SANY India, a prominent construction equipment manufacturer, announces the grand opening of its new company-owned, company-operated (COCO) office in Delhi.

This new office in Delhi will play an important role in the company’s mission of increasing customer happiness and driving growth in the Indian market. SANY India remains at the forefront of the construction machinery industry, emphasising innovation, quality, and customer-centricity.

Deepak Garg, Managing Director, led the inauguration ceremony, which also included Shashank Pandey, Business Unit Head, and other top management members from SANY India. Other important visitors and industry partners attended the ribbon-cutting ceremony and saw the cutting-edge facilities. The new office has modern infrastructure and superior technology to support SANY India’s activities while also providing a pleasant working environment for its workers.

Deepak Garg, VC and MD of SANY India, expressed his enthusiasm over the new office”The opening of our new COCO office in Delhi reflects Sany India’s ongoing growth and commitment to delivering exceptional service to our customers. This office will enable us to better serve the needs of our clients in the region and further strengthen our presence in the Indian market.”

Shashank Pandey, Business Unit Head, added, “We are thrilled to open our new office in Delhi. This facility will help us improve our operational efficiency and foster closer relationships with our customers. Our team is committed to delivering innovative solutions and exceptional service, ensuring that Sany India remains a trusted partner in the construction industry.”

The new COCO office, which spans 3,000 square feet and is conveniently placed in Delhi’s Mohan Cooperative Industrial Estate, is a big step forward in Sany India’s expansion strategy. It demonstrates the company’s dedication to providing outstanding service and support to its valued clients in the northern region. This office will serve as a hub for operations, sales, and after-sales services, resulting in increased client engagement and improved processes.

For more information, visit: https://www.sany.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The SEM-SAFE® technology successfully controls, suppresses, and extinguishes flames, ensuring optimal structure and life safety and preventing/minimising disruptions to tunnel operations.

Danfoss Fire Safety is happy to announce the successful installation of its cutting-edge SEM-SAFE® high-pressure water mist fire protection system in the Samruddhi Motorway Tunnel in Maharashtra, India. This breakthrough project represents a significant advancement in fire safety technology and infrastructure development, with the goal of establishing a secure environment for people to evacuate in the event of a fire while also protecting the tunnel structure.

The Samruddhi Motorway, which connects Mumbai and Nagpur, is a driver for Maharashtra’s general socioeconomic development. The Samruddhi tunnel, located in the heart of the Mumbai-Nagpur megaproject, is an 8-kilometre, three-lane marvel that allows travellers to safely cross the Western Ghats Mountains in less than ten minutes. Ensuring reliable fire protection in the tunnel is critical. Following this, Danfoss Fire Safety was chosen to supply the active fire prevention system for this project. Thus, Danfoss Fire Safety’s SEM-SAFE® high-pressure water mist system has been installed in the tunnel.

Fires in tunnels can spread quickly, endangering lives and infrastructure. To address this issue, the Samruddhi tunnel has 26 cross-passages for emergency evacuation and 54 ventilation fans per tube to provide proper airflow and smoke clearing. What distinguishes this tunnel is its use of the SEM-SAFE® high-pressure water mist system, a cutting-edge technology developed to effectively suppress and manage flames.

“Pioneering the implementation of our SEM-SAFE® high-pressure water mist system in the Samruddhi Expressway Tunnel is a testament to Danfoss’s commitment to innovation and safety. We are proud to be involved in a project vital to the development of Maharashtra, India, ensuring that road users can travel with peace of mind while preserving the environment for future generations,” says Qusai Alasad, Global Manager- Transportation Infrastructures, and Danfoss Fire Safety.

“I am honoured to witness the successful implementation of our SEM-SAFE® high-pressure water mist fire protection system in the Samruddhi Expressway Tunnel. This milestone not only showcases Danfoss Fire Safety’s unwavering commitment to pioneering safety solutions but also reflects our relentless dedication to elevating infrastructure safety standards. Our extensive fire testing at RISE in Norway witnessed and verified by UL and meeting the SOLIT2 and NFPA502 criteria, underscores the depth of our investment in ensuring the utmost safety and reliability of our technology. With this project, we continue to lead the industry, setting new benchmarks in fire protection for tunnels worldwide.” – says Poul Harder, CEO of Danfoss Fire Safety.

High-pressure water mist is perfectly safe for humans yet highly efficient against fires. Test results reveal that high-pressure water mist systems effectively extinguish even deep-seated or difficult-to-reach fires. The combined cooling and oxygen displacement provide up to 7 times more cooling capacity than sprinklers, and the technology efficiently inhibits reignition.

This ingenious solution covers both tunnel tubes. The SEM-SAFE® high-pressure water mist system includes pump units, section valves, nozzles, pipes, and fittings. High-quality stainless-steel components, energy-efficient high-pressure Danfoss pumps, and a sturdy system all contribute to the system’s long life.

The SEM-SAFE® system is designed to meet the customer’s sustainability needs while using very little water. This sustainability-focused approach is consistent with the project’s dedication to environmental preservation, especially given its closeness to the UNESCO World Heritage Site of the Western Ghats.

Danfoss Fire Safety not only supplies the system but also provides full technical design, engineering capabilities, and site supervision to ensure smooth and comprehensive project management and support. Afcons Infrastructure Limited, one of India’s leading infrastructure development corporations, will build the Samruddhi Tunnel.

Danfoss Fire Safety’s SEM-SAFE® high-pressure water mist system establishes a new level for fire prevention at the Samruddhi Motorway Tunnel. Danfoss Fire Safety remains committed to providing an unsurpassed competitive advantage through uncompromising performance and cost-effective solutions.

Key Benefits:

For more information, visit: https://www.danfoss.com/en-in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

MB Crusher transforms infrastructure by allowing on-site material reuse, lowering costs and environmental effects, and increasing efficiency in road, railway, and utility projects for modern, linked cities.

MB Crusher is at the vanguard of revolutionising infrastructure development worldwide, improving the efficiency and sustainability of building roads, trains, utility networks, and overall connectivity to drive national development.

Modern life is fast-paced, with busy schedules and tight deadlines. People require better infrastructure, upgraded road systems, faster train connections, and dependable utilities. To promote urban development, MB Crusher units meet the complicated challenges of modern infrastructure projects by allowing for on-site material reuse. MB Crusher attachments significantly minimise the requirement for transportation, lower construction costs, and limit environmental effects.

In road construction, MB Crusher’s equipment is critical for producing a strong and durable road foundation. The crusher buckets efficiently treat various materials, chewing through old asphalt, concrete, and stones before spitting fresh aggregate suitable for new roadways. This expedites the construction process and ensures the longevity of the roadways.

Consider David, a South African farmer who bought a BF90.3 jaw crusher for his excavator to minimise potholes while reducing mechanical wear and tear, operating slowdowns, and cargo loss. The MB Crusher unit has provided David with a superior product, allowing him to operate more quickly and efficiently. This enhancement enables him to allocate resources and people to other important parts of farm management while providing a profitable sideline business.

MB Crusher is vital in railway construction and maintenance, working as a backstage crew to keep everything running properly. The crusher can lay the foundation and manage the ballast, while the drum cutter can dig deep to create tunnels. In reality, the MB Crusher’s MB-R500 drum cutter and the Hyundai R210 excavator made a big breakthrough in surfacing a 44-kilometre-long tunnel in the Sivoke Rangpo Railway Lines project. Traditional rock breakers generated surface concerns, but MB Crusher’s unique technology resolved these issues, turning a difficult process into a smooth operation.

MB Crusher’s products greatly enhance utility infrastructure, water, gas, and electricity networks. From moving to bedding, MB Crusher machines can complete pipeline jobs in restricted urban settings and tough surroundings, ensuring that utility projects run smoothly and efficiently.

MB Crusher helps establish contemporary, connected communities by improving construction processes and infrastructure durability, enabling economic growth, improved quality of life, and sustainable development worldwide. In Italy, a grapple MB-G1200 worked tirelessly to repair a trench that secured the area’s water network, a task made easier and faster by MB Crusher units.

Infrastructure is the foundation of economic and social development. By speeding building processes and improving the longevity of infrastructure projects, MB Crusher’s technology directly contributes to the creation of modern, networked communities. The company’s equipment is used all over the world to construct roads, trains, and utilities that boost economic growth, improve quality of life, and promote sustainable development. So, the next time you’re enjoying a smooth drive, a quick train ride, or reliable utility services, take a moment to appreciate the hard work and creativity that goes into them. MB Crusher isn’t simply creating infrastructure; they’re building for the future.

