Trimble’s Tekla User Days 2024, held virtually on September 25-26, brought over 4,000 professionals together, showcasing advancements in BIM, digital twins, AI, and launching the “Made in Tekla 2.0” initiative.

Trimble (NASDAQ: TRMB), a global construction technology provider, has successfully finished the 2024 edition of Tekla User Days (TUD) India, the company’s annual flagship meeting for Tekla software users. The highly anticipated TUD India 2024 took place online on September 25-26, 2024, and drew over 4,000 participants, including those from the country’s major engineering and construction organisations.

TUD India 2024 was a must-attend conference for all design and detailing practitioners, offering participants an unmatched opportunity to obtain in-depth information and hands-on experience with Tekla’s cutting-edge tools. The event offered a variety of lectures from seasoned practitioners on themes such as BIM evolution, constructible models, digital twins, AI-based solutions, and data-driven decision-making. These sessions were developed to provide professionals with the skills and insights they need to succeed in an ever-changing construction landscape.

The concept of community development was central to TUD2024, emphasising Trimble’s commitment to cultivating a supportive and innovative professional community. Attendees got the opportunity to participate in collaborative discussions, network with their peers, and provide valuable input to Tekla engineers.

Rajan Aiyer, Vice President & Managing Director, of Trimble India, highlighted the importance of this community focus: “This year’s Tekla User Days underscored our commitment to cultivating a collaborative ecosystem for engineering and construction professionals. It’s a platform where the best minds come together to exchange insights, share expertise, and collectively push the boundaries of innovation. Through this community-driven approach, we aim to enhance our customers’ experiences and empower them to maximise the potential of Tekla’s cutting-edge solutions.”

Tekla User Days 2024 offered critical topics to empower construction and engineering professionals. The event opened with a keynote lecture by Anurag Sinha, Executive Director of Engineers India Ltd. (EIL), followed by a Fireside Chat on the theme “Technology as a Growth Catalyst – Transforming Complexities to Successes,” chaired by Harsh Pareek, Regional Sales Director, Trimble Solutions India. The panel discussion featured esteemed speakers such as J P Shivakumaraswamy, COO of Sanria Engineering, Vasudev Rao, Director – Engineering at Zamil Steel, and Srivathsan L., Vice President at Pan Gulf Technologies, who presented in-depth insights into the future of construction technology. Furthermore, renowned industry participants such as Telge Projects and Esskay Design displayed world-class projects, showing significant worldwide initiatives and demonstrating the practical application of Tekla’s solutions.

Another important aspect of the event was the launch of the Made in Tekla 2.0 program, which showcases innovative construction projects that use Tekla software, highlighting the efficiency, precision, and collaboration achieved through its advanced Building Information Modelling (BIM) solutions for structural engineering and construction.

Every year, Tekla User Days offers users an unparalleled platform for learning, building community relationships, and experiencing the most recent breakthroughs in construction software technology solutions.

For more information, visit: https://www.trimble.com/en

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Interarch Building Products Ltd. has purchased 51,926 square metres of land in Gujarat for INR 7 crore, increasing production capacity to satisfy surging PEB demand.

Interarch Building Products Limited (BSE Code: 544232) (NSE: INTERARCH), a key player in the Pre-Engineered Building (PEB) Industry, has announced the acquisition of 51,926 square meters of land in Gujarat. The land was acquired for an expenditure of INR 7 crore. This strategic move is part of the company’s long-term goal of expanding its national footprint and meeting the growing demand for high-quality pre-engineered structures across the country.

The newly acquired land in Gujarat will increase the company’s usable capacity, allowing it to satisfy the growing demands of its discerning consumers. This strategic investment demonstrates the company’s commitment to improving its supply chain skills in Western India while remaining near its clients and providing great service. Furthermore, Western India, notably Gujarat, is growing as a hub for cutting-edge industries such as semiconductors, data centres, and renewable energy. Interarch is ready to capitalise on these opportunities.

Interarch has completed several big projects in Gujarat for clients including Asian Paints, Timken, Micron (via Tata Projects Limited), Asahi Glass, MG Motors, and others.

Commenting on the development, Arvind Nanda, Managing Director of Interarch Building Products Ltd. states, “This land acquisition in Gujarat is a significant milestone for us as we continue to expand our operational base across India. With this investment, we aim to boost our production capabilities and cater to the rising demand for high-quality pre-engineered building solutions in key markets. Our endeavour has always been to provide customer delight, and this is a significant step in that direction”

The company presently operates four fully integrated, cutting-edge manufacturing facilities: one in Athivaram, Andhra Pradesh; one in Sriperumbudur, Tamil Nadu; one in Pantnagar, Uttarakhand; and one in Kichha, Uttarakhand.

For more information, visit: https://www.interarchbuildings.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Ador Fontech merges with Ador Welding to improve market position, global reach, and R&D capabilities, exploiting synergies and cross-selling opportunities to generate growth in both domestic and international markets.

Ador Welding Limited, India’s largest maker of welding products, announces the successful merger of Ador Fontech Limited and Ador Welding Limited. The merger will help to create a more efficient and integrated business structure, consolidate the company’s market position, expand its local and worldwide reach, and strengthen research and development capabilities. The operations management teams of both firms will remain unchanged.

Aditya Malkani, Managing Director of Ador Welding Limited shares “We are excited about the potential opportunities that this merger presents. It will enable us to leverage the benefits of scale, revenue and cost synergies, cross-sell combining the customer base, and tap into best practices from both organisations. With this, we are poised to expand our product and service offerings to our customers and accelerate our growth in both domestic and international markets. Most importantly, with our combined strengths, including a stronger manufacturing presence and a more resilient workforce, we are better equipped to Make, Research & Create in India.”

Following the merger, J.B. Advani and Co Pvt Ltd (JBA) would own 44.83 percent of the stock, the other promoters will own 8.24 percent, and the general public will own 46.93 percent. Ador also intends to restructure its businesses to focus on two different verticals: products and services. This will allow the organisation to improve its operations and better meet the different needs of its clients.

With its roots in India as the ultimate ‘Make in India’ brand, Ador has left an indelible worldwide imprint by providing excellent, cutting-edge welding solutions. With over seven decades of experience, the company is committed to providing the greatest welding experience for its clients by investing in people, technology, and R&D.

Ador’s Research and Development Centre is recognised by the Department of Scientific and Industrial Research for its significant contributions to R&D and innovation, including the Rhino E, India’s first battery-powered electric welder. Ador’s commitment to quality is evidenced by its numerous international prizes and research papers, which have been presented at numerous international conferences.

For more information, visit: https://www.adorwelding.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Knauf India proudly announces full compliance with BIS ISI plasterboard standards, demonstrating its commitment to quality and safety in modern construction materials.

Knauf India, a renowned construction materials company and part of the global Knauf Group, has announced that all of its plasterboard products now meet Bureau of Indian Standards (BIS) ISI criteria. Knauf is one of the first companies in India to comply with new government regulations requiring gypsum-based building materials to meet severe Indian Standards Institution (ISI) criteria.

With a strong emphasis on quality and innovation, Knauf India has consistently developed products that exceed industry standards. Knauf is well-known for its contributions to the building materials industry, which include sophisticated plasterboard systems, gypsum ceilings and plasterboards. The company continues to set the standard for quality construction solutions. Knauf India, a member of the Knauf Group, which works in over 90 countries and has over 300 production sites worldwide, is committed to international and local quality standards.

Sumit Bidani, the CEO of Knauf India says “Knauf India, is proud to be the first company in the market to achieve full compliance with the new ISI standards for plasterboards. This milestone is a reflection of our ongoing commitment to quality, safety and sustainability. We believe these standards will further enhance the trust our customers and partners place in us.”

Knauf India’s plasterboards are now IS 2095 (Part 1): 2023 compliant, manufactured in cutting-edge facilities in Rajasthan and Andhra Pradesh. These requirements ensure that the goods meet the high safety, fire-resistance, and durability criteria required for modern construction.

