EPACK Prefab’s prefabricated solutions offer distinct advantages over traditional construction methods, including faster build times, cost savings, and enhanced sustainability. Unlike conventional methods with high land and labour costs, prefabrication accelerates project completion by up to 50 percent, reduces carbon emissions, and minimises environmental impact.

How has the adoption of prefabricated building technology evolved in India over the past decade?

Prefabricated construction has witnessed remarkable growth in India. The government’s emphasis on sustainable construction has pushed the use of Prefabricated Engineered Buildings (PEBs) and other green construction practices. This technology has gained traction in warehousing and industrial projects due to its efficiency and rapid construction timelines. Additionally, PEBs have addressed quick accommodation needs effectively. Despite this progress, there remains significant potential for further expansion. Continued government support, including subsidies for green construction, stricter sustainability regulations, and increased awareness of PEB benefits, could further commercialise this technology and extend its use in the real estate and tourism.

EPACK Prefab provides various products, from site offices to cold storage rooms. What are the key differentiators of your prefabricated solutions compared to conventional construction methods?

Prefabricated construction stands out from conventional construction methods due to benefits such as cost-effectiveness, rapid construction timelines, and sustainability. The traditional approach faces high hard costs, including land acquisition, labour, and materials, constituting a substantial portion of total expenses. Prefabricated construction, in contrast, accelerates project timelines by 30 to 50 percent, reducing build times, weather delays, and labour-intensive activities. Additionally, prefab’s simultaneous site development and construction, automation, quality control, and efficient material supply contribute to its cost-effectiveness. Compared with conventional construction, prefabricated construction reduces carbon emissions by up to 60 percent, making it highly beneficial for the environment.

How do you ensure the quality and durability of prefabricated structures?

At EPACK, we practice advanced manufacturing processes, rigorous quality control measures, and the use of high-grade materials. Each component undergoes thorough testing to meet stringent industry specifications, ensuring it can withstand diverse and challenging environments. Additionally, our designs are tailored to address specific environmental conditions, such as extreme temperatures, high winds, or seismic activity, providing resilience and longevity to the structures. By combining innovative technology with expert craftsmanship, we deliver durable prefabricated solutions that can perform reliably in any setting.

EPACK Prefab uses advanced technologies like Light Gauge Steel Framing (LGSF) and PUF insulated panels. How do these technologies enhance the efficiency and performance of your structures?

LGSF provides a strong yet lightweight framework, allowing for faster construction and greater design flexibility while maintaining structural integrity in diverse environments. PUF insulated panels offer superior thermal insulation, reducing energy consumption for heating and cooling and improving overall resource efficiency (saving of natural resources like sand, limestone, water, etc.): Eco-friendly technology, leading to almost zero pollution. Its structures are designed for 25 years of life and can be designed for 50+ years, too. Additionally, it is very easy to execute.

Can you elaborate on the sustainability aspects of your prefabricated structures?

Prefabricated structures are built in a controlled factory environment and then assembled on-site. This construction method minimises material waste, reduces on-site pollution, and lowers energy consumption through efficient manufacturing practices. Our structures use eco-friendly materials, such as steel, and are engineered to enhance thermal insulation, substantially reducing the need for heating and cooling and thereby conserving energy. The materials used are also reusable, making them sustainable and economical even in the long run, particularly in cases of building demolition. Additionally, the controlled prefabrication environment ensures superior quality and durability, leading to a longer lifespan and less frequent need for repairs or replacements, reducing the overall environmental footprint.

What are the most common challenges when customising prefabricated solutions, and how do you overcome them?

Some of the challenges include environmental considerations and compliance with local regulations. To address these, we adopt a collaborative approach, engaging clients early to understand their specific needs and using advanced design software to align solutions accordingly. We also work closely with local authorities to ensure all regulatory standards are met and maintain strong communication with all stakeholders throughout the project. By proactively tackling these challenges, we ensure that our prefabricated solutions are precisely tailored to client specifications and fully compliant with all necessary standards.

For more information, visit: https://www.epack.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Avians is a pioneering manufacturer and provider of solutions for high-end automatic entrance doors and loading bay equipment.

With an unwavering dedication to innovation, service, and excellence, Avians take pride in delivering top-notch products. Their high-end automatic doors are renowned for setting industry benchmarks and leading trends. At Avians, they focus on Sustained Innovation, service orientation, and unwavering Commitment to delivering world-class solutions that redefine the way we experience doorways.

Avians Product Range:

High-speed doors: Avians High-Speed Doors with the CE standard are designed for safe, fast, efficient, and simple operation on any internal busy doorways. We manufacture products that provide durable, fast and efficient entrance solutions. These high-speed doors can be used inside and outside in sheltered areas with low wind loads and moderate temperatures. High-speed roll-up door curtains are of high quality and have high tear tensile strength PVC material.

Rolling shutters: Avians Rolling Shutters are an ideal solution for environments where consistency is essential. At the same time, they enhance the overall appearance, complementing any modern architecture while adhering to CE-certified standards. Various rolling shutters are available in M.S / G.I/S.S / Double wall insulated aluminium/ galvalume / Transparent / Grill & perforated material. These can be integrated with operational accessories like pull cords and remote control.

Fire-rated rolling shutters & sliding doors: When protecting premises during fires economically, safely, and efficiently, fire-rated shutters/doors are the best closing system. Avians fire-rated shutters help prevent loss of life and property damage by stopping the fire from spreading and creating partitions. BS 476 part 22, Tested in Warrington Fire Research Centre UK, has 2 hrs and 4 hrs fire-rated resistance.

Sectional overhead doors: Avians Industrial Sectional Overhead Doors are made of steel panels, guaranteeing maximum security and reliability. The double-skinned PUF (polyurethane foam) core design is heat-insulating and particularly suitable for heated halls. These doors provide good air tightness and insulation. They can also be supplied as fully covered or semi-glazed versions for optimal daylight exposure.

Dock Levelers: Avians Dock Leveler is straightforward and efficient equipment designed for Indian conditions, ensuring continuous operations. It facilitates easy vehicle loading and unloading while also significantly reducing dispatch time and vehicle exports. This high-quality docking system offers an optimal cost/performance ratio, meeting all the latest European standard EN 1398 requirements. It is CE-marked and operates with just a single push button.

Dock house, dock seal & shelters: Avians offers CE-certified Dock Shelters suitable for various uses and situations, including protection from outside cold conditions, heat, rain, breeze, snow, and dirt. Our range of Dock Shelters and Dock Seals, including retractable and inflatable dock shelters, effectively seal the space between the truck, trailer, and building, making them ideal for sites with a tight seal. Additionally, the design of dock seals takes up minimal space outside the dock, making them a practical choice for areas with limited space.

Motorised entrance gates: Automatic gates with CE-certified standards regulate access into secure areas. Typically, these gates are installed at the entrance of a facility. Motorised gates are suitable for industrial, commercial, and residential premises. Motorised sliding gates provide a safe and convenient entrance system, making hands-free access their major advantage. Sliding gates can be integrated with PLC and BMS (building management systems). K4/K8/K12 Crash Rated Gates are also available for enhanced perimeter security.

Hangar doors: Avians hangar doors are paramount for the aviation sector due to their specially designed features. They are specially designed for easy, smooth, and safe operation, requiring minimal service and maintenance. Tailored exclusively for the aviation sector, these doors are crafted with the finest quality materials and the latest technology, ensuring optimum safety features and functionality. They play a vital role in maintaining aviation facilities’ security and smooth operations.

Automatic sliding doors: Avians Sliding doors are designed for larger opening dimensions, making them ideal for spaces where door parking is impossible. These doors feature double-walled panels with various insulation options, making them a perfect solution for buildings requiring good insulation. In addition to their noiseless and smooth operation, sliding doors offer a great customised solution for entrance door automation systems.