For more information, visit: https://www.mbcrusher.com/en/in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Gadkari emphasised that pollution—air, water, and land—remains the most serious concern, and the government’s principal goal is to minimise and finally eliminate it.

Union Minister for Road Transport and Highways Nitin Gadkari presented the government’s five-year infrastructure programme at the Infrashakti Awards. Gadkari underlined the Modi government’s ongoing efforts to develop India into a $5 trillion economy. Over the last decade, the government has made considerable progress in various infrastructure sectors, including energy, highways, urban infrastructure, trains, and airports, led by Prime Minister Narendra Modi. The Infrashakti Awards, organised by NDTV, aim to recognise these achievements in infrastructure development across India.

Gadkari announced a significant overhaul to the toll tax system at the event. He explained, “Now the more you travel, the more toll you will have to pay,” and revealed that the first phase of a GPS and satellite-based toll system will commence in three months, with plans for nationwide implementation.

Gadkari outlined the government’s initiatives for the third term. He highlighted that pollution reduction is a top concern, especially in Delhi, where increasing the number of electric buses will reduce pollution and save money. In addition, efforts to promote electric taxis are underway.

Gadkari also emphasised the benefits of ethanol, which may cut pollution while saving money. He stated that electric vehicles powered by ethanol instead of fuel could drastically reduce costs—from ₹ 120 for petrol to ₹ 65 for ethanol. Ethanol is being investigated as a potential alternative to grid electricity, reducing the requirement for plug-in systems to charge lithium batteries.

Expanding on biofuel, Gadkari stated, “We need to adopt a larger format with biofuel to reduce transport costs.” He stated that operating a diesel bus now costs ₹ 115, but with government subsidies, this figure could be decreased by 40 percent.

A pilot project in Nagpur, in conjunction with the Tata Group, is scheduled to begin soon. A comparable proposal, inspired by a 132-passenger tram bus seen in Yugoslavia, is being developed in collaboration with Hitachi.

The transit minister emphasised the importance of making public transit cheaper, with plans to deploy electric buses, vehicles, scooters, and CNG and ethanol-powered tractors, shortly.

For more information, visit: https://www.ndtv.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Echon, a global leader in building materials, enters the Indian market with 25 years of experience, intending to enhance construction and renovation with eco-friendly solutions.

Echon, a worldwide-recognised maker of unique building materials for house interiors, exteriors and signage, has announced a planned expansion into the Indian market. With over 25 years of experience and a strong global footprint, Echon strives to revolutionise India’s construction and home renovation industries with eco-friendly and cutting-edge solutions.

Echon’s organised five-phase development into India signals the start of a vast distribution network commencing in Gujarat. The organisation is prepared to meet the changing needs of Indian consumers in the residential, commercial, and industrial markets. The debut of its flagship product, ‘Masterboard’, aimed at revolutionising standards in construction, remodelling, and signage solutions, is at the heart of this launch. These offers prioritise durability, cost-effectiveness, and modern design to meet the growing demand in India’s real estate and infrastructure sectors.

Shubham Taylia, Managing Director of Echon, emphasised the company’s commitment to utilise Indian manufacturing skills while serving worldwide markets. “Echon is proud to be one of India’s largest exporters in our category, supplying premium products to leading retailers and distributors worldwide,” he stated. “With sustained double-digit growth and state-of-the-art technology, we have established ourselves as a dependable leader. Our expansion in India underscores our dedication to quality and innovation. Echon serves best-in-class global multi-billion MNC retailers and distributors while sourcing raw materials from global leaders. We consistently produce world-class products through long-serving leadership talent, some with the company for 15 to 25 years, creating a product portfolio that started with only 10 SKUs in 1998 and now exceeds 900 SKUs developed based on customer demand and ongoing innovation, which Echon delivers with shortest turnaround times, a key strength of Echon.”

Echon’s strategic focus is on developing a strong distribution network across India to ensure widespread availability of its full product line, which includes doors, wall panels and ‘Masterboard’, as well as ceilings and signage solutions. This programme intends to provide architects, interior designers, contractors, builders, carpenters, and construction firms with high-quality building materials and signage solutions. Echon also holds a global record for its corporate social responsibility programme “Save a Life,” which has achieved social media success.

The organisation’s continual profitability is any business litmus test for a solid team, products, and experience. Echon is a debt-free company with cash reserves and has an incredibly solid financial position to capitalise on future growth opportunities, demonstrating smart capital allocation. Echon’s 60 percent year-over-year growth from 2022 to 2023 illustrates the company’s strategic efforts and market expansion capabilities, as well as client acceptance of its value proposition and superior quality.

For more information, visit: https://www.echon.co/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Concrete GPT is powered by the GPT-4 OpenAI and Perplexity Models and is aimed at improving user interaction through chatbots, audio prompts, and WhatsApp conversations.

AJAX Engineering, India’s leading manufacturer of concrete equipment, recently unveiled Concrete GPT, the country’s first AI-powered platform for the construction and concreting industries. The website promises to serve millions of construction and concrete professionals by providing them with a massive collection of expert-validated technical knowledge on the most recent industry insights, innovations, and regulatory updates.

Concrete GPT is powered by OpenAI’s GPT-4 model and the Perplexity engine, and it is intended to improve user interaction via chatbots, voice prompts, and WhatsApp chat. Concrete GPT was created to address the language divide in the construction and concrete industries. It presently offers audio interactions in English, Hindi, Telugu, Marathi, and Kannada languages. It serves the demands of industry experts, customers, and suppliers who do not speak English as their primary language, assuring simplicity of use and comprehension.

Concrete GPT, which is trained on a wide range of global construction standards and newest trends and is available for the concrete and construction industry until March 2024, can be used for extensive skill development, project workflow optimisation, and overall industry knowledge enhancement. It can provide fast technical assistance and practical maintenance advice to improve machinery performance and assure adherence to safety rules. Integrating Concrete GPT’s cutting-edge AI-driven learning provides industry experts and customers with access to a wide range of study resources that will help them make better decisions.

Commenting on the launch of Concrete GPT Shubhabrata Saha, MD & CEO of AJAX Engineering, says, “AJAX has always been at the forefront of innovation and Concrete GPT is poised to have a profound impact on the construction and concrete industry. This platform will play an integral role in skilling by providing individuals with the necessary knowledge and resources to help them excel in their roles. We are confident that Concrete GPT will help foster a culture of continuous improvement, learning, and upskilling, thereby equipping people with the expertise needed to meet the evolving demands of the industry.”

He further added, “The platform will empower professionals to make data-driven decisions and drive business growth and profitability. We want to ensure that our clients and partners have access to the most advanced tools and insights to stay ahead of the curve.”

Concrete GPT will transform the construction and concrete industries by providing tailored training, information on sustainable practices, and regulatory updates to industry experts, students, clients, and suppliers.

For more information, visit: https://www.ajax-engg.com/

To explore Concrete GPT please visit https://concreteai.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Vögele’s SUPER 1900-3 G-Tier and SUPER 1900-3 P-Tier are adaptable road pavers with various purposes. Both models have a powerful, low-emission engine and are equally suited to motorway and rural road construction.

The SUPER 1900-3 G-Tier tracked paver is cost-effective and heavy-duty, while the SUPER 1900-3 P-Tier paver is strong and sophisticated. Both pavers are exclusively built for the Indian market and provide users with simple operations, each with a unique set of functions.

Joseph Vögele AG is introducing two new pavers to the Indian market: the cost-effective SUPER 1900-3 G-Tier with the ErgoBasic operating concept and the advanced P-Tier version of the SUPER 1900-3 with the enhanced ErgoPlus 3 operating concept and additional convenience features. Both pavers can lay down up to 1,000 t/h, and their tough material handling components allow them to efficiently and effectively pave asphalt mixes and abrasive materials such as cement-treated base (CTB).

Modern drive technology with low emissions

Vögele’s contemporary driving concept is tailored to the diverse applications of multifunctional pavers. Both are driven by a high-performance 6-cylinder diesel engine rated at 145 kW that meets CEV Stage V emission regulations. The engine includes an ECO mode, which reduces the nominal speed from 2,000 to 1,700 rpm, significantly lowering operating expenses and noise pollution. All drive components, from the diesel engine to the hydraulic system, function at peak efficiency. The SUPER 1900-3 P-Tier is also fitted with the Vögele EcoPlus low-emissions package, which reduces emissions even further and decreases fuel consumption by up to 25 percent.

