Moglix introduces a Next-Day Delivery service across major cities, reducing delivery times significantly and enhancing supply chain efficiency for SMEs in the B2B sector.

Moglix, the leading B2B e-commerce platform, has announced the launch of its Next-Day Delivery (NDD) service, a significant advancement in the B2B market. This service is currently available in twelve major Indian cities, with a corridor expansion strategy for forty cities in the next six to twelve months.

Moglix’s effort addresses a significant pain point in the B2B sector: extended delivery times. Moglix is altering customer expectations and raising the bar for efficiency by reducing delivery time from the industry standard of 72-96 hours to a new normal of 12-24 hours.

In the following months, the NDD service will expand to over 10,000 stock keeping units (SKUs) throughout forty cities. This rapid rise is driven by rising demand in India’s fast commerce market, which is estimated to reach USD 5.5 billion by 2025.

Moglix’s NDD service is a direct answer to changing business needs, particularly for small and medium-sized enterprises (SMEs), which rely heavily on the timely delivery of industrial items. Moglix enables businesses to boost productivity and optimise operations by removing supply chain bottlenecks and leveraging technology.

“At Moglix, data drives our innovation. Our analysis showed that 25 percent of our orders come from 12 major urban centres, where growth rates surpass the national average, but conversion rates were lower. This insight led us to develop our Next-Day Delivery service. It’s more than just faster delivery; it’s about transforming the B2B e-commerce experience. By pioneering this service, we’re setting a new industry standard and enhancing the efficiency of India’s industrial sector. Supporting the ‘Viksit Bharat’ vision, our focus is on transforming supply chain and procurement processes with innovation, speed, and customer centricity,” says Rahul Garg, Founder & CEO, of Moglix.

To keep its promise of next-day delivery, Moglix has undergone a full operational revamp. It has streamlined internal processes, strengthened supplier partnerships, and invested in cutting-edge technology to optimise its supply chain for speed and efficiency. A specialised logistics staff, together with innovative tools for demand forecasting, route optimisation, and real-time tracking, has been critical in reaching this milestone. This strategic strategy has allowed Moglix to drastically shorten delivery times, hence increasing customer satisfaction and setting a new industry benchmark for B2B e-commerce.

Moglix is committed to spreading this capability to larger enterprises to improve productivity and efficiency. Moglix is the global leader in B2B e-commerce, providing unrivalled value that drives the B2B industry’s expansion and efficiency.

For more information, visit: https://business.moglix.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The panel discussion focused on “BLAZING TRAILS: CUTTING & WELDING EXCELLENCE” leaders Mr. ANOOP SINGHAL, Mr. Rituraj Bose, Mr. Amlan Saha, Mr. Duraiswamy Ravichandran, Mr. Amrityoga, GM (Marketing & Strategy) at Great-Yuva Welding Expert.

Don’t miss this opportunity to learn about Cutting and Welding Excellence Hosted by B2B Purchase Magazine.

Speakers:

Mr. ANOOP SINGHAL – Sales & Operations (India) Director at CRP Robot EU Technology Co. Ltd.

Mr. Rituraj Bose, Quality Management Consultant at Honorary Secretary General, IIW-India.

Mr. Amlan Saha, Segment Management National – Automation at Fronius India Private Limited.

Mr. Duraiswamy Ravichandran, AGM – Product Management at Messer Cutting Systems India Pvt. Ltd.

Mr. Amrityoga, GM (Marketing & Strategy) at Great-Yuva Welding Expert.

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Amlan Saha has over 25 years of experience in the welding industry and is currently the Segment Management National for Welding Automation projects at Fronius India Pvt Ltd, which oversees India and SAARC countries. He is an AWS Certified Welding Inspector (AWS-CWI) and began his career with Garden Reach Shipbuilders and Engineers Kolkata in 1998. He worked at L&T-Eutectic-Welding Products Business for 11 years, rising from Application Specialist Engineer to Regional Manager, and then at Linde India Limited as Manager of Application Development in Welding, Laser, and Heating Technology. He has performed various Welding Technology training programs.

Topic: Robotics and Automation in Welding

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Duraiswamy Ravichandran is the Assistant General Manager of Product Management at Messer Cutting Systems India, where he has been a key player for over 11 years. With a distinguished career spanning 34 years, Ravichandran brings a wealth of experience in industrial design, machine tools, and automation. His journey includes significant tenures as Product Manager and R&D Manager at Messer Cutting Systems, and roles at PARI, Gedee Weiler Pvt Ltd, SGS Equipments, and more. His expertise in designing advanced machinery and leading product development initiatives has made him a prominent figure in the thermal cutting industry. Ravichandran holds a Bachelor’s degree in Mechanical Engineering from Tamil Nadu College of Engineering, Coimbatore.

Topic: Material handling and Automation in plate cutting industry

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Rituraj Bose is a Quality Management Consultant with 39 years of experience and started his career with L&T Construction Group in 1985. He worked as a QA/AC Manager at Tecnimont SpA for 15 years. He is a PMI-certified Project Management Professional who is also qualified in welding, NDT, and Management System Audits. He is a Project management Professional, certified by PMI, USA, and the first person in India to get recognition as ‘CII Certified Quality Professional – Level A’. He is the Honorary Secretary General of IIW-India, Chairman of the IIW-India Certification Division, and a representative of the International Institute of Welding. He is also interested in skill development and has served on several national and international councils.

Topic: Green Welding practices to reduce Environmental Impact

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Anoop Singhal oversees the operations of CRP Robot Technology Co. Ltd. in India. With over 21 years of extensive industrial experience as a professional Electrical & Electronic Engineer, he has honed his skills in Sales, Marketing, Distribution Management, and Customer Relationship Management. Under his leadership, CRP Robot has initiated direct operations in India, aiming to address the acute shortage of skilled manpower with cost-effective and innovative robotic solutions. Mr. Singhal believes this initiative will create a win-win scenario for both CRP Robot and Indian customers, given the user-friendly and affordable nature of CRP’s products.

Topic: Innovation in Robotic Welding Technology

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Mr. Amrityoga is a B.Tech. Mechanical Engineering graduate from R.E.C. Calicut (1996) and has 27 years of expertise in Technical Sales and Marketing. He has worked in various industries, including automotive and shipbuilding, boosting production and lowering costs. He developed Technical Training Institutes such as MACE Manesar and IACE Gandhinagar to improve welding skills. He has also organized training sessions with business associations and government bodies, as well as worked with Japanese organizations such as METI and JWRI-Osaka University. He is an expert in arc welding, including equipment, consumables, and shielding gases.

Topic:- Fiber Laser Welding-An Emerging Trend

#construction #development #industry #infrastructure #technology #transformingindia #b2bpurchase

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Together, Mighty Buildings and Honeywell are utilising low-GWP foam insulation in 3D-printed homes to improve energy efficiency and sustainability while giving homeowners better temperature control.

Honeywell (NASDAQ: HON) has announced that Mighty Buildings would incorporate Honeywell Solstice® Liquid Blowing Agent (LBA) as a vital component in the substance used to construct 3D-printed dwellings. Honeywell’s low-GWP technology will replace standard foam insulation, allowing Mighty Buildings to cut emissions while producing robust, energy-efficient building panels. The collaboration with Mighty Buildings helps Honeywell integrate its portfolio with three significant megatrends, including the energy transformation.

According to a recent UN Environment Programme estimate, the construction and building industry accounts for 37 percent of total global greenhouse gas emissions. Solstice LBA can lessen the industry’s environmental effect because its GWP is 99.9 percent less than other blowing agents widely used in construction. Solstice LBA allows 3D-printed homes to be created with almost no waste and in less time than traditional construction methods.

“When used with our patented 3D-printing technology, Solstice LBA will enable us to build comfortable and climate-resistant housing,” says Scott Gebicke, CEO of Mighty Buildings. “The construction industry needs fast, safe and reliable alternatives to traditional building materials. By incorporating Solstice into our production process, we can further enhance the performance and sustainability of our 3D-printed products while reducing the construction industry’s overall carbon footprint.”