Automatic folding doors: Avians sliding doors are designed for bigger openings, perfect for places with limited door parking space. These doors have double-walled panels with different insulation choices, making them an excellent solution for buildings that need effective insulation. They operate smoothly and quietly, providing a custom-made solution for entrance door automation systems, enhancing both functionality and aesthetics.

Physical access solution: Avians provides a wide range of Physical Access Solutions specifically designed to regulate and control entry into secured areas. These solutions encompass products such as access control systems, turnstiles, barriers, and other effective measures to manage entry and exit in diverse environments. These solutions suit various settings, whether it’s commercial buildings, industrial facilities, educational institutions, government offices, or more. With Avians’ comprehensive offerings, security and access control can be efficiently maintained to ensure the safety and protection of the designated areas.

Vehicular access solution: Avians specialises in Vehicular Access Solutions for efficient and secure vehicle entry and exit control. These solutions improve traffic management and enhance security in various settings, such as parking facilities, commercial establishments, high-security sites, and industrial locations. Avians’ expertise ensures smooth operations and optimised access control, making premises safer and traffic flow smoother.

Please feel free to connect with the team for any support on the High-Speed Door requirement or queries: Email: sales@avians.co.in Contact No. 8390300400, Website: www.avians.co.in

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The demand for TMT bars is soaring, reaching new heights, with trends such as eco-friendly practices and the incorporation of micro-alloying elements leading the way. This article provides an overview of the booming TMT market in India and explores the promising opportunities it presents for construction professionals.

Choosing premium TMT bars is essential for guaranteeing the durability and strength of any project, be it residential or commercial construction. Given the varied climate and difficult topography, it is imperative to select TMT bars that can withstand the test of time to protect investment for years to come.

TMT bars offer additional safety and stability in regions prone to seismic activity or extreme weather conditions. Their superior ductility allows them to absorb and dissipate seismic energy, reducing the risk of structural failure during earthquakes. Additionally, their resistance to corrosion and high-temperature performance ensures that structures remain robust and reliable under challenging environmental conditions.

The need for TMT bars in India is growing due to private sector investments and the government’s emphasis on building high-quality earthquake-resistant structures. As the best option for reinforcing concrete structures, TMT bars are renowned for their exceptional strength and longevity. Beyond maintaining structural integrity, they improve safety, offer superior corrosion resistance, remarkable ductility and elongation, and are reasonably priced and dependable over the long run.

Market trends

The consumption of TMT bars in India saw a notable rise, with 50.3 million tonnes (MT) used in FY23 compared to 46 MT in the previous fiscal year. This growth is attributed to increased government-backed infrastructure projects, housing schemes, and urbanisation. During the same period, domestic production of TMT bars also increased to 51 MT from 47.2 MT in FY22. This uptick underscores the steel industry’s capability to meet rising demand, with TMT bars constituting a significant portion of total steel production. In FY23, out of 123 MT of steel produced, 52 MT were TMT bars and rods.

As Er. Abinash Mishra, Chief Marketing Officer at Captain Steel India Limited, says, TMT bars offer a blend of strength and flexibility crucial for earthquake-prone regions. The 600 EQR rebars provide superior protection against seismic forces, while FBE-coated rebars address corrosion challenges, significantly extending the lifespan of steel structures.

One of the significant trends reshaping the TMT bar industry is the use of micro-alloying elements. These trace elements, such as vanadium, titanium, niobium, zirconium, boron, molybdenum, and rare-earth metals, enhance TMT bars’ strength, durability, and performance. For instance, vanadium improves strength by forming robust carbide compounds, while titanium refines the grain structure, promoting uniformity. Niobium enhances toughness and weldability, and zirconium controls grain size during heat treatment. Boron increases hardenability, molybdenum improves strength and corrosion resistance, and rare-earth metals contribute to grain structure and impurity removal. Incorporating these elements makes TMT bars suitable for high-stress environments, extreme weather conditions, and seismic zones.

Precision in rolling and quenching processes is essential for TMT bar production. Automated technologies have significantly improved control over pressure and temperature, resulting in uniform cooling and superior mechanical properties. Automated quenching systems prevent internal stress and enhance the overall quality of the bars, contributing to their durability and performance.

Another important trend is the application of corrosion-resistant coatings. Fusion-bonded Epoxy (FBE) coatings provide a protective layer that shields TMT bars from rust and corrosion, particularly in humid or coastal regions. This uniform application ensures extended durability and reduced maintenance costs, making TMT bars more reliable in challenging environments.

Automating material handling, including conveyor systems and robotic arms, has revolutionised manufacturing. These innovations enhance load capacity, reduce manual errors, and improve productivity, setting a new standard for efficiency and accuracy in TMT bar production.

The integration of smart sensors with TMT bars represents a cutting-edge trend. These sensors provide real-time data on load distribution, temperature, and structural stress, allowing for better monitoring and maintenance. This technology helps ensure construction projects’ long-term performance and safety, offering valuable insights for engineers and builders.

The environmental impact of steel production has led to a growing focus on sustainability. Leading TMT bar manufacturers are adopting greener practices to mitigate their environmental footprint. Recycling steel is a significant initiative, reducing reliance on new raw materials and minimising waste. Using renewable energy sources in production processes helps lower greenhouse gas emissions. Optimising production processes to reduce waste and treating by-products before release also contribute to a more sustainable industry.

Demand drivers

Urbanisation is a major driver for the increased demand for TMT bars. The expanding urban population and the development of smart cities are fueling the need for high-quality construction materials. Government initiatives such as the Smart Cities Mission and Pradhan Mantri Awas Yojana (PMAY) are also contributing to this demand, particularly in large-scale infrastructure and housing projects. Furthermore, the booming real estate sector is significantly increasing the use of TMT bars in construction.

Key properties of TMT bars

TMT bars are known for their exceptional strength, which is attributed to the hardened martensite layer formed during the thermomechanical treatment. This strength allows them to support heavy loads and withstand significant external forces, making them suitable for high-stress applications in construction.

Their impressive ductility enables them to deform under stress without fracturing, preventing sudden failures and ensuring structural safety under bending, twisting, or seismic forces. The self-tempering process further enhances ductility by refining the bars’ microstructure, allowing them to bend and stretch without compromising integrity.

Corrosion resistance is a major consideration in construction, and TMT bars are designed to resist corrosion effectively, extending their service life even in harsh environments. The controlled cooling process reduces internal stresses, minimising the likelihood of corrosion.

TMT bars are highly weldable and bendable, making them versatile for various structural configurations. Their refined microstructure ensures that welding does not compromise strength or ductility, and their bendability allows them to be shaped according to design requirements.

In terms of fire resistance, TMT bars maintain their strength at elevated temperatures, which is crucial for ensuring structural integrity during fires and contributing to safer evacuation and firefighting efforts. Their enhanced seismic resistance makes them effective in absorbing and dissipating seismic energy, reducing structural damage during earthquakes and improving safety.

The ribbed surface of TMT bars provides excellent bond strength with concrete, ensuring effective load transfer and contributing to overall structural stability. Additionally, the high tensile strength of TMT bars allows for fewer bars than traditional mild steel reinforcement, resulting in reduced material and labour costs and faster construction timelines.

Challenges

Despite their benefits, TMT bars face several challenges. Variations in raw material costs, such as iron ore and coal, can impact production costs and profitability. Manufacturers also face regulatory compliance with diverse standards and certifications. Additionally, intense market competition among numerous players puts pressure on pricing and profit margins.

Testing, standards, and certifications

Several tests are conducted to ensure the quality and performance of TMT bars. The tensile strength test measures the maximum load a TMT bar can withstand before breaking, assessing its suitability for construction. The elongation test determines the bar’s deformability without fracturing, indicating its ductility. The bend test evaluates the bar’s flexibility and ability to withstand bending forces without cracking. The corrosion resistance test assesses the bar’s resistance to corrosion from environmental elements, ensuring long-term durability.