Optimum material management

A continual flow of mix is critical to guaranteeing consistent, high-quality paving, which is why Vögele prioritises skilled material management when developing its pavers. It is also required when the new pavers are used for road-based applications. The large, expanded hopper with a capacity of 15 t allows for fast truck unloading, while the powerful conveyor system (longitudinal, lateral) provides a high throughput rate and continuous material flow.

Easy operation

The latest models, like all of this road paver manufacturer’s machines, are extremely simple and intuitive to use. All Vögele pavers and material feeders follow the same operational logic, making it simple to transfer between machine and operator. The SUPER 1900-3 G-Tier offers customers the straightforward ErgoBasic operating concept, which includes all of the major operations required for high-quality paving. The SUPER 1900-3 P-Tier is outfitted with the enhanced ErgoPlus 3 operating concept, which gives operators with extra features and a particularly handy operator’s platform, as well as safe working conditions with complete all-around visibility.

For more information, visit:https://www.wirtgen-group.com/en-us/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Reinforcing its commitment to innovation and growth, Doosan Bobcat India inaugurates a state-of-the-art manufacturing factory expansion at Gummidipundi.

Doosan Bobcat, a pioneer and industry leader in Compact Construction Equipment, announces the completion of an 11,300-square-meter compact excavator production facility on the current Chennai plant site following nine months of construction. The small excavators are planned to begin full-scale production in 2025, following the installation and stabilisation of the production line. Doosan Bobcat India’s production portfolio now comprises mini excavators, in addition to backhoe loaders and skid-steer loaders, following the completion of this facility.

Since last year, the Chennai company has increased its export production, with an emphasis on the S70 Skid-steer Loader and Backhoe Loaders. Over the last five years, the Indian unit has had strong growth, with an average annual growth rate of 22 percent. Doosan Bobcat’s Indian business expects to sell 8,900 units per year by 2028, including Bobcat Portable Power equipment made at its Bengaluru plant.

The inauguration brought together Doosan Bobcat’s global leadership team to witness the opening of the new facility. Doosan Bobcat India’s enlarged floor space and enhanced gear will help it fulfil the ever-increasing demand for its equipment by improving production efficiency, quality control, and product innovation. The new facility is designed with sustainability in mind, using eco-friendly practices and technologies to reduce environmental impact and carbon footprint. This expansion project would offer several job possibilities for skilled people in the local community, thereby promoting economic growth and prosperity.

For more information, visit: https://www.doosanbobcat.com/en

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Doka has completed its 28-month contract on the Rookwood Weir, a significant water project that will improve regional water security and economic development.

Doka Australia has completed its engineering and formwork contract for Australia’s newest major water infrastructure project, with a storage yield capacity of 86,000 ML. Sunwater, a government-owned firm that delivers bulk water to more than 5,000 clients in regional Queensland, completed the project.

The Queensland and Australian governments have each contributed $191.6 million to the project’s overall cost, with Sunwater covering the remaining.

Working with Acciona Construction Australia and McCosker Contracting, Doka provided a complete formwork solution for the major spillway monoliths, abutments, and intricate fish lock systems. Doka provided design, materials, site supervision, and engineering support from start to finish. The full supply level was set at 16.2 metres above the riverbed, and the weir also had an impoundment length of around 60 km, a spillway length of 202 metres, and a structural length of around 350 metres. The fishlock is roughly 26 metres tall, with intricate compartments for valves, water input, and fish passage.

In addition to its size, the project was located approximately an 11-hour drive from Doka’s closest yard, requiring workers to stay on-site while logistics had to be carefully planned to maintain progress, particularly in terms of the pouring sequence, without incurring unnecessary costs.

Working closely with the client from the start, Doka carefully calculated a formwork solution based on planning and overlapping the various areas to understand the required amount of products, equipment, and manhours to complete the project in the shortest amount of time. The project’s peak required roughly 2,500 m2 of Framed formwork Framax Xlife panels and 440 single-sided Dam formwork D22 brackets. By choosing a crane-operated repositioning solution, the combination of the Framax panels and the D22 provided enough adjustability to match the pour sizes and bracket distances, while also taking into account the low concrete strength to allow for the pour sequence and ensure quick repositioning. As a result, Doka used three-metre-high shutters and a 2×1.5-metre pour before each relocation.

With early collaboration from Doka’s engineering team and the client’s construction team, the customer met the goal and had a clear view of the approach, resources, logistics, and engineering from the outset. As a result, the project team was able to follow the suggested workflow while being flexible enough to adjust its approach in response to obstacles that developed. The site construction team stated that Doka’s team supplied all of the necessary supervision from start to finish, notably in terms of adherence to the permanent and temporary work designs. The client was particularly impressed with the endurance of the Framax Xlife panels, which remained fully functional throughout the installation.

Doka began work on Rookwood Weir in July 2021 and was proud to finish in November 2023, contributing to the innumerable projects that will support agricultural, industrial, and urban growth in central Queensland.

For more information, visit: https://www.doka.com/in/index

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The VE Commercial Vehicles business unit Eicher Trucks & Buses announces the launch of its 50,000th factory-built bus from its cutting-edge Baggad Plant in Madhya Pradesh.

The milestone vehicle, an Eicher Skyline Pro E electric bus, demonstrates the Baggad factory’s steadfast dedication to serving the rapidly evolving Indian public transport market.

Vinod Aggarwal, VECV’s MD & CEO, says, “We take immense pride in reaching this milestone. VECV has consistently remained ahead of the curve with significant advancements that offer best-in-class products across segments and are compliant with all regulatory norms. This milestone further underscores our dedication to shaping the future of the Indian bus industry. We extend our gratitude to our dedicated team, esteemed customers, and channel partners for their unwavering support and for making this achievement possible.”

Established in 2013, the distinguished facility, spanning 43 acres in Baggad, Madhya Pradesh, produces an extensive assortment of buses, encompassing light, medium, and heavy-duty models with diesel, CNG, and electric drivetrains. Additionally, this facility serves the needs of personnel, schools, intercity travellers, route permits, and international markets. In addition to having state-of-the-art robotic paint systems and an Integrated Management Systems certification, VECV’s Bus Plant is a prime example of Eicher’s commitment to effectiveness, excellence, and environmental responsibility.

In its industrial operations, Eicher has implemented a comprehensive sustainability programme that emphasises social, economic, and environmental sustainability. Among these efforts are energy management systems, which maximise energy use and minimise waste by utilising cutting-edge energy monitoring and management technologies like VFD (variable frequency drive)-enabled panels and energy-efficient motors. To reach zero waste, Eicher has also implemented safe disposal procedures for hazardous products and reduced packaging waste. The Eicher facility uses mini-hydro and solar power for 42 percent of its operations, demonstrating a proactive attitude towards reducing its environmental impact. The factory received the 2021 Smart Factory of the Year award after being recognised as a Platinum Green Factory building by the IGBC in 2016.

Going forward, in addition to its electric vehicle projects, Eicher Trucks & Buses is dedicated to furthering alternative fuel technologies like CNG, LNG, and HCNG (hydrogen compressed natural gas). With its Skyline Pro-E 9m model, the 50,000th bus represents the most recent developments in electric vehicle technology from Eicher. Its efficient, clean, and silent operation is guaranteed by the integration of a dependable all-electric driveline with high-energy-storing batteries, making it ideal for urban settings. Prioritising safety and comfort features has helped passengers achieve strict regulatory requirements while also improving the passenger experience.

For more information, visit: https://www.eichertrucksandbuses.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Ramky Infrastructure Limited secures ₹131.19 crore in contracts from Power Grid Energy Services Limited for infrastructure enhancement under the RDSS in Ladakh.

Ramky Infrastructure Limited, a leading infrastructure development organisation, has obtained two orders from Power Grid Energy Services Limited to carry out the distribution of the Ladakh Power Development Department’s infrastructure works. The first contract, worth ₹ 107.39 Cr (excluding GST), and the second contract, worth ₹ 23.80 Cr (excluding GST), for the supply of plant and installation services in the districts of Leh and Kargil of UT Ladakh.

PowerGrid Energy Services Limited, a wholly-owned subsidiary of PowerGrid Corporation of India Limited, has awarded the contracts to Ramky Infrastructure Limited for 30 months of execution. The contracts were granted for loss reduction work in the Leh district through the Revamped (results-linked) Distribution Sector Scheme (RDSS).

The RDSS system is intended to reduce aggregate technical and commercial (AT&C) losses in Ladakh, expected to fall from 49.04 percent in 2021–22 to 27.85 percent by 2024–25. The RDSS, which has a sanctioned cost of ₹ 687.05 crores, involves grid connectivity in the Changthang Region, downline infrastructure in the Zanskar Region, and loss reduction works in the Leh and Kargil Districts of the UT of Ladakh.