Knauf India continues to ensure that its products pass rigorous BIS testing and certification, providing customers and stakeholders with piece of mind about construction safety and quality.

For more information, visit: https://knauf.com/en

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

At India Water Week, Shri C. R. Paatil reveals iPUMPNET, Pump Academy’s revolutionary AI and IoT technology that improves water management efficiency and won the Economic Times Infra Focus Award 2024.

Shri C. R. Paatil, Hon’ble Union Minister of Jal Shakti, unveils iPUMPNET, a revolutionary solution created in-house by Pump Academy Private Limited, at the 8th India Water Week event in Bharat Mandapam, New Delhi. He was accompanied by Vini Mahajan, Secretary-Jal Shakti; Debashree Mukherjee, Secretary of Water Resources, River Development, and Ganga Rejuvenation; and other senior Ministry officials.

During his visit to the Pump Academy booth at the India Water Week Expo, the Hon’ble Union Minister of Jal Shakti was briefed on the iPUMPNET technology, which has enormous potential for making water pumping stations smart and responsive. This cutting-edge solution uses artificial intelligence (AI) and the Internet of Things (IoT) to improve the efficiency of water pumping stations and encourage a wiser, more sustainable approach to water management.

With its superior remote monitoring and control capabilities for pumping infrastructure, iPUMPNET transforms critical water asset management by increasing efficiency in water distribution, wastewater management, and irrigation. The technology increases productivity by up to 35 percent, reduces energy consumption by up to 25 percent, reduces water loss, lowers carbon emissions, and increases equipment lifespan by up to 50 percent, resulting in cost savings and increased sustainability.

Pump Academy Private Limited has received the coveted Economic Times Infra Focus Award 2024, making it the Best Brand in Water Technology for its breakthrough solution, iPUMPNET. The award acknowledges the company’s unique approach to water management and significant contribution to the water infrastructure sector. It was introduced on September 19, 2024, during the ET Infra Focus Summit in Delhi. This distinction demonstrates the company’s dedication to developing solutions that address important water management issues while encouraging sustainability and resource optimisation.

Anil Sethi, the Founder Chairman of Pump Academy Private Limited, comments, “The advanced technology embedded in iPUMPNET has great potential to optimise water asset management across India. By leveraging AI and IoT, we are not just improving efficiency; we are paving the way for a more sustainable and water-secure future. This solution aligns perfectly with the government’s vision for smart water management and could play a crucial role in addressing India’s water challenges. We are elated by the appreciation from the Hon’ble Minister and look forward to contributing to the nation’s water conservation efforts with technology interventions.”

He further says, “We are deeply honoured to receive this prestigious recognition from the Economic Times. iPUMPNET represents our dedication to innovation in water technology. This award not only validates our efforts but also motivates us to continue pushing the boundaries of what’s possible in smart water management. We believe that technologies like iPUMPNET will play a crucial role in shaping a water-secure future for India.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

EPACK Prefab’s prefabricated solutions offer distinct advantages over traditional construction methods, including faster build times, cost savings, and enhanced sustainability. Unlike conventional methods with high land and labour costs, prefabrication accelerates project completion by up to 50 percent, reduces carbon emissions, and minimises environmental impact.

How has the adoption of prefabricated building technology evolved in India over the past decade?

Prefabricated construction has witnessed remarkable growth in India. The government’s emphasis on sustainable construction has pushed the use of Prefabricated Engineered Buildings (PEBs) and other green construction practices. This technology has gained traction in warehousing and industrial projects due to its efficiency and rapid construction timelines. Additionally, PEBs have addressed quick accommodation needs effectively. Despite this progress, there remains significant potential for further expansion. Continued government support, including subsidies for green construction, stricter sustainability regulations, and increased awareness of PEB benefits, could further commercialise this technology and extend its use in the real estate and tourism.

EPACK Prefab provides various products, from site offices to cold storage rooms. What are the key differentiators of your prefabricated solutions compared to conventional construction methods?

Prefabricated construction stands out from conventional construction methods due to benefits such as cost-effectiveness, rapid construction timelines, and sustainability. The traditional approach faces high hard costs, including land acquisition, labour, and materials, constituting a substantial portion of total expenses. Prefabricated construction, in contrast, accelerates project timelines by 30 to 50 percent, reducing build times, weather delays, and labour-intensive activities. Additionally, prefab’s simultaneous site development and construction, automation, quality control, and efficient material supply contribute to its cost-effectiveness. Compared with conventional construction, prefabricated construction reduces carbon emissions by up to 60 percent, making it highly beneficial for the environment.

How do you ensure the quality and durability of prefabricated structures?

At EPACK, we practice advanced manufacturing processes, rigorous quality control measures, and the use of high-grade materials. Each component undergoes thorough testing to meet stringent industry specifications, ensuring it can withstand diverse and challenging environments. Additionally, our designs are tailored to address specific environmental conditions, such as extreme temperatures, high winds, or seismic activity, providing resilience and longevity to the structures. By combining innovative technology with expert craftsmanship, we deliver durable prefabricated solutions that can perform reliably in any setting.

EPACK Prefab uses advanced technologies like Light Gauge Steel Framing (LGSF) and PUF insulated panels. How do these technologies enhance the efficiency and performance of your structures?

LGSF provides a strong yet lightweight framework, allowing for faster construction and greater design flexibility while maintaining structural integrity in diverse environments. PUF insulated panels offer superior thermal insulation, reducing energy consumption for heating and cooling and improving overall resource efficiency (saving of natural resources like sand, limestone, water, etc.): Eco-friendly technology, leading to almost zero pollution. Its structures are designed for 25 years of life and can be designed for 50+ years, too. Additionally, it is very easy to execute.

Can you elaborate on the sustainability aspects of your prefabricated structures?

Prefabricated structures are built in a controlled factory environment and then assembled on-site. This construction method minimises material waste, reduces on-site pollution, and lowers energy consumption through efficient manufacturing practices. Our structures use eco-friendly materials, such as steel, and are engineered to enhance thermal insulation, substantially reducing the need for heating and cooling and thereby conserving energy. The materials used are also reusable, making them sustainable and economical even in the long run, particularly in cases of building demolition. Additionally, the controlled prefabrication environment ensures superior quality and durability, leading to a longer lifespan and less frequent need for repairs or replacements, reducing the overall environmental footprint.

What are the most common challenges when customising prefabricated solutions, and how do you overcome them?

Some of the challenges include environmental considerations and compliance with local regulations. To address these, we adopt a collaborative approach, engaging clients early to understand their specific needs and using advanced design software to align solutions accordingly. We also work closely with local authorities to ensure all regulatory standards are met and maintain strong communication with all stakeholders throughout the project. By proactively tackling these challenges, we ensure that our prefabricated solutions are precisely tailored to client specifications and fully compliant with all necessary standards.

For more information, visit: https://www.epack.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Sterling and Wilson Renewable Energy has secured two domestic solar projects worth INR 512 crore, including a 200 MW plant in Gujarat and a 50 MW project in Maharashtra, highlighting strong client trust.

Sterling and Wilson Renewable Energy Limited (SWREL) (BSE Scrip Code: 542760; NSE Symbol: SWSOLAR), a prominent domestic renewable EPC, has won two new domestic orders from Private IPPs worth around INR 512 crore. The company was awarded an order for the engineering, procurement, and construction of a 200 MW AC / 250 MWp DC PV plant for a PV project in Gujarat, India. It also acquired a letter of authorisation (LOA) for the engineering, procurement, and construction of a 50 MW AC / 65 MWp DC PV project in Maharashtra, India.