TMT bars in India are governed by specific standards set by the Bureau of Indian Standards (BIS) and international organisations. IS 1786 specifies requirements for high-strength deformed steel bars and wires used in concrete reinforcement, outlining mechanical properties, chemical composition, dimensions, and tolerances. The revised version, IS 1786-2008, establishes requirements for hot-rolled steel bars for concrete reinforcement. International standards such as ASTM A615 and BS 4449 cover deformed and plain carbon steel bars for concrete reinforcement, specifying mechanical properties and dimensions. By understanding the advantages, properties, and challenges associated with TMT bars, stakeholders can make informed decisions to enhance construction projects’ durability, safety, and efficiency.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Since 2007, Captain Steel has been at the forefront of TMT bar manufacturing in India. Leveraging cutting-edge German Thermex technology, the company produces high-quality TMT bars that are the backbone of resilient structures nationwide.

Can you provide an overview of your company’s history and experience in manufacturing TMT bars?

Captain Steel has established itself as a premium TMT bar manufacturer in India. Our commitment to quality and innovation is evident in every product we produce. Since our inception in 2007, we’ve harnessed state-of-the-art German Thermex technology to create superior-quality TMT bars that meet the most stringent industry standards. Our production facilities in West Bengal and Bihar enable us to efficiently meet the growing demands of the Indian construction industry. Our TMT bars have become the foundation of countless durable and reliable structures across the nation.

With advancements in steel manufacturing, what are the latest innovations that have significantly improved the strength and durability of steel used in construction?

Advancements in steel manufacturing, such as Thermo-Mechanically Treated (TMT) bars, 600 EQR rebars, and Fusion Bonded Epoxy (FBE) coated rebars, have greatly enhanced the strength and durability of steel used in construction. TMT bars offer an ideal balance of strength and flexibility, making them crucial in earthquake-prone regions. The 600 EQR rebars, with their high strength and ductility, provide superior protection against seismic forces, ensuring structural safety. FBE-coated rebars address the challenge of corrosion by forming a protective barrier that significantly extends the lifespan of steel in harsh environments. These innovations by Captain Steel India Limited ensure the durability, safety, and longevity of modern construction projects.

How are steel manufacturers integrating sustainable practices into their production processes to reduce environmental impact?

Steel manufacturers are increasingly integrating sustainable practices to reduce environmental impact. They adopt energy-efficient technologies like electric arc furnaces (EAFs) that use recycled scrap steel, significantly lowering carbon emissions. They also implement waste heat recovery systems to minimise energy consumption and use closed-loop water recycling to reduce water usage. Additionally, manufacturers are focused on reducing waste through comprehensive recycling programs for by-products like slag. These efforts decrease the environmental footprint and contribute to more sustainable and eco-friendly steel production processes.

What are the latest advancements in corrosion-resistant coatings for Steel Bars? How do these coatings enhance durability and extend the lifespan of steel structures in harsh environments?

The latest advancements in corrosion-resistant steel bars coatings include Fusion Bonded Epoxy (FBE) coatings. FBE-coated rebars offer superior protection against corrosion by forming a tough, continuous barrier on the steel surface, preventing moisture, salts, and chemicals from reaching the metal. This coating is applied through a powder coating process, which ensures a uniform and durable protective layer. In harsh environments, such as coastal areas or industrial settings, FBE-coated rebars significantly enhance the durability of steel structures by reducing the risk of rust and corrosion, extending their lifespan and reducing maintenance costs. These coatings ensure that steel bars maintain structural integrity and performance over time, even in the most challenging conditions.

What advancements have been made in developing self-healing and self-repairing mechanisms for Steel Bars? How do these technologies contribute to maintaining structural strength and integrity over time?

Advancements in self-healing and self-repairing mechanisms for steel bars are still in the early stages of development and will take time to become widely adopted. One promising approach involves incorporating microcapsules containing healing agents within the steel. When damage occurs, these microcapsules break open, releasing the healing agents that react with the surrounding material to seal cracks and restore the bar’s integrity. Although this technology shows great potential for maintaining structural strength and reducing the need for repairs, it will require further research and testing before it can be fully integrated into mainstream construction practices.

In the context of smart construction materials, how are Steel Bar manufacturers leveraging nanotechnology to enhance performance characteristics such as toughness, thermal stability, and resistance to chemical degradation?

Steel bar manufacturers are exploring nanotechnology to enhance performance characteristics like toughness, thermal stability, and resistance to chemical degradation. These bars can achieve superior strength and durability by incorporating nanoparticles, such as carbon nanotubes, into the steel matrix. Nano-coatings are also being developed to protect steel from chemical degradation. However, this technology is still in its early stages and will take time to become widely adopted in construction.

How does integrating digital monitoring systems enhance Steel Bars’ quality assurance and performance evaluation during production, storage, and construction phases?

Integrating digital monitoring systems has revolutionised quality assurance and performance evaluation for steel bars across their entire lifecycle, from production to construction. In production, real-time sensor data ensures precise control over key parameters like temperature and composition, resulting in consistent, high-quality steel. IoT-enabled sensors monitor environmental conditions during storage, preventing quality degradation by ensuring optimal storage conditions. In construction, RFID tags and embedded sensors track each bar’s history and monitor stress in real-time, providing valuable insights into the structural health of the building. This continuous monitoring allows for early detection of potential issues, enhancing the durability and safety of steel-reinforced structures while enabling data-driven improvements in manufacturing and construction processes.

For more information, visit: https://www.captainsteel.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The ZAXIS 38U is designed for maximum performance and efficiency, combining revolutionary technology with durable construction to provide improved productivity and ease of use across various applications.

Tata Hitachi introduces the all-new 3.5-ton Mini Excavator ZAXIS 38U. This machine is specifically built for Indian application conditions and to satisfy the changing needs of the construction sector. The ZAXIS 38U provides unrivalled performance, efficiency, and durability, making it an excellent choice for various applications.

The ZAXIS 38U compact excavator combines innovative technology with a strong design, resulting in excellent productivity and ease of operation in restricted situations. The ZAXIS 38U is designed with a compact, low tail swing radius to operate efficiently in limited locations, making it suitable for various applications such as urban construction, landscaping, and utilities. This model’s high-output Japanese engine provides outstanding power and performance, while an innovative hydraulic system ensures smooth and efficient operation, increasing total productivity on the job site.

Tata Hitachi prioritises operator comfort and safety in the ZAXIS 38U. The machine has a large canopy with ergonomic controls to alleviate operator fatigue during lengthy working hours. It also includes modern safety measures such as a strengthened structure and a rear-view camera for improved visibility.

The ZAXIS 38U is also developed with fuel efficiency in mind, which lowers operational expenses and decreases environmental effects by meeting the most recent emission requirements. Maintenance is simplified with easily accessible service locations, saving downtime and assuring the ZAXIS 38U’s continued optimal performance.

Siddharth Chaturvedi (General Manager, Marketing, Tata Hitachi) says, “The introduction of the ZAXIS 38U is a testament to our commitment to delivering innovative and reliable solutions that meet the evolving needs of our customers. This model is not only designed to perform but also to ensure the highest levels of efficiency and safety on the job site.”

The ZAXIS 38U delivers exceptional performance thanks to its renowned Yanmar engine, improved hydraulic system, and increased digging reach and depth. Its appealing appearance, multi-functional monitor system, broad opening covers, and sturdy safety measures provide comfort and ease of maintenance. The excavator has outstanding manoeuvrability and versatility because of its short tail swing, boom swing feature for small places, shorter distance between the blade and bucket, compatibility with a wide range of attachments, and ease of transportation. It also offers a high return on investment due to its great fuel efficiency, low operating expenses, and increased resale value.

To summarise, the ZAXIS 38U helps clients keep ahead of the competition by delivering on its promises of performance, fuel efficiency, and cost savings.