The project’s scope broadly includes the building and commissioning of seven 66KV power substations, 70 km of new distribution lines, 550 km of AB cable reconditioning, and the installation of about 400 distribution transformers.

On receiving the contracts in India’s northernmost union territory, Y. R. Nagaraja, Managing Director of Ramky Infrastructure Limited, states, “We are pleased to be awarded the contracts for the loss reduction works in the Leh district of the Ladakh union territory as it reflects our commitment and adherence to quality standards. This project strengthens our expertise in designing urban infrastructure projects in tough and complex terrains. We anticipate signing the contract in late 2027 or early 2028.

With these projects, the government hopes to increase operational efficiency and financial sustainability. They will provide DISCOMs with results-based financial assistance for improving supply infrastructure, subject to satisfying pre-qualifying conditions and reaching fundamental benchmarks.

For more information, visit: https://ramkyinfrastructure.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

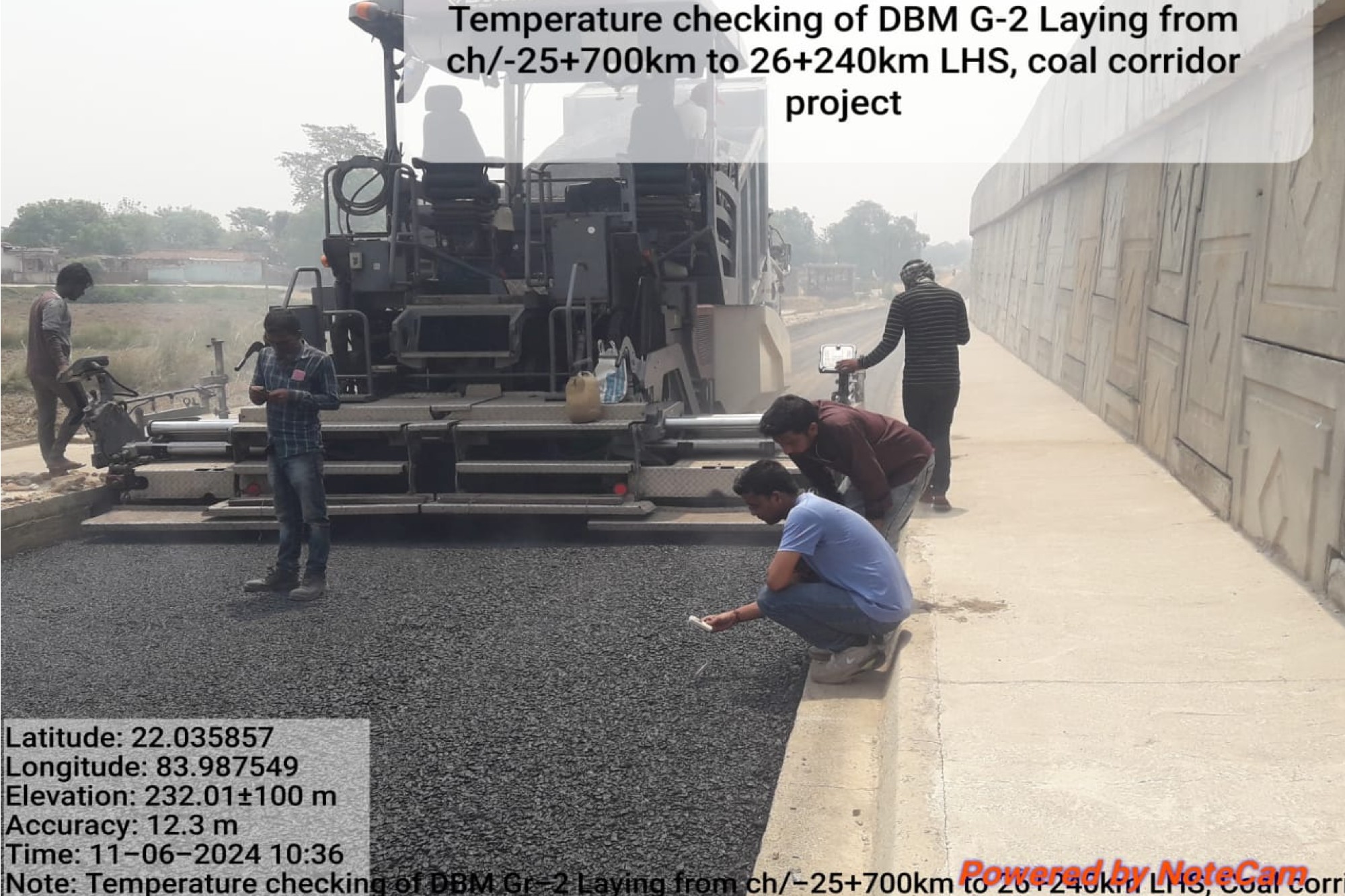

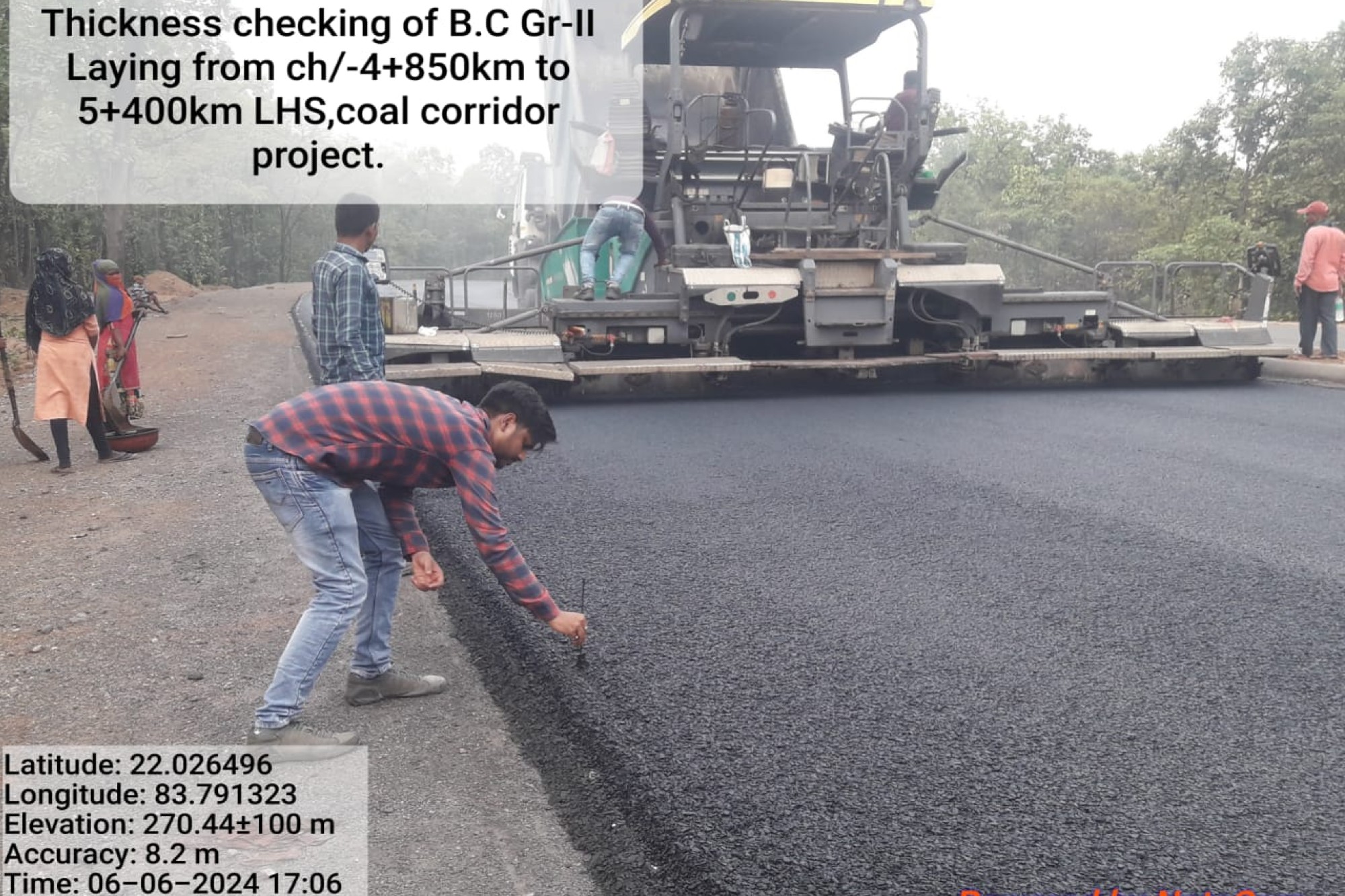

Chaitanya Projects Consultancy Pvt. Ltd. completes a 30.811 km coal corridor between Bankibahal to Bhedabahal (SH 10) in Odisha, serving 2.8 million people with a ₹277 crore project began on April 23, 2024.

