in the construction sector, with margins remaining stable in FY2025.

ICRA forecasts Indian construction firms to sustain solid revenue growth in FY2025e, with a projected YoY growth of 12–15 percent this fiscal year, aided by an acceptable order book position and the government’s focus on infrastructure development. This is seen in the increase in the Government of India’s (GoI) overall capital spending to ₹11.1 trillion in the FY2025 revised budget estimates (RBE), which bodes well. ICRA maintains a stable outlook for the industry, citing consistent increases in operating income, moderate leverage, and adequate coverage criteria.

Giving more insights on this, Chintan Lakhani, Vice President and Sector Head, Corporate Ratings, ICRA, says, “The aggregate order book-to-sales ratio of ICRA’s sample set of companies remained stable at 3.3x as of March 2024 (3.4 times during March 2023), thereby indicating healthy revenue growth prospects over the medium term. Certain construction entities have witnessed pressure on road sector-related order inflows in FY2024, in the backdrop of muted order awarding from the Ministry of Road Transport and Highways. However, diversification into other segments like drinking water, metro segments, or railway station development has helped them sustain their order book. ICRA expects revenue growth to remain healthy at 12-15 percent in FY2025”.

Over the past five years, ending March 2024, the order book of ICRA’s sample construction companies has remained between 3.3x and 4.0x of operational income, owing to the government’s increasing capital investment in the infrastructure sector. The transportation (roads, metro, airport, bridges, flyovers) and building (residential, commercial, mixed-use, industrial) categories continue to dominate the order book; however, their combined share has dropped to 62 percent in FY2024 from 77 percent in FY2020. Over the same period, the proportion of orders for mining, water, and energy has climbed.

The reduction in prices of some major commodities, such as steel, boosted the profitability profile of construction companies in FY2024; nevertheless, steel prices have begun to rise and could be a spoilsport in the current fiscal year. The NHAI / the Ministry of Road Transport and Railways continue to award engineering, procurement, and construction projects with hybrid annuity models; however, competition in categories such as sewage and drinking water remains very mild. Despite increased competition, operating margins are estimated to remain constant at 11 percent ± 25bps in FY2025e, thanks to leverage benefits.

“ICRA expects the cash conversion cycle to elongate, with no further extensions in Atma Nirbhar Bharat scheme-related relaxations beyond March 2024. Consequently, the debt levels are expected to increase to support the enhanced working capital requirements. However, the corresponding operational leverage benefits are anticipated to keep the interest cover at ~4.0 times in FY2025e,” Lakhani added.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

SATO, LIXIL’s creative sanitation leader, has partnered with Supreme Industries to utilise their market reach and production experience, increasing access to safe, affordable sanitation solutions across India by the end of August.

SATO, LIXIL’s award-winning social business and a global leader in innovative sanitation and hygiene solutions, is excited to announce a strategic partnership with Supreme Industries, the nation’s largest plastics processor, which offers a diverse and comprehensive range of plastic products.

Supreme Industries will use its extensive market penetration and gold-standard production capabilities to manufacture and distribute SATO’s award-winning hygiene and sanitation solutions, increasing the availability of safe and affordable sanitation products throughout India.

Suguru Sakata – Leader Asia, SATO, states, “This partnership marks a significant step towards achieving our purpose of providing accessible and affordable sanitation solutions to people across India. Supreme Industries’ manufacturing expertise aligns with our commitment to innovation and consumer-centric focus, ensuring that our award-winning products reach even more households.”