For more information, visit: https://www.tatahitachi.co.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

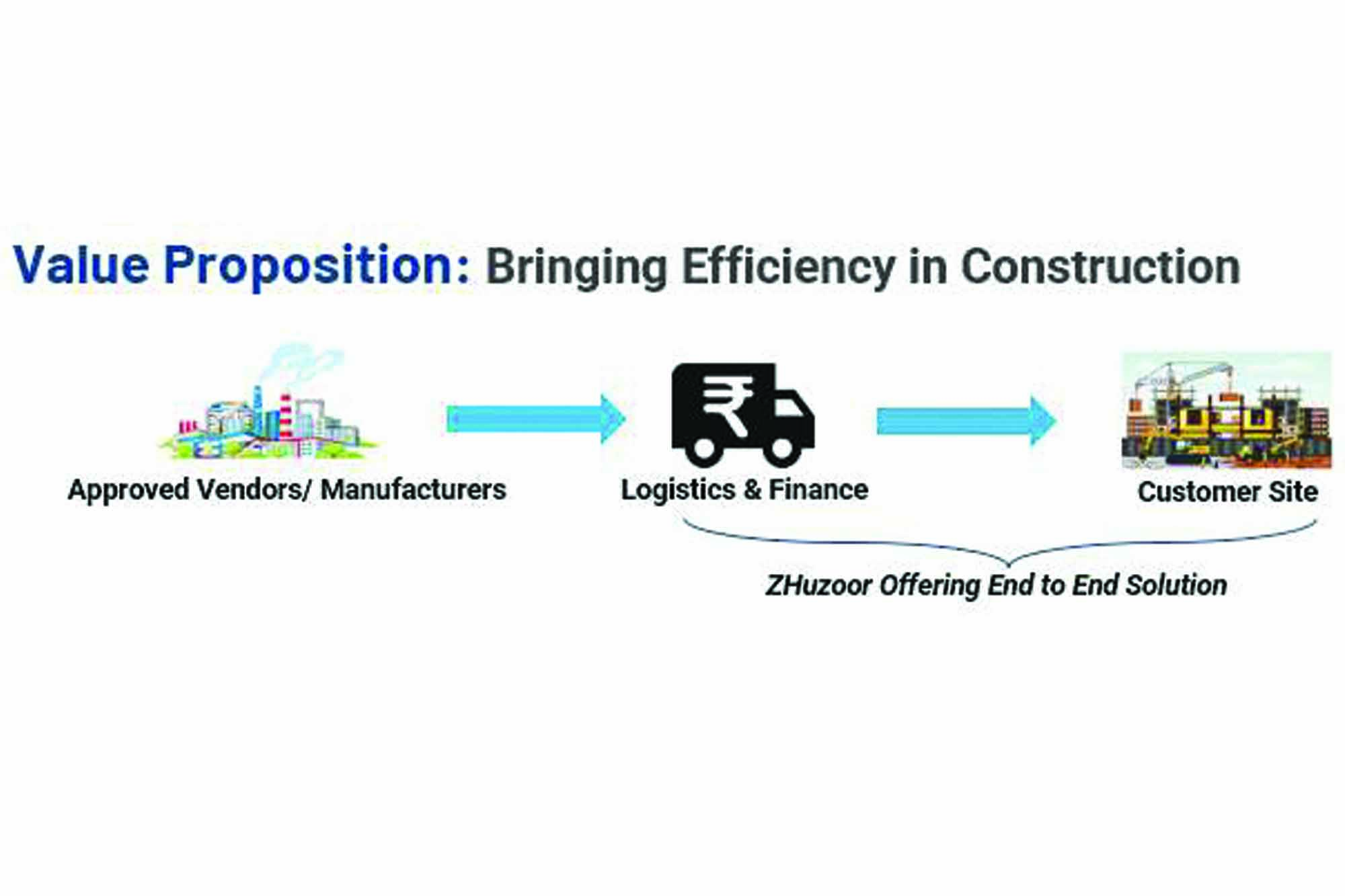

By consolidating products from various brands and offering flexible payment options, Zhuzoor alleviates financial stress for contractors and drives efficiency with its digital solutions.

How does your company transform the construction materials market and support infrastructure contractors and builders?

We are not just another player in the construction materials market; we are a transformative force that simplifies procurement complexities. Acting as a comprehensive marketplace, we aggregate products from various brands, offering various options under one roof. From TMT bars to structural steel and pipes to crash barriers, we cater to every need of infrastructure contractors and builders.

One of our standout features is our commitment to easing the financial burden on our customers. By providing materials on credit terms, LC, and BG, we enhance liquidity for contractors, allowing them to focus on project execution rather than financial constraints. Additionally, our dedicated customer website and application offer transparency and real-time tracking of material movements, marking a significant step towards digitisation in the construction industry.

Our mission is to revolutionise material procurement in the infrastructure and construction industry while resolving our customers’ pain points. We envision ourselves as one of the industry’s most trusted and reputed B2B aggregators, always upholding our core values of integrity, teamwork, respect, customer service, diversity, inclusion, and social responsibility.

How do you address infrastructure companies’ critical challenges and enhance their procurement processes?

We tackle the critical challenges faced by infrastructure companies every day. Our deep understanding of industry hurdles — such as fragmented material sourcing, logistical bottlenecks, and cash flow constraints — positions us as a strategic partner for infrastructure development projects of all scales. By offering quality products from approved manufacturers, flexible payment terms, and efficient delivery options, we empower contractors to overcome traditional procurement challenges and focus on achieving project success.

What are the key milestones and achievements that highlight your rapid growth?

While Zhuzoor was officially incorporated in December 2021, our commercial operations started in June 2022. In just eight months, we achieved a remarkable turnover of INR 100 Crores, showcasing our rapid rise in a competitive market. Our growth trajectory remained strong throughout the fiscal year FY23, with revenues surpassing INR 250 Crores. By March 2024, our revenue stream surged past INR 550 Crores, reflecting our sustained momentum and market impact.

Beyond these financial milestones, our influence and partnerships within the industry tell a compelling story. With over 120 valued customers and a robust network of more than 60 suppliers across 10+ product categories, Zhuzoor has emerged as a transformative force in the B2B ecosystem. The speed of our ascent and our significant market footprint within a short period highlight our exceptional journey in the business world.

What are your plans for expanding its market presence and ensuring continued growth in the coming years?

Our growth prospects extend well beyond our current North and Eastern India stronghold. Our strategic roadmap includes a focused effort to expand our presence in Western and Southern India through local offices, a team of experienced sales professionals, and strategic alliances with manufacturers. This expansion is driven by our unwavering commitment to our core value propositions, which will enhance customer acquisition and consolidate our market share.

Our strategic diversification into new product categories will further boost our growth trajectory and market relevance. We remain dedicated to innovation, customer satisfaction, and industry leadership, with plans for strategic expansions, deeper market penetration, and ongoing investments in technology and talent.

Our impact on the construction industry is both tangible and extensive. By revolutionising material procurement processes, we contribute to faster project timelines, cost optimisation, and improved project outcomes. Our role as a trusted partner for infrastructure companies highlights the significant value we bring to the broader ecosystem of construction and development.

For more information, visit: https://zhuzoor.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Suhas Dhuri, with 45 years in concrete innovation, has pioneered high-performance solutions, including M-75 grade concrete and ultra-thin pavements, and continues to advance concrete technology.

Suhas Dhuri began his civil engineering career with the ACC R&D section in 1980, where he worked on numerous R&D projects and concrete development. He has almost 45 years of expertise in the concrete sector. The Suhas switched to ready-mix concrete in 1995, and by 1998, they were part of the team that developed one of India’s first ready-mix applications. Creating M-75-grade concrete for the JJ flyover was a watershed moment in his career, as it was both innovative and unique at the time. While M-90-grade concrete is now widely used, producing M-75 back then posed major obstacles.