Chaitanya Projects Consultancy Pvt. Ltd., India’s innovative leader in integrated infrastructure consultancy, announces the complete completion of the dedicated 4-lane coal corridor road from Bankibahal to Bhedabahal (SH 10). The corridor is a vital link for the region, improving the lives of 2.8 million villagers in Hemgir, Lefripada, Tangarpali, Bilashakara, and Sadar.

The 7-kilometre route, built with concrete instead of bitumen and costing 277 crore, aims to improve coal transportation efficiency while ensuring safety and environmental sustainability. Significantly decreasing noise, dust pollution, and accident risks caused by the daily movement of around 200 coal-carrying heavy vehicles. This groundbreaking infrastructure project, covering 30.811 km, was officially launched on April 23, 2024, marking a watershed moment in the state’s infrastructure growth.

Sanjay Kumar Sinha, Founder & Managing Director of Chaitanya Projects Consultancy, states “Better road conditions will facilitate more efficient coal transportation, potentially saving significant amounts of money currently lost to delays and blockages. Completing the 4-lane dedicated Coal Corridor Road from Bankibahal to Bhedabahal is a testament to our commitment to the ongoing pursuit of sustainable development and environmental conservation.”

“We are proud to contribute to Odisha’s infrastructure evolution, aligning with global sustainability goals,” Mr. Sinha added. “This project enhances regional connectivity and underscores our role in shaping a resilient and interconnected future for communities and industries.”

The corridor is a crucial link in Odisha’s infrastructure network; it improves logistical capacities and strives to reduce carbon footprints through creative engineering and operational excellence.

Chaitanya Projects Consultancy has carried out the project following international standards and best practices, as directed by the Ministry of Roads and Building Department. By using cutting-edge technologies and sustainable approaches, the corridor demonstrates Chaitanya’s commitment to upgrading India’s infrastructure and serves as a model for future projects around the country. On the fringes of government infrastructure development, we are aligning 11 more bridges to change the landscape of Odhisa.

The completion of this project demonstrates the government’s unwavering commitment to promoting economic growth, maintaining public safety, and conserving the environment. The project was funded by Mahanadi Coalfields Ltd. and built by Odisha’s R&B department.

The opening of the corridor to traffic marks the beginning of a new era of prosperity and advancement for Sundargarh and the neighbouring communities.

For more information, visit: https://chaitanyaprojects.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

JK Cement, a significant Indian grey cement manufacturer and a major global white cement producer, has launched a new grinding unit at its Prayagraj Plant in Uttar Pradesh.

This remarkable milestone, achieved in less than ten months, demonstrates JK Cement’s dedication to meeting the expanding demand for cement and solidifying its position as an industry leader. The Prayagraj Plant is a 2 MTPA Clinker Grinding Unit project that will boost the company’s overall capacity from 22 MTPA to 24 MTPA. This strategic step helps the company easily meet the growing demand for cement in Eastern Uttar Pradesh.

The Prayagraj grinding machine is outfitted with cutting-edge German technology, resulting in increased energy efficiency and lower input and fixed costs. This strategic growth enables JK Cement to meet the changing needs of a varied client base in important areas.

The Eastern Uttar Pradesh cement market is considerable, owing to the region’s increasing infrastructural development. The government’s significant investment in infrastructure projects, including roads, bridges, and buildings, continues to drive growth. JK Cement’s deliberate entry into this market uses its experience and resources to fulfil rising demand, cementing its position as a significant player in the industry.

Dr. Raghavpat Singhania, Managing Director, JK Cement Ltd., says, “We are thrilled to launch this new grinding unit at Prayagraj, which marks a significant milestone in our expansion strategy. As India accelerates its infrastructure development to sustain robust economic growth, we are continually scaling our capacities to cater to escalating demands from the infrastructure, housing, and construction sectors. Our commitment to quality, innovation, and contributing to socio-economic development remains unwavering. We anticipate that these endeavours will foster our growth and actively contribute to the overall development of the region and the nation.”

Madhavkrishna Singhania, Deputy Managing Director and CEO of JK Cement Ltd., added, “Our relentless pursuit of excellence has led us to this momentous occasion. Cementing our market foothold emerges as a paramount objective, seamlessly harmonising with our overarching vision of achieving sustainable and profitable expansion. This strategic addition ensures our steadfast role in nation-building and ushers in an array of employment opportunities within the state. We are committed to operational brilliance and innovative contributions, amplifying growth and progress on regional and national horizons.”

JK Cement currently runs two operating operations in Uttar Pradesh, located in Aligarh and Hamipur, with capacities of 1.5 MTPA and 2 MTPA, respectively. The project, which is being built using cutting-edge technology, is expected to create large direct and indirect job possibilities, contributing considerably to the local economy and fostering regional growth.

JK Cement’s dedication to quality, innovation, and sustainability is obvious in the design and operation of its new grinding machine. The facility is equipped with cutting-edge technology and meets the highest environmental and safety standards. This strategic development strengthens JK Cement’s position as India’s premier cement manufacturer, ready to satisfy the expanding demands of the building and infrastructure industries.

For more information, visit: https://www.jkcement.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

SANY India, a prominent construction equipment manufacturer, is happy to announce the signing of a Memorandum of Understanding (MoU) with the Union Bank of India.

Through this strategic partnership, SANY India aims to provide significant growth and development opportunities across the country and improved financial support to its customers, making it easier to access SANY India’s advanced product line and readily available financial solutions.

The MoU was signed in the presence of Naveen Jain, Union Bank of India’s Zonal Head, Pune, and Sanjay Saxena, COO of SANY India, as well as top personnel from both organisations.

This collaboration between SANY India and Union Bank of India is deliberately designed to maximise both companies’ strengths, resulting in a range of customised financial services tailored to the needs of customers. This alliance aims to improve the financing process, making it more effective and customer-friendly, empowering businesses across multiple sectors.

Sanjay Saxena, the COO of SANY INDIA, stated, “We are happy to join hands with Union Bank of India, a leading institution of economic well-being within its operational areas. This MoU is a testament to our commitment to delivering exceptional financial services alongside our cutting-edge products, empowering customers across India.”

Highlighting the significant reliance on Union Bank of India for equipment financing, Mr. Saxena added, “The MSME schemes offered by Union Bank of India benefit all profiles of construction equipment customers. This partnership highlights the bank’s strong commitment to funding construction equipment. With Union Bank of India as our preferred financier, customers can conveniently access financing solutions for our earthmoving and construction equipment without exploring alternative options.”

Naveen Jain, Zonal Head, Pune, of Union Bank of India, commented, “We are pleased to enter this strategic partnership with SANY India and continuously strive to provide beneficial opportunities for our customers. With construction and infrastructure activities thriving across the country, the demand for earth-moving and construction equipment is on the rise. Through our Construction Equipment Finance schemes, prospective buyers of SANY equipment can easily avail themselves of financing tailored to meet their financial requirements.”

This alliance represents a watershed moment in the finance and construction industries, promising a collaborative connection that will benefit clients, promote industry growth, and support national development goals.

For more information, visit: https://www.sany.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Shree Cement Ltd, India’s third largest cement manufacturer by capacity, is pleased to announce that it has reached a historic milestone of one gigawatt (1,000 megawatts) of installed electricity capacity.

This achievement was highlighted by the commissioning of a 19.5 MW solar power plant at its manufacturing facility in Andhra Pradesh.

The 1 GW capacity consists of a mix of solar, wind, thermal, and waste heat recovery power facilities, demonstrating Shree Cement’s diverse approach to satisfying cement manufacturing electricity demands.

Significant investments of ₹ 4000 crore have been undertaken to enhance the renewable portfolio, which now accounts for approximately 50 percent of the installed electricity capacity (499 MW). Notably, Shree Cement’s 244 MW capacity from waste heat recovery is among the largest in the global cement sector.