Speaking on the order wins, Amit Jain, Global CEO of Sterling and Wilson Renewable Energy Group shares, “We are very happy to bag two more prestigious domestic solar projects from leading Private IPPs and these project wins showcase our strong positioning in a fast-growing market. Both orders have been received from repeat clients thereby reaffirming our robust execution credentials. In the current year, out of the 6 major domestic orders received, 5 are from our existing clients showing the confidence customers have reposed in us to be a part of their growth in the domestic renewable market. “

For more information, visit: https://www.sterlingandwilsonre.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

At the 4th Global RE-INVEST Summit, Adyant Enersol, a subsidiary of Datta Infra, announces a ₹1,500 crore funding agreement with REC Limited to create 500 MW renewable energy projects.

Adyant Enersol Private Limited, a wholly owned subsidiary of Datta Infra, has signed a strategic Memorandum of Understanding (MoU) with REC Limited, a ‘Maharatna’ firm under the Ministry of Power, Government of India. The company has inked an MOU with REC to receive ₹1,500 crore in finance for 500 MW of renewable energy projects. Datta Infra will develop 2 GW of Wind, Solar, and Wind-Solar Hybrid projects across the country following the signing of this MoU. The Memorandum of Understanding was signed at the 4th Global RE-INVEST Summit in Gujarat. It is a critical milestone in the company’s efforts to drive India’s green energy revolution.

Renewable energy projects will be installed in states like as Rajasthan, Madhya Pradesh, and Andhra Pradesh. Such projects are planned to provide 800-900 million units (MU) of renewable energy per year, providing stable and clean power from a combination of solar and wind resources. The projects are planned to be completed within 18 to 24 months of signing the Power Purchase Agreement (PPA).

Varchasvi Gagal, CEO and Managing Director of Datta Infra, comments on the proposal., “Datta Infra aims to become front runners in the renewable energy sector. By adding 2 GW of renewable energy projects across the country in the next 2-3 years, we shall help scale up India’s renewable energy capacity, aligning with the Viksit Bharat vision of the Government of India for a sustainable future. The MoU is aimed at enhancing renewable energy capacity and will serve as a cornerstone for India’s clean energy transition. The association will deliver economic, social, and environmental benefits, making a substantial impact on India’s renewable energy landscape resulting in renewable energy capacity expansion, creating jobs, reducing carbon emissions, enhancing infrastructure, and fostering innovation.”

Datta Power also intends to strengthen its position in the Independent Power Producer segment, with a focus on supporting renewable transition, enhancing growth and innovation, leveraging policies for India’s renewable electrification initiatives, and mitigating climate change through its wind, solar, and wind-solar hybrid projects. Datta Infra now offers total energy solutions, including transmission line engineering, procurement, construction, and maintenance, as well as solar and wind parks. Between 2020 and 2024, the corporation experienced tremendous expansion, executing projects reaching 5,600 MW and culminating in a 6 GW Ultra Mega Park in 2024.

The MOU was signed by Vivek Kumar Dewangan, Chairman & Managing Director of REC Limited; Saurabh Rastogi, Executive Director of REC Limited; Arun Chaturvedi, GM-RE Division of REC Limited; Harsh Baweja, Director Finance of REC Limited; Hemank Sindhu, Director of Adyant Enersol Private Limited; Rajeev Kumar Bansal, CFO of Datta Power Infra Private Limited; and Shubham Roy, Head of Business Development & Regulatory at Datta Power Infra Private Limited.

For more information, visit: https://dattainfra.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Critical risk safety audits are a cornerstone of construction site safety, addressing major hazards like falls and electrocution. As the sector evolves, these audits provide a comprehensive review of safety practices, helping companies manage risks effectively and maintain a safer working environment for all employees.

India’s construction sector stands as a colossal employment powerhouse, engaging an estimated 7.1 crore workers and ranking just behind agriculture as the largest job creator in the country. By 2030, this figure is set to soar beyond 10 crore, reflecting the sector’s growing significance. However, alongside its role as a major employer, the industry grapples with a serious downside: a troubling rate of accidents, injuries, and fatalities.

A study featured in the Scientific World Journal highlights a stark reality: India’s construction workforce, which represents 7.5% of the global labor pool, is responsible for 16.4% of fatal occupational accidents worldwide. The most common causes of these fatal injuries include falls from heights, electrocution, being struck by moving objects, and accidents involving vehicles. Such incidents are critical safety risks and pose significant threats to business operations, potentially halting construction projects and leading to severe injuries or fatalities.

In light of these risks, construction companies and developers must adopt a proactive approach. One effective strategy is to conduct specialised critical risk audits regularly. These audits are essential for identifying and mitigating risks that pose significant threats to both workers and assets.

Understanding the critical risks safety audit

A critical risks safety audit is a comprehensive examination aimed at identifying and addressing high-risk situations that could lead to injury or damage. The audit scrutinises various high-risk tasks, such as working at heights, confined space entry, lifting operations, and electrical and fire safety. It also evaluates specific areas like ground excavation, contractor safety, and specialised tasks such as handling molten metal.

The audit process includes a detailed assessment of an organisation’s safety practices, leadership commitment, risk management procedures, and permit-to-work systems. It involves engaging with employees, conducting on-site inspections, and reviewing documentation meticulously. By focusing on critical risks, the audit helps companies identify potential hazards and areas for improvement, fostering a safer working environment and reducing the likelihood of accidents.

Benefits of conducting a critical risks safety audit

Implementing a critical risks safety audit offers numerous advantages for businesses in the construction sector. For one, it provides construction workers with hands-on learning experiences about hazard reduction, enhancing their understanding of and ability to manage potential risks. The audit also serves as a platform for identifying safety hazards and evaluating the effectiveness of existing safety measures.

By raising awareness and promoting positive safety behaviours, the audit can improve a company’s safety record. It reduces accidents, injuries, and near misses while facilitating root cause analysis and corrective actions. This process helps in setting up on-the-job training for supervisors and workers, ensuring that safety protocols are continuously refined and enforced.

The audit process typically begins with pre-audit meetings to address any questions and plan the audit procedures. During the audit, safety hazards are documented, and necessary corrective actions are outlined. Post-audit discussions are held to review findings, propose improvements, and monitor the implementation of recommendations.

The audit process: A four-step approach

The critical risks safety audit unfolds in four essential phases. First, Leadership Commitment and Planning involves obtaining buy-in from leadership and carefully planning the audit process. This sets the stage for an effective audit. Next, in the Implementation and Operation phase, the safety measures are put into practice throughout the organisation. Monitoring and Measurement follow, focusing on evaluating the effectiveness of these protocols to ensure they align with organisational goals. Finally, Evaluation and Continuous Improvement assess the results and drive ongoing enhancements to safety protocols, promoting a culture of continuous improvement.

Throughout these phases, the active participation and commitment of all organisational levels are crucial for success.

Key takeaways

For industries like construction, which regularly deal with hazardous operations, prioritising critical risks safety audits is essential. Ongoing evaluation and enhancement of safety systems are vital for improving performance across departments. Regular monitoring of policies, systems, and risk control techniques helps maintain a high standard of safety.

It is important to partner with reputable audit and consultancy firms that are globally recognised for their expertise in health and safety systems. Such firms employ experienced auditors who adhere to professional standards, ensuring that audit reports are technically verified and reliable.

By embracing critical risks safety audits, construction companies can significantly improve their safety performance, protect their workforce, and enhance overall operational efficiency.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

JK Lakshmi Cement has expanded its association with cricketer Rohit Sharma, underscoring their common ideals of strength and quality as he continues to represent the company in upcoming advertisements.

JK Lakshmi Cement (JKLC), one of India’s top cement makers, has extended its successful association with cricket superstar Rohit Sharma as its brand ambassador. This extended partnership highlights the brand’s dedication to quality as well as the common ideals that characterise JKLC and Rohit Sharma.

Rohit Sharma, noted for his leadership and consistent performance on the cricket field, exemplifies the key characteristics of strength, dependability, and excellence that JKLC symbolises. His prior engagement with the brand was a huge success, appealing to both consumers and stakeholders.