Dhuri founded his concrete consulting firm in 2005, offering technical assistance to the concrete sector. As concrete technology has advanced considerably, people are increasingly required to manage it properly—an act formerly held by RCC consultants. Suhas’ consulting meets this requirement by providing professional services for various projects around India.

High-Performance Concrete (HPC)

According to him, high-performance concrete is critical to increasing the longevity of construction projects. Structural issues generally necessitate frequent repairs; however, high-performance concrete can greatly reduce the need for these repairs, extending the structure’s life.

Recognising the advantages of high-performance concrete, MSRDC discovered that employing M-75-grade concrete may produce better outcomes than normal concrete, a revolutionary notion at the time. They introduced worldwide tests for this concrete, and Mr Dhuri’s team tested it extensively for six months despite the limited availability of high-quality admixtures.

Since then, chemical admixtures have advanced dramatically, with the development of third- and fourth-generation polycarboxylate (PC) admixtures. Initially, they focused on sulfonated naphthalene formaldehyde (SNF) admixtures.

Using his significant R&D knowledge, he persuaded Bharat Diamond Bourse that concrete is a sophisticated substance that demands management expertise. They displayed a thorough understanding of raw components and their impacts on concrete. As a result, Bharat Diamond Bourse decided to detach the concrete supply from the primary contractor and assign it to Suhas’ team. In 1993, they developed high-performance, long-lasting concrete for the Bharat Diamond project.

Ultra-thin white topping

He says traditional pavements typically employ M40 grade concrete, as specified by the Central Building Research Institute (CBRI), with a thickness of approximately 300 mm. Using hybrid concrete, such as M60, the pavement thickness can be decreased to 50–75 mm. This provides a significant advantage, allowing for the restoration of old roads while reducing the risk of cracking. Mr Dhuri’s team initially implemented this strategy in Thane in 2006, and the road has operated admirably since then, with no potholes. This result demonstrates the significant advantages of ultra-thin, broad pavement overlays.

Thermal cracking

Controlling the temperature is crucial. The first stage is to design a concrete mixture. Ordinary Portland Cement (OPC) produces a quantity of heat during hydration. To address this, it is recommended to lower the amount of OPC used and mix additional cementitious elements that can reduce heat generation while keeping the requisite strength. Another option is to use an ice-concrete mix and modify the other parameters accordingly. The first step in this method is to create a concrete mix that includes a substantial amount of extra cementitious elements and high-performance admixtures.

Rheological properties

Admixtures interact with cement particles by generating charges that repel each other, enhancing workability without altering water content. However, adding viscosity-modifying compounds significantly affects the concrete’s rheological properties. In certain cases, these advanced admixtures can eliminate the need for extra energy in concrete consolidation, showcasing their unique ability to create self-compacting concrete, concludes Mr. Dhuri.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Godrej & Boyce TUFF brand pioneers sustainable, customisable RMC solutions certified by Green Pro. It utilises sophisticated technology and circular economy methods to produce high-quality, eco-friendly concrete products.

Please provide an overview of your current solutions in the concrete segment.

The Godrej TUFF Construction Materials brand provides a groundbreaking range of customisable and environmentally friendly solutions. Godrej & Boyce’s Construction company, which is part of the Godrej Enterprises Group, has obtained the Indian Green Building Council’s (IGBC) ‘Green Pro’ certificate for Ready-Mix Concrete (RMC) products such as Enviro TUFF, Xtra TUFF, and Easy TUFF.

Enviro TUFF is an eco-friendly concrete mix made by integrating industrial byproducts such as recovered Fly Ash or Grounded Granulated Blast Furnace Slag (GGBS). It reduces a project’s carbon footprint while improving its Green Building Rating. Similarly, we offer Xtra TUFF, a high-strength concrete version created utilising various cementitious material blends, resulting in dense, refined microstructures. Xtra TUFF is utilised in projects that demand thinner RCC beams and columns, such as high-rise buildings.

The Maharashtra State Electricity Board gave Green Energy Certificates to six of our Godrej Ready Mix Concrete Plants. We used the Circular Economy design concepts of ‘Recover, Recycle and Rebuild’ to recycle concrete trash into prefabricated concrete goods like construction blocks, pavers, culverts, ducts and other bespoke precast concrete products. We have established an automated Recycled Concrete Materials (RCM) manufacturing factory in Vikhroli, Mumbai. This industrial plant produces concrete blocks for walls and pavers from concrete rubble recycled from demolished concrete structures from building and infrastructure projects that would otherwise end up in overflowing municipal landfills. We have already recycled over 30,000 metric tonnes of concrete waste using circular economy concepts.

We are among the first RMC sectors to transition to 100% green energy. Similarly, our Recycled Concrete Materials (RCM) plant in Vikhroli West, Mumbai, uses only green energy.

How does your product range cater to the needs of different types of construction projects?

We recognise that each building job is unique. That is why we provide customised RMC solutions to match the unique needs of each project. Our skilled engineers collaborate with clients to fully grasp their requirements. We create customised RMC mixes that ensure optimal performance and cost-efficiency using this collaborative approach.

In addition to the quality of RMC, client-centricity is important to our company processes. For over a decade, we have conducted third-party customer satisfaction surveys (CSS) through Nielsen across all of our three lines of business. Customer feedback has supplied us with insights that have enabled us to implement relevant improvement activities to improve our service quality. As a result, we have achieved best-in-class Net Promoter Scores (NPS) across all three of our business lines. Our NPS scores are 70 for Construction Materials, 89 for Real Estate Leasing, and 92 for Real Estate Development.

Over the last few years, our Construction Materials team has launched some pioneering initiatives to address our clients’ difficulties in the Real Estate and Construction industries. To deliver a seamless client experience, we used digital technology to create a one-of-a-kind mobile application called the ‘Godrej Go Tuff’ app. The ‘Godrej Go Tuff’ app includes convenient features such as real-time delivery tracking, which ensures transparency in optimising and managing every step of construction material supply from order to delivery. Godrej Construction’s Concrete Testing ‘Squad’ Van provides on-site testing services. It allows our customers to complete the approval process for ready-mix concrete mix design more quickly, as the results of mix design trials, cube testing, compressive strength, and sieve testing may be measured in hours.

What innovative technologies and practices do you employ to produce high-quality and durable concrete?

We have embraced cutting-edge technology by incorporating IoT devices and data analytics into our manufacturing operations. IoT is used to monitor mixer gearbox vibrations to predict gearbox failure, track the movement of transit mixers, deliver concrete and provide an estimated time of arrival (ETA) for the concrete ordered, and assist trucks in properly positioning on the weighing scale, allowing for accurate weighing. These advances allow for real-time monitoring of numerous parameters, resulting in exact control over the mixing and pouring processes. We continuously optimise our production procedures by studying data collected via IoT devices. This improves the quality of our RMC products and enables us to respond quickly to any deviations, assuring constant quality across production cycles.

Our top aim is to ensure the highest quality RMC goods. Our RMC plants are certified by the Quality Council of India (QCI). Regular material testing, on-site inspections, and compliance with industry standards are all part of our quality control efforts. These stringent processes ensure that our RMC products are of the highest quality and comply with all applicable norms and regulations. Our RMC Central Quality Laboratory in Vikhroli, Mumbai, recently acquired a Certificate of Accreditation from the National Accreditation Board for Testing and Calibration Laboratories (NABL) per ISO/IEC 17025:2017. NABL accreditation demonstrates our commitment to providing high-quality products and services.

How is Godrej & Boyce incorporating sustainable practices into its RMC and concrete production processes?

Environmental stewardship is important to our business operations. We have introduced environmentally friendly production techniques and energy-saving technologies to reduce our carbon footprint. We also follow strict waste management guidelines and recycle water and other commodities.

