Building envelope insulation: emerging solutions

By Edit Team | August 21, 2014 5:05 am SHARE

In order to save energy and reduce CO2 emission, envelope insulation has become the prime objective of a new project

A building envelope is one of the most important components that add or reduce heat load inside the building, depending on its design. A well-insulated building puts resistance to the heat flow path and avoids adiabatic condition. We have discussed with N. Srinivas of Lloyd Insulations and Biswajit Roy of U.P Twiga Fiberglass who share how insulated building envelope helps save energy and cost.

Saving energy and cost

A building needs to be protected from hot external environment to the cooler interior spaces which are maintained at lower comfortable temperatures. N. Srinivas, Mentor, Lloyd Insulations (India) Ltd., describes, “Since all the cooling of the building interiors is achieved by the use of HVAC system involving expenditure of electrical energy, it really matters whether we allow heat to enter and increase the load on the HVAC system or whether we choose to limit such heat ingress to manageable levels so that the load on the cooling system is minimized.”

He adds, “Our summer conditions are extreme in their severity and temperature controlled built environment is demanded in almost all types of buildings today.”

According to Biswajit Roy, Manager – Building Solution, U.P Twiga Fiberglass Ltd., “When heat load is down, the required cooling load is also reduces. It means the capacity of the HVAC can be lowered to save some capital or equipment cost. It also signifies, air conditioning system would consume less energy and save on running cost.

“If the building is not air conditioned, envelope insulation helps achieve comfortable living condition inside the buildings. In hot and dry climatic zone an insulated envelope along with a suitably designed evaporative cooling system is quite effective and economic solution.”

“What stands between the aggressive exterior and the pleasant interiors is the building envelope,” remarks Mr Srinivas. “When insulated well, this envelope allows limited amount of heat (or cold) to enter the conditioned space. This limits the load on the air conditioning system, which runs for fewer hours in a day to maintain comfort levels. This directly impacts the power consumed in the process. A well-insulated envelope substantially limits the power consumed in the process of maintaining comfort conditions in a building.”

Benefits with sustainable solution

There are, of course, several benefits in building envelope insulation. “The direct benefits are thermal comfort and saving on capital cost, and indirect benefits are saving on running cost of air conditioning and reduction of CO2 emission,” says Mr Roy. Insulation also helps achieve acoustic privacy inside the building. An insulated building envelope can cut down the noise transmission that might be generated because of nearby road traffic, airport, railways etc.

He also gives an example of a research paper from U.S based Energy Conservation Management Inc. The paper reveals that for every Btu consumed in the production of insulation in America, 12 Btus are saved each year by the use of insulation.

He also points out, “Inorganic insulation products like fibreglass wool are manufactured in a sustainable way where no hazardous agents (which may otherwise be present in blowing agent and fire-retardant solutions of insulations) are used. Hence, it neither possesses any health issues nor any environmental adversity. Moreover, the embodied energy of fibreglass wool is quite low in comparison to the other organic insulating materials that are manufactured from petroleum-based resources. The insulation material can easily be reclaimed from

site and reused too.

Going green

Going green is the buzz word in today’s world. Even Mr Srinivas thinks so. He says, “Sustainability issues, green building norms and concern for environment/ecology, which have seen very high priority among designer community, gives me great hope that we are proceeding in the right direction. Implementation tends to lag behind in pace as a natural phenomenon due to inertia, but I see various positive factors, including high levels of preference our buyers of building premises are showing for green options these days.”

Mr Roy also expects that insulated building envelope will be a part of standard construction practices. “With higher consumption of insulation, the cost will come down further because of economy of scale,” he predicts. “It is important for the future, that the present day emerging solutions are affordable and simple or in word more practical.”

Emerging products

Both Lloyd Insulations and Twiga Fiberglass are prominent names in thermal and building insulation solutions.

One of the well-known Lloyd products is Lloydpanel System, which features metal faced high-efficiency sandwich panels. These have been engineered to meet highest levels of fire safety, with capability to withstand every kind of externally applied mechanical loads and exceptional weather integrity.