Commenting on the renewal, Arun Shukla, President and Director of JK Lakshmi Cement, says, “Rohit Sharma’s exceptional talent and achievements have made him a beloved figure in India and beyond. His association with JK Lakshmi Cement has aided in strengthening our brand’s connection with consumers. We are pleased to continue this journey and look forward to achieving even greater heights together. Rohit’s spirit of soaring ambition mirrors our product’s promise of durability and trustworthiness. Together, we aim to build not just structures but lasting relationships with our customers.”

Commenting on the partnership, Rohit Sharma, exclusively represented by RISE Worldwide, says, “I’m excited to continue my journey with JK Lakshmi Cement. Their commitment to quality and innovation aligns with my approach to life and cricket—always striving for excellence and pushing boundaries. Together, we’ve built an enduring relationship with consumers, and I look forward to what we can achieve in the coming year.”

With this extended agreement, Rohit Sharma will continue to appear in JKLC’s commercials and brand communications around the country and across platforms. The tagline “India’s Best Performer” has been highly embraced throughout the sales network and among consumers, resulting in higher brand scores and business valuation. The partnership between Rohit Sharma and JK Lakshmi Cement exemplifies their shared principles of excellence, customer attention, collaboration, trust, and honesty. Rohit, as a leader and captain on and off the pitch, embodies resilience and strength, all of which are synonymous with JKLC’s goods. JK Lakshmi Cement is looking forward to another successful year with Rohit Sharma, cementing its position as the market’s leading cement brand.

For more information, visit: https://www.jkcement.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Ramco Cements’ Jaggayyapet factory received the ‘Excellent Energy Efficient Unit’ award at CII’s 2024 National Energy Management Awards.

The Ramco Cements Limited Jaggayyapet factory near Vijaywada received the ‘Excellent Energy Efficient Unit’ award at the 25th National Award for Excellence in Energy Management 2024.

This award from the Confederation of Indian Industry (CII) is based on the panel of judges’ evaluations at the National Award for Excellence in Energy Management, which will be hosted in Hyderabad from September 10 to 12, 2024.

Ramco Cements’ Jaggayyapet factory was named the ‘Excellent Energy Efficient Unit’ out of 26 selected entries from major cement manufacturing companies.

For more information, visit: https://ramcocements.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Hitachi Construction Machinery will commence mass production of the EX1200 ultra-large hydraulic excavator at its Indonesian factory in November 2024, to meet expanding demand in Indonesia’s mining sector.

Hitachi Construction Machinery Co., Ltd. (TSE: 6305, President and Executive Officer: Masafumi Senzaki; “Hitachi Construction Machinery”) will begin mass production of the EX1200 ultra-large hydraulic excavator (operating weight: approx. 120-ton class) at its Indonesian production base P.T. Hitachi Construction Machinery Indonesia (headquarters: West Java, Indonesia; Managing Director: Kozo Nagao; “Hitachi Construction Machinery Indonesia”) from November 2024 to address the demand for ultra-large hydraulic excavators in the Republic of Indonesia (“Indonesia”).

Hitachi Construction Machinery currently manufactures ultra-large hydraulic excavators and rigid dump trucks at the Hitachinaka-Rinko Works (Hitachinaka, Ibaraki Prefecture, Japan) for delivery to customers all over the world. In addition to medium hydraulic excavators, Hitachi Construction Machinery Indonesia manufactures front structures (booms, arms, and buckets) for ultra-large hydraulic excavators, truck frames, rigid dump truck beds, and other welded mining machinery structures.

Indonesia, Southeast Asia’s largest market for mining machinery, has a fairly significant number of small and medium-sized mines, as well as a high demand for hydraulic excavators in the 120-ton class. Furthermore, the entire Group’s manufacturing capacity needed to be strengthened to meet the global demand for mining goods, particularly in the Americas region, where the Hitachi Construction Machinery Group is advancing its independent expansion.

Against this backdrop, the Group chose to expand Hitachi Construction Machinery Indonesia’s Cibitung 2 Factory and construct new manufacturing and assembly facilities to manufacture the EX1200 ultra-large hydraulic excavator. Furthermore, modern welding technology will be used in the expanded area to increase the production of welded structures for mining products.

To meet global demand, the Hitachi Construction Machinery Group will continue to develop and manufacture products in accordance with client needs at each base.

For more information, visit: https://www.hitachicm.com/global/en/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The MK 120-5.1 is the most recent addition to Liebherr’s mobile construction crane lineup. The five-axle machine spans the gap between the MK 88-4.1 and the MK 140-5.1. Along with lots of lifting power, it includes a redesigned display and an optional smaller load hook for working in tight places.

With a jib length of 52 metres and a maximum lifting capability of 2,100 kilogrammes at the jib head, the new MK 120-5.1 provides remarkable performance. The crane expands Liebherr’s existing MK portfolio, filling the gap between the MK 88-4.1 and the MK 140-5.1. One of the mobile construction crane’s main advantages is its agility; its small turning circle allows for easier site access through narrow streets and crossroads.

The new crane is based on the existing MK 140-5.1. Crane operators who are familiar with the previous model can use the new one without requiring extensive additional training.

New crane, new display

The MK 120-5.1 features the new Liebherr TC-OS display. The TC-OS (Tower Crane Operating System) user interface is designed for ease of use and flexible adaptation by crane operators. The 12-inch touch display supports split and full-screen modes. This means that various types of information can be presented over many screen areas. The display is scheduled to replace the current version in all mobile construction cranes by the end of 2025.

Smaller load hook for better load location

The MK 120-5.1 can be supplied with a smaller load hook. This version is particularly useful on sites with existing buildings when scaffolding is present and the weight must be shifted between the building and the scaffolding. It takes only a few minutes to alter the load hook on-site. The smaller load hook has the same lifting capacity as its larger counterpart and will soon be available on all Liebherr mobile construction cranes.

“Exactly the right crane for our fleet”

The first clients have already praised the latest addition to Liebherr’s mobile construction crane line. “The MK 120-5.1 is exactly the right crane for our fleet. Its jib length and lifting capacity make it ideal for our customers’ construction sites,” says Stephan Zaugg, Managing Director at Zaugg AG Rohrbach (Switzerland). “We are excited to be the first-ever customer to acquire the new MK. Reliability, customer service and the great reputation of Liebherr’s mobile construction cranes were deciding factors for our purchase”A firm from Belgium has already placed an order for the MK 120-5.1. Deliveries will begin in the summer 2025.

For more information, visit: http://www.liebherr.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Scania India has named Silvio Munhoz as its new Managing Director, beginning September 1, 2024. Silvio follows Johan P. Schlyter and brings decades of experience in the automobile business to his new position.

Silvio’s leadership experience includes positions such as Managing Director of Codema and Interim President and CEO of Scania Brazil. Throughout his career, he has displayed a strong strategic vision, a customer-centric approach, and a profound dedication to long-term innovation, resulting in success across numerous sectors. His hiring signals a new chapter in Scania India’s expansion, as the firm continues to focus on offering cutting-edge transport solutions while also bolstering its regional sustainability initiatives.

Commenting on his new role, Silvio Munhoz says, “I am truly honoured to lead Scania India during a time of immense transition within the automotive industry. My focus will be on reassuring Scania’s commitment to the Indian market while expanding the adoption of sustainable and innovative power and transport solutions. I look forward to working with the talented team at Scania India and building upon the solid foundation established by my predecessor, Johan P. Schlyter.”

Under Silvio’s leadership, Scania India is ready to continue its commitment to offering comprehensive solutions to India’s transportation and energy industries, including premium goods and services.

For more information, visit: https://www.scania.com/in/en/home.html

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Rushabh Surendra Karnavat is a Chartered and Government Approved Structural Engineer and the principal consultant at M/s. Rushabh Surendra Karnavat. With extensive experience in structural engineering and project management, he excels in structural audits, risk assessments, and building preservation. His meticulous approach ensures accurate evaluations and compliance with codes and standards. Known for his attention to detail, Rushabh addresses complex engineering challenges, manages disputes, and coordinates with stakeholders to ensure safety and integrity in building projects, making him a trusted advisor in his field.