Given rising infrastructure demands, the Ready-Mix Concrete (RMC) sector is approaching a tipping point. Ongoing trends, such as urbanisation, sustainable construction, and the requirement for quick project completion, create enormous prospects. The RMC concrete industry is on the verge of a significant transition, with an emphasis on sustainability, efficiency, and innovation. New product advancements and technologies, including smart concrete, 3D printing, carbon capture and utilisation, self-healing concrete, and recycled and green concrete, are poised to transform how we create buildings and infrastructure. At Godrej Construction, we are strategically aligned with these trends. We intend to capitalise on these opportunities by focussing on developing specialised goods in our sustainable line of TUFF Concrete solutions that address specific infrastructure requirements, guaranteeing that our clients receive the most efficient and dependable products.

What cutting-edge mix design methodologies are enhancing RMC performance?

As a specialised player in Ready Mix Concrete, we have always prioritised ongoing progress in concrete mix design, ensuring that the quality requirements for a project are continuously reached. We worked hard to create sustainable concrete mixtures that reduce carbon footprints while maintaining performance standards. Eco-friendly options, such as our TUFF line of products built from recycled concrete, are IGBC Green Pro certified and have standards, strength, and other properties comparable to those made from virgin materials. We are thrilled to participate in the prestigious Mumbai Coastal Road project, for which we have provided 440 big precast concrete box culverts weighing between 30 and 35 metric tonnes. These box culverts were utilised to construct a stormwater outfall into the Arabian Sea. The box culverts were designed to endure the severe coastal environments and significant traffic loads. To contribute to sustainable development, our concrete mix design uses up to 10 percent recycled concrete mix to produce these box culverts. This consideration was factored into the design of these concrete structures in close collaboration with the relevant project consultants and authorities.

For more information, visit: https://www.godrejenterprises.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Reducing fuel consumption and carbon footprints is crucial for green mining. MMD’s In-Pit Sizing and Conveying (IPSC) technology offers a solution by replacing traditional drum trucks and shovels, leading to significant diesel savings and emission reductions. Discover how MMD’s innovations are advancing greener mining practices.

Can you elaborate on how MMD’s products contribute to sustainable mining?

Sustainable mining focuses on conducting mining operations to minimise environmental impact and support local communities. Our solutions, particularly the patented sizing technology and In-Pit Sizing and Conveying (IPSC) systems, are designed to reduce the reliance on traditional drum trucks and shovel combinations. This lowers carbon emissions and enhances safety on site while increasing throughput and productivity. Our technology significantly reduces operational expenditures, thereby promoting economic growth and wealth creation for future generations.

MMD has been in the industry for over 40 years. How have you seen mining evolve during this time?

Our journey began in 1980, focusing initially on underground coal applications in the UK. We developed compact, low-profile machines ideal for underground environments with limited headroom. Over the years, our technology has expanded globally, with over 2000 machines supplied across 120 countries and for 80 different minerals. Our success lies in understanding and adapting to local conditions while continuously innovating. We have introduced several products, like the Sizer and Bulk Ore Sorting systems, which integrate seamlessly with IPSC technology to enhance mining efficiency.

How is MMD addressing reducing fuel consumption and carbon footprint in mining operations?

Our IPSC technology reduces reliance on traditional drum trucks and shovels, significantly lowering consumption and reducing harmful gas emissions, which is crucial for maintaining ecological balance and improving the overall environmental footprint of mining operations. Although adopting such technology can be challenging, particularly in markets like India, we are committed to advancing and adapting these solutions to promote a greener mining industry.

Your company seems deeply engaged with the industry. How do you ensure you’re meeting the specific needs of your clients?

We work closely with mine planners, designers, and process engineers from concept to commissioning. Our approach involves sharing comprehensive information, including technical data and site footage, to demonstrate the benefits of our technology. In India, we use a bottom-up approach, engaging senior decision-makers and end-users to ensure that our solutions meet practical needs and enhance operational efficiency.

How do you support mining operations with your solutions?

We provide robust, plug-and-play solutions that integrate with existing systems. Our machines are designed for ease of maintenance and long-term sustainability. In India, we have installations operational for up to 30 years. We offer 24/7 support and preventive maintenance services to ensure optimal performance.

We aim to help clients achieve low carbon footprints and minimise harmful emissions. We work with them to set and achieve their environmental goals, ensuring our systems contribute to a more sustainable mining operation.

Can you tell us about MD Heavy Machinery India’s role within the global MMD network?

MD Heavy Machinery India is a crucial part of the MMD global network. While our contribution to the global revenue is modest, we are dedicated to promoting and implementing our technology. We’ve achieved notable milestones, such as supplying high-capacity equipment to major projects like the Sasam Ultra Mega Power Project and handling challenging materials in various applications. Despite some hurdles, such as slow adaptation in India, we are optimistic about future growth.

We initially invested around ₹ 70 crore in our Sri City facility, which has expanded significantly over time. The mining industry’s growth has generally been affected by various factors, including regulatory changes and market conditions. However, we remain committed to our strategic goals and anticipate improvements as the sector stabilises.

Are there any new product launches or developments on the horizon?

We are continuously innovating and expanding our product offerings. We are focused on developing new technologies that enhance mining efficiency and sustainability. We aim to stay at the forefront of industry advancements and provide cutting-edge solutions to our clients.

For more information, visit: https://www.mmdsizers.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Columbia Machine India is reinventing concrete production via cutting-edge technology and commitment to sustainability. Their batching, mixing, and recycling innovations meet strong demand while promoting eco-friendly construction techniques.

What are the latest advancements in concrete mixing and batching technology that enhance efficiency and quality on construction sites?

Columbia Machine India is a major producer and supplier of Concrete Batching Mixing Plants designed to work alongside our concrete block machines and wet presses. Our cutting-edge machinery is intended to produce a wide range of high-quality goods, such as hollow blocks, solid blocks, fly ash bricks, kerb stones, retaining wall blocks, and paver blocks. Furthermore, our Wet Presses excel in producing specialised goods such as kerb stones, saucer drains, paving slabs, and drain covers, ensuring versatility in various construction applications.

Our batching mixing plants are powered by an Allen Bradley PLC system and cutting-edge programming designed exclusively for precast applications. Our batching mixing units are fitted with sophisticated moisture control technologies to withstand difficult situations such as rainy seasons or fluctuating incoming material quality. These devices are intended to maintain ideal moisture levels, ensuring the manufacture of consistent and long-lasting concrete mixtures.

Our batching mixing plants are generally used in controlled production, generating high-quality goods with unparalleled efficiency. However, their utility extends beyond the manufacturing floor. These units are also used on-site for large-scale infrastructure projects, such as constructing retaining wall blocks for the National Highways Authority of India (NHAI). This adaptability enables our equipment to fulfil the demanding needs of factory-based manufacturing and on-site building, establishing Columbia Machine India as a reliable industry partner.

How is your company integrating sustainability practices into concrete manufacturing processes, such as reducing carbon emissions, incorporating recycled materials, or optimising energy use?

Many steel plant owners in India are turning to our machines for innovative industrial slag waste management solutions. Our sophisticated Batching Mixing Plants are designed to convert this byproduct into high-quality concrete mixes, creating long-lasting bricks, blocks, and pavers. This method maximises industrial slag’s utility and helps create a more sustainable construction process by repurposing what would otherwise be considered waste.

Furthermore, numerous of our customers who work near power plants are addressing the environmental difficulties posed by fly ash, a byproduct of power generation renowned for its potential to inflict considerable environmental damage. These customers can use our cutting-edge batching mixing systems to incorporate fly ash into manufacturing fly ash bricks efficiently. This reduces the environmental impact of fly ash disposal and produces a useful construction material that surpasses industry standards for strength and durability.

Our commitment to sustainability extends beyond simply providing trash management solutions. Customers are making tremendous environmental progress by implementing our technologies. They reduce their carbon footprint by converting industrial wastes such as slag and fly ash into usable construction materials. Furthermore, these environmentally friendly actions are being recognised by issuing carbon credits and giving our clients economic and environmental incentives to continue their efforts towards sustainable development.