The 3D-printed panels created with Solstice LBA will be fabricated at Mighty Buildings’ production facility in Monterrey, Mexico. The factory can presently print enough panels for two homes each day, and Mighty Building’s average building time for a 3D-printed home is less than a week. Because Solstice LBA provides higher thermal insulation, these dwellings require less energy for heating and cooling after completion than those created with other regularly used blowing agents.

“Honeywell offers a range of solutions to help customers reach their emissions reduction and energy efficiency goals,” states Jeff Dormo, President of Honeywell Sustainability and Decarbonization. “Our Solstice technology is constantly being used in new ways, and by offering a non-ozone depleting, nonflammable and high-performance foam blowing agent, our work with Mighty Buildings has the potential to transform the future of homes and the building and construction industry as a whole.”

The Environmental Protection Agency has included Honeywell Solstice LBA in their Significant New Alternatives Policy (SNAP) program, which encourages the research and use of alternatives to ozone-depleting materials.

Honeywell has invested more than $1 billion in research, development, and increased capacity for its Solstice technology, which is now used in refrigerants, blowing agents, aerosols, and solvents and is being considered for broader usage in metered dose inhalers. Since its launch in 2011, Honeywell Solstice technology has helped avoid the potential release of more than 395 million metric tonnes of carbon dioxide into the environment, comparable to the carbon emissions from almost 94 million gasoline-powered passenger vehicles each year.

For more information, visit: https://www.honeywell.com/in/en/hail

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Everything you need to know about the peculiar applications of MB Crusher accessories.

Heavy machinery attachments are commonly associated with construction, demolition, and roadworks. But what if we told you that the MB Crusher units can perform virtually anything? When we say they’re versatile, we mean it.

The MB Crusher screener for loader: Rock ‘n’ Roll Recycling

Most people associate battery recycling with arduous tasks involving tiny boxes and cumbersome gloves. Not any more!

Since 1996, this Belgian company has been revolutionising the recycling industry by salvaging alkaline and salt batteries from Belgium and beyond. How? With the MB-LS170 screening bucket installed on a Manitou loader, they perform a headline-worthy feat, separating battery dust from the good stuff like a DJ spinning vinyl. This revolutionary procedure prevents operators from inhaling undesired battery dust while recycling an amazing 5 to 6 tonnes of batteries daily. Rock on!

Link: https://vimeo.com/878253209

The MB Crusher Grapple: from chaos to order

Let’s face it, recycling isn’t always glamorous. But with the MB Crusher Grapple, it’s like having a personal helper who never complains about the odd things you ask it to perform. Whether it’s rearranging the plastic layers of the automobile’s windscreen or organising a yard full of old automotive parts, this grapple handles it everything with a wink and a smile.

Link: https://vimeo.com/942247176?share=copy

The efficiency anthem

“We’ve gone from processing 120 tons of glass waste to 200 tons, an 80 percent increase, if you get what I mean…” This outstanding performance speaks for itself, transforming regular recycling into a blockbuster hit. The dynamic pairing of the MB Crusher padded bucket and the JCB excavator created a symphony of productivity and precision. By fine-tuning the recycling process, it ensures that each piece of glass is perfectly prepared before proceeding to the next stage.

Link: https://vimeo.com/947297662?share=copy

Your all-purpose problem solver

Have you ever had to lift a life-sized unicorn statue? What about a gigantic rubber duck? Or confronted by a mountain of rubble resembling the aftermath of a rock concert? MB Crusher attachments are ready to handle anything you throw at them, making difficult chores a snap. It’s like having a superhero on speed dial—if superheroes were serious about recycling.

For more information, visit: https://www.mbcrusher.com/es/es/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Join NetNex for Connect 2024 in Mumbai on August 29, with an emphasis on “Smart Logistics.” This premium event brings together CSCOs to discuss innovation, efficiency, and sustainability in the dynamic supply chain world.

In a period of unparalleled change, the role of the supply chain leader has expanded far beyond its traditional confines, emerging as a critical strategic function within organisations. Supply chain leaders now have a diverse set of responsibilities that include driving innovation, improving operational efficiency, and creating future strategies. Today’s supply chain experts are on the cutting edge of organisational growth and change, from improving logistics and nurturing supplier relationships to harnessing data and technology and advocating sustainability efforts.

NetNex is pleased to deliver the inaugural edition of Connect 2024 in Mumbai on August 29, 2024. The theme of this edition is Smart Logistics: Improving Control and Collaboration in the Supply Chain. This crucial event is intended to bring together a dynamic community of CSCOs in the region, providing a place for sharing experiences, ideas, and future perspectives.

Connect 2024 provides a forum for lively debates about developing trends and cutting-edge technologies in the supply chain area. Supply chain leaders who attend will learn about creative ideas and methods for achieving long-term and meaningful results. More than just an exchange of knowledge, Connect 2024 catalyses active engagement with the industry’s vision, allowing executives to play a critical role in determining its future. As peers connect to share best practices and establish growth strategies, this platform transforms into a hub of learning and innovation, encouraging supply chain professionals to play major roles in strategic change.

Connect 2024 will provide guests with an in-depth look at the increasing issues and possibilities that modern supply chain leaders face. The event will provide useful insights and a comprehensive grasp of the fundamental problems influencing today’s supply chain and logistics landscape through engaging presentations led by industry professionals and interactive discussions with participants.

The event style is designed to engage participants in dynamic talks that promote collective learning and dynamic ideation, resulting in actionable takeaways for long-term and effective consequences.

The Connect 2024 will cover the wide-ranging issues and possibilities facing today’s supply chain leaders, including…

This pioneer of Connect 2024 hosts a stellar line-up of Chief Supply Chain Officers & experts on the speaking panel from…

Tata Chemicals | Piramal Pharma | Shell India | Reliance Retail | Hersheys India | Nivea | Hindustan Coca Cola | EPL Limited | Ashland | Rebel Foods | Alkem Laboratories | Ultratech Cement | Hindustan Platinum | Pidilite Industries | Apcotex Industries | Sugar Cosmetics

The initiative is supported by top solution providers who deliver dynamic solutions to improve the output of the Supply Chain function and achieve business objectives. Stellium is the event’s Gold Partner, Anaplan is the Silver Partner, and Unbox, Ritco, and OMP are the Networking Partners.

The CONNECT 2024 | Mumbai is co-sponsored by “The Association of Supply Chain Professionals”, “All India Association of Industry”, “Association of Indian Manufacturing”, “Container Freight Station Association Of India” & “All India Food Processor Limited”.

India Strategic, The Global Hues, International Business Magazine, Silicon India, Startupnews.fyi, APACE Digital Cargo, Asia Business Outlook, Industry Outlook, SupplyChain Brain, OEM Update, and B2b Purchase & Thermal Control Business Magazine have all contributed to the content and outreach efforts.

This event promises to shape the future of the Supply Chain Fraternity.

To learn more about Connect 2024 Mumbai, including registration and collaboration options, please visit the website: https://nextechsummit.com/connect/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

CJ Darcl hauled 34 excavators utilising customised rakes, including models from Volvo CE, Komatsu India Private Limited, and Gainwell Commosales Private Limited, a renowned dealer of Caterpillar Inc. (CAT), from Chennai (Tamil Nadu) to Ballabgarh (Haryana).

CJ Darcl Logistics Ltd. (CJ Darcl), a major logistics company, is intended to change the transportation of heavy construction equipment, such as excavators, using specialist rail rakes. This groundbreaking project establishes CJ Darcl as the first in the industry to use the Indian Railways network to aggregate machines from several OEMs and transport them from Chennai (Tamil Nadu) to Ballabgarh (Haryana).