Looking ahead, an estimated outlay of ₹ 1000 crore is planned for FY25 to install more RE capacity. This would include 132 MW of solar capacity in five states—Jharkhand, Haryana, Rajasthan, Uttar Pradesh, and Uttarakhand, 36 MW of wind power in Rajasthan, and 34 MW of waste heat recovery capacity in Karnataka and Rajasthan.

Commenting on this milestone, Neeraj Akhoury, Managing Director of Shree Cement, says, “Achieving a power capacity portfolio of this size ensures that we have abundant electricity to power our existing cement production and expansion projects. We will contribute the surplus power to states and the central grid.”

“Significant integration of green electricity has helped us produce cement more sustainably and cost-effectively. Today, nearly 56 percent of our power requirement is met from renewable resources, which is the highest in the Indian cement industry. We aim to set a benchmark for sustainability within the cement sector and inspire positive change throughout the industry,” Mr. Akhoury added.

Shree Cement recently confirmed its participation in the RE100 programme, aiming to use 100 percent renewable electricity for all activities by 2050. Shree Cement has been a pioneer in adopting innovative technology to reduce non-renewable resource usage and emissions. The organisation is also looking into sophisticated strategies to increase renewable electricity utilisation, such as battery storage, pump storage, and green hydrogen.

Shree Cement is on pace to become a modern and environmentally friendly construction materials company, with plans to boost current capacity from 56.4 MTPA to 80 million metric tonnes by 2028.

For more information, visit: https://www.shreecement.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

MB Crusher provides effective on-site concrete recycling, converting demolition waste into high-quality recycled concrete aggregates (RCA).

In response to the increased need for sustainable construction techniques, MB Crusher has developed a technology for recycling demolished concrete into valuable materials. Businesses may now efficiently crush concrete debris on-site using MB Crusher equipment, transforming it into high-quality Recycled Concrete Aggregates (RCA).

The conventional method of dumping concrete rubble, Malba, is being revolutionised. Instead of facing costly landfill fees and operational costs associated with obtaining new aggregates, businesses may now use MB Crusher’s unique technology to recycle garbage immediately on the demolition site.

Why Recycled Concrete Aggregates (RCA)?

Recycled Concrete Aggregates (RCA) provide substantial advantages over conventional approaches. Recycling concrete decreases landfill trash by recycling concrete debris, allowing businesses to contribute to reducing landfill volumes and environmental implications. Furthermore, recycling concrete reduces disposal costs because enterprises can avoid disposal fees and transportation expenses, resulting in significant savings. Furthermore, recycling protects natural stone aggregates, which promotes environmental sustainability by conserving natural resources.

The MB Crusher advantage:

MB Crusher units are designed to provide exceptional performance in on-site recycling, with numerous significant advantages. They are cost-effective because manufacturing Recycled Concrete Aggregates (RCA) with MB Crusher units is less expensive than sourcing virgin aggregate. These units’ adaptability allows recovered aggregates to be used in various applications, including road bases, foundations, landscaping, and more. Furthermore, MB Crusher units provide considerable environmental benefits by removing the need for transportation to distant processing plants, promoting local sustainability.

How it works:

Integrating MB Crusher attachments into current excavator or backhoe loader fleets enables efficient on-site recycling, which provides numerous benefits. MB’s mobile jaw crusher produces high-quality output with homogeneous product sizes, making it suited for a wide range of applications. Furthermore, customised solutions are available, allowing users to change output sizes and accomplish accurate size separation using MB’s Trommel bucket. MB Crusher encourages the reuse of existing resources, which promotes sustainable practices and reduces the environmental impact of construction activities.

Take the lead in environmentally friendly construction techniques with the MB Crusher. Contact us today to learn more about how our creative solutions can revolutionise your concrete recycling strategy.

For more information, visit: https://www.mbcrusher.com/en/in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Propel and Omega are well-positioned to provide outstanding products and services to their clients around the world by leveraging their complementary strengths.

Propel Industries, a market leader in Indian crushing and screening, has formed a strategic partnership with Ireland’s Omega Crushing and Screening, a pioneer in zero-emission mobile crushing and screening in European and American markets, to provide innovative and sustainable solutions to the global crushing and screening industry.

Senthil Kumar Varadharajan, Managing Director of Propel Industries, says, “We are thrilled to join hands with Omega in this strategic partnership. This collaboration marks a significant milestone for us as we combine our strengths to drive innovation and growth in the global crushing and screening industry. Together, we aim to set new benchmarks in product quality and customer satisfaction.”

The alliance is positioned to increase product development and accelerate the release of cutting-edge crushing and screening systems by combining both firms’ technical competence and industry understanding. Advanced manufacturing facilities in both locations will be used, assuring high-quality production standards and efficient distribution methods to satisfy rising demand. The collaboration will focus on developing a new line of products that include cutting-edge crushing and screening technologies, as well as eco-friendly and energy-efficient solutions customised to the industry’s changing needs.

Speaking about the relationship, Colin Daly, Sales Director of Omega Crushing and Screening, stated, “This partnership represents a perfect synergy of our capabilities and ambitions. By working closely with Propel, we are confident in our ability to deliver exceptional value to our customers worldwide. Our combined efforts will enhance our product offerings and expand our global footprint.”

Propel and Omega’s extensive distribution networks will broaden both brands’ market reach, improve access to growing countries, and boost their presence in established regions. Omega’s Northern Ireland industrial site will serve as a parts centre for the Propel and Omega brands in the European and American markets. Customers will benefit from consistent maintenance and easy access to replacement components, ensuring the longevity and peak performance of their equipment. This relationship is characterised by a shared commitment to sustainability.

For more information, visit: https://www.propelind.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

JK Tyre & Industries, an Indian tyre manufacturer and leader in Truck Bus Radial tyres, has created an upgraded line of tyres designed to fulfil the transportation sector’s increasing needs.

JK Tyre intends to expand its Truck & Bus Radial lineup with four new models: the JETWAY JUM XM, JETWAY JUC XM, JETSTEEL JDC XD, and the groundbreaking JETWAY JUXe for electric buses. The development of JK Tyre’s product line demonstrates the company’s commitment to providing sophisticated, high-performance solutions that combine exceptional performance, economic benefits, and environmental responsibility.

These new tyres represent a key milestone in JK Tyre’s commitment to promoting sustainable transportation solutions. JK Tyre continues to lead the way in transforming India’s transport sector by providing tyres that improve performance, operational efficiency, cost savings, and sustainability.

Speaking at the event, Anuj Kathuria, President (India), JK Tyre & Industries Ltd, says “As a leader in this category, we have a deep understanding of the segment and feel a responsibility to introduce sustainable solutions with advanced technology. Our latest offerings demonstrate our unwavering commitment to delivering high-performance, economically viable, and environmentally conscious solutions. We are confident that these tyres will serve as a dependable companion for fleet operators, ensuring safety on the move.”

These innovations were developed in large part because to JK Tyre’s excellent R&D centre in Mysuru and cutting-edge manufacturing techniques. All four tyres have been extensively tested in a range of settings to ensure the highest levels of quality and performance.

There are four innovative tyres:

JETWAY JUM XM:

The JETWAY JUM XM has a 4-star rating and an RRc value of 4.9 KN/n, making it the most energy-efficient model in its category. This next-generation tubeless tyre is specifically designed for buses and trucks, setting new standards for fuel efficiency and cost-effectiveness. This results in significant fuel savings for carriers, which is important given that fuel expenses account for over 50 percent of total operating costs in India. Furthermore, reducing fuel usage will contribute to considerable reductions in carbon emissions, providing a sustainable and economically viable option for the transportation industry.

JETWAY JUC XM and JETSTEEL JDC XD:

In response to India’s vigorous infrastructure development, the business has introduced its cutting-edge X-Series product line, which includes JETWAY JUC XM and JETSTEEL JDC XD tyres. These two tyres, designed to match current demand, provide superior performance, durability, and efficiency.

The JUC XM boasts a remarkable 10 percent longer tyre life and was designed for tippers and trailers, resulting in lower operational costs and better efficiency, making it an excellent choice. The JDC XD tyre, on the other hand, is designed to meet the severe needs of heavy-load transportation, ensuring long-term performance and reliability in both on- and off-road circumstances. The tyre, known for its endurance and sturdiness, is designed for use in tippers with driving and dummy axles.

JETWAY JUXe:

The JETWAY JUXe, specifically built for electric buses, is a new tyre in the category that is expected to revolutionise performance and sustainability norms in the electric vehicle (EV) industry. The low RRc tyres allow electric buses to drive further per charge, resulting in increased efficiency and operational cost savings. In addition to its energy-efficient design, the JUXe represents JK Tyre’s entry into low-noise tyres, which aligns with the company’s dedication to sustainability. Low-noise tyres contribute to a quieter urban environment and encourage environmentally responsible transportation alternatives, making them appropriate for India’s changing sustainable mobility scenario.