We are happy to assist our customers in transitioning to more responsible and sustainable construction techniques, which will allow them to meet industry criteria and positively impact the environment.

Which infrastructure sectors, such as highways, metros, and real estate, are currently driving the demand for concrete equipment in India, and how is your company positioned to cater to these sectors?

The Indian government’s ambitious plan to connect all major cities via a vast and modern road network has prompted the construction of multiple flyovers on highways across the country. These large-scale infrastructure projects necessitate long-lasting and robust retaining walls to support the elevated structures. Leading construction corporations, soil stabilisation providers, and subcontractors have entrusted us with meeting this vital need. Our machines are well-known for producing high-quality retaining walls, ensuring these critical roads’ long-term viability and safety.

Parallel to the growth of the road network, the government has launched some metro projects to improve urban mobility. As a result, metro development is already ongoing in several cities throughout India. These projects necessitate building materials with remarkable strength and dependability. Our machine’s superior capabilities enable users to produce high-strength solid blocks with compressive strength exceeding 10 N/m². These durable blocks are delivered to contractors in charge of building metro stations, where structural integrity is critical.

Our machine’s adaptability and precision are not limited to huge infrastructural projects. Prominent builders and suppliers throughout India rely on our machines to produce many construction materials, including precious paver bricks, high-strength solid blocks, and ecologically friendly fly ash bricks. These goods are essential for real estate developments where quality and durability are critical. Builders can use our equipment to verify that their projects meet the highest quality standards, whether building residential complexes, business spaces, or public infrastructure.

We are happy to play an important part in India’s infrastructure development, supporting public and private sector projects with cutting-edge technology. Our commitment to quality and innovation guarantees that our customers may confidently take on the most difficult building problems, contributing to the nation’s progress and modernisation.

What are the most significant technological advancements and innovations in concrete machinery that your company has introduced or plans to meet the growing market demand?

We rely on the Vertical Mould Vibration principle, which greatly benefits our customers by allowing us to produce concrete blocks with remarkable strength and perfect dimensional correctness. This sophisticated process minimises the amount of cement used and reduces water absorption in the blocks, resulting in higher quality and economic effectiveness.

In addition, we have started manufacturing the Columbia Wil-El-Mil Wet Press at our Columbia Machine India site. This development is a game changer for the industry, particularly for prominent West cast manufacturers, because it gives them access to the world’s best wet press technology at a reasonable cost. Making this cutting-edge equipment available locally enables our customers to attain outstanding product quality while promoting sustainable practices.

What innovations are made in concrete production using recycled aggregates or other secondary materials?

Many historic buildings in India’s major cities have reached the end of their structural life and are being demolished to make room for modern, high-rise structures. The waste materials generated by these demolished structures are recovered and processed into aggregates of various sizes, helping to promote sustainable construction methods.

Recognising the potential of these recycled materials, major industry players have chosen our machine to make high-quality blocks, bricks, and pavers from these aggregates. Our machines are specifically designed to address the problems of using recycled materials, guaranteeing that the end products satisfy the highest strength, durability, and precision requirements. By incorporating our machines into their production processes, these enterprises promote the circular economy and lead the way in environmentally responsible building.

For more information, visit: https://www.colmac.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Empowering the mining industry with a robust range of ‘Bharat Ka Tire’.

Balkrishna Industries Ltd. (BKT), a global leader in the Off-Highway tire market and an Indian multinational business is excited to announce its participation in the 17th International Mining and Machinery Exhibition (IMME). The Confederation of Indian Industry (CII) will host this important event from October 23 to 26, 2024, at the Science City Exhibition Ground in Kolkata.

As one of the most prominent players in the off-highway tire industry, BKT is all set to showcase its extensive ‘Bharat Ka Tire’ product portfolio, which is ‘Built-in Bharat, Built for Bharat, and Building Bharat’, featuring cutting-edge solutions tailored to meet the diverse needs of the Indian mining sector. Attendees of IMME 2024 will have the unique opportunity to interact with the BKT team at OD5 and see firsthand the cutting-edge technology that defines BKT’s latest offers.

Commenting on the company’s participation, Rajiv Poddar, Joint Managing Director of BKT, remarked, “We are excited to be part of IMME 2024, especially when the mining sector in India is undergoing significant transformation. With the government’s focus on boosting domestic production and modernising mining operations, our latest tire technologies are designed to meet these evolving demands. Our robust, high-performance tires are engineered to enhance efficiency and safety in challenging mining environments. IMME offers us a valuable opportunity to connect with industry leaders, exchange ideas, and align our innovations with the future needs of the mining industry in India.”

With over three decades of experience in the Off-Highway tire market, BKT is regarded as a pioneer in innovation and dependability. The company’s dedication to cutting-edge technology and quality has cemented its reputation as a reliable industry leader. At IMME 2024, BKT invites participants to visit Booth OD5 to learn about the latest innovations in their tire solutions. The BKT team will be ready to discuss how their products may improve mining operations and fulfil industry-specific requirements.

For more information, visit: https://www.bkt-tires.com/in/en/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

CASE is transforming construction with IoT, telematics, and AI in equipment, optimising performance and minimising downtime while teaching operators to flourish with cutting-edge, technology-driven machinery.

How are smart technologies such as IoT and telematics integrated into excavators and backhoe loaders to enhance job performance and efficiency on the job site?

At CASE, innovation is a critical pillar that keeps us updated with the industry’s changing needs. Our use of telematics and remote technologies demonstrates our commitment to improving operational efficiency, productivity, and the overall user experience with our equipment. These modern systems give operators and fleet managers real-time information, allowing them to assess equipment utilisation, monitor performance, and improve security.

We have improved our backhoe loaders and compactors by implementing cutting-edge telematics such as Sitewatch, improving cabins, and making other practical improvements. This technology enables customers to remotely monitor machine status, measure fuel use, and receive service reminders, allowing for more preventative maintenance. It improves fleet management while adhering to AEMP 2.0 telematics standards. These sophisticated elements, such as telematics, provide real-time data on fuel levels, battery health, and security, allowing for more efficient maintenance and fewer downtimes.

Looking ahead, we focus on automating tasks with minimal human participation. We’re also developing technologies that help operators with sensing and perception and AI-powered solutions that lessen the need for human intervention. This strategic direction broadens our product choices and has the potential to profoundly impact the construction industry, strengthening our dedication to technical innovation.

What role do autonomous and semi-autonomous features play in modern earthmoving equipment, and what benefits do they bring to construction projects?

Modern earthmoving equipment has autonomous and semi-autonomous characteristics, altering the construction business by lowering the need for manual operation and increasing efficiency. These technologies, such as operator-less cabins and AI-assisted systems, enable robots to complete tasks with minimal human participation, increasing precision and lowering errors. The equipment can generate autonomous solutions by adding sensors and perception systems, resulting in more consistent and safe operations.

These advancements have significant benefits: they streamline construction processes, lower operational costs, and increase overall productivity. Additionally, integrating electrification and green technologies further enhances sustainability in construction projects. As these technologies evolve, they promise to redefine how construction sites operate, making them more efficient, cost-effective, and environmentally friendly.

How do data analytics and real-time monitoring enhance the management of excavators and backhoe loaders?

Data analytics and real-time monitoring enable critical data collection on topics such as engine health, fuel consumption, and operational efficiency. By analysing this data, fleet managers may optimise maintenance plans, ensuring machines are serviced only when necessary, increasing machine longevity and reducing downtime. Furthermore, having real-time visibility into machine performance allows operators to make modifications, increasing operational efficiency and lowering costs.

Predictive maintenance relies heavily on connectivity through these systems. Potential faults can be recognised before they cause equipment failure by recognising patterns and abnormalities in the data. This proactive strategy dramatically decreases unexpected downtime by addressing problems before they escalate. Furthermore, the ability to do remote diagnostics enables speedy troubleshooting, reducing the time machines are out of service and ensuring job site productivity remains high.

At CASE, all our equipment is improved with real-time monitoring, which assists operators on construction sites and ensures the machine’s fuel economy.

How are workforce training and upskilling evolving with these advancements?

Training and skill development in the earthmoving equipment sector are increasing to keep up with technical improvements, focusing on comprehensive, industry-aligned programmes. For example, the Infrastructure Equipment Skill Council (IESC) has played a key role in developing a comprehensive skilling environment that meets the needs of today’s tech-driven sector. These programmes now emphasise traditional operational abilities and the integration of digital literacy, allowing operators to operate modern gear outfitted with IoT, telematics, and other intelligent technologies. Collaborative efforts, supported by industry associations and government bodies, support ongoing upskilling and reskilling opportunities, ensuring that the workforce is proficient in using the most recent equipment. This progression in training is critical for maintaining high levels of efficiency, safety, and innovation in the industry, ultimately contributing to the successful completion of increasingly complex construction projects.

In addition to IESC’s activities, CASE Construction is tackling the talent gap with programs like the Hunar program. This rigorous 32-day training program is designed to provide impoverished kids with the skills required to operate sophisticated backhoe loaders, combining theoretical education with hands-on practical practice. The curriculum also emphasises digital literacy, ensuring that trainees are current on the newest technology breakthroughs. CASE is educating a new generation of operators to meet the expectations of a tech-driven business by offering a comprehensive learning environment that incorporates soft skills development and community-building activities. The success of such programs is evident, with many trainees finding work, and attempts are underway to expand this model to include dealers and suppliers, further contributing to the sector’s skill development.

For more information, visit: https://www.casece.com/en/india

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

This article explores the growing relevance of gensets in India’s construction industry, examining their role, emerging trends, and the shift toward cleaner, greener alternatives.

Generators, commonly known as gen-sets, have become essential to construction operations, especially in remote or off-grid locations. They power construction machinery and light sites and run temporary offices. With an increasing focus on sustainability, the genset market is evolving, introducing new technologies to minimise environmental impact while maintaining operational efficiency.

The need for reliable power in construction

India’s construction industry is one of the fastest-growing sectors in the world, contributing over 7 percent to the country’s GDP. Projects such as highways, metro rail networks, smart cities, and affordable housing drive this growth. With infrastructure development at an all-time high, construction sites, especially those far from urban centers, often require reliable power sources. The primary challenge in such locations is the lack of grid access, making gensets the go-to solution.

Gensets provide consistent, portable power critical for running heavy machinery, lighting, and temporary site offices. They ensure that work continues without interruptions, even in areas where the electricity supply is unstable or unavailable. Diesel gensets have traditionally dominated the market due to their high power output, reliability, and durability.

The dominance of diesel gensets

Diesel gensets have long been favoured in the Indian construction industry due to their capability to deliver high power over extended periods. A typical 1 MVA diesel generator consumes about 225 kg of diesel per hour at full load and emits roughly 720 kg of CO2. Despite their environmental impact, diesel gensets are still popular because they are cost-effective, readily available, and can operate in remote areas.

Diesel gensets are prized for their reliability, making them well-suited for the demanding conditions of construction sites. Diesel is widely available across India, which is advantageous for remote locations. Additionally, diesel engines have a long operational life, making them a durable choice for continuous power needs. They also provide high power density, suitable for running heavy equipment.

However, growing environmental awareness and stricter emissions regulations are prompting a shift in the industry. With increasing regulatory pressure, the construction sector is beginning to explore alternative fuel options, leading to an evolution in the genset market.

The environmental impact and growing regulations

Diesel gensets, while highly efficient, contribute significantly to greenhouse gas emissions. As mentioned earlier, a 1 MVA genset running at full load emits 720 kg of CO2 per hour and substantial NOx (Nitrogen Oxide) and SOx (Sulfur Oxide) emissions. These pollutants contribute to air pollution, acid rain, and global warming. As a signatory to the Paris Agreement, India is committed to reducing its carbon footprint, with the construction industry being a key focus area for decarbonisation.

The Ministry of Environment, Forest and Climate Change (MoEFCC) has tightened emissions standards for diesel gensets in India. The Central Pollution Control Board (CPCB) introduced CPCB-II standards to regulate particulate matter, NOx, and SOx emissions from gensets. This move has prompted construction companies to reassess their power generation strategies and seek more sustainable alternatives.

For instance, in metropolitan areas like Delhi, where air pollution is a severe concern, diesel gensets are banned during certain periods to control emissions. Other states are expected to follow suit, making it crucial for construction firms to explore cleaner alternatives to avoid operational disruptions.

The shift to cleaner alternatives

To address diesel generators’ carbon footprint, the industry is increasingly turning to alternative fuels such as biodiesel and renewable diesel. Though each has limitations, these options offer a way to cut emissions while leveraging existing diesel infrastructure.

Biodiesel, derived from organic materials like vegetable oils and animal fats, is a renewable alternative to traditional diesel. It can somewhat reduce carbon emissions but requires engine modifications when used in blends exceeding 20 percent. Additionally, biodiesel performs poorly in cold weather compared to fossil diesel and has relatively high NOx emissions.

On the other hand, renewable diesel is chemically similar to fossil diesel and can be used in existing engines without modifications. While it helps lower CO2 emissions, its sustainability is questioned due to the land use and water resources needed for its production.

Though biofuels offer a temporary solution for emission reduction, the construction industry requires a more comprehensive strategy for long-term decarbonisation. Hydrogen fuel cells present a promising alternative for achieving deeper reductions in greenhouse gas emissions.

Hydrogen fuel cells: A clean power revolution

Hydrogen fuel cells are emerging as a promising alternative to traditional diesel gensets, offering a cleaner and more efficient power solution. These cells generate electricity through an electrochemical reaction between hydrogen and oxygen, with water and heat as the only byproducts. This makes them particularly appealing for construction sites, especially where emissions regulations are stringent.

Hitachi Energy’s HyFlexTM hydrogen power generator is a notable innovation in this field. Designed specifically for remote construction sites, this fully integrated, plug-and-play unit produces zero emissions and operates quietly, addressing environmental and noise concerns commonly associated with diesel gensets.

Hydrogen fuel cells offer several advantages over diesel and biofuel-powered gensets. They produce no CO2, NOx, or SOx emissions, making them an environmentally friendly option. They are also more efficient than diesel gensets, lowering fuel consumption and operational costs. Additionally, fuel cells operate quietly, reducing noise pollution—a growing concern in urban construction areas. Hydrogen, particularly when derived from renewable energy sources, is a clean and sustainable fuel. Even with “grey hydrogen” produced from natural gas, emissions are 30 percent lower than those from diesel gensets.

While hydrogen fuel cells are still in the early stages of adoption in the Indian construction industry, they represent a promising solution for long-term sustainability. As hydrogen production costs decrease and green hydrogen availability increases, fuel cell gensets are likely to become a mainstream power solution for construction operations.

Battery storage: A complementary technology

Another alternative to diesel gensets being explored is battery energy storage systems (BESS). When charged using renewable energy sources, batteries can provide clean power for construction sites. However, they have significant limitations regarding capacity and practicality for large construction operations.

For example, a 20-foot container of batteries can store approximately 1 MWh of energy, enough to power a 250 kW site for about four hours. This is insufficient for the high energy demands of construction sites, which often require continuous power for extended periods. As such, batteries are more suited for smaller applications or as a complementary technology alongside hydrogen or biofuel gensets.

Economic considerations: Total cost of ownership (TCO)

When evaluating the different genset options, construction companies must consider the Total Cost of Ownership (TCO), which includes both the capital expenditure (CAPEX) and operational expenditure (OPEX) over the equipment’s lifetime. While diesel gensets have a lower upfront cost, fuel and maintenance expenses can be substantial over time.