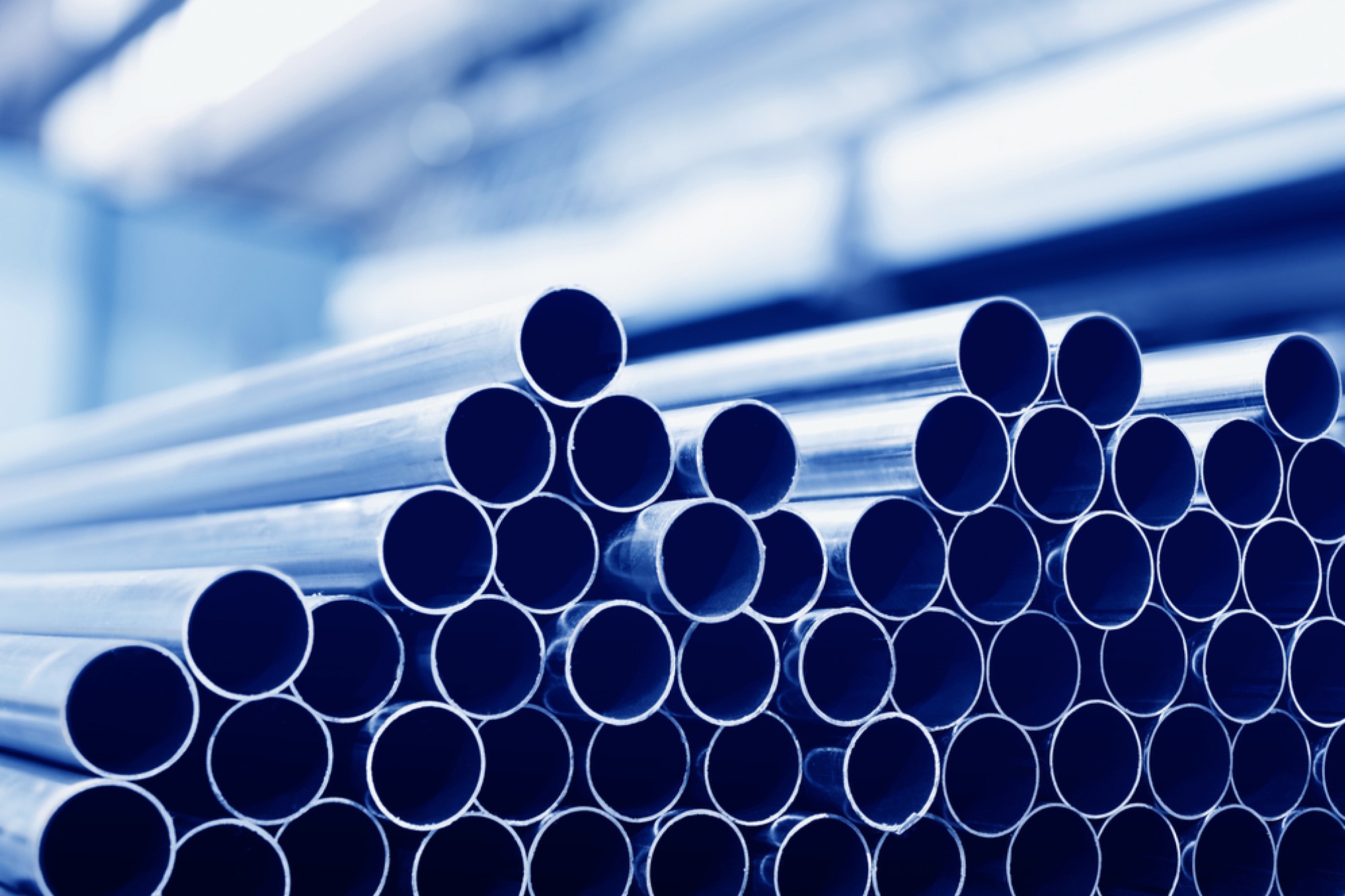

Stainless steel pipes are better for cost-effective, low maintenance

By Edit Team | June 7, 2023 5:56 pm SHARE

Using stainless steel is witnessing remarkable innovations, replacing previously employed metals in various industries.

Rahul Gaur of Apex Tubes stressed in an interview with B2B Purchase Magazine that becoming quality sensitive and staying connected to clients allows them to stay ahead of the curve.

What key factors should be considered when selecting industrial pipes, tubes, and fittings for a specific application?

Technical design and usage requirements should guide material selection for pipes, tubes, or fittings. For instance, stainless steel is the material of choice if the equipment is subject to corrosion, requires a hygienic medium to transfer liquids or semi-solids, or is looking for longer life at lower lifecycle maintenance costs. One should go for SS tubes, pipes, or fittings in such cases. Once the material has been decided, users should look for reliable brands available in the market with proven credentials and a satisfied clientele. In 2022, APEX has completed a very rewarding 30 years of service to the industry.

How are industrial pipes, tubes, and fittings tested for quality and safety?

At APEX Tubes, we offer a wide range of stainless steel pipes and tubes as per various specifications (like ASTM, IS, and EN) to our customers. During manufacturing and at the final stage, all pipes and tubes are tested for conformance to quality norms as per these specs, including the proper chemical composition of the SS grade, physical and mechanical parameters, visual and dimensional accuracy, and, most importantly, leakproof testing. As a confirmation of our quality testing, each of our tubes and pipes is marked with our brand, grade, size, and heat number or job number for correlation, and Material Test Certificates are provided.

What common challenges can arise when working with industrial pipes, tubes, and fittings, and how can they be addressed?

Working with and fitting stainless steel tubes and pipes in equipment or open lines involves some basic care. One should understand that what makes stainless steel really “stain-less” is a thin layer of chromium oxide, which is present on the surface of any good stainless steel and does not let any corrosion happen. This layer should be preserved, and conditions should be provided to maintain it so SS can provide the intended benefits. While fitting and fabricating, SS should not be subjected to continual abrasion by dirt, grease, oil, etc. Also, it should not be

in continuous contact with other metals like MS, etc. Further, the effort should be made to select tubes and pipes with the best quality credentials.

What innovations and advancements are currently being made in industrial pipes, tubes, and fittings, and how are they improving the industry?

We see innovations in using stainless steel in fields where other metals were used earlier. For instance, in air pre-heaters in boilers in the sugar industry, customers are now choosing stainless steel over corten steel because of heat exchange efficiencies and corrosion resistance. In the architecture, building, and construction (ABC) sector, stainless steel piping is increasingly used for plumbing piping, whereas earlier GI or FRP piping was used.

These innovations lead to fewer lifecycle costs for the industry and attractive appearances with low maintenance.

How do environmental regulations impact the production and use of industrial pipes, tubes, and fittings?

At the customer end, we see increasing usage of stainless steel, where industries are compelled by law to use less polluting solutions for their processes. At Apex, we comply with all the laid-down environmental regulations, which

are verified regularly by the relevant authorities.

What are your business’s future trends and opportunities, and how can companies stay ahead of the curve?

With each passing day, newer SS usage areas are being discovered. Also, governmental pushes in infrastructure and certain industries like ethanol and the Make in India concept are bound to affect our industry positively. One needs to be quality-conscious and attentive to customer requirements to stay ahead of the curve.

For more details visit: https://www.apextube.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.