CJ Darcl hauled 34 excavators using customised rakes, including models from Volvo CE, Komatsu India Private Limited, and Gainwell Commosales Private Limited, India’s premier Caterpillar Inc. (CAT) dealer. This programme is consistent with the company’s objective to incorporate environmentally friendly practices into its logistics operations.

Expressing his passion for a sustainable tomorrow, KK Agarwal, CMD, CJ Darcl, says, “At CJ Darcl, we are driving a transformative shift in how heavy equipment is transported across the nation. Embracing rail transport is in line with India’s vision of modern, eco-friendly infrastructure. This initiative is a testament to our unwavering commitment to innovation, sustainability, and leadership in the logistics sector. We are proud to pave the way for a more sustainable future.”

“Our decision to employ rail transport for excavators marks a significant advancement in our sustainability commitment. This initiative minimises our carbon footprint and underscores our dedication to leading the logistics industry towards a more environmentally friendly and efficient future,” addresses Nikhil Agarwal, President of CJ Darcl. “We are establishing a new standard in sustainable logistics, demonstrating that innovation and responsibility can coexist. We also extend our sincere gratitude to our valued customers for supporting this movement.”

The utilisation of rail rakes to move excavators constitutes a significant development in logistics. Rakes, which are a vital part of the Indian Railways’ infrastructure, are intended to manage big loads efficiently. CJ Darcl can reduce the carbon footprint associated with road transport by consolidating multiple excavators into a single transport unit. The company’s use of rail rakes to transport heavy construction equipment, which aggregates demand advances greener logistics and promotes the government’s infrastructure aims. Rail transport, which is known for its efficiency and low carbon footprint, provides a solution that supports the government’s focus on improving logistics infrastructure and lowering environmental effects.

CJ Darcl’s project demonstrates its commitment to combining innovative technology with environmentally friendly practices. The organisation is setting new norms for environmentally friendly logistical solutions in the construction industry.

For more information, visit: https://cjdarcl.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Gensol Engineering Ltd. establishes Scorpius Trackers Inc. in Delaware, to transform the solar tracker business in the United States with revolutionary technology and a new California office. The company will make its RE+ conference debut.

Gensol Engineering Ltd. (BSE: 542851, NSE: GENSOL) has announced the formation of Scorpius Trackers Inc., a Delaware-based company, to enter the US market. Scorpius plans to launch its cutting-edge tracker technology at the RE+ Conference in Anaheim from September 9 to 12, 2024, with further showcases planned in Austin and San Diego. Scorpius Trackers’ first office in the United States will be ideally positioned in California, placing the company at the centre of one of the world’s most dynamic renewable energy marketplaces.

This strategic decision demonstrates Scorpius’ commitment to capitalising on the tremendous potential of the United States solar tracker sector, which is the world’s largest, with trackers deployed totalling over 25,000 MW each year. Importantly, the US tracker market is expanding at a CAGR of more than 20 percent. With an ambitious objective of supplying over 2,000 MW per year by 2028, Scorpius Trackers Inc. plans to use its (Scorpius India) decade of experience and 1,000 MW+ of contracted orders in important areas including as India, Africa, Japan, and the Middle East. The company’s innovative technology, which is designed to function well on both flat and hilly terrains, combined with its cheap pricing, is expected to drive this expansion.

Commenting on the expansion, Anmol Singh Jaggi, Chairman and Managing Director of Gensol Engineering Ltd., says, “The U.S. market is pivotal to our global strategy, and the launch of Scorpius Trackers Inc. marks a significant milestone in our growth journey. With the USA leading the world in solar tracker adoption, our entry into this market aligns perfectly with our vision to provide designed in India and made-in-India high-technology products to the world. We are confident that under the leadership of Shailesh Vaidya, Scorpius Trackers will rapidly establish itself as a key player in the U.S. and help us tap into the potential of solar energy across the world.”

Shailesh Vaidya, Co-founder and CEO of Scorpius Trackers Pvt. Ltd. (India), who will lead the U.S. operations as CEO of Scorpius Trackers Inc., adds, “Entering the U.S. market is a landmark achievement for Scorpius Trackers. Our proven technology and deep expertise in diverse global markets will ensure that we develop cutting-edge, reliable, and cost-effective solutions that will cater to the unique needs of U.S. utility-scale plants. This expansion will pave the way for substantial growth and further establish Scorpius Trackers as a leader in the solar tracking industry.”

Scorpius Trackers, founded in 2012, has quickly established itself as a solar tracking industry leader, renowned for its proactive, end-to-end single-axis tracking systems. The company touts worldwide patented technology and has installations in Japan, the Middle East, India, and Africa. Gensol Engineering Limited’s acquisition in 2023 has strengthened its market position and expanded its capabilities through a track record of successful cooperation on a wide range of solar projects throughout the world.

For more information, visit: https://www.gensol.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

EET Fuels has advanced its Hydrogen Fuel Switching project with Wood to the FEED stage, with a final investment decision expected in 2025 to further its decarbonisation efforts.

EET Fuels (or “the Company”, the commercial name of Essar Oil UK), which intends to build the world’s leading low-carbon process refinery, has advanced to the front-end engineering design (FEED) stage of its Hydrogen Fuel Switching project. The Company’s co-located Track One low-carbon hydrogen production company, EET Hydrogen, will deliver the hydrogen.

To carry out this project phase, EET Fuels has hired Wood, a global leader in consulting and engineering, to coordinate final fuel system designs for the company’s hydrogen-ready crude distiller furnace. Wood will also redesign the key infrastructure and control systems to ensure hydrogen combustion is efficient and safe.

The completion of FEED will allow EET Fuels to make a final investment decision (FID) on the hydrogen fuel switching project next year.

The initiative will allow for fuel switching to assets such as EET Fuels’ hydrogen-ready crude distiller furnace. This is the first of its sort in a UK refinery, and it can run on either 100% hydrogen or a fuel-gas combination. Once the furnace is powered by hydrogen from EET Hydrogen’s manufacturing plant, it will lower emissions at the Stanlow Refinery by 0.2 million tonnes per year.

Once hydrogen is available from EET Hydrogen, all fired heaters on site will be able to switch fuel. The progress of this project indicates the company’s strong momentum in meeting its goal of decreasing CO2 emissions at the Stanlow Refinery by 95 percent by 2030.

Deepak Maheshwari, CEO of EET Fuels, says, “We have groundbreaking plans for EET Fuels in the UK with the Stanlow Refinery at its heart. Hydrogen Fuel Switching is an integral part of these plans, and conducting the FEED alongside a great partner in Wood will allow us to confidently move forward to final investment decision. We remain on track to become the world’s first low carbon process refinery, providing security of fuel supply to the UK, as well as building and maintaining employment in the UK’s industrial heartlands.”

Martin Simmonite, Senior Vice President for UK Operations at Wood, adds, “We are delighted to be working on this decarbonisation project with EET Fuels, providing critical infrastructure that is fundamental to the energy transition and UK energy security.”

For more information, visit: http://www.eetfuels.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Trimble’s Tekla User Days 2024, on September 25-26, offers virtual learning, networking, and expert insights for construction professionals, focusing on innovation and enhancing skills in digital construction.

Trimble (NASDAQ: TRMB), a global construction technology leader, is delighted to announce the much-anticipated Tekla User Days 2024 (TUD2024), which will take place virtually on September 25th and 26th, from 2pm to 6.30pm on both days. The yearly event aimed at design and detailing practitioners is expected to provide the best platform for learning, establishing, and growing the construction industry’s professional community. The two-day conference is jam-packed with fast learning, fresh ideas, and the opportunity to meet and connect with Trimble experts, clients, and product specialists from all across the country.

“We take immense pleasure in extending the invitation of the Tekla User Days 2024 to the design and detailing community,” says Rajan Aiyer, MD, SAARC, Trimble. “This event is a demonstration of our strong commitment towards developing and fostering a strong and healthy cooperative community of practice as well as a forum for sharing and nurturing knowledge services. Through such an approach and actual opportunities to engage, we would like to improve the customer’s experience and make him/her a more effective user of Tekla’s advanced tools in increasing efficiency and achieving better results in the projects. We will be glad to hear from the community and continue to contribute to the construction industry as its technology partner.” He added.

Customer experience at the core

Tekla User Days 2024 will focus on customer-centricity. Visitors will have the opportunity to engage in talks with specialists and submit input to Tekla software developers, with an emphasis on novel structural design solutions. The event will thus contain different periods for activities like presentations, live demonstrations, and question and answer sections, ensuring that users have a perfect opportunity to enhance their knowledge and practice the numerous possibilities of Tekla. “At Tekla User Days, attendees have the opportunity to learn from industry experts, engage in hands-on workshops, and share insights and experiences with fellow professionals,” emphasises Arun Kumar, National Service Manager, Trimble.

Building a stronger community

Trimble is committed to creating a robust and encouraging network to assist construction professionals in adopting digital and data-driven connected construction. Tekla User Days is a cornerstone of this initiative, bringing together a wide collection of people with one common goal: to stimulate improved performance and creativity in construction. Members can build working relationships and gain insights by participating in collaborative talks and networking activities.

A platform for knowledge exchange

Tekla User Days are defined first and foremost by the desire to exchange experience. The conference will include multiple presentations from experienced practitioners on themes such as BIM evolution, constructible models, digital twins, AI-based solutions, and data-driven decision-making. These seminars are intended to help working professionals obtain information and skills that will allow them to succeed in ever-changing environments.

Virtual engagement and global reach

Holding the event virtually guaranteed that Tekla User Days 2024 will attract more experts from around the country and beyond. The virtual platform should be designed to allow for free-flowing interaction and engagement points, as attendees will need to be absorbed into event activities from wherever they are located.

Tekla User Days provide an exciting opportunity to connect with like-minded individuals who value construction innovation. Whether you’re looking to learn something new or network with people in your field, this online gathering will undoubtedly provide you with valuable information and chances.

For more information, visit: https://www.trimble.com/en

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Union Minister Nitin Gadkari signed off the Eicher Pro 6055 LNG trucks at Nagpur’s new BLNG station, with the goal of promoting green trucking routes and expanding India’s LNG corridor.

VE Commercial Vehicles (VECV) Limited, a joint venture between the Volvo Group and Eicher Motors, has signed a memorandum of understanding with Baidyanath LNG Private Limited to deploy 500 Eicher Pro 6055 LNG trucks. Nitin Gadkari, Honourable Minister of Road Transport and Highways, flagged off Eicher Pro 6055 LNG trucks at the B-LNG station’s opening in Nagpur.

According to the conditions of the MOU, which will be further defined in formal agreements, the establishment of the LNG fleet will permit the expansion of the LNG station network across multiple important areas in Central India. This will accelerate the development of the broader supply-side ecosystem, assisting the long-haul transportation market in transitioning to cleaner fuel.

Commenting on the occasion, Vinod Aggarwal, Managing Director and CEO of VECV says ” As LNG becomes a crucial fuel for clean long-haul transportation, Eicher is actively working with partners to deliver state-of-the-art vehicles backed by superior technology. We wish Baidyanath LNG the very best on the inauguration of their latest LNG dispensing facility. This will further encourage transporters across Maharashtra to consider LNG vehicles as a viable and sustainable alternative.”

The Pro 6055 LNG truck is fuelled by Volvo Group’s globally proven engine technology, including a VEGX8 6-cylinder engine that generates 260HP at 2200RPM and 1000Nm of torque between 1100-1800RPM. The vehicle features the best gearbox in the business, with great torque handling capability. The truck has a range of up to 1100 kilometres with two tanks, ensuring long-haul efficiency, best-in-class fuel tank safety, and zero fuel theft. The vehicle’s cutting-edge cabin, complete with HVAC and an air-suspended driver seat, provides improved comfort and increases driver productivity.

Gagandeep Singh Gandhok, EVP, HD Trucks- Sales and Marketing, VECV, comments, “Eicher Trucks continue to drive change in the Indian commercial vehicle industry by introducing the most innovative solutions. Eicher’s Pro 6055 LNG truck showcases our strive towards developing sustainable solutions that drive innovation and efficiency. With its robust engine technology, the Eicher Pro 6055 LNG offers the best in industry transmission and comes with the longest LNG Fuel holding time. Like all Eicher vehicles, the Pro 6055 LNG truck comes equipped with advanced telematics solutions connected to an industry-first uptime center that ensures a superior experience for the customers.”

To assure the best-in-class customer experience, all Eicher vehicles are linked to the industry’s first Uptime Centre, which uses AI/ML capabilities for remote and predictive diagnostics. When connected to the ‘My Eicher’ fleet management app, these cars deliver significant real-time performance insights. Eicher’s comprehensive nationwide network of 850+ touchpoints, including 425+ authorised service centres and 8000+ retail centres, supplemented by ‘Eicher Site Support’ at 240+ locations, provides seamless assistance to all Eicher Truck and Bus customers.

For more information, visit: https://www.vecv.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Trelleborg Sealing Solutions India has promoted Vinay Balakrishnan to General Manager. Balakrishnan, who previously served as Director of Sales, will succeed Ranjan Sen, who retired on July 31, 2024, following a remarkable career with the company.

Balakrishnan, who has played a key role in Trelleborg Sealing Solutions India’s expansion plan, will now oversee the company’s operations throughout the nation. His ascension is viewed as a strategic move to propel the company’s next stage of expansion and innovation.

Balakrishnan brings approximately 30 years of experience in the industrial sector, namely in the Sealing and Bearing industry, to his current post. He started his career with Rane Brake Linings in 1996 and then moved on to the Sealing & Bearing industry, working with companies like Fenner India Ltd, Timken India Ltd, and Freudenberg NOK India. His career has included substantial achievements in sales, business development, and strategic management.

In July 2022, he joined Trelleborg Sealing Solutions as Director of Sales. Balakrishnan is well-known at Trelleborg Sealing Solutions for his excellent ability to manage complex sales processes and create customer-centric solutions. His demonstrated track record of producing outcomes and developing strong client relationships solidifies his position as an industry leader. He has a bachelor’s degree in mechanical engineering and a postgraduate degree in business administration.

“I am honoured to take on this new role and excited about the opportunities that lie ahead,” says Balakrishnan. “Our focus will be on leveraging our strong market presence to further innovate and deliver solutions that exceed our customers’ expectations. Asia, especially India is one of the strategic focus areas for Trelleborg. We have recently inaugurated an R&D Material lab in India, which will enhance our ability to collaborate closely with customers, offering superior support in material testing and design,” he explained. “Additionally, we plan to invest in expanding our manufacturing capabilities to provide local solutions that support our customers more effectively. We aim to benefit the customer with global expertise and local support and be the partner of first choice for Sealing Solutions in the country.”

Balakrishnan’s appointment demonstrates Trelleborg Sealing Solutions India’s commitment to strong leadership and industry performance. His significant experience in sales and strategic planning is expected to improve operational efficiencies and the company’s competitive advantage. The leadership move is also considered a reflection of Trelleborg Sealing Solutions India’s commitment to internal talent development and its belief in Balakrishnan’s vision for the future.

For further information, please contact: tssindia@trelleborg.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Kobelco India unveiled the “Made in India” SK80 Excavator in Chennai, highlighting innovative technology, outstanding performance, and versatility, marking a significant step forward in mid-segment excavation equipment.

Takemichi Hirakawa, Managing Director of Kobelco, introduced this much-anticipated addition to the excavator family at a lavish event in Chennai. This event marks a key milestone in the company’s 17+ year history in the Indian CE market.

A new era in mid-segment excavation

The SK80 is an 8-ton mid-segment excavator designed to provide enhanced performance, improved fuel efficiency, and best-in-class adaptability. As building projects in developing India become more demanding and complicated, there is a greater need for modern gear that can handle a variety of jobs with ease and efficiency. The SK80 is Kobelco’s response to these changing needs, combining cutting-edge technology and rugged engineering to deliver powerful and dependable performance.

Features and benefits

The SK80 Excavator boasts several innovative features that set it apart from its competitors. Key highlights include:

A commitment to innovation and excellence

Kobelco Construction Equipment India Pvt Ltd has a long history of supplying high-quality Excavators to fulfil the growing demands of Indian customers. The debut of the SK80 Excavator demonstrates the company’s continuous commitment to innovation, excellence, and the “Make in India” initiative.

A grand unveiling in Chennai

The SK80 launch ceremony was a spectacular occasion, attended by channel partners and media representatives. Attendees were able to see the SK80 Excavator up close and experience its capabilities. The event also included talks by technical specialists from Kobelco and Yanmar (a Japanese engine manufacturer), who presented attendees with comprehensive insights into the SK80’s features, advantages, and benefits.

Conclusion

The introduction of the SK80 Excavator represents a significant advancement for Kobelco Construction Equipment India Pvt Ltd in the Indian construction equipment business. It will also be a game changer in the mid-category excavator market, positioning Kobelco as a “True Solution Provider” in the excavator business.

For more information, visit: https://www.kobelco-in.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Godrej & Boyce has introduced India’s first lithium-ion battery-powered forklifts with an indigenous Battery Management System, boosting efficiency and helping the “Make in India” mission in material handling.

Amid India’s tremendous infrastructural development and the pressing demand for green energy solutions, Godrej & Boyce, a member of the Godrej Enterprises Group, has once again grabbed the lead with its latest innovation. The conglomerate’s Material Handling Business has announced the launch of lithium-ion battery-powered forklifts with an indigenously developed Battery Management System (BMS). This will be the first product of its sort from an Indian company. The solution meets a major demand in the Indian material handling industry by offering a self-sufficient and secure Li-Ion battery system.

Li-ion technology provides more than four times longer battery life than typical lead-acid batteries. Li-ion batteries have 5,000 charge cycles compared to 1,200 for lead-acid batteries, which reduces long-term expenditure. They provide opportunity for charging, zero emissions when charging, and lower maintenance requirements. Li-ion batteries charge from 20 percent to 80 percent in 2.5 hours, compared to 6 hours for lead-acid batteries, and consume 30 percent less energy. Li-ion batteries provide up to 15 percent more operating time for two- and three-tonne forklifts. The modular architecture also enables scaling. Godrej & Boyce intends to apply this technique to other material handling devices. Automotive, fast-moving consumer goods, consumer durables, retail (including e-commerce), medicines, and other significant manufacturing industries are expected to profit.

Anil Verma, Executive Director & Chief Executive Officer, Godrej & Boyce Manufacturing Co. Ltd., part of the Godrej Enterprises Group says, “India’s logistics sector is at a pivotal juncture, experiencing robust growth driven by infrastructure advancements across sectors such as automotive, FMCG, consumer durables, retail including e-commerce, pharmaceuticals, fueled by rising consumer demand. At Godrej & Boyce, we are committed to ‘Make in India’ strategies, playing a vital role in driving this growth. Our focus on integrating cutting-edge, technology-enabled solutions remains a key priority, addressing the complex challenges of modern supply chains. These innovations are crucial for enhancing operational efficiency and ensuring the sector’s continued evolution. The future of India’s logistics will be shaped by this commitment to nation-building and innovation, securing a more resilient and adaptive industry.”

Anil Lingayat, Executive Vice President & Business Head of the Material Handling Business of Godrej & Boyce, part of the Godrej Enterprises Group says, “We are delighted to introduce our Li-ion powered forklift trucks featuring indigenously developed Battery Management System. This launch underscores our commitment to ‘Make in India’ and building self-reliant capabilities in critical technologies for the material handling industry. By leveraging our engineering expertise, we have created a solution that enhances safety and optimises performance. We believe this is the start of a transformative journey that will revolutionise material handling and inspire industries nationwide to reimagine what’s possible when we commit to self-reliance.”

The new battery systems, created in collaboration with Log9 Materials, combine lithium-ion cells with 30 percent localised production with a patented Battery Management System (BMS) that is entirely designed and manufactured in India. The company intends to achieve 100 percent cell localisation by next year.

Traditionally, the Indian market relied significantly on imported batteries and BMS systems, which were primarily obtained from China. Localising this technology demonstrates the company’s steadfast commitment to the “Make in India” strategy and its desire to build a strong domestic supply chain.

For more information, visit: http://www.godrejenterprises.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

CASE Construction Equipment has expanded its footprint in southern India by opening a new dealership in Vijayawada, which will provide a full range of equipment as well as after-sales servicing and support.

CASE Construction Equipment, a CNH brand, has expanded its dealer network by signing a new partner in Vijayawada. The new facility, SEPS (Srinivasa Edifice Power Services) located in Srinivasa Nagar Bank Colony, Vijayawada, provides a wide range of goods and extensive after-sales service and spare parts. The new dealership will also serve neighbouring areas such as Guntur, Krishna, East and West Godavari, Vishakapatnam, Vijayanagaram, and Srikakulam.

Shalabh Chaturvedi, Managing Director of CASE Construction Equipment – India and SAARC area, spoke about the strategic cooperation, “The opening of this dealership in Vijayawada marks a significant enhancement of our market footprint in southern India. This facility is strategically located to serve the growing demands of the region’s construction sector, offering a complete range of innovative products and services. We at CASE, are committed to supporting the government’s focus on infrastructure development in the country by providing reliable equipment and robust after-sales support, ensuring our customers are fully equipped to meet the challenges of modern construction projects.”

This cutting-edge facility will house CASE’s entire line of construction equipment and provide an exceptional customer experience. It will address the needs of customers by providing amenities such as a fully equipped workshop, a training and conference room, genuine components, a staff of trained sales and service experts, an impending telematics centre, and a customer lounge.

CASE, a global leader in construction equipment since 1842, has been operating in India since 1989. Since its beginnings, it has continually been a market leader in the Vibratory Compactor section and a major player in the backhoe loader category. The company manufactures Made-in-India products in its cutting-edge manufacturing plant in Pithampur, Madhya Pradesh, for domestic and export markets in over 105 countries.

For more information, visit: https://www.casece.com/en/india

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Roff, Pidilite Industries’ main tile adhesive brand, has launched a new eco-friendly manufacturing factory in Jadcherla, near Hyderabad, to address expanding regional demand.

Roff, a leading tile adhesive brand from Pidilite Industries, has opened a new manufacturing plant at Jadcherla, near Hyderabad. This facility will be critical in supplying the increasing demand for high-quality tile adhesive products in the Andhra Pradesh, Telangana, and Northeastern Karnataka markets.

Bharat Puri, the Managing Director of Pidilite Industries Ltd., states, “We have observed a steady increase in demand for premium, specialised products in Andhra Pradesh and Telangana markets. Our Jadcherla project aligns with our vision to modernise and transform tile and stone fixing in India. Our goal is to provide consumers with superior adhesives and to bring manufacturing closer to the markets.”

Aligned with Pidilite Industries’ sustainability aims, the facility is a zero-waste plant that runs on 80 percent solar power, setting new norms for environmentally friendly manufacturing in the construction chemicals sector.

The plant’s enhanced automation ensures excellent precision, consistency, quality, and efficiency during manufacturing. Its strategic position will improve supply chain efficiency, helping to meet the growing demand for specialised, high-quality tile adhesive products.

As a greenfield project, the Jadcherla facility provides considerable room for future expansion, which aligns with Pidilite’s long-term growth strategy. Over 350 dealers and users attended the inaugural event, which highlighted the facility’s cutting-edge technology and environmentally friendly practices.

For more information, visit: https://www.pidilite.com/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Hi-Tech Pipes got a ₹105 crore contract for ERW steel pipes in the renewable energy sector. The project will be operated from its advanced Sanand Unit-II facility. The company expects to raise ₹ 600 crore through equity issues.

Hi-Tech Pipes, a well-known manufacturer of steel tubes and pipes, has achieved a key milestone by winning a ₹ 105 crore contract from customers in the renewable energy sector. This large project will be carried out from the company’s cutting-edge facility at Sanand Unit-II in Gujarat, which is outfitted with superior technology to satisfy the needs of modern infrastructure.

The deal, which focuses on supplying electric resistance welded (ERW) steel pipes, demonstrates Hi-Tech Pipes’ critical role in supporting renewable energy projects. The supply orders, worth ₹ 105 crore, are expected to be completed within the next three months, demonstrating the company’s capacity to provide high-quality items on tight deadlines.

Hi-Tech Pipes maintains six integrated manufacturing plants in India, including Sikandrabad (UP), Sanand (Gujarat), Hindupur (near Bangalore), and Khopoli (Maharashtra). These factories manufacture a wide variety of products, including steel pipes, hollow sections, tubes, cold-rolled coils, strips, and galvanised items.

In addition to landing this significant contract, Hi-Tech Pipes has announced plans to fund up to ₹ 600 crore through the issue of equity. This move is part of the company’s ambition to boost its position and expertise in the rapidly expanding renewable energy sector.

For more information, visit: https://hitechpipes.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

To relieve traffic congestion, the government is building an elevated corridor on the East Coast Road between Thiruvanmiyur and Uthandi, with completion scheduled for April 2025.

The government intends to finish the elevated corridor project from Thiruvanmiyur to Uthandi on the East Coast Road (ECR) within 18 months to alleviate traffic congestion in the area. Until the corridor is completed, road extension construction on the 8.8-kilometre stretch from Thiruvanmiyur to Akkarai will be prioritised and completed by April 2025.

On August 19, 2024, Highways Minister E V Velu visited the work on the East Coast Road. The elevated corridor will run from the TIDEL Park intersection to Uthandi, passing across significant places like the LB Road junction, Kottivakkam, Neelankarai, Injambakkam, and Akkarai. Once completed, the corridor is intended to cut travel time to 20 minutes. On-ramps and off-ramps will be installed at the LB Road junction, the Thiruvanmiyur RTO office, and Neelankarai to provide residents with convenient access.

The government has approved 940 crores for road widening, with the entire project projected to be completed by April 2025. Land acquisition for the six-lane road, which connects Chennai to Kanyakumari, is currently happening in six villages: Thiruvanmiyur, Kottivakkam, Palavakkam, Neelankarai, Injambakkam, and Sholinganallur.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

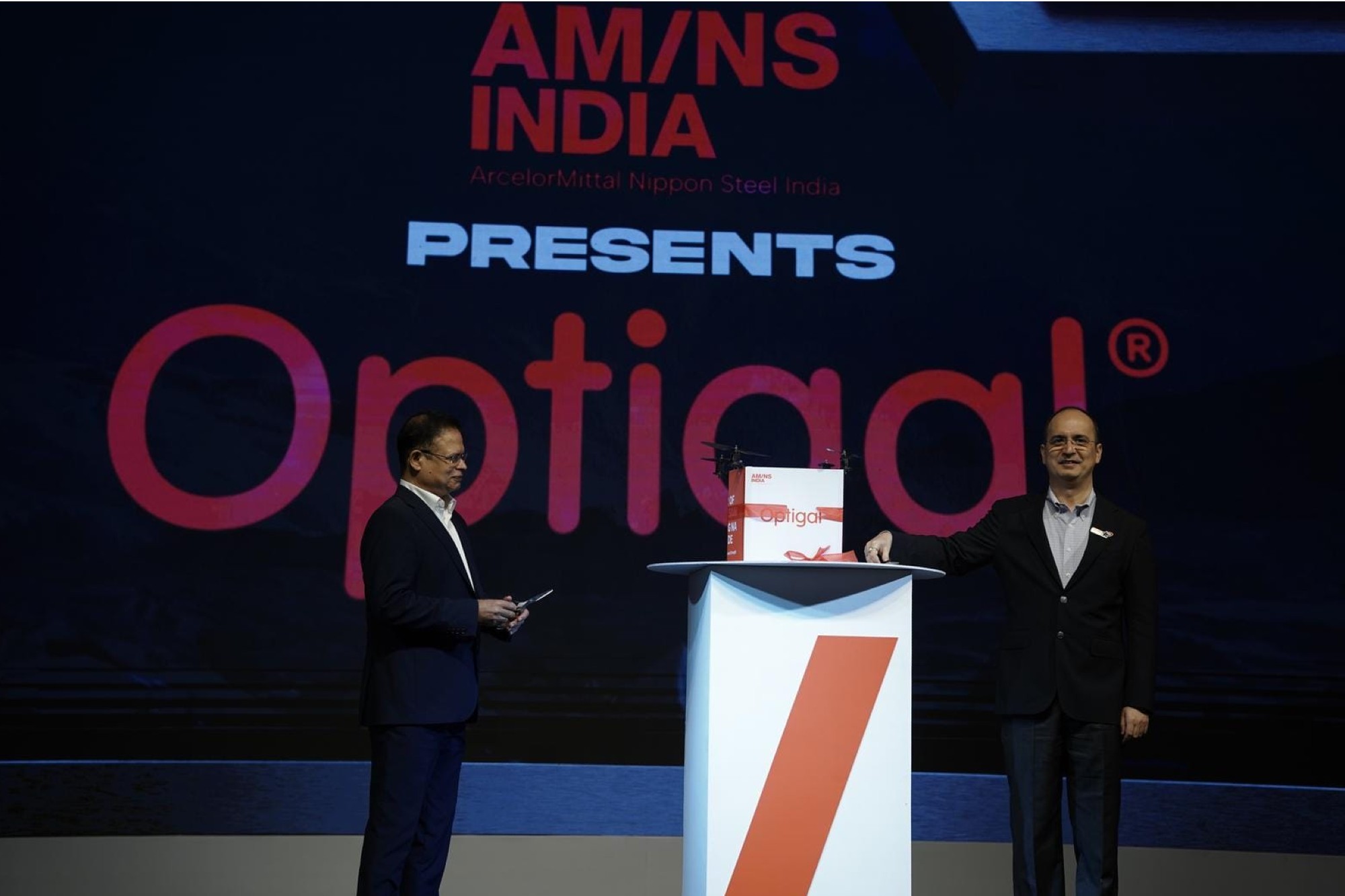

AM/NS India introduces Optigal®, a novel colour-coated steel with zinc-aluminium-magnesium coating and a 25-year warranty. This environmentally friendly, high-performance product promotes the ‘Make in India’ effort.

ArcelorMittal Nippon Steel India (AM/NS India), a joint venture between ArcelorMittal and Nippon Steel, two of the world’s top steelmakers, has announced the debut of Optigal®, a world-class colour-coated steel brand with a revolutionary Zinc-Aluminum-Magnesium (ZAM) metallic coating.

This high-end value-added steel ‘Optigal®’, patented by ArcelorMittal Europe, is currently available in global markets and AM/NS India is now producing and distributing it in India for the first time. The new offering builds on the company’s pioneering efforts to introduce internationally benchmarked quality products to fulfil the growing demand for indigenous superior quality coated steel.

This product, launched by AM/NS India’s Chief Executive Officer (CEO) Dilip Oommen at a spectacular ceremony recently in Kochi, Kerala, also demonstrates the company’s dedication to the ‘Make in India’ effort. Optigal® offers the longest warranty of any colour-coated steel product in India, up to 25 years, making a disruptive entry into India’s speciality steel business.

The annual demand for colour-coated products in India, which presently stands at 3.2 million tonnes, is expected to increase at a compound annual growth rate (CAGR) of 8-10 percent. Optigal’s manufacturing has begun at the company’s plant in Pune, Maharashtra, marking the first phase of a larger production strategy that will soon be expanded to include other facilities.

AM/NS India currently has a colour-coated capacity of around 700,000 tonnes, with ambitions to increase capacity to one million tonnes by 2026. With this capacity development, the company’s market share is expected to increase from 20-22 percent to 25-27 percent.

The new offering’s production process employs a novel ZAM alloy technique, which involves hot dip coating steel strip in a bath of zinc, aluminium, and magnesium alloy. The addition of magnesium improves both performance and durability. The ideal substrate-paint mix ensures good formability and better corrosion resistance for building products. Optigal® is an eco-friendly product that is devoid of hexavalent chromium and heavy metals, reducing environmental impact while promoting safety and sustainability.

Ranjan Dhar, Director and Vice-President of Sales & Marketing at ArcelorMittal Nippon Steel India (AM/NS India), says, “The introduction of Optigal® is an important addition to our growing product portfolio. This launch reaffirms our commitment to delivering world-class, innovative, and sustainable steels to our customers nationwide in line with our brand promise – ‘Smarter Steels, Brighter Futures’. The efforts also reflect our corporate campaign ‘Banaunga Main, Banega Bharat’, apart from highlighting our contribution to the ‘Make in India’ initiative.”

Optigal®’s versatility makes it an appealing choice for a variety of applications, including roofing, fencing, and cladding for residential and commercial projects, dependable materials for pre-engineered buildings, and high-performance steel for architectural facades such as airports, industrial warehouses, and stadiums.

Key benefits of Optigal® include:

For more information, visit: https://www.amns.in/

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Indian Navy and BEML Ltd. have joined forces to promote the indigenisation of naval equipment and systems.

In a massive attempt to indigenise crucial marine engineering equipment for the Indian Navy. BEML Ltd., a ‘Schedule A’ business under the Ministry of Defence and one of India’s premier defence and heavy engineering manufacturers, signed a Memorandum of Understanding (MoU) with the Indian Navy.

The MoU was signed at the Naval Headquarters in New Delhi by Rear Admiral K Srinivas, ACOM(D&R), Indian Navy, and Shri Ajit Kumar Srivastav, Director of Defence, BEML. This program is a vital step towards strengthening bilateral cooperation for indigenous design, development, manufacturing, testing, and product support of critical marine engineering equipment and systems.

The cooperation, which is aligned with the Government of India’s Aatmanirbhar Bharat policy, intends to increase self-sufficiency in defence manufacture while decreasing reliance on foreign OEMs.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Kolkata Chapter of the Construction Chemical Knowledge Leadership Initiative (CC KLI) facilitated knowledge exchange and collaboration among industry experts to advance construction practices.

The discussions emphasised the transformative impact of smart construction technologies on the speed and durability of construction projects. Speakers underscored the importance of meticulous planning and the adoption of modern construction technologies. Key topics included the use of ultra-high-performance concrete (UHPC) and high-performance concrete (HPC) in infrastructure projects.

The Keynote Speaker, Dr. Debasish Bandopadhyay, discussed corrosion in concrete, showing that even high-quality concrete can be vulnerable without proper maintenance.

This was followed by a panel discussion. Col. Mahesh Narayan shared insights from large-scale projects like IIM Shillong and railway electrification. Mr. Tarun Dey emphasised that effective waterproofing is crucial for structural durability, relying on proper implementation and oversight. Dr. Syed Shahid highlighted the importance of advanced monitoring systems for maintaining structural integrity. Dr. Dipesh Majumdar examined how rapid construction may lead to early deterioration, contrasting with techniques from Japan and Korea. Mr. Krishnendu Ghosh stressed the importance of project planning, cash flow management, and minimising design changes.

The panel noted that logistical challenges, such as material transport to remote sites, can delay projects. They suggested using basic technology for on-site monitoring, as advanced tools like AI and robotics may not be feasible in all settings. They also discussed new digital platforms for improving project management and communication, especially given reduced skilled labour.

The panel concluded by underlining that waterproofing is vital for protecting structures, with its success dependent on proper application and skilled supervision. Overall, meticulous planning, effective technology use, and rigorous quality control are essential for overcoming construction challenges and ensuring structural longevity.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Pune Chapter of CC-KLI took off with an insightful keynote address by Prof. K.V. L. Subramaniam, from the Department of Civil Engineering, IIT Hyderabad.

He endorsed the shift from prescriptive to performance-based design, noting that modern concrete can now achieve strengths up to 200 megapascals. He lauded precast concrete for its efficiency but acknowledged challenges in ensuring continuity and load transfer.

This was followed by a panel discussion to discuss construction and waterproofing challenges. Speakers highlighted the evolving landscape of construction technologies, emphasising innovations such as 3D concrete printing, advanced reinforcement techniques, and optimised formwork.

Mr. Ujwal Kunte, MD of CQRA, focused on rheology to maintain material integrity and strength. Challenges discussed included integrating reinforcement, addressing material anisotropy, and optimising forms for efficiency. Innovations like fibre integration and robotics were explored as potential solutions. Mr. J. V. Inamdar, MD of Strudcom Consultants Pvt. Ltd. and JVI Prestressing Systems, shared his insights on Aluminium Formwork shuttering innovations that significantly reduce construction time for high-rises, proposing bamboo as a sustainable alternative to steel.

Ar. Vishwas Kulkarni, Founder and Director of VK Architecture, emphasised modern quality control techniques like Pareto analysis and control charts to ensure consistent project standards.

Dr. Dilip Prabhakar Mase, Director of P. T. Mase & Associates, stressed the advantages of ultra-high-performance concrete (UHPC) in accelerating construction and enhancing durability, particularly in large-scale infrastructure projects such as highways. He highlighted the importance of rigorous testing and quality control due to high chloride levels in soil, advocating for high-grade concrete solutions like M60 to prevent leakage issues.

Mr. Kavish Thakwani, Managing Director of Avishkar Realty, discussed advancements in pre-planning and project execution technologies since 2011. He stressed integrating modern tools like mobile technology, 360-degree cameras, and RFID in construction inspections for enhanced accuracy and real-time problem-solving. He underscored the necessity of advanced waterproofing techniques for high-rise buildings with multiple basements to prevent water stagnation and ensure long-term durability.

The panel also addressed crucial aspects of construction maintenance and material selection. Speakers recommended utilising advanced materials such as glass fibres to enhance durability and cost-effectiveness, managing concrete shrinkage for longevity, and employing fibre reinforcement in non-structural elements to reduce costs. Overall, the panel underscored the pivotal role of innovative materials, stringent testing protocols, and effective design practices in extending the lifespan and reliability of structures.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Innovative techniques and smart technologies are redefining the construction landscape. The industry is poised to achieve unprecedented efficiency and sustainability with technology advancements.

CC KLI Hyderabad focused on the transition, challenges, and future of the construction industry, with a particular emphasis on concrete’s role as a key material in infrastructure development. The session explored critical themes such as the importance of construction chemicals, technological advancements, and the shift towards performance-based specifications in modern construction practices.

Prof. KVL Subramaniam, Department of Civil Engineering, IIT Hyderabad, highlighted the need for innovative construction techniques like 3D concrete printing, which allows for creating nonrectangular beams, optimising material use and reducing waste. Mr. Ramesh Mantha, Director of MA Consulting Services, emphasised the transition towards performance-based concrete designs over traditional mix proportions, noting the rising role of smart technologies, including drones for painting and façade cleaning and equipment for quality assessment through scanning.

Mr. Gunes Bardakci, General Manager at Phoenix Turner PMO, discussed the advanced systems used in constructing highrise buildings, stressing the integration of cutting-edge materials and technologies, such as automated form systems and modular construction. Ar. Tirunagari Srinivasulu, Senior Architect at CPWD, emphasised BIM’s transformative impact on architecture, highlighting how it facilitates real-time data sharing and efficient resource management, reducing time and cost overruns. He also addressed how smart technologies help architects tackle climate change and sustainability challenges, particularly through real-time control of lighting and HVAC systems based on occupancy.

Mr. Nagareddayya Subbagari, Corporate Quality Leader at My Home Constructions, underscored the vital role of construction chemicals in enhancing the quality and longevity of structures, discussing how advanced chemicals are being integrated to meet durability and sustainability goals. Ar. Sharavan Nagabandi, CEO of Space Max Consultant and Partner at ADS, emphasised the importance of integrating various technologies to address the complexities of urban development, advocating for a holistic approach that extends beyond BIM and Virtual Reality (VR). The panelists collectively underscored the need for the construction industry to embrace new technologies and materials to meet future demands. The transition towards performance-based concrete, coupled with innovations like 3D printing, is expected to drive the industry forward, ensuring infrastructure projects are both durable and efficient. The session served as a call to action for industry professionals to engage with these emerging trends and prepare for the future of construction. The discussion emphasised the importance of thoughtful and sustainable implementation of technological advancements. They also highlighted how continuous innovation, effective training, and integration of advanced tools are essential for achieving sustainable and high-quality construction outcomes. The conversation also stressed the role of technology in urban development, particularly in addressing sustainability challenges and climate change, illustrating how smart construction can contribute to more efficient, sustainable, and responsible urban environments.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Amidst rapid urban growth and tight deadlines, the construction industry is turning to smart technologies to balance speed and durability.

At CC KLI 2024 in Bangalore, experts discussed innovations reshaping the sector. The expert panel included Dr. K S Nanjunda Rao, Mr. Manjunath Prasad, Mr. Subramaniam Swamy, Mr. Manoj Rastogi, and Dr. Radhakrishna G. Pillai.

Dr. K S Nanjunda Rao emphasised sustainability through recycled aggregates, addressing the environmental and economic benefits of using recycled materials. Mr. Subramaniam Swamy, touched upon technological advancements, such as drone surveys and modular construction, which streamline building processes and reduce construction time. Mr. Manjunath Prasad, discussed using aluminium formwork and composite construction methods to enhance speed and structural integrity, noting significant time savings in project completion. Prof. Dr. Radhakrishna G Pillai, underscored the growing importance of green building certifications and integrating sustainable practices in every construction stage.

The panel agreed on the necessity of industry-academia collaboration, as seen in initiatives like the Center of Excellence, to bridge gaps between theoretical research and practical applications. The consensus was clear: smart technologies are crucial for accelerating construction and ensuring durability, paving the way for a sustainable future in the construction industry. Embracing these innovations will enable the sector to meet current demands and foster a more resilient and efficient construction landscape.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

CC KLI Ahmedabad brought together a distinguished group of experts to explore the transformative impact of smart technologies on the construction and infrastructure sectors, focusing on creating durable and sustainable structures. The session offered valuable insights from notable panellists, each sharing unique perspectives on the challenges and innovations in the field.

Mr. Rajesh Agrawal, Chief Project Manager at National High-Speed Rail Corporation Limited (NHSRCL), discussed advancements in smart technologies applied to large-scale railway projects, highlighting the significant differences between conventional methods and modern practices, especially in high-speed rail construction. Mr. Ashutosh Chandwar, COO of Dr. Agrawal Infracon Pvt. Ltd., shared his experiences constructing the world’s highest and largest tunnel projects, addressing the challenges posed by high-altitude environments. Mr. Apoorv Dhonde, Director of Apoorv Dhonde Engineering Consultants Pvt. Ltd., explored integrating smart technologies in structural engineering, emphasising the importance of predictive maintenance and data analysis for extending infrastructure longevity. Mr. K K Doshi, Chairman of Doshi Consultants Pvt. Ltd., leveraged his extensive experience to discuss the role of advanced materials and techniques in building durable structures. He underscored the critical need for high-quality materials and precise construction practices to ensure long-term performance. Mr. Devendra Prakash, Superintending Engineer and Project Director at IIT Gandhinagar focused on the complexities of managing large-scale infrastructure projects, stressing the importance of effective project management and technological integration. Mr. Sushil Kumar Sinha, Senior Bridge Structural Engineer at Assystem STUP, addressed the specific challenges of bridge construction, including the need for advanced materials and techniques to withstand diverse environmental conditions.

The panel highlighted the crucial role of smart technologies in advancing infrastructure projects, particularly in challenging environments. These technologies enhance precision, efficiency, and safety, paving the way for more sustainable and durable infrastructure development. The discussion highlighted the need to adopt smart technologies, sustainable practices, and a skilled workforce in construction. Experts pointed out challenges such as improved training, quality control, and integrating advanced materials and practices. They emphasised the role of consultants in ensuring project success and maintaining high industry standards. The discussion also revolved around the benefits of high-performance concrete for durability, challenges with material availability like fly ash, and the significance of smart technologies and local materials in cost-effective construction. Fibre reinforcement, including steel and glass fibres, was highlighted for enhancing concrete performance, and the integration of 3D modelling and BIM was recognised as essential for managing complex systems in buildings.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Asian Paints held the 7th Edition of CC-KLI: Construction Chemicals Knowledge Leadership Initiative in June and July 2024.

CC-KLI, India’s leading construction chemicals summit, is a platform for industry experts to share knowledge and promote advanced construction practices. The event series took place in 8 major cities, including Ahmedabad, Hyderabad, Bengaluru, Mumbai, Kolkata, and Pune chapters. The events featured the “Innovation Station-SmartCare System Solutions Exhibit,” showcasing advancements in Waterproofing, Repair and Restoration, Floor Coating, and Additives. The events bring together industry elites and professionals from Academia, Government bodies, Civil Construction Companies (CCCs), Project Management Companies (PMCs), Builders Firms & Structural Consultants and Architects.

The Mumbai Chapter brought together a distinguished group of experts to explore advancements in precast concrete, high-performance materials, and modern road infrastructure techniques. Key topics of discussion included the utilisation of admixtures like fly ash and slag to lower carbon footprints, the role of Building Information Modelling (BIM) and drones in improving project management, and the significance of corrosion inhibitors for extending concrete durability. The experts touched upon the need for updated industry standards, transitioning from traditional cube testing to maturity testing, and advocating for policy adjustments in EPC contracts.

The Mumbai Chapter of CC-KLI took off with an insightful keynote address by Prof. K.V. L. Subramaniam, from Department of Civil Engineering, IIT Hyderabad. He stressed on emerging technologies such as high performance concrete, precast construction, and artificial intelligence (AI) as game-changers, with a notable example being a 12-story building completed in just 36 days using precast methods. He underscored the importance of mastering concrete production to enhance efficiency and sustainability, aligning with India’s net-zero emissions goal. He noted that advancements now enable precise engineering of material properties, marking a shift from conventional mix ratios.

The keynote address was followed by a panel discussion where, Mr. Rajesh Pandit, Vice President of Integrated Management Systems at Hindustan Construction Company Ltd, discussed innovations in material sourcing, including the shift from natural sand to crushed sand and the incorporation of Ground Granulated Blast Furnace Slag (GGBFS) and micro silica. Mr. Suhas Dhuri, Promoter and Partner at e-Cube Concrete Consultants LLP, highlighted how AI and IoT transform the construction industry. Mr. Amit Barde, Head of Precast Initiatives at Larsen & Toubro Limited, shared insights on the evolution of construction technologies, noting the industry’s gradual adoption of hybrid technologies and digitalisation in response to labour shortages and site challenges.

Mr. S. K. Survase, Chief Engineer at MSRDC, discussed advancements in road construction technologies, especially in challenging terrains, and using satellite imagery for precise road alignment. Mr. Shailesh Agrahari Gupta, AVP of Quality at Tata Projects Limited, emphasised the crucial role of modern concrete technologies in ensuring structural integrity and durability for mega projects. Lastly, Mr. Debjyoti Roychowdhury, Chief Engineer at CPWD Mumbai, shared his experiences with greenfield road projects and using ultra-high-strength concrete and performance-based admixtures.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.