Topic: Regulatory Consideration for High-Performance Concrete (HPC)

#ConstructionSecurity #SafeConstruction #ConstructionWebinar #EquipmentSecurity #construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Manish Mokal is currently the Joint General Manager (Quality Excellence Cell) for AFCONS Infrastructure Ltd. He has substantial experience from past positions with Hindustan Construction Company, GVK, and Gammon India Ltd. In 24 years, he has worked on several renowned infrastructure projects, including the Bandra-Worli Sea Link, the Rajasthan Atomic Power Plant, hydro projects in Ladakh, the Mumbai International Airport, the Rohtang Tunnel, and the Kolkata Metro.

Topic: Importance of aggregate quality in HPC

#ConstructionSecurity #SafeConstruction #ConstructionWebinar #EquipmentSecurity #construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Sajin Noorjahan, Director, of Conmach Solution has developed a deep understanding of the concrete machinery industry and the challenges that come with it. His expertise lies in devising effective sales and marketing strategies that boost revenue and foster long-term relationships with clients. At conmach solution, he is committed to bridging the gap between machine manufacturers and end users, ensuring seamless procurement and delivery of high-quality equipment. His experience at Simem India has given him valuable insights into global sales operations and allowed him to hone his skills in planning, management, and implementation of sales strategies.

Topic: Fiber dosing solution in concrete plant

#ConstructionSecurity #SafeConstruction #ConstructionWebinar #EquipmentSecurity #construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Avijit Chaubey is head of Technical for RDC Concrete Ltd and Ultrafine Minerals Pvt Ltd. He has worked in companies like Ultratech, ACC, HCC, Gammon India Ltd, and Shapoorji Pallonji in various capacities. He has won a Gold Medal from the Union Ministry of Water Resources for a paper published in the IEI journal “Design of Parabolic Channels”. He has authored an international book “Practical Concrete Mix Design” and has been declared one of the top 5 technical Books of Asia.

Topic: Ultrafine Materials and their Importance in High-performance Concrete

#ConstructionSecurity #SafeConstruction #ConstructionWebinar #EquipmentSecurity #construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Supporting Atmanirbhar Bharat, the project decreases import dependency and delivery times while aiming for more than 50 percent market share in India’s solar sector, boosting native capabilities and energy independence.

ArcelorMittal Nippon Steel India (AM/NS India), a joint venture between ArcelorMittal and Nippon Steel, has launched Magnelis®, a steel brand known for its corrosion resistance and self-healing capabilities.

The new steel brand was launched during a dazzling Mumbai event. Magnelis®, ArcelorMittal’s proprietary brand, is now made and sold in India, increasing supply efficiency in strategically vital, high-growth industries like renewable energy while decreasing the country’s reliance on imported speciality steel goods.

Dilip Oommen, Chief Executive Officer (CEO), ArcelorMittal Nippon Steel India (AM/NS India), says, “The launch of Magnelis® in India is a testament to our commitment to fulfilling the nation’s growing demand for high-performance steel while contributing to the vision of Atmanirbhar Bharat. By producing this world-class, imported substitute steel; we deliver quality infrastructure solutions and contribute to accelerating India’s clean energy transition. Magnelis® is the future of sustainable materials, and its introduction marks a significant step towards building the nation’s global-standard infrastructure.”

Ranjan Dhar, Director and Vice-President of sales & marketing, ArcelorMittal Nippon Steel India (AM/NS India), says, “The launch of magnelis® in India is a pivotal moment for us as this unique solution has proven its performance in the global solar projects, contributing to 50 GW of installed capacity. The production of the new offering here is cutting down delivery time and drastically reducing logistics costs, thus providing domestic customers with a faster and more efficient solution for their infrastructure needs as India is stepping up its nation-building initiatives. Other end-use sectors include road infrastructure (crash barriers), agriculture infrastructure (grain silos, farm equipment) and construction (pre-engineered building structures).”

Magnelis®, an alloy-coated steel brand containing Zinc, Aluminium, and Magnesium, provides superior corrosion resistance and self-healing qualities. Previously, this high-end value-added steel was imported mostly from Korea, Japan, and China, with delivery times of several months.

AM/NS India invested about ₹ 1000 crores in establishing a production line for Magnelis® with a capacity of ₹ 5 lakh tonnes per year at its flagship plant in Hazira, Gujarat. AM/NS India intends to acquire more than half of the domestic market share for steel supplied to solar projects. The product’s demonstrated effectiveness in harsh settings makes it appropriate for solar panel mounting systems and other renewable energy applications that will aid India’s energy transition. AM/NS India is already in advanced talks to supply Magnelis® to major players in India’s renewable energy and infrastructure sectors, including Adani Green Energy, Reliance Industries, and NTPC. Magnelis® will play a key role in advancing renewable energy projects nationwide through collaborations.

For more information, visit: https://www.amns.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Trelleborg Sealing Solutions inaugurates a new R&D facility providing local innovation backed by global expertise in Bangalore, India.

The new facility serves as an innovation hub, with an emphasis on research customised to the demands of the area market. Trelleborg’s footprint in the region grows, strengthening ties with local companies and improving responsiveness and expertise in Asia-Pacific’s dynamic market landscape. It focuses on a wide spectrum of sophisticated sealing technologies, including material and design advancements. Teams of researchers and engineers will collaborate to develop novel solutions that address sector-specific difficulties in industries such as hydraulics, off-highway vehicles, and industrial automation.

Dr. Konrad Saur, VP of Innovation and Strategic Business Development with Trelleborg Sealing Solutions, says, “This R&D facility is our second in Asia and our first in India and it significantly enhances our local capabilities. Our R&D centres are essential in driving material and product development, ensuring the performance excellence of our solutions across diverse applications. We’ve always prioritised substantial R&D investments to meet the dynamic demands of the industry. The facility is part of our strategic approach to get closer to our customers and foster stronger partnerships in the Asia Pacific region and specifically in India. It is configured to meet both global and local needs, particularly in material testing, materials application conditions and media compatibility. This will enable us to effectively address the stringent regulatory compliance and material compatibility requirements that industries are increasingly adhering to.

“We are committed to driving innovation and look forward to forging even stronger partnerships with our customers to help them achieve their goals with our advanced sealing solutions.”

Initially, the R&D centre will focus on analysing physical properties such as tensile strength, elongation, modulus, and tear strength of elastomer compounds, as well as the compatibility of high-performance materials with essential application fluids. Trelleborg’s equipment includes ageing ovens for conducting compatibility tests in air and fluid media, allowing them to examine the compatibility of materials with customer-specific fluids, whether purchased locally or from global labs.

Plans include introducing new capabilities such as analytical testing, benchmark analysis, and product testing. It will also assist local sales and manufacturing teams with failure analysis and consumer feedback, allowing the corporation to better service customers and enhance goods. The new capabilities augment the existing local engineering, simulation, and design expertise.

Vinay Balakrishnan, General Manager of Industrial Asia Pacific, says, “This reflects our dedication to building robust relationships with local companies and industries. We’re focused on delivering tailored, high-quality solutions that meet the specific needs of the Indian market, including the demand for durable solutions with long lifetimes. We aim to be a trusted partner and a key contributor to the growth and success of our customers in India. With the new R&D centre, we can partner on early development with customers and validate the designs. It enhances our ability to provide customers and partners with a more personalized and responsive approach to their needs, making us better equipped to collaborate closely with our customers and meet their unique challenges by delivering tailored solutions.”

The investment reflects Trelleborg’s strong commitment to the Indian market by bringing sophisticated research capabilities closer to customers, allowing for faster and more effective assistance.

Salome Martin, Director of R&D Services India, says, “This is a big step forward by Trelleborg in the Asia region. The development is carried out in a structured manner understanding the current needs of our customers and developing capabilities, solutions, and technical expertise accordingly. The Indian market is different and having a local presence enables this centre to focus on the needs of our customers and collaborate with them to meet their growth aspirations.”

For more information, visit: https://www.trelleborg.com/en/seals

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Caterpillar Inc. (NYSE: CAT) reveals an innovative OEM-designed solution to assist in addressing one of the most complicated parts of the mining industry’s energy transition: energy management.

Cat® Dynamic Energy Transfer (DET) is a Caterpillar-developed technology that can supply energy to both diesel-electric and battery-electric heavy mining trucks while they work on a mine site. It can also charge a machine’s batteries while operating at higher speeds on grade, increasing operational efficiency and equipment uptime. The revolutionary Cat DET system gives the sector choices to support both short-term and long-term sustainability initiatives.

“We believe Cat DET provides a technological leap for the mining industry. Our team of innovators designed this system to provide immediate benefit to miners who want to lower their operating costs and greenhouse gas emissions today while also creating flexibility for the future,” says Denise Johnson, Caterpillar’s Resource Industries group president. “We know customers need choices to fit their unique site objectives. We are proud to deliver an innovative, integrated solution that can support their needs of today and those of the future.”

Enhanced flexibility through innovative design

Cat DET is made up of several interconnected components, including a power module that transforms energy from a mining site’s power supply, an electrified rail system that transports the energy, and a machine system that transfers the energy to the truck’s motor.

The rail system is a highly deployable, mobile solution that can be tailored to each customer’s site layout, including high-speed and curving haul routes, resulting in increased efficiency. The connecting arm can be put on either side of a truck and various truck models, giving clients options tailored to their operations. It can also be employed on mature or developing sites and is readily moved or enlarged to ensure complete mine site coverage.

Cat DET will interact with Cat MineStar™ Command for hauling solutions, combining autonomy and electrification technologies to offer a comprehensive site solution.

Caterpillar Senior Vice President Marc Cameron explains, “We believe mine sites will benefit from enhanced efficiency with the integration of electrification and automation. When combined, these technologies will help miners achieve production targets while simultaneously managing energy demands.”

The Cat DET system will be on display at Caterpillar’s MINExpo 2024 show, located in Central Hall booth #6333 at the Las Vegas Convention Centre from September 24-26.

For more information, visit: https://www.caterpillar.com/en.html

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

An innovative crusher bucket solution improves productivity and overcomes logistical challenges in high-altitude road construction.

In a ground-breaking step that will alter road construction in remote and difficult terrains, MB Crusher successfully outfitted a top road contractor in Leh with its adaptable and highly efficient Crusher Bucket. This ingenious method allowed the contractor to navigate the difficult climate and logistical challenges of Leh, ensuring the timely completion of two critical road projects totalling 19 kilometres.

Leh, famed for its magnificent vistas and harsh weather conditions, poses unique obstacles to infrastructure development. The road contractor, tasked with building two essential roads—one 7 kilometres and the other 12 kilometers—faced tremendous challenges due to the isolated location, lack of local infrastructure, and a limited operating season of only 4-5 months each year. Traditional fixed crushers were not a viable choice due to the complexity of putting up in such terrain and the lack of nearby crushing facilities.

MB Crusher’s solution

MB Crusher, a global pioneer in crushing and screening equipment, presented the contractor with a cutting-edge crusher bucket. This attachment, which works with the contractor’s current Tata Hitachi Z-axis 220 and Komatsu PC 210 base equipment, proved to be a game changer. The MB Crusher Bucket was designed to crush hill rock into the necessary output size of less than 60 mm, allowing for on-site material processing without the need for transportation to distant crushing plants.

What was the result? A significant improvement in productivity, with the Crusher Bucket producing a continuous output of 20-25 TPH (Tonnes Per Hour), ensuring that projects are completed on time despite tight deadlines.

Key benefits of the MB Crusher Bucket:

Transforming road construction in remote areas

The successful implementation of MB Crusher’s novel solution in Leh is a watershed moment in road construction, particularly in remote and difficult places. This instance shows how advanced technology can overcome logistical problems, increase efficiency, and provide high-quality infrastructure in the most demanding environments.

For more information, visit: https://www.mbcrusher.com/en/in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The cement industry is on the cusp of a technological revolution, with innovations that promise to enhance sustainability and efficiency. From the development of low-carbon cement to the integration of digital technologies and renewable energy, these advancements are setting the stage for the future of construction.

The cement industry, a cornerstone of modern construction, is experiencing a transformative shift driven by several critical technological advancements. As the industry strives to meet sustainability goals and improve efficiency, these innovations pave the way for a more sustainable and cost-effective future. This article explores the key technological advancements in the cement industry, their impact on construction practices, and emerging trends shaping the industry’s landscape.

Advancements in cement technology

One of the most significant advancements in cement technology is developing and adopting low-carbon and alternative cement. These innovations aim to reduce the carbon footprint of cement production, which is traditionally a major source of CO₂ emissions. Low-carbon cement incorporates supplementary cementitious materials (SCMs) such as fly ash, slag, and calcined clays. By reducing the clinker factor in cement, these materials help lower CO₂ emissions significantly. Globally, this shift has reduced the clinker-to-cement ratio to approximately 0.7. In India, the use of blended cement has led to a reduction in emissions by around 15 percent per ton compared to Ordinary Portland Cement (OPC). This advancement not only supports environmental sustainability but also enhances the cement’s overall performance.

Integrating digitalisation and Industry 4.0 technologies is another crucial advancement reshaping the cement industry. Artificial intelligence (AI) and machine learning are now employed to optimise production processes, predict equipment failures, and enhance energy efficiency. These technologies have resulted in energy savings of up to 10 percent and significant reductions in operational costs. By leveraging real-time data and predictive analytics, cement manufacturers can achieve greater efficiency and sustainability globally and within India.

The use of alternative fuels is also a game-changer for the cement industry. Biomass and waste-derived fuels have helped achieve thermal substitution rates of up to 40-60 percent globally, significantly reducing CO₂ emissions and waste. The current thermal substitution rate in India is around 4-5 percent, but efforts are underway to increase this to 25 percent by 2025. This transition supports the industry’s sustainability goals and reduces reliance on conventional fossil fuels.

Advancements in energy efficiency and carbon capture technologies are substantially impacting the cement industry. Technologies such as vertical roller mills and waste heat recovery systems are reducing energy consumption and greenhouse gas emissions. Carbon capture, utilisation, and storage (CCUS) technologies offer the potential for further reductions, contributing to a more sustainable future for cement production.

Renewable energy adoption is another significant trend within the cement industry. Many cement manufacturers globally are investing in renewable energy sources such as wind and solar power, with some achieving up to 30 percent of their energy needs from renewables. In India, leading companies target up to 25 percent of their energy requirements from renewable sources by 2030. This shift aligns with India’s renewable energy goals and commitment to reducing greenhouse gas emissions.

Impact of high-performance cement on construction practices

Advances in high-performance cement and concrete have revolutionised construction practices by improving durability, strength, and efficiency. High-performance concrete (HPC), with compressive strengths often exceeding 60 MPa, enhances the structural integrity of buildings. This allows for the use of thinner elements and results in up to 20 percent material savings. Ultra-high-performance concrete (UHPC), with strengths over 120 MPa, has enabled the construction of taller skyscrapers and longer-span bridges that were previously unfeasible.

Research indicates that HPC and UHPC can extend the service life of structures by 50 to 100 years, significantly reducing maintenance costs. The incorporation of SCMs in these concretes also lowers the clinker content, resulting in a reduction of CO₂ emissions by 30-50 percent. In India, applying high-performance cement and concrete has been instrumental in infrastructure projects such as highways and metro systems, enhancing durability in diverse climates and reducing long-term costs.

These advancements improve construction quality and align with global sustainability efforts. High-performance cement and concrete contribute to the broader goals of sustainability and environmental responsibility by providing stronger, more resilient structures with a reduced environmental footprint.

The role of ready-mix concrete (RMC) in sustainable construction

Ready-Mix Concrete (RMC) plays a significant role in advancing sustainable construction practices in India. RMC production allows for precise control of mix proportions, reducing raw material wastage and optimising cement use. This precision leads to a 10-15 percent reduction in cement consumption, which is crucial for minimising the carbon footprint associated with cement production.

RMC facilitates the use of SCMs, such as fly ash and slag. In India, RMC plants commonly include up to 30-35 percent fly ash in their mixes. This practice enhances the concrete’s durability and strength and helps manage industrial waste more sustainably.

From a project efficiency standpoint, RMC reduces on-site labour and construction time by up to 30 percent, thanks to its streamlined delivery and batching process. This efficiency is particularly beneficial in urban and two-tier cities where RMC is increasingly used due to rapid infrastructure development and the need for high-quality, consistent concrete.

Enhancing corrosion resistance with modern additives and coatings

Modern additives and coatings significantly enhance the corrosion resistance of cementitious materials. Using SCMs such as silica fume, fly ash, and ground granulated blast-furnace slag (GGBS) improves the microstructure of concrete, reducing its porosity and permeability. This, in turn, limits the ingress of chloride ions and aggressive chemicals responsible for corrosion. In India, incorporating fly ash and GGBS in concrete has shown a reduction in chloride diffusion coefficients by up to 50 percent.

Chemical admixtures, such as calcium nitrite and amine-based inhibitors, are gaining traction due to their effectiveness in forming a protective oxide layer on reinforcing steel. Recent studies indicate that these inhibitors can reduce the corrosion rate of steel in concrete by up to 85 percent, even in coastal and industrial zones prone to high chloride exposure.

Advanced coatings, including epoxy, polyurethane, and silane-based sealers, are increasingly adopted for surface protection. These coatings create hydrophobic barriers that prevent moisture and chlorides from penetrating the concrete. Research shows that applying silane-siloxane coatings can reduce water absorption by over 70 percent and decrease chloride ingress by up to 65 percent, effectively extending the service life of structures exposed to harsh environmental conditions.

Optimising concrete rheology: Temperature and mix composition

Temperature significantly affects the rheology of concrete, influencing its workability and setting time. In India, high temperatures, often reaching 45°C, accelerate cement hydration, reducing setting times and workability. Research indicates that for every 10°C rise in temperature, the setting time of concrete decreases by about 15-20 percent. To manage this, retarders such as hydroxycarboxylic acids are used, with dosages between 0.1 percent and 0.5 percent of cement weight, and cooling methods like using ice can lower mix temperatures by 5-10°C.

The composition of the concrete mix, including the type and proportion of cement and aggregates, also affects its rheology. Higher cement content or specific types of cement, such as Portland Pozzolana Cement (PPC), can increase viscosity and reduce workability. To optimise mix properties, superplasticisers like polycarboxylate ethers (PCE) improve workability without adding extra water, potentially increasing slump by up to 150 mm. Proper aggregate gradation enhances cohesion and workability, reducing cement needs by up to 20 percent.

In practice, projects in high-temperature regions of India use evaporative cooling for aggregates and mixed water. In contrast, coastal projects use high-range water reducers and fly ash to control workability and setting times. These measures help manage the rheological properties of concrete effectively across varied Indian climates.

Best practices for waterproofing systems

Successful application and long-term performance of waterproofing systems depend on several best practices. Thorough surface preparation is crucial, as removing contaminants like dust and efflorescence can improve adhesion by up to 30 percent, leading to better system performance.

High-quality materials should be selected based on local conditions. For instance, polymer-modified bitumen membranes are ideal for coastal areas due to their high resistance to saline environments, potentially reducing water ingress by up to 90 percent. Proper application techniques are essential, with correct overlap and coverage following manufacturer guidelines to prevent issues such as blistering and peeling. Maintaining the recommended thickness can enhance durability by around 40 percent.

Regular maintenance is vital, with inspections recommended every 6-12 months to address minor issues before they become significant problems. Integrating waterproofing systems with building design, including adequate drainage systems, is also critical. For instance, designing drainage to manage local rainfall, which can exceed 1,000 mm annually in some Indian regions, helps prevent water accumulation and system failure.

Investing in high-quality waterproofing materials and proper application can reduce long-term repair costs. Initial waterproofing costs can range from ₹70 to ₹120 per square foot, but the reduced need for repairs and maintenance over the system’s lifespan offsets these costs. Adhering to these best practices ensures the effectiveness and longevity of waterproofing systems, providing substantial cost savings and enhanced protection.

Trends in construction chemicals

The construction chemicals industry is seeing increased demand for high-performance admixtures, such as advanced superplasticisers and high-range water reducers. These products improve concrete performance by enhancing workability, strength, and durability. Innovations like polycarboxylate ethers (PCEs) reduce water content by up to 30 percent while increasing compressive strength by 10-15 percent.

Sustainability is driving the development of eco-friendly construction chemicals. Biodegradable additives and products with low volatile organic compounds (VOCs) are gaining popularity. In India, green building materials, including low-VOC adhesives and sealants, align with the Green Building Council’s standards and help achieve certification.

Self-healing concrete, which incorporates capsules containing healing agents that activate upon cracking, is emerging as a significant trend. These materials can self-repair small cracks, extending the service life of structures. Smart materials, including sensors embedded in concrete, monitor structural health in real time, providing data for maintenance and repair.

Adherence to regulatory standards and certifications is increasingly important. In India, compliance with standards set by the Bureau of Indian Standards (BIS) and certifications such as ISO 9001 ensure the quality and performance of construction chemicals. This focus on quality and compliance supports the industry’s growth and reliability.

The market for construction chemicals is expanding, driven by infrastructure development and increasing demand for high-performance materials. The global construction chemicals market is projected to grow at a CAGR of 6.2 percent from 2023 to 2028. In India, the market growth is supported by government initiatives such as the Pradhan Mantri Awas Yojana and increased investments in urban infrastructure.

The future of cement technology

Emerging trends such as digitalisation, advanced materials, and increased automation are shaping the future of cement technology. Innovations in digital twins, which create virtual replicas of physical cement production systems, are expected to enhance process monitoring and control. Integrating blockchain technology for supply chain transparency and traceability is also on the horizon, potentially revolutionising the industry’s quality assurance and fraud prevention approach.

Sustainability will continue to be a major focus, with the development of carbon-neutral and carbon-negative cement technologies. Research into new types of cement, such as magnesium-based cement, holds promise for further reducing carbon emissions. Adopting circular economy principles, including using recycled materials and waste minimisation, will be crucial in shaping the industry’s future.

Globally, the cement industry is expected to see a shift towards more sustainable practices, with regulatory pressures driving innovation. In India, increased infrastructure development and government policies supporting green construction practices likely boost demand for advanced cement technologies. The industry must adapt to these evolving market dynamics by investing in research and development and embracing new technologies.

The future of cement technology presents numerous opportunities for innovation, particularly in areas such as material science, process optimisation, and environmental impact reduction. Companies that invest in these areas and stay ahead of industry trends will be well-positioned to lead the market and drive the next wave of advancements in cement technology.

Technological advancements are reshaping the cement industry, driving sustainability, efficiency, and innovation. From low-carbon cement and digitalisation to high-performance materials and waterproofing systems, these innovations are setting new standards for construction practices. As the industry evolves, embracing these technologies will be crucial for meeting future challenges and achieving long-term sustainability goals.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Orient Cement leads the cement industry with innovative, eco-friendly products like Birla A1 OrientGreen, modern technologies, and a customer-centric strategy; all backed up by targeted marketing and skilled on-site technical assistance.

Could you elaborate on the most impactful innovations Orient Cement has introduced in cement production over the past few years?

Orient Cement has introduced several innovations to improve the performance and sustainability of its products. Birla A1 Dolphin Cement, with its capillary sealing qualities, provides excellent protection against moisture, corrosion, and sulphate attack. Birla A1 StrongCrete, with OptiMix18™ technology, provides high-performance concrete with superior strength, durability, and fast-setting qualities. It is ideal for essential applications such as foundations and beams.

The GreenPro-certified Birla A1 OrientGreen cement is environmentally benign throughout its lifecycle. Birla A1 Premium Cement, manufactured with fine-grained fly ash, also improves strength and durability by producing denser, more resilient concrete. Because of these developments, we are at the forefront of the cement industry’s sustainability and performance.

What are the advancements in concrete technology that you are integrating into the solutions?

We are a concrete technology leader, providing efficient, long-lasting, and sustainable solutions. Birla A1 OrientGreen decreases CO2 emissions by 15 percent during manufacture, saving energy and water and making it a perfect choice for sustainable building. Birla A1 StrongCrete’s high strength allows for speedier construction and post-tensioning, resulting in earlier de-shuttering and cost savings.

Birla A1 Dolphin Cement improves concrete durability by incorporating a hydrophobic ingredient that protects against moisture damage. Our OPC products provide remarkable strength and workability in demanding applications such as Mivan construction and ultra-high-performance concrete. We continue to develop through R&D, focusing on sustainability and performance in the construction industry.

How does Orient Cement address sustainability in its production processes and product offerings?

In line with India’s net-zero goal 2070, we intend to achieve net-zero Scope 1 and 2 emissions by that year. To reach this goal, the corporation is boosting its Thermal Substitution Rate (TSR), utilising renewable energy, and implementing cutting-edge technologies. It has also invested in dust control systems, decreased water consumption, and created a patent-pending coal-saving system to reduce CO2 emissions.

Sustainability extends to our goods, like Birla A1 OrientGreen, which has a lower carbon footprint. We have been recognised for our human resource practices, ranking in the Top 50 “Great Place to Work” and Top 25 Best Workplaces in Manufacturing in India.

Our plants have also received numerous honours. The Jalgaon Plant received the “Energy Efficient Unit Award 2023” and the “Platinum Award” for energy efficiency. The Devapur Plant got the “Safety Award 2023” and recognition for environmental excellence. The “National Energy Management Leader” and “Energy Efficient Unit” awards were given to the Chittapur Plant in recognition of its energy efficiency, safety, and sustainability.

Can you share insights into the quality control processes and certifications that validate your commitment to excellence?

We offer robust quality control methods and certifications demonstrating our dedication to producing outstanding cement. Our laboratory is ISO/IEC 17025-2017 approved, which ensures that tests are accurate. Certified by the Bureau of Indian Standards (BIS) for PPC and OPC production, we employ a three-step quality control method that includes raw material inspection, in-process monitoring, and finished product analysis with modern techniques like XRF.

We are also certified for quality, environmental management, health and safety, energy management, and information security, with ISO 9001:2015, ISO 14001:2015, and ISO 50001:2018. BIS has recognised the company for achieving zero product failures in the last three years, emphasising its commitment to high-quality cement.

For more information, visit: https://orientcement.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

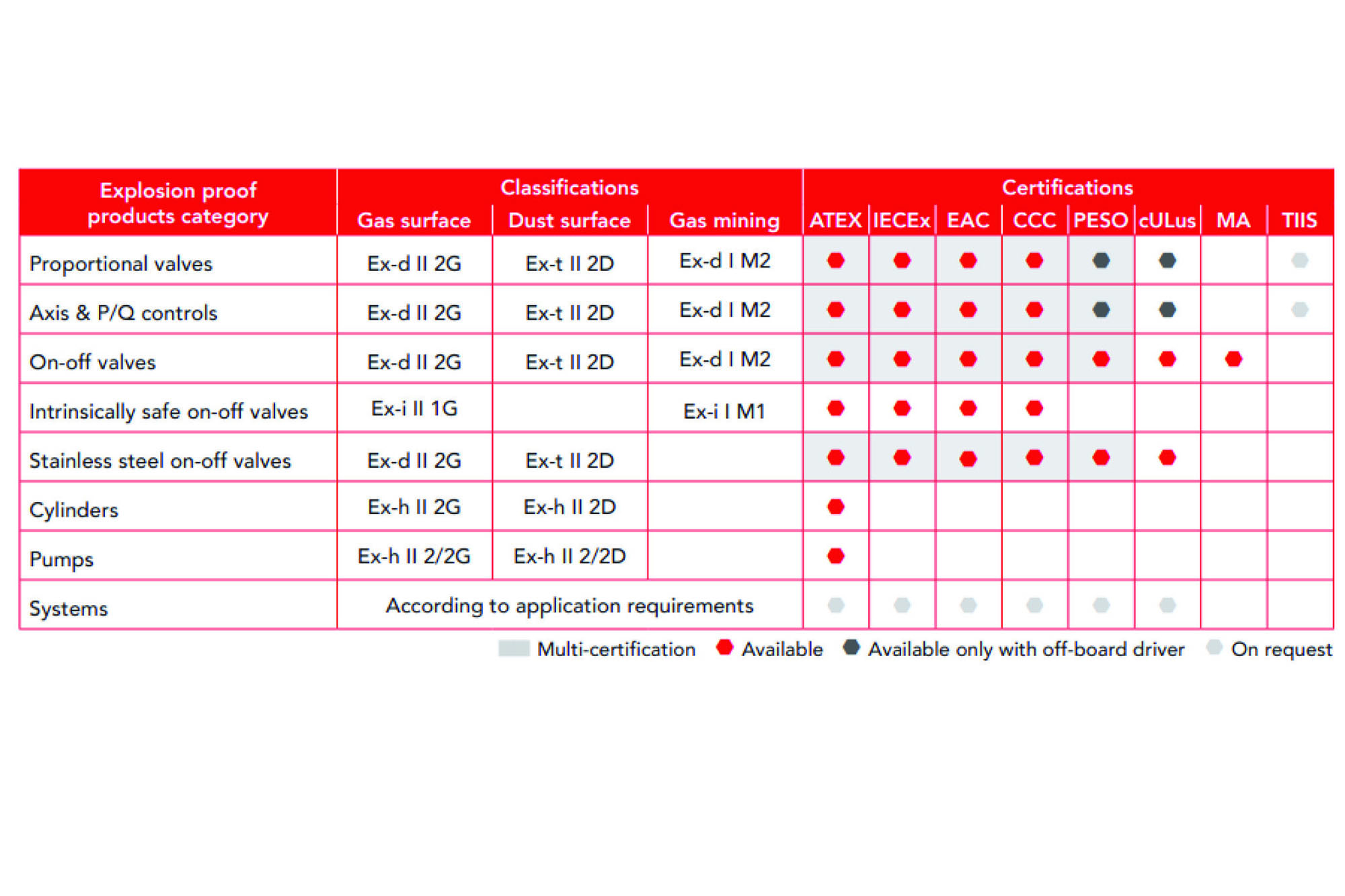

ATEX and IECEx-certified systems applied to customised and innovative solutions for onshore and offshore transfer systems.

Atos provides innovative electro-hydraulic systems for marine loading arms for onshore and offshore use with several applications in the Oil & Gas industry.

Customised hydraulic solutions include ex-proof stainless steel valves, global equipment certifications such as ATEX and IECEx, and ex-proof proportionals with on-board digital electronics with optional fieldbus communications.

Loading arms: essential systems for loading and unloading operations in oil terminals

Loading arms are devices used to load or unload oil or gas from tankers or storage stations. They can be installed on a fixed structure such as a refinery or oil terminal (onshore systems) or on offshore platforms.

Designed to facilitate safe and efficient loading/unloading without leakage or safety hazards, they can rotate and extend to serve different vessels sizes.

In order to be able to monitor and manage the internal loading/unloading process safely, loading arms must meet oil and gas industry stringent requirements using only explosion-proof devices with high reliability and corrosion resistance, such as ex-proof stainless steel valves certified to operate in hazardous environments according to applicable international standards.