The JETWAY JUXe tyre will also be installed on TATA Motors’ electric buses, highlighting a combined effort to foster innovation and sustainability in India’s public transport sector.

For more information, visit: https://www.jktyre.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Vadhvan Port will be built as an all-weather Greenfield deep draft Major Port in Vadhvan, Palghar District, Maharashtra, using the ‘Land Lord’ model.

The Union Cabinet, chaired by Prime Minister Shri Narendra Modi, has approved the establishment of a Major Port at Vadhvan near Dahanu in Maharashtra by Vadhvan Port Project Limited (VPPL), an SPV formed by the Jawaharlal Nehru Port Authority (JNPA) and the Maharashtra Maritime Board (MMB), with 74 percent and 26 percent shareholdings, respectively.

Speaking on this significant occasion, the Chairman of Jawaharlal Nehru Port Authority, Unmesh Sharad Wagh, stated, “As we set sail towards the development of the Vadhvan port, it brings us immense pride and eager anticipation to unveil the collaborative effort between the Jawaharlal Nehru Port Authority (JNPA) and the Maharashtra Maritime Board. This alliance aims to cater to the burgeoning maritime traffic, marking the dawn of a new chapter filled with growth and opportunities. The project will be implemented by Vadhvan Port Project Limited, a SPV of JNPA and MMB. We express our sincere gratitude to Hon’ble Union Minister Shri Sarbananda Sonowal, Ministry of Ports Shipping and Waterways, and Hon’ble Secretary Shri T K Ramachandran, Ministry of Ports Shipping and Waterways for their leadership and guidance in charting the course of the port.”

Vadhvan port outlay

The total project cost, including land purchase, is ₹ 76,220 crore. This will contain core infrastructure, terminals, and additional commercial infrastructure in PPP mode. The Port infrastructure consists of nine container terminals, each 1000 metres long, four multipurpose berths, four liquid cargo berths, a Ro-Ro dock, a coastal freight berth, and a Coast Guard berth. The project entails reclaiming 1,448 hectares of offshore land and building 10.14 kilometres of breakwater and container/cargo storage spaces. The cabinet also approved MoRTH’s efforts to develop road connectivity between the Port and National Highways, as well as rail linkage to the existing rail network and the planned Dedicated Rail Freight Corridor.

India’s trade policies and maritime transport sector improvements have resulted in rapid containerisation in the country. The Global Maritime India Summit announced a comprehensive roadmap for India’s maritime sector, which will revolutionise it. The Ministry of Ports, Shipping, and Waterways developed the Amrit Kaal Vision 2047, which builds on the Maritime India Vision 2030 and aspires to establish world-class ports while also promoting inland water transit, coastal shipping, and a sustainable maritime industry. The capacity of three major container handling ports on the west coast will be fully utilised by 2029, with capacity requirements of 24 million TEUs estimated to be reached by Vadhvan.

The projected deep draft all-weather Major Port at Vadhvan will increase national container handling capacity by 23.2 million TEUs and allow mega-sized container boats capable of transporting 24,000 TEUs to dock. With the construction of Vadhvan Port, India will become one of the top ten container ports in the world. The expanded capacity would also help EXIM commerce flow through IMEC (India Middle East Europe Economic Corridor) and INSTC (International North South Transportation Corridor). World-class maritime terminal facilities encourage public-private partnerships (PPP), leverage efficiencies, and modern technologies to create cutting-edge terminal facilities capable of handling mainline mega vessels plying international shipping lanes between the Far East, Europe, the Middle East, Africa, and the Americas.

Green port initiative

This project is based on a dedication to environmental care. The Vadhvan port is planned as a “greenfield” venture, with a focus on sustainable techniques and little harm to local ecosystems. We seek for a balance between advancement and conservation through thorough planning and consultation. The proposed Vadhvan port aspires to combine sustainable solutions, ranging from renewable energy adoption to efficient port operations such as shore power for ships, and only electric or green fuel vehicles will be permitted in the Port ecosystem. By adopting green initiatives and innovative technologies, VPPL aims to set new standards for port development in India by becoming a zero-emission port, ushering in a more sustainable and prosperous future.

The project development will offer job opportunities and assist in the skilling of local youth both during the building and operation of the terminals, and fishermen whose livelihoods will be negatively impacted will be compensated following State Government laws. The Project will stimulate additional economic activity while also providing direct and indirect employment possibilities for over 10,00,000 people.

Speaking about the several benefits of the Vadhvan port, Mr Wagh remarked, “The strategic placement of the Vadhvan port will facilitate the call of container traffic. The port will bridge international and Indian coasts, that will accelerate economies of scale and mitigate logistics cost. Moreover, the port will also address the EXIM needs of industries situated in Vapi, Indore, Karnataka and Maharashtra. The vision under Amrit Kaal 2047 to develop a mega Port with 300MTPA will be fulfilled by Vadhvan Port.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Through innovative digital initiatives, the organisations are unwaveringly pursuing operational excellence and customer-centric solutions.

The diversified Adani Portfolio’s cement and building material companies, Ambuja Cements Limited and ACC Limited are thrilled to announce their dedication to innovation, which will transform the construction industry through several ground-breaking digital projects.

Ajay Kapur, CEO of Cement Business, Adani Group, says, “With the continuous evolution of the digital landscape across the nation and globally, we wholeheartedly embrace the need for the construction sector to adapt and create more efficient and effective solutions. Our digital journey reflects our dedication to innovate and deliver best-in-class products and solutions to all our stakeholders efficiently. Ambuja Cements and ACC’s digital initiatives emerge as beacons of progress. The process of modernising the entire digital landscape, as well as using AI and IoT technologies for enhancing the plants, stands as a testament to the company’s unwavering commitment to progress.”

The NexGen Sales & Reward Platform, a forward-thinking digital ecosystem created to streamline coordination and operations on a contemporary technology stack, is at the forefront of this initiative. Its purpose is to foster seamless collaboration among customers, channel partners, retailers, influencers, and sales partners. Through the standardisation and simplification of business processes, the organisations hope to greatly improve results for both internal teams and external partners.

Furthermore, Ambuja Cements and ACC are putting the “Plants of the Future” plan into action, which aims to digitally transform manufacturing processes in order to lower costs and enhance production quality. This covers the use of robots for automation, drones for maintenance, robotics process automation for plant shutdown management, automated weighbridges, in-plant automation, automated quality testing, and robotics.

Their Industry 4.0-based Command-and-Control programme, a ground-breaking platform that provides stakeholders with a visual depiction of crucial business data together with insights and exceptions for the smooth and proactive operation of the business, is also included in the digital transformation. Using cutting-edge analytics, this platform gives decision-makers the tools they need to optimise plans for optimal results. The firms created the Cement Network Operating Centre (CNOC) dashboard as part of the programme’s first phase.

Collaborating with the Adani Group’s AI Labs will facilitate the smooth utilisation of artificial intelligence by incorporating AI models with generative AI, video-based analytics, and optimisation features. Decision-making procedures will move more quickly as a result, and customer interactions will become even more effective.

Furthermore, by modernising their transportation management and vehicle tracking systems, the corporations are putting their cutting-edge fleet management and logistics capabilities into practice. These improvements will offer real-time car positions and predicted arrival times, enabling driver safety and smooth coordination between buyers and sellers for increased efficiency. They will do this by using technology like GPS, RFIDs, and sophisticated track-and-trace algorithms. For improved project management capabilities, the new expansion projects will make full use of digital tools.

The entire environment is included in the digital transformation, including the network, data, business applications used by all of its plants, and cybersecurity. The businesses will have strengthened their company information systems with cutting-edge and contemporary cybersecurity solutions since they understand how important cybersecurity is. Adani’s enterprise-grade security is guaranteed by its ISO 27k-certified central cyber defence and security operations centre, which protects the business’s operational integrity.

Ambuja Cements and ACC’s commitment to providing outstanding solutions is demonstrated by their emphasis on digitalisation and AI-driven strategies. Through the adoption of state-of-the-art technologies and the promotion of an innovative culture, the organisation persists in spearheading innovations that transform the industry.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

ConstructMonitor is a Software as a Service (SaaS) product that Neilsoft, a focused provider of Engineering Services & Software Solutions (ER&D) for global customers in the AEC/Construction, Manufacturing, and Industrial Plants areas, has launched.

To address construction project quality issues in larger construction projects like commercial offices, high-rise buildings, data centres, hospitals, industrial plants, factories, malls, IT parks, and other infrastructure projects, Neilsoft and Tokyo-based Fujita Corporation collaborated to develop the solution.

The Building Information Modelling (BIM) approach is being used in a number of large-scale, intricate building projects throughout the world. It unifies different stakeholders, including owners, architects, engineers, and contractors, with a single source of truth throughout the project by using a Common Data Environment (CDE). Construction quality and deviation from as-designed BIM models during the construction phase remain an issue, even though BIM adoption has increased dramatically throughout the project’s design phase. ConstructMonitor was created to detect deviations from the BIM model as intended and to provide improved quality and progress monitoring.

The construction sequence is affected in a cascading manner by quality problems found at the construction site, such as missing structural pieces, erroneous element sizes, and design deviations. These also result in delays, material waste, safety risks, cost overruns, and the requirement for rework. Using LiDAR-enabled iPhones (daily or weekly) and/or terrestrial 3D laser scanners (once a month), ConstructMonitor allows General Contractors, EPC firms, Architects, Project & Construction Management firms, and Owners to remotely monitor design deviations at construction sites (vis-à-vis Design BIM models). Our cloud platform transfers point cloud data that captures the reality of a construction site to a processing server. There, object-level comparisons with the BIM design data are performed by specialised algorithms to detect any differences.

Speaking at the launch, Raghuram NM, President of Neilsoft India Solutions Business, says, “Neilsoft’s BIM journey started around 2007, and we have been fortunate to get to support leading architects, engineering firms, / Contractors globally on several BIM projects. BIM as a methodology has seen increasing acceptance over the last 15+ years and the construction industry today is very actively embracing technology to improve efficiencies across the project life-cycle. At Neilsoft, we are constantly investing in developing multi-disciplinary engineering and technology capabilities to add higher value to our customers in their Digital Transformation initiatives. We are developing our IP-led Solutions to address real-world customer challenges across the Design-Construct-Operate phases and ConstructMonitor is our first IP-led solution for addressing Quality issues during the Construction phase.”

For every client or project, ConstructMonitor is provided as a Software as a Service (SaaS) option that may be installed on a public or private cloud. The system enables distant users to ascertain the correctness of the structure that is still under construction, and it provides customisable visualisation capabilities and user-friendly dashboards that offer a comprehensive perspective of the construction project. Early detection of costly variations and faults in the construction project lifecycle facilitates quick remote monitoring of quality and progress without requiring frequent site visits, helps regulate construction quality, and maintains projects on schedule.

For more information, visit: https://neilsoft.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

MYCRANE, the first global platform for online crane leasing, has expanded its rapidly growing company in India by appointing Mumbai-based Ashishkumar Tiwari as sales director, in India.

Tiwari has two decades of professional experience in India, where he has worked closely with both the construction industry and engineering, procurement, and construction (EPC) clients. His career highlights include serving as senior manager, of plant and machines at Reliance Industries Limited, India’s largest public enterprise.

“India is proving to be one of the most receptive markets for our vision to digitalise the construction industry and help clients work more productively, safely, and sustainably,” says Andrei Geikalo, MYCRANE Founder & CEO. “We are delighted to welcome Ashish to our expanding team and his contributions are already proving invaluable.”

In less than a year, MYCRANE has signed up many of India’s largest industrial businesses as customers. MYCRANE’s Indian clients can access over 300 rental companies and thousands of cranes through the platform, which is free to use. Tiong Woon, one of Asia’s leading proprietors of heavy lift equipment, has recently registered as a supplier.

According to Ashishkumar Tiwari, sales director for MYCRANE India, “There is strong demand for cranes across the country, much of it driven by wind energy projects. With lifting equipment in such high demand, MYCRANE has an even more important role to play in helping our clients secure the cranes they need. I look forward to contributing to the digital transformation underway in our industry.”

After completing a simple and free registration, MYCRANE users can quickly and easily find lifting equipment using the platform, saving time and money as they do so.

For more information, visit: http://www.my-crane.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Volvo Construction Equipment (Volvo CE India) has introduced the EC210, a powerful 20-tonne hydraulic excavator for India’s expanding construction and mining sectors, with sophisticated technology and a commitment to exceptional performance.

Volvo Construction Equipment (Volvo CE India) has launched the new EC210, a ‘Built for Bharat’ 20-tonne hydraulic excavator. The introduction of this excavator demonstrates the company’s strong commitment to the burgeoning Indian CE industry, which requires innovative and technologically advanced solutions tailored precisely to the needs of consumers in the nation. The EC210 excavator includes several innovations that assure great performance, exceptional fuel efficiency, and minimum maintenance. Kamel Sid, (Global) Head of Operations at Volvo CE, launched the new excavator in front of Dimitrov Krishnan, Managing Director, Volvo CE India, and other senior executives.

Volvo CE has launched a new brand campaign called “Karo Zyada Ki Umeed” to coincide with the debut of the EC210. This campaign’s soul film captures the human mindset of expecting more, striving for perfection, and pushing boundaries. It emphasises EC210’s primary value proposition across the four pillars of Zyada Performance, Zyada Value, Zyada Savings, and Zyada Uptime.

The all-new EC210, a 20-tonne crawler excavator, delivers exceptional performance, versatility across applications, industry-leading safety and operator comfort, and ease of maintenance. With its best-in-class attachment arrangement and next-generation positive control hydraulics technology, it provides unrivalled precision and faster response time. It also includes a Made in India T3 electronic engine that can generate tremendous torque even at low RPM while remaining extremely fuel efficient thanks to 10 operational modes for various applications. The do-it-all excavator provides great reliability and exceptional fuel efficiency in a variety of light, medium and heavy-duty applications, including road building, rock breaking, general construction, waste management, quarries and sand mining. Furthermore, users may arrange a service at their convenience using its user-friendly mobile app and receive a service assurance within 48 hours to maximise equipment uptime.

“As India embarks on its remarkable infrastructure growth journey driven by the government’s vision and commitment, we foresee exponential demand for construction and mining equipment across sectors such as rail, road, ports, airports, and power projects. At Volvo CE, we are committed to leading this transformation by offering India-centric solutions through our latest technological innovations,” says Dimitrov Krishnan, Managing Director of Volvo CE India. “The all-new EC210 exemplifies our commitment and approach to delivering products that deliver ‘Zyada’ performance and reduced cost of ownership to the value-conscious Indian customer. With this product launch, we have also built a supporting ecosystem by widening our sales network, investing in digital technologies to enable 48-hour service assurance and strategically partnering with Shriram Automall for easy exchange or disposal of used machines, thus enabling circularity. ” he added.

Along with the EC210 introduction, Volvo Construction Equipment (Volvo CE) has teamed with Shriram AutoMall (SAMIL), India’s largest ‘phygital’ marketplace for used vehicles and construction equipment. This alliance intends to build a strong ecosystem for machine exchange and disposal, enabling customers interested in purchasing new Volvo equipment to replace their existing fleet. This project is consistent with Volvo’s strategic goal of increasing circularity in equipment lifecycle management by encouraging sustainable approaches for second- and end-of-life disposal.

For more information, visit: https://www.volvoce.com/india/en-in/products/excavators/karo-zyada-ki-umeed/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

On International Day of Women in Mining, Hindustan Zinc, India’s largest and exclusive producer of zinc, lead, and silver, proudly emphasises its substantial progress in promoting gender diversity and inclusivity in the mining industry.

With one of India’s largest cohorts of over 200 female mining engineers, the firm is driving change in its mining operations. With around 22 percent gender diversity, Hindustan Zinc’s workforce comprises over 600 female personnel in core operations who make significant contributions to the sector. This represents a considerable percentage when compared to its Indian counterparts in the core industrial sector and metal and mining companies. Among the many successes, Hindustan Zinc is home to India’s first women mine supervisors working in underground mines, as well as the country’s first and second all-women underground mine rescue teams.

Diversity and inclusivity are essential elements of Hindustan Zinc’s concept, which is woven into the very fabric of the company’s culture. With a comprehensive portfolio of metals catering to a wide range of customers globally for sophisticated applications, the company values worker diversity, which provides new insights and leads to sound decision-making. This is supported by Hindustan Zinc’s dedication to assisting women at all stages of their lives, both personally and professionally, by expanding career advancement possibilities such as night shifts, meaningful job content, and progressive workplace rules. These initiatives have resulted in a significant increase in the number of women professionals selecting Hindustan Zinc to work in essential mining functions.