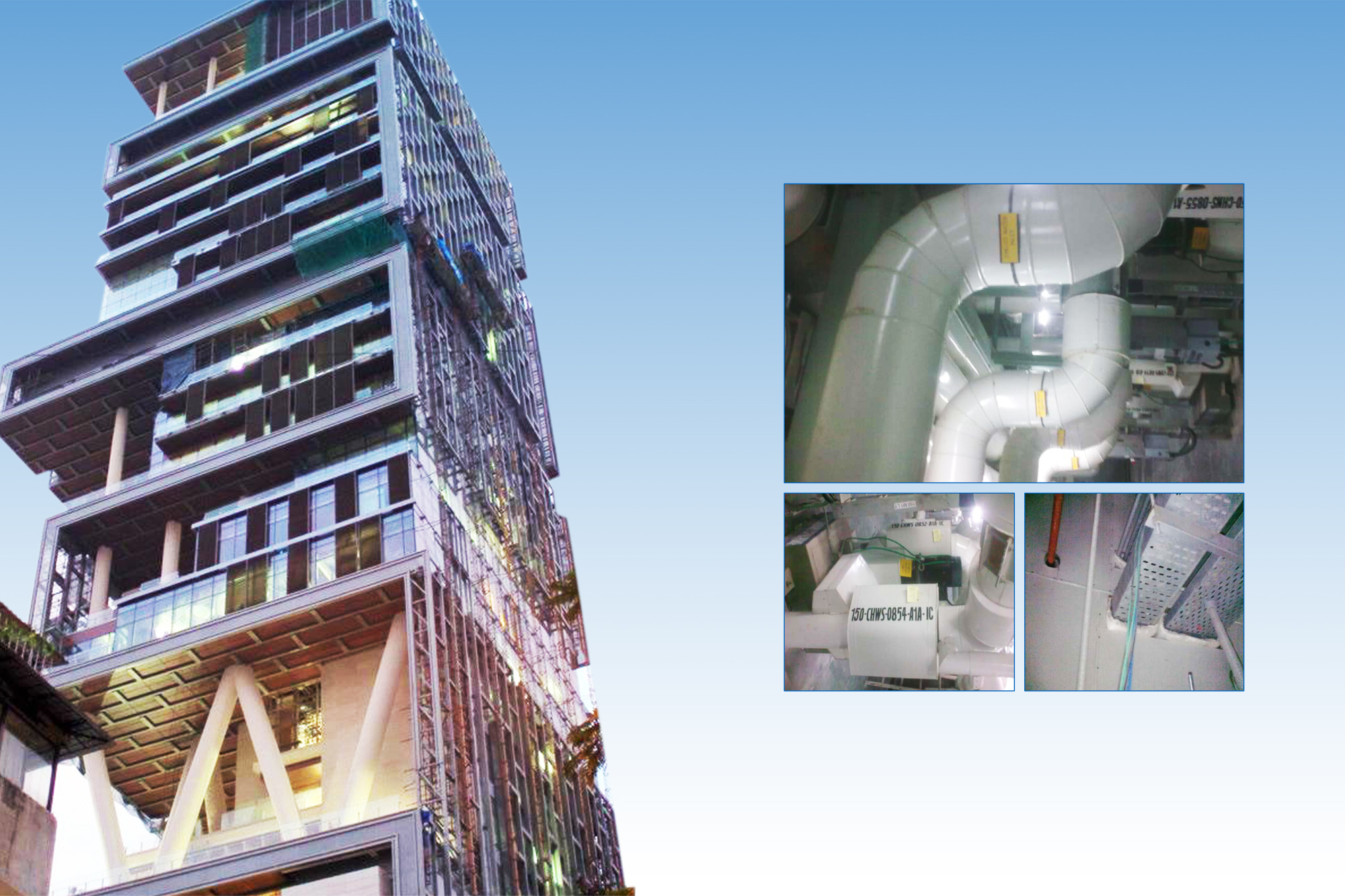

Then there is Twiga Insul, recommended for duct wrap and pipe insulation for central air-conditioning systems. Aluminium or special polypropylene faced flexible blankets are used as duct thermal along with compatible sealing system. Twiga also provides flexible insulated or un-insulated ducts and prefabricated non-metallic duct boards against conventional metal ducting plus insulation.

Lloyd Insulations also offers a complete set of built-up options like dry walls, external insulation and finishing systems for walls, insulated roofing systems with metal as well as weather/waterproof coverings like TPO/EPDM membranes to meet any architectural and structural challenge.

Twiga’s low density resilient fiberglass wool helps achieve high acoustic isolation in dry wall partition without increasing the load in the assembly. Different acoustic tests as per international standards established the compatibility of Twiga Insul with drywall system/products of various manufacturers.

“A well insulated thermal envelope,” as Mr Srinivas puts in, “not only limits power consumption and the running cost of a building, also helps reduce the size of the air-conditioning equipment one needs to install in the first place.” No wonder right building envelope insulation substantially reduces the cost of a new project.

It is important for the future that the present day, emerging solutions are affordable, simple or more practical.

Biswajit Roy,

Manager – Building Solution,

U.P Twiga Fiberglass Ltd.

Insulated building envelope helps energy efficiency and sustainability while being delightfully green.

N. Srinivas, Mentor,

Lloyd Insulations (